technical specifications Seat Ibiza SC 2012 Owners Manual

[x] Cancel search | Manufacturer: SEAT, Model Year: 2012, Model line: Ibiza SC, Model: Seat Ibiza SC 2012Pages: 280, PDF Size: 3.67 MB

Page 185 of 280

183

Accessories, replacement of parts and modifications

Accessories, replacement of parts and modifications

Accessories and spare parts

Always consult a SEAT dealership before purchasing acces-

sories and parts.

Your vehicle is designed to offer a high standard of active and passive safe-

ty.

Before purchasing accessories and parts, and before making technical

changes to your vehicle, we recommend you to consult your SEAT Technical

Service.

SEAT dealerships will be happy to provide you with the latest information

about the use, legal requirements and recommendations from the manufac-

turer regarding accessories and parts.

We recommend you use only SEAT Approved Accessories®

and SEAT Ap-

proved Spare Parts ®

. This way, SEAT can guarantee that the product in

question is suitable, reliable and safe. SEAT Technical Services have the

necessary experience and facilities to ensure that parts are correctly and

professionally installed.

Despite a continuous observation of the market, SEAT is not able to assess

the reliability, safety and suitability of those parts SEAT has not approved.

For this reason, SEAT cannot assume responsibility for any non-genuine

parts used, even if these parts have been approved by an official testing

agency or are covered by an official approval certificate.

Any equipment subsequently installed which has a direct effect on the driv-

er's control of the vehicle (e.g. cruise control system or electronically-con-

trolled suspension) must be approved by SEAT and bear the e mark (the Eu-

ropean Union's authorisation symbol). If any

additional electrical components are fitted which do not serve to con-

trol the vehicle itself (e.g. refrigerator box, laptop or ventilator fan), these

must bear the CE mark (European Union manufacturer conformity declara-

tion).

WARNING

Accessories, for example telephone holders or cup holders, should never

be fitted on the covers, or within the working range, of the airbags. Oth-

erwise, there is a danger of injury if the airbag is triggered in an accident.

Technical modifications

Modifications must always be carried out according to our

specifications.

Unauthorised modifications to the electronic components or software in the

vehicle may cause malfunctions. Due to the way the electronic components

are linked together in networks, other indirect systems may be affected by

the faults. This can seriously impair safety, lead to excessive wear of compo-

nents, and also invalidate your vehicle registration documents.

The SEAT Technical Service cannot be held liable for any damage caused by

modifications and/or work incorrectly performed.

For this reason, we recommend having all work performed by a SEAT Techni-

cal Service using SEAT Original Spare Parts ®

.

Safety FirstOperating InstructionsPractical TipsTechnical Specifications

Page 187 of 280

185

Accessories, replacement of parts and modifications

Note

Please observe the operating instructions of your mobile telephone/two-

way radio.

Fitting a towing bracket*

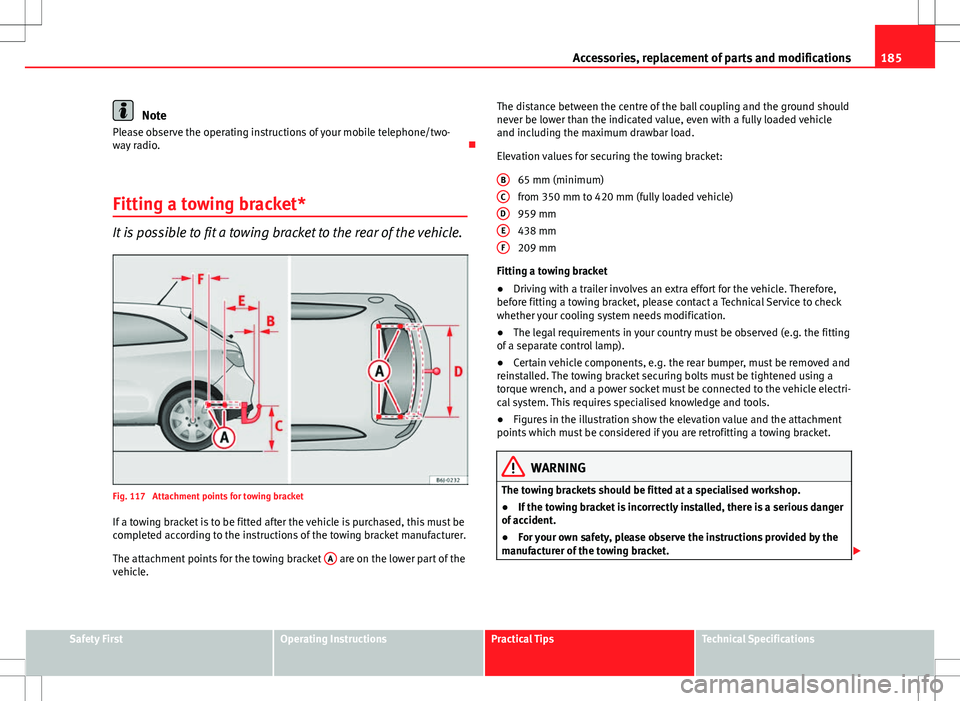

It is possible to fit a towing bracket to the rear of the vehicle.

Fig. 117 Attachment points for towing bracket If a towing bracket is to be fitted after the vehicle is purchased, this must be

completed according to the instructions of the towing bracket manufacturer.

The attachment points for the towing bracket A

are on the lower part of the

vehicle. The distance between the centre of the ball coupling and the ground should

never be lower than the indicated value, even with a fully loaded vehicle

and including the maximum drawbar load.

Elevation values for securing the towing bracket:

65 mm (minimum)

from 350 mm to 420 mm (fully loaded vehicle)

959 mm

438 mm

209 mm

Fitting a towing bracket

● Driving with a trailer involves an extra effort for the vehicle. Therefore,

before fitting a towing bracket, please contact a Technical Service to check

whether your cooling system needs modification.

● The legal requirements in your country must be observed (e.g. the fitting

of a separate control lamp).

● Certain vehicle components, e.g. the rear bumper, must be removed and

reinstalled. The towing bracket securing bolts must be tightened using a

torque wrench, and a power socket must be connected to the vehicle electri-

cal system. This requires specialised knowledge and tools.

● Figures in the illustration show the elevation value and the attachment

points which must be considered if you are retrofitting a towing bracket.

WARNING

The towing brackets should be fitted at a specialised workshop.

● If the towing bracket is incorrectly installed, there is a serious danger

of accident.

● For your own safety, please observe the instructions provided by the

manufacturer of the towing bracket.

BCDEF

Safety FirstOperating InstructionsPractical TipsTechnical Specifications

Page 189 of 280

187

Checking and refilling levels

Checking and refilling levels Refuelling

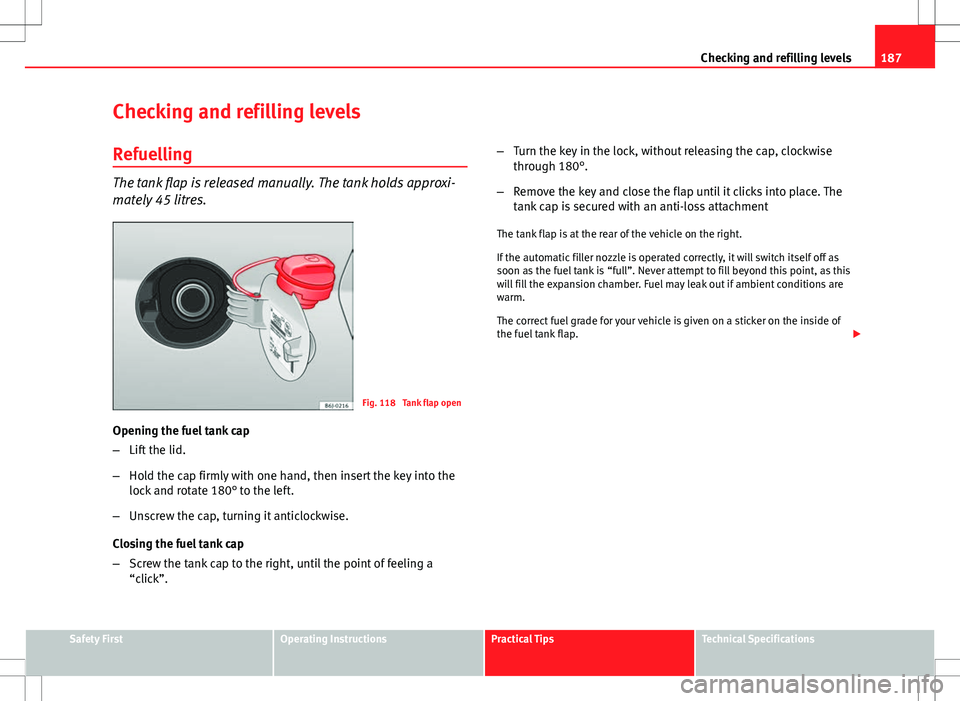

The tank flap is released manually. The tank holds approxi-

mately 45 litres.

Fig. 118 Tank flap open

Opening the fuel tank cap

– Lift the lid.

– Hold the cap firmly with one hand, then insert the key into the

lock and rotate 180° to the left.

– Unscrew the cap, turning it anticlockwise.

Closing the fuel tank cap

– Screw the tank cap to the right, until the point of feeling a

“click”. –

Turn the key in the lock, without releasing the cap, clockwise

through 180°.

– Remove the key and close the flap until it clicks into place. The

tank cap is secured with an anti-loss attachment

The tank flap is at the rear of the vehicle on the right.

If the automatic filler nozzle is operated correctly, it will switch itself off as

soon as the fuel tank is “full”. Never attempt to fill beyond this point, as this

will fill the expansion chamber. Fuel may leak out if ambient conditions are

warm.

The correct fuel grade for your vehicle is given on a sticker on the inside of

the fuel tank flap.

Safety FirstOperating InstructionsPractical TipsTechnical Specifications

Page 191 of 280

189

Checking and refilling levels

LPG system*

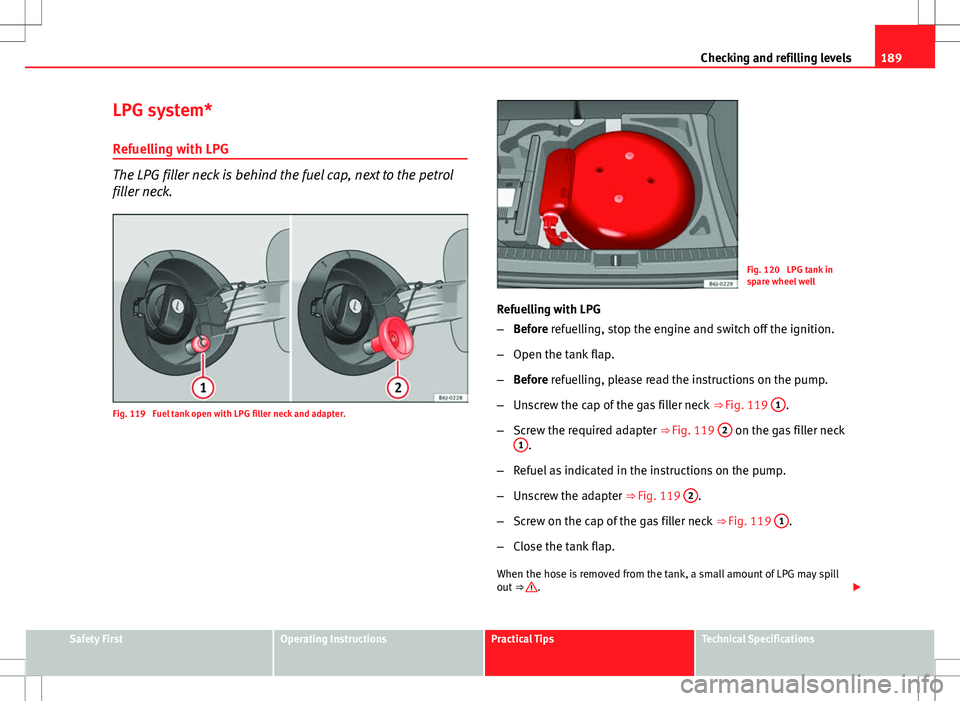

Refuelling with LPG

The LPG filler neck is behind the fuel cap, next to the petrol

filler neck.

Fig. 119 Fuel tank open with LPG filler neck and adapter.

Fig. 120 LPG tank in

spare wheel well

Refuelling with LPG

– Before refuelling, stop the engine and switch off the ignition.

– Open the tank flap.

– Before refuelling, please read the instructions on the pump.

– Unscrew the cap of the gas filler neck ⇒ Fig. 119 1

.

– Screw the required adapter ⇒ Fig. 119 2

on the gas filler neck

1.

– Refuel as indicated in the instructions on the pump.

– Unscrew the adapter ⇒ Fig. 119 2

.

– Screw on the cap of the gas filler neck ⇒ Fig. 119 1

.

– Close the tank flap.

When the hose is removed from the tank, a small amount of LPG may spill

out ⇒

.

Safety FirstOperating InstructionsPractical TipsTechnical Specifications

Page 193 of 280

191

Checking and refilling levels

Note

The four most common types of adapter in Europe are the ACME adapter 1,

the Dish Coupling adapter 2, the bayonet adapter 3 and the EURO adapt-

er 4. On the whole, we recommend you carry all four adapters in your vehi-

cle, as some countries use more than one type of filling system. The intro-

duction of a single system (Euronozzle) throughout Europe is being studied.

LPG fuel

LPG is an alternative vehicle fuel and is a blend of propane and butane.

The success of LPG is due to the strict regulations concerning exhaust gas

emissions. Compared to other fossil fuels, LPG is characterised by its re-

duced emissions.

LPG quality and consumption

Quality requirements for LPG are regulated for all Europe in DIN EN 589 and

permit the use of LPG throughout Europe.

A difference is drawn between winter gas and summer gas. Winter gas has a

higher proportion of propane gas. As a result, the driving range of winter

gas may be lower (due to increased consumption) than that of summer gas.

LPG supplier network

The number of LPG pumps is constantly increasing.

Lists of existing LPG pumps may be found on Internet.

LPG safety

A series of collision tests performed on this vehicle while running with LPG

have confirmed its high level of safety. The safety of the LPG system guarantees operation without risk. The follow-

ing safety measures have been adopted:

●

The LPG tank has a solenoid valve which closes automatically when the

engine is switched off (ignition off) or when running on petrol.

● A solenoid type main valve disconnects the supply of gas to the engine

compartment when the engine is switched off or running on petrol.

● A safety valve in the LPG tank with pipes to the outside prevents the gas

from entering the vehicle interior.

● All anchorage points and materials have been designed to ensure the

maximum possible levels of safety.

The condition of the LPG system should be checked regularly to guarantee

safe driving conditions ⇒

. These checks are included in the Maintenance

Programme.

WARNING

● If there is a smell of gas or a suspected leak, stop the vehicle immedi-

ately and switch off the ignition. Open the doors to ventilate the vehicle.

Do not carry on driving! Take the vehicle to a specialised workshop and

have the fault repaired.

● Immediately extinguish any cigarettes and remove from the vehicle

any objects which might produce a spark or cause a fire, and switch off

immediately if gas is smelt or a leak is detected.

● LPG tanks are subject to pressure and must be checked regularly. The

owner of the vehicle must check that these services are performed cor-

rectly.

● When parking the vehicle in a closed area (for example in a garage),

make sure that there is adequate ventilation, either natural or mechani-

cal, to neutralise the LPG in the event of a leak.

Note

For any fault in the LPG system, please refer to the SEAT web page, which

lists the workshops authorised to repair these faults.

Safety FirstOperating InstructionsPractical TipsTechnical Specifications

Page 195 of 280

193

Checking and refilling levels

Winter driving

Diesel can thicken in winter.

Winter-grade diesel

When using “summer-grade diesel fuel”, difficulties may be experienced at

temperatures below 0°C because the fuel thickens due to wax separation.

Therefore, “winter-grade diesel fuel” is available in some countries during

the cold months. It can be used at temperatures as low as -22°C.

In countries with different climatic conditions the diesel fuel generally sold

has different temperature characteristics. Check with the Technical Services

or filling stations in the country concerned regarding the type of diesel fuels

available.

Filter pre-heater

Your vehicle is fitted with a fuel filter glow plug system, making it well

equipped for operation in winter. This ensures that the fuel system remains

operational to approx. -24°C, provided you use winter-grade diesel which is

safe to -15°C.

However, if the fuel has waxed to such an extent that the engine will not

start at temperatures of under -24°C, simply place the vehicle in a warm

place for a while.

CAUTION

Do not mix fuel additives (thinners or similar products) with diesel fuel. Working in the engine compartment

Safety instructions on working in the engine compartment

Any work carried out in the engine compartment or on the

engine must be carried out cautiously.

Before starting any work on the engine or in the engine compart-

ment:

1. Switch off the engine and remove the key from the ignition.

2. Apply the handbrake.

3. Move the gear lever to neutral or the selector lever to position P.

4. Wait for the engine to cool down.

5. Keep children away from the vehicle.

6. Raise the bonnet ⇒ page 195.

You should not do any work in the engine compartment unless you know ex-

actly how to carry out the jobs and have the correct tools! Have the work car-

ried out by a specialised workshop if you are uncertain.

All service fluids and consumables, e.g. coolant, engine oil, spark plugs

and batteries, are under constant development. SEAT provides a constant

flow of information to the Technical Services concerning modifications. For

this reason, we recommend you to have service fluids and consumables re-

placed by a Technical Service. Please observe the relevant instructions

⇒ page 183. The engine compartment of the vehicle is a hazardous area

⇒

.

Safety FirstOperating InstructionsPractical TipsTechnical Specifications

Page 197 of 280

195

Checking and refilling levels

For the sake of the environment

Service fluids leaks are harmful to the environment. For this reason you

should make regular checks on the ground underneath your vehicle. If you

find spots of oil or other fluids, have your vehicle inspected in a specialised

workshop.

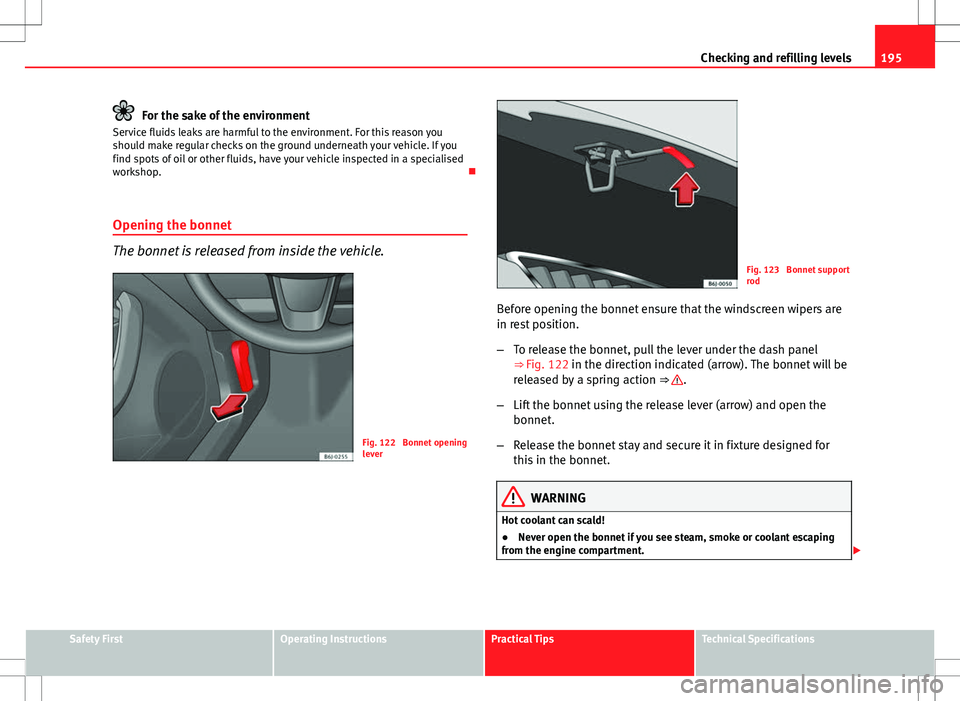

Opening the bonnet

The bonnet is released from inside the vehicle.

Fig. 122 Bonnet opening

lever

Fig. 123 Bonnet support

rod

Before opening the bonnet ensure that the windscreen wipers are

in rest position.

– To release the bonnet, pull the lever under the dash panel

⇒ Fig. 122 in the direction indicated (arrow). The bonnet will be

released by a spring action ⇒

.

– Lift the bonnet using the release lever (arrow) and open the

bonnet.

– Release the bonnet stay and secure it in fixture designed for

this in the bonnet.

WARNING

Hot coolant can scald!

● Never open the bonnet if you see steam, smoke or coolant escaping

from the engine compartment.

Safety FirstOperating InstructionsPractical TipsTechnical Specifications

Page 198 of 280

196Checking and refilling levels

WARNING (Continued)

● Wait until no more steam, smoke or coolant is emitted from the bon-

net, then carefully open the bonnet.

● When working in the engine compartment, always observe the safety

warnings ⇒ page 193.

Closing the bonnet

– Slightly raise the bonnet

– Release the bonnet stay and replace it in its support.

– At a height of about 30 cm let it fall so it is locked.

If the bonnet does not close, do not press downwards. Open it once more

and let it fall as before.

WARNING

If the bonnet is not closed properly, it could open while you are driving

and completely obscure your view of the road. Risk of accident.

● After closing the bonnet, always check that it is properly secured. The

bonnet must be flush with the surrounding body panels.

● If you notice that the bonnet latch is not secured when the vehicle is

moving, stop the vehicle immediately and close the bonnet properly.

Risk of accident.

Engine oil

General notes

The engine comes with a special, multi-grade oil that can be used all year

round.

Because the use of high-quality oil is essential for the correct operation of

the engine and its long useful life, when topping up or changing oil, use on-

ly those oils that comply with VW standards.

The specifications (VW standards) set out in the following page should ap-

pear on the container of the service oil; when the container displays the

specific standards for petrol and diesel engines together, it means that the

oil can be used for both types of engines.

We recommend that the oil change, indicated in the Maintenance Pro-

gramme, be performed by a Technical Service or a specialised workshop.

The correct oil specifications for your engine are listed in ⇒ page 197, Oil

properties.

Service intervals

Service intervals can be flexible (LongLife service) or fixed (dependent on

time/distance travelled).

If the PR code that appears on the back of the “Maintenance Programme”

booklet is QG1, this means that your vehicle has the LongLife service pro-

grammed. If it has the codes QG0 or QG2 the interval service is dependent

on time/distance travelled.

Flexible service intervals (LongLife service intervals*)

Special oils and processes have been developed which, depending on the

characteristics and individual driving profiles, enable the extension of the

oil change service (LongLife service intervals).

Page 199 of 280

197

Checking and refilling levels

Because this oil is essential for extending the service intervals, it must only

be used observing the following indications:

● Avoid mixing it with oil for fixed service intervals.

● Only in exceptional circumstances, if the engine oil level is too low

⇒ page 198 and LongLife oil is not available, it is permitted to top up

(once) with oil for fixed service intervals ⇒ page 197 (up to a maximum of

0.5 litres).

Fixed service intervals*

If your vehicle does not have the “LongLife service interval” or it has been

disabled (by request), you may use oils for fixed service intervals, which al-

so appear in ⇒ page 197, Oil properties. In this case, your vehicle must be

serviced after a fixed interval of 1 year/15 000 km (10 000 miles)(whatever

comes first) ⇒ Booklet Maintenance Programme.

● In exceptional circumstances, if the engine oil level is too low

⇒ page 198 and you cannot obtain the oil specified for your vehicle, you

can put in a small quantity of oil conforming to the specification ACEA A2 or

ACEA A3 (petrol engines) or ACEA B3 or ACEA B4 (diesel engines) (up to 0.5

l).

Vehicles with diesel particulate filter*

The “Maintenance Programme” states whether your vehicle is fitted with a

diesel particulate filter.

Only VW 507 00 engine oil, with reduced ash formation, may be used in die-

sel engines equipped with particulate filter. Using other types of oil will

cause a higher soot concentration and reduce the life of the DPF. Therefore:

● Avoid mixing this oil with other engine oils.

● Only in exceptional circumstances, if the engine oil level is too low

⇒ page 198 and you cannot obtain the oil specified for your vehicle, you

can use a small quantity of oil (once) conforming to the VW 506 00,

VW 506 01, VW 505 00, VW 505 01 or ACEA B3 / ACEA B4 specification. (up

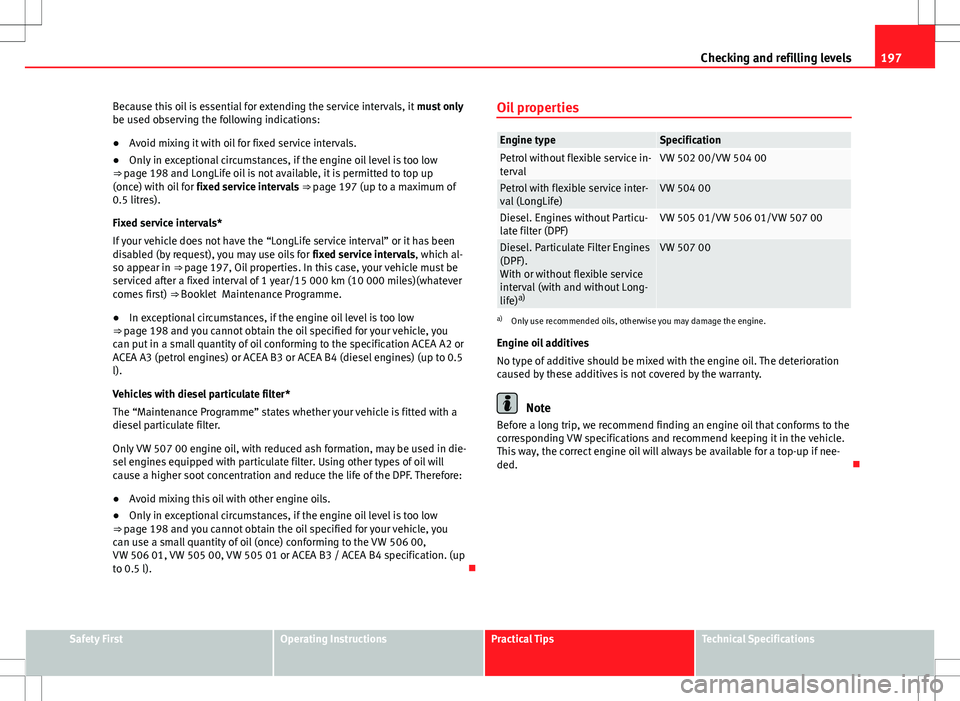

to 0.5 l). Oil properties

Engine typeSpecificationPetrol without flexible service in-

tervalVW 502 00/VW 504 00

Petrol with flexible service inter-

val (LongLife)VW 504 00

Diesel. Engines without Particu-

late filter (DPF)VW 505 01/VW 506 01/VW 507 00

Diesel. Particulate Filter Engines

(DPF).

With or without flexible service

interval (with and without Long-

life)

a)VW 507 00

a)

Only use recommended oils, otherwise you may damage the engine.

Engine oil additives

No type of additive should be mixed with the engine oil. The deterioration

caused by these additives is not covered by the warranty.

Note

Before a long trip, we recommend finding an engine oil that conforms to the

corresponding VW specifications and recommend keeping it in the vehicle.

This way, the correct engine oil will always be available for a top-up if nee-

ded.

Safety FirstOperating InstructionsPractical TipsTechnical Specifications

Page 201 of 280

199

Checking and refilling levels

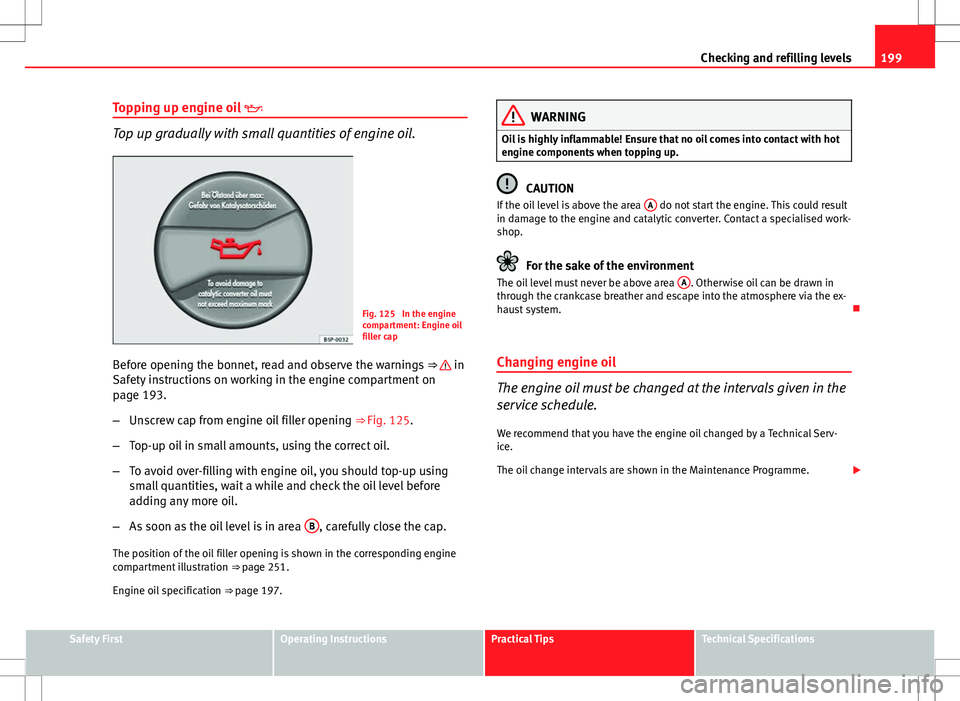

Topping up engine oil

Top up gradually with small quantities of engine oil.

Fig. 125 In the engine

compartment: Engine oil

filler cap

Before opening the bonnet, read and observe the warnings ⇒

in

Safety instructions on working in the engine compartment on

page 193.

– Unscrew cap from engine oil filler opening ⇒ Fig. 125.

– Top-up oil in small amounts, using the correct oil.

– To avoid over-filling with engine oil, you should top-up using

small quantities, wait a while and check the oil level before

adding any more oil.

– As soon as the oil level is in area B

, carefully close the cap.

The position of the oil filler opening is shown in the corresponding engine

compartment illustration ⇒ page 251.

Engine oil specification ⇒ page 197.

WARNING

Oil is highly inflammable! Ensure that no oil comes into contact with hot

engine components when topping up.

CAUTION

If the oil level is above the area A do not start the engine. This could result

in damage to the engine and catalytic converter. Contact a specialised work-

shop.

For the sake of the environment

The oil level must never be above area A. Otherwise oil can be drawn in

through the crankcase breather and escape into the atmosphere via the ex-

haust system.

Changing engine oil

The engine oil must be changed at the intervals given in the

service schedule. We recommend that you have the engine oil changed by a Technical Serv-

ice.

The oil change intervals are shown in the Maintenance Programme.

Safety FirstOperating InstructionsPractical TipsTechnical Specifications