ECU Seat Exeo 2008 Service Manual

[x] Cancel search | Manufacturer: SEAT, Model Year: 2008, Model line: Exeo, Model: Seat Exeo 2008Pages: 303, PDF Size: 10.02 MB

Page 216 of 303

Checking and refilling levels

214

NoteOn right-hand drive vehicles some of the containers/ reservoirs mentioned

below are located on the other side of the engine compartment.Closing the bonnet– To close the bonnet, pull it down to overcome the spring pres- sure.

– Leave the bonnet secured in the locking part. Do not tighten

⇒ .

WARNING

•

For safety reasons the bonnet must always be completely closed when

the vehicle is moving. After closing it always check that it is properly

secured. The bonnet must be flus h with the adjacent body panels.

•

Should you notice that the bonnet is not safely secured when the

vehicle is moving, stop the vehicle immediately and close the bonnet.

Failure to do so could result in an accident.

Engine oilGeneral notesWe recommend you to entrust the oil change with your Technical Service or a

qualified workshop, according to the Maintenance Program. The correct oil specifications for your engine are listed in the

Technical data

section ⇒page 282.

Check that the specifications quoted (VW standards) appear on the container

either singly or in combination with other specifications.

Fixed service intervals*

You can use oils for service intervals - ⇒ page 282. In this case, your car must

be serviced after a fixed interval of 1 year / 15,000 km (10,000 miles) see

Service Schedule.

•

In exceptional circumstances, if the engine oil level is too low

⇒ page 215 and you cannot obtain the oi l specified for your vehicle, you can

put in a small quantity of oil conforming to the specification ACEA A2 or

ACEA A3 (petrol engines) or ACEA B3 or ACEA B4 (diesel engines) (up to 0.5l).

Vehicles with diesel particulate filter*

The Service Schedule states whether your vehicle is fitted with a diesel partic-

ulate filter.

•

Vehicles with a diesel particulate filter must only b e f ill e d wi th VW 507 00

engine oil.

•

Avoid mixing this oil with other engine oils.

•

Only in exceptional circumstances, if the engine oil level is too low

⇒ page 215 and you cannot obtain the oi l specified for your vehicle, can you

put in a small quantity of oil (once) conforming to the VW 506 00, VW 506 01,

VW 505 00, VW 505 01 or ACEA B3 / ACEA B4 specification. (up to 0.5l).

Exeo_EN.book Seite 214 Freitag, 17. Oktober 2008 11:24 11

Page 226 of 303

Checking and refilling levels

224Winter operations

The battery is drained more in cold weather, which means that the starting

power is reduced. For this reason, have the battery checked and charged if

necessary before the start of winter.

Replacing the battery

A replacement battery must have the same capacity, voltage and current

rating. It must also have the same dimensions as the original, factory-fitted

battery and have sealed caps. The SEAT batteries which have been specially

developed fulfil the maintenance, performance and safety specifications for

your vehicle.

We recommend you use maintenance-free batteries.

WARNING

•

All work on batteries requires speciali st knowledge. If work is required

on the battery, this should be pe rformed by a Technical Service or

specialist garage. Danger of caustic burns and explosion!

•

The battery must not be opened. Never try to change the battery's

liquid level. Explosive gas is released from the battery that could lead to an

explosion.Caution

•

The battery holder and clamps must always be correctly secured.

•

Before starting any work on the battery, always observe the warnings

listed below ⇒.For the sake of the environment

Batteries contain toxic substances including sulphuric acid and lead.

Therefore, they must be disposed in line with environmental regulations and

must not be disposed of with ordinary household waste. Make sure discon-

nected batteries cannot tip over . Sulphuric acid could be spilt!

Important safety warnings for handling a car batteryThe battery is located at the back of the engine compartment ⇒page 282.

WARNING

Always be aware of the danger of injury and chemical burns as well as the

risk of accident or fire when work ing on the battery and the electrical

system:•

Wear eye protection. Protect your eyes, skin and clothing from acid and

particles containing lead.

•

Battery acid is very corrosive and caustic. Wear protective gloves and

eye protection. Do not tilt the batter ies. This could spill acid through the

vents. Rinse battery acid from eyes immediately for several minutes with

clear water. Then seek medical care immediately. Neutralize any acid

splashes on the skin or clothing with a soapy solution, and rinse off with

plenty of water. If acid is swallowed by mistake, consult a doctor immedi-

ately.

•

Fires, sparks, naked lights and smoking are prohibited. When handling

cables and electrical equipment, avoid causing sparks and electrostatic

charge. Never short the battery terminals. High-energy sparks can cause

injury.

Wear eye protection

Battery acid is very corrosive and caustic. Wear protec-

tive gloves and eye protection!

Fires, sparks, naked lights and smoking are prohibited!

A highly explosive mixture of gases is released when the

battery is under charge.

Keep children away from acid and batteries!

Exeo_EN.book Seite 224 Freitag, 17. Oktober 2008 11:24 11

Page 236 of 303

Wheels and tyres

234

For the sake of the environmentOld tyres must be disposed of according to the laws in the country concerned.

Note

•

For technical reasons, it is not generally possible to use the wheels from

other vehicles. This can also apply to wheels of the same model. The use of

wheels or tyres which have not been approved by SEAT for use with your

model may invalidate the vehicle's type approval for use on public roads.

•

If the spare tyre is not the same as the tyres that are mounted on the

vehicle - for example with winter tyres - you should only use the spare tyre for

a short period of time and drive with extra care. Refit the normal road wheel

as soon as possible.

Wheel bolts

Wheel bolts must be tightened to the correct torque.The design of wheel bolts is matched to the rims. If different wheel rims are

fitted, the correct wheel bolts with the right length and correctly shaped bolt

heads must be used. This ensures that wheels are fitted securely and that the

brake system functions correctly.

In certain circumstances, you may not use wheel bolts from a different car -

even if it is the same model ⇒page 206.

After the wheels have been changed, the tightening torque of the wheel bolts

should be checked as soon as possible with a torque wrench ⇒. The tight-

ening torque for steel and alloy wheels is 120 Nm.

WARNING

If the wheel bolts are not tightened correctly, the wheel could become

loose while driving. Risk of accident.•

The wheel bolts must be clean and turn easily. Never apply grease or oil

to them.

•

Use only wheel bolts which belong to the wheel.

•

If the torque of the wheel bolts is too low, they could loosen whilst the

vehicle is in motion. Risk of accident! If the tightening torque is too high,

the wheel bolts and threads can be damaged.Caution

The prescribed torque for wheel bolts for steel and alloy wheels is 120 Nm.Winter tyres

Winter tyres will improve the vehicles handling on snow and

ice.In winter conditions winter tyres will considerably improve the vehicles

handling. The design of summer ty res (width, rubber compound, tread

pattern) gives less grip on ice and snow.

Winter tyres must be inflated to a pressure 0.2 bar higher than the pressures

specified for summer tyres (see sticker on tank flap).

Winter tyres must be fitted on all four wheels.

Information on permitted winter tyre sizes can be found in the vehicle's regis-

tration documents. Use only radial winter tyres. All tyre sizes listed in the

vehicle documentation also apply to winter tyres.

Exeo_EN.book Seite 234 Freitag, 17. Oktober 2008 11:24 11

Page 238 of 303

If and when

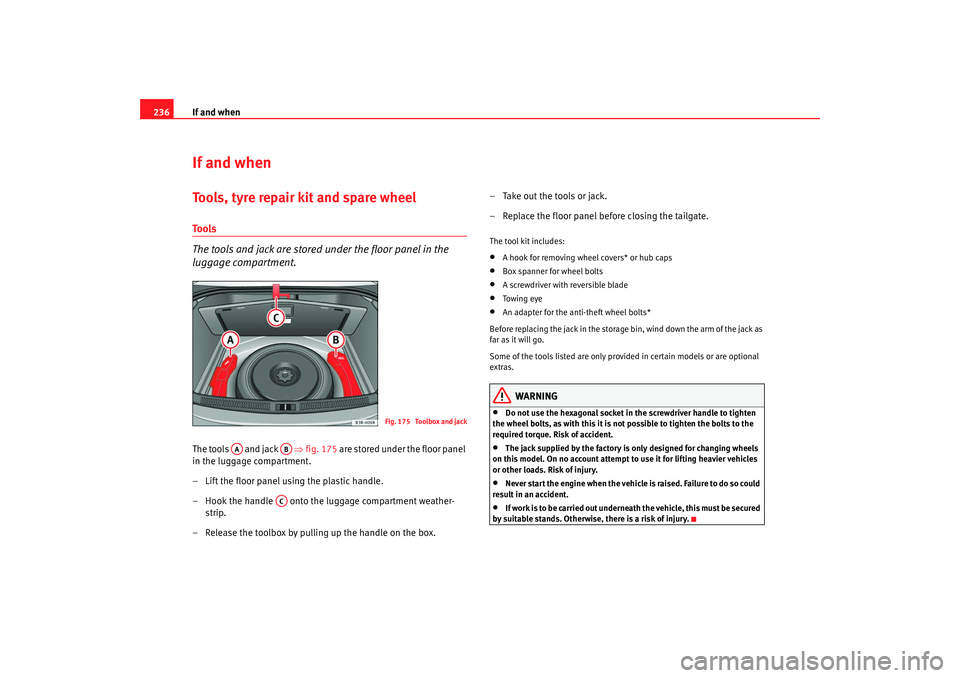

236If and whenTools, tyre repair kit and spare wheelTools

The tools and jack are stored under the floor panel in the

luggage compartment.The tools and jack ⇒fig. 175 are stored under the floor panel

in the luggage compartment.

– Lift the floor panel using the plastic handle.

– Hook the handle onto the luggage compartment weather- strip.

– Release the toolbox by pulling up the handle on the box. – Take out the tools or jack.

– Replace the floor panel before closing the tailgate.

The tool kit includes:•

A hook for removing wheel covers* or hub caps

•

Box spanner for wheel bolts

•

A screwdriver with reversible blade

•

Towing eye

•

An adapter for the anti-theft wheel bolts*

Before replacing the jack in the storage bin, wind down the arm of the jack as

far as it will go.

Some of the tools listed are only provid ed in certain models or are optional

extras.

WARNING

•

Do not use the hexagonal socket in the screwdriver handle to tighten

the wheel bolts, as with this it is not possible to tighten the bolts to the

required torque. Risk of accident.

•

The jack supplied by the factory is only designed for changing wheels

on this model. On no account attempt to use it for lifting heavier vehicles

or other loads. Risk of injury.

•

Never start the engine when the vehicle is raised. Failure to do so could

result in an accident.

•

I f wo r k is t o b e ca r r i e d o u t un d e r n ea th the vehicle, this must be secured

by suitable stands. Otherwise, there is a risk of injury.

Fig. 175 Toolbox and jac

k

AA

ABAC

Exeo_EN.book Seite 236 Freitag, 17. Oktober 2008 11:24 11

Page 239 of 303

If and when237

Safety First

Operating instructions

Practical tips

Te c h n i c a l D a t a

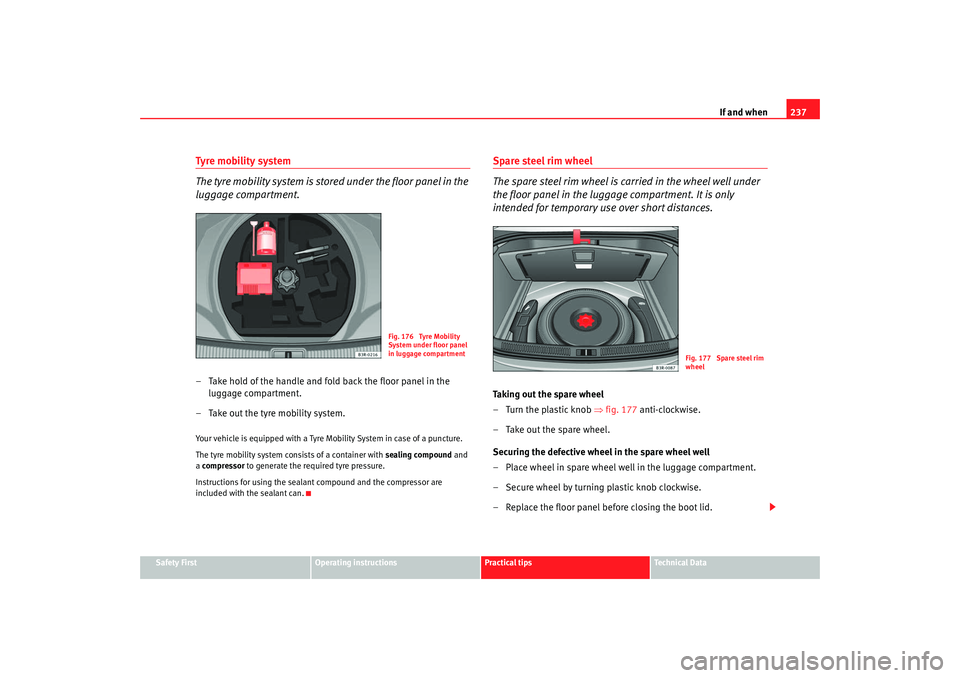

Tyre mobili ty system

The tyre mobility system is stored under the floor panel in the

luggage compartment.– Take hold of the handle and fold back the floor panel in the

luggage compartment.

– Take out the tyre mobility system.Your vehicle is equipped with a Tyre Mobility System in case of a puncture.

The tyre mobility system consists of a container with sealing compound and

a compressor to generate the required tyre pressure.

Instructions for using the sealant compound and the compressor are

included with the sealant can.

Spare steel rim wheel

The spare steel rim wheel is carried in the wheel well under

the floor panel in the luggage compartment. It is only

intended for temporary use over short distances.Taking out the spare wheel

– Turn the plastic knob ⇒fig. 177 anti-clockwise.

– Take out the spare wheel.

Securing the defective wheel in the spare wheel well

– Place wheel in spare wheel well in the luggage compartment.

– Secure wheel by turning plastic knob clockwise.

– Replace the floor panel before closing the boot lid.

Fig. 176 Tyre Mobility

System under floor panel

in luggage compartment

Fig. 177 Spare steel rim

wheel

Exeo_EN.book Seite 237 Freitag, 17. Oktober 2008 11:24 11

Page 241 of 303

If and when239

Safety First

Operating instructions

Practical tips

Te c h n i c a l D a t a

Note

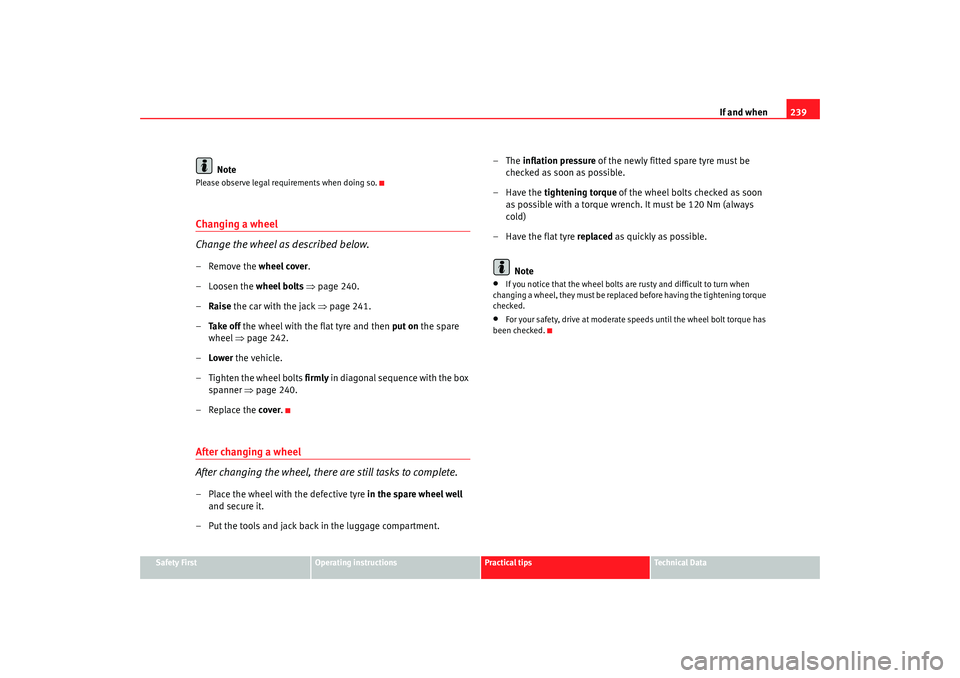

Please observe legal requirements when doing so.Changing a wheel

Change the wheel as described below.– Remove the wheel cover.

– Loosen the wheel bolts ⇒ page 240.

– Raise the car with the jack ⇒ page 241.

– Ta k e o f f the wheel with the flat tyre and then put on the spare

wheel ⇒page 242.

– Lower the vehicle.

– Tighten the wheel bolts firmly in diagonal sequence with the box

spanner ⇒page 240.

–Replace the cover.After changing a wheel

After changing the wheel, there are still tasks to complete.– Place the wheel with the defective tyre in the spare wheel well

and secure it.

– Put the tools and jack back in the luggage compartment. –The

inflation pressure of the newly fitted spare tyre must be

checked as soon as possible.

– Have the tightening torque of the wheel bolts checked as soon

as possible with a torque wrench. It must be 120 Nm (always

cold)

– Have the flat tyre replaced as quickly as possible.

Note

•

If you notice that the wheel bolts are rusty and difficult to turn when

changing a wheel, they must be replaced before having the tightening torque

checked.

•

For your safety, drive at moderate speeds until the wheel bolt torque has

been checked.

Exeo_EN.book Seite 239 Freitag, 17. Oktober 2008 11:24 11

Page 264 of 303

If and when

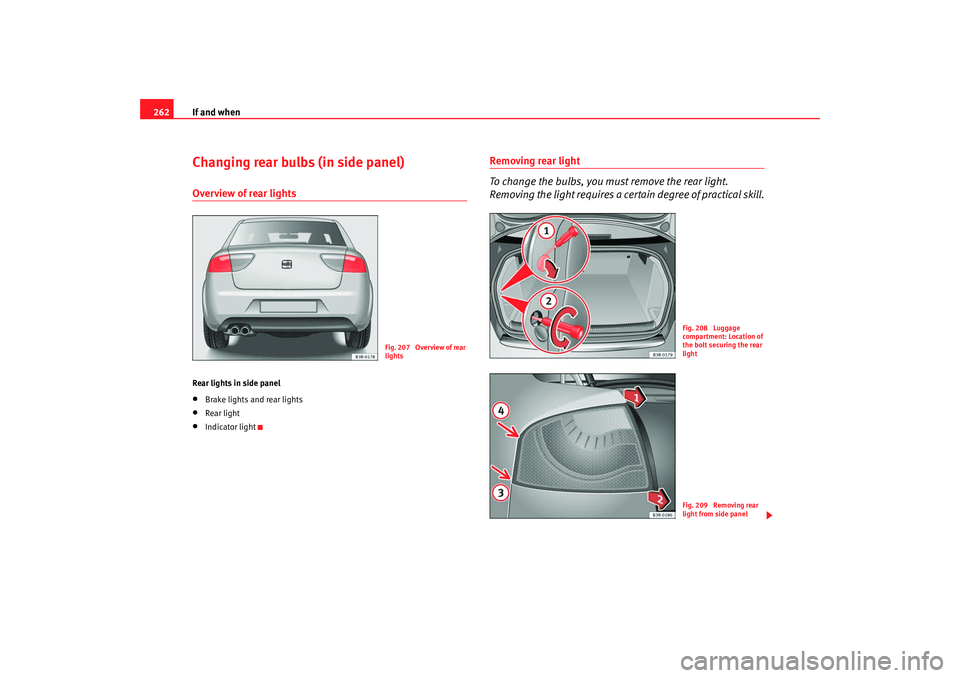

262Changing rear bulbs (in side panel)Overview of rear lightsRear lights in side panel•

Brake lights and rear lights

•

Rear light

•

Indicator light

Removing rear light

To change the bulbs, you must remove the rear light.

Removing the light requires a certain degree of practical skill.

Fig. 207 Overview of rear

lights

Fig. 208 Luggage

compartment: Location of

the bolt securing the rear

lightFig. 209 Removing rear

light from side panel

Exeo_EN.book Seite 262 Freitag, 17. Oktober 2008 11:24 11

Page 265 of 303

If and when263

Safety First

Operating instructions

Practical tips

Te c h n i c a l D a t a

A special retaining screw is used to secure and guide the rear light.

– Check which of the bulbs is defective.

– Open the tailgate.

– Take the screwdriver out of the vehicle's tool kit ⇒ page 236.

– Use the flat-blade side of the reversible screwdriver insert.

– Prise open the cover at the slot with the screwdriver ⇒page 262,

fig. 208 .

– Use the screwdriver to loosen the screw (arrow) located behind the cover.

– Gradually ease the rear li ght out of the mounting (⇒page 262,

fig. 209 positions and ) by pulling alternately in positions and .

– Remove the bulb holder ⇒page 263.

CautionTake care when removing the rear light to make sure there is no damage to

the paintwork or any of its components.

Note

Make sure you have a soft cloth ready to place under the glass on the rear

light, to avoid any scratches.

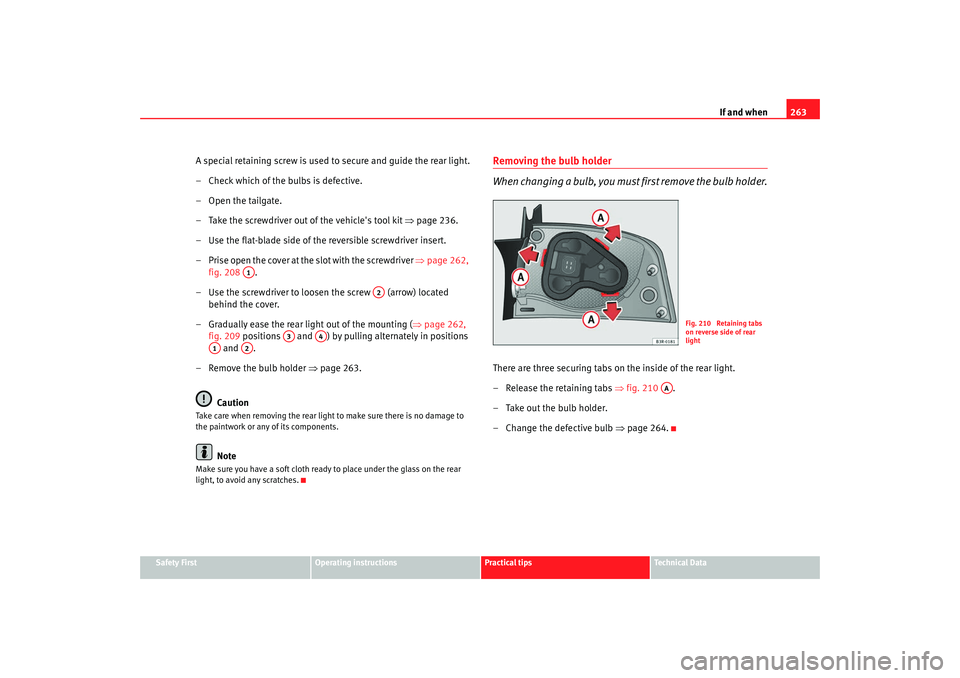

Removing the bulb holder

When changing a bulb, you must first remove the bulb holder.There are three securing tabs on the inside of the rear light.

– Release the retaining tabs ⇒fig. 210 .

– Take out the bulb holder.

– Change the defective bulb ⇒page 264.

A1

A2

A3

A4

A1

A2

Fig. 210 Retaining tabs

on reverse side of rear

light

AA

Exeo_EN.book Seite 263 Freitag, 17. Oktober 2008 11:24 11

Page 266 of 303

If and when

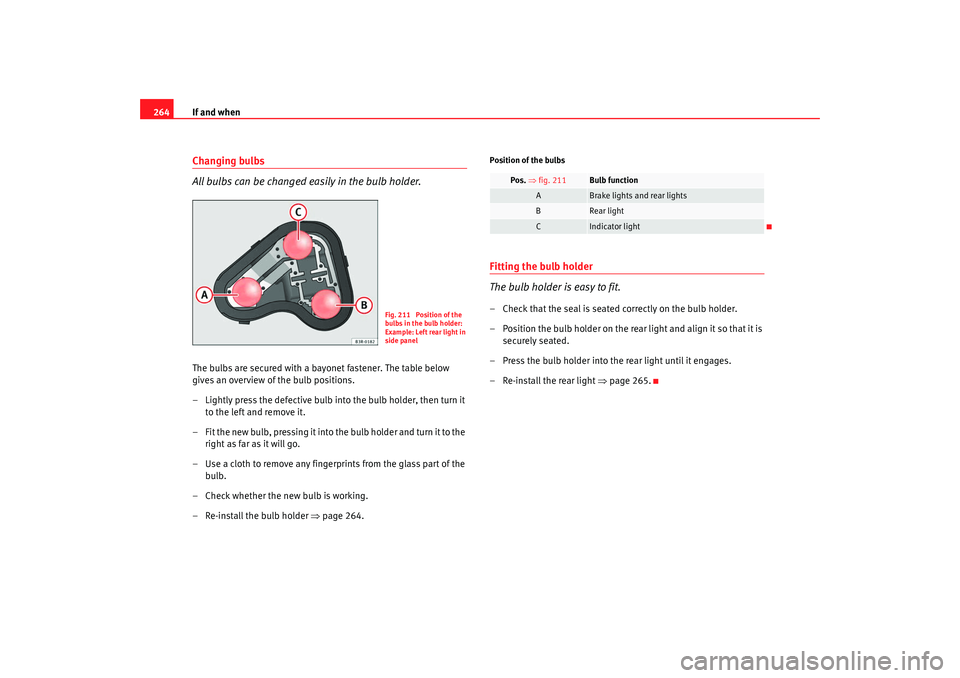

264Changing bulbs

All bulbs can be changed easily in the bulb holder.The bulbs are secured with a bayonet fastener. The table below

gives an overview of the bulb positions.

– Lightly press the defective bulb into the bulb holder, then turn it

to the left and remove it.

– Fit the new bulb, pressing it into the bulb holder and turn it to the right as far as it will go.

– Use a cloth to remove any fingerprints from the glass part of the bulb.

– Check whether the new bulb is working.

– Re-install the bulb holder ⇒page 264.

Position of the bulbsFitting the bulb holder

The bulb holder is easy to fit.– Check that the seal is seated correctly on the bulb holder.

– Position the bulb holder on the rear light and align it so that it is

securely seated.

– Press the bulb holder into the rear light until it engages.

– Re-install the rear light ⇒page 265.

Fig. 211 Position of the

bulbs in the bulb holder:

Example: Left rear light in

side panel

Pos. ⇒ fig. 211

Bulb function

A

Brake lights and rear lights

B

Rear light

C

Indicator light

Exeo_EN.book Seite 264 Freitag, 17. Oktober 2008 11:24 11

Page 267 of 303

If and when265

Safety First

Operating instructions

Practical tips

Te c h n i c a l D a t a

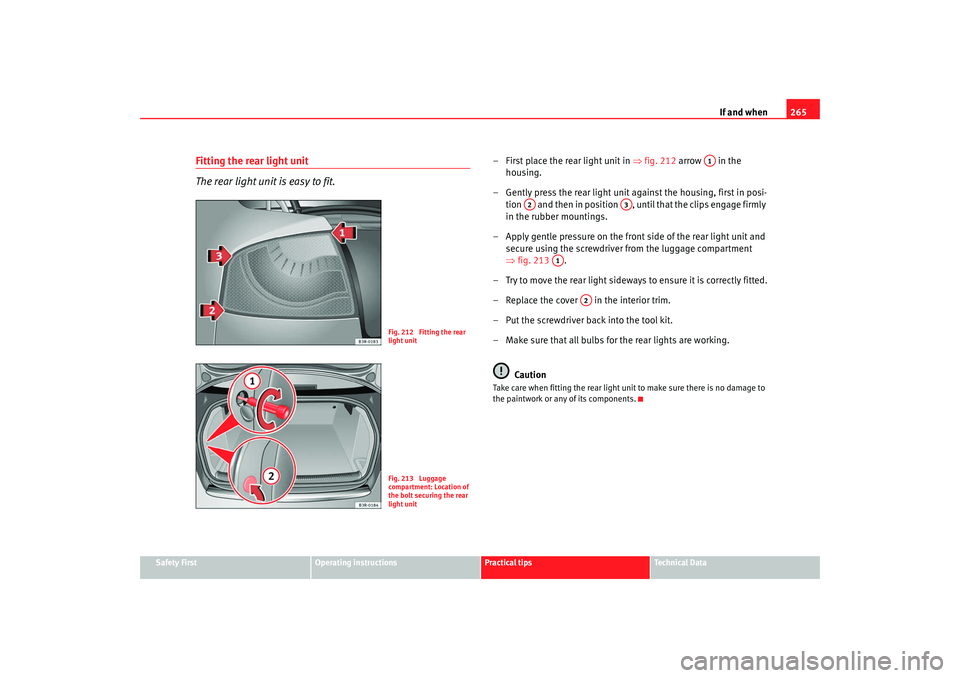

Fitting the rear light unit

The rear light unit is easy to fit.

– First place the rear light unit in ⇒fig. 212 arrow in the

housing.

– Gently press the rear light unit against the housing, first in posi- tion and then in position , until that the clips engage firmly

in the rubber mountings.

– Apply gentle pressure on the front side of the rear light unit and secure using the screwdriver from the luggage compartment

⇒ fig. 213 .

– Try to move the rear light sideways to ensure it is correctly fitted.

– Replace the cover in the interior trim.

– Put the screwdriver back into the tool kit.

– Make sure that all bulbs for the rear lights are working.

CautionTake care when fitting the rear light unit to make sure there is no damage to

the paintwork or any of its components.

Fig. 212 Fitting the rear

light unitFig. 213 Luggage

compartment: Location of

the bolt securing the rear

light unit

A1

A2

A3

A1

A2

Exeo_EN.book Seite 265 Freitag, 17. Oktober 2008 11:24 11