lock Seat Toledo 2014 Workshop Manual

[x] Cancel search | Manufacturer: SEAT, Model Year: 2014, Model line: Toledo, Model: Seat Toledo 2014Pages: 200, PDF Size: 4.37 MB

Page 130 of 200

Advice

Removing stains

Remove fresh water-based

stains such as cof-

f

ee, tea, juices, blood, etc. with an absorbent

cloth or kitchen roll. Use the special deter-

gent to clean dried-on stains.

Remove fresh

fat-based stains such as but-

ter

, mayonnaise, chocolate, etc. with an ab-

sorbent cloth or paper towel or use the spe-

cial detergent if the stain has not yet soaked

through the surface.

Use a grease-dissolving product to treat

dried-in, fat-based stains.

Treat less common stains such as ball-pen

and other inks, felt-tip pens, nail polish,

emulsion paint, shoe cream etc. with a spe-

cial leather stain remover.

Leather care

The leather should be treated regularly

(about twice a year) with a leather-care prod-

uct.

Apply the protective product very sparingly.

Dry the leather with a soft, dry cloth. CAUTION

● Avoid exposing leather to direct sunlight

for long periods so that it does not lose its

colour. If the car is left for a prolonged period

outdoors, cover the leather so that it does

not lose its colour. ●

Sharp-edged objects on clothing, such as

zips, rivets or belts can leave permanent

scratches and rough marks on the surface of

the leather.

● Use of a mechanical steering wheel lock

can damage the leather surface of the steer-

ing wheel. Note

● Use a suitable impregnating cream with ul-

tra-violet protection at regular intervals and

after cleaning. The cream will nourish and

moisturise the leather, keep it supple and

able to breathe. In addition, it will also help

to protect the surface of the leather.

● Clean the leather every 2 to 3 months and

remove fresh dirt as necessary.

● Preserve the colour of the leather. A special

coloured cream for leather will renew the col-

our of more heavily worn areas as required.

● Leather is a natural material with specific

properties. During vehicle use, the appear-

ance of parts of the leather covers may

change; folds or wrinkles may appear as a re-

sult of their use. Seat belts

Keep the seat belts clean!

Wash soiled seat belts with mild, soapy wa-

ter, removing any heavier dirt with a soft

brush.Check the condition of all seat belts at regu-

lar intervals.

Very soiled belts may not retract properly.

WARNING

● The seat belts should never be removed

from the vehicle for cleaning.

● Never clean using chemical products, as

chemical detergents destroy the fabric. En-

sure that the seat belts do not come into con-

tact with corrosive fluids such as acids, etc.

● If you find any damage to the belt webbing,

belt fittings, the belt retractor or the buckle,

the belt in question must be replaced by an

Official Service.

● Make sure that the inertia reel seat belts

are completely dry before allowing them to

retract. 128

Page 131 of 200

Checking and refilling levels

Checking and refilling levels

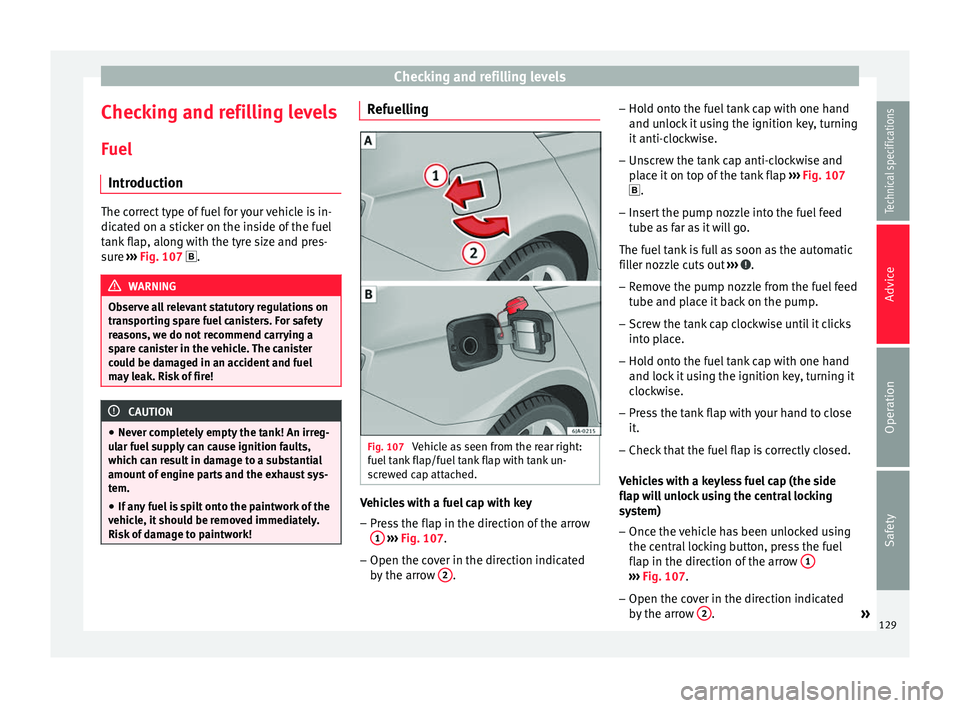

Fuel Introduction The correct type of fuel for your vehicle is in-

dicated on a sticker on the inside of the fuel

tank flap, along with the tyre size and pres-

sure

››› Fig. 107 . WARNING

Observe all relevant statutory regulations on

transporting spare fuel canisters. For safety

reasons, we do not recommend carrying a

spare canister in the vehicle. The canister

could be damaged in an accident and fuel

may leak. Risk of fire! CAUTION

● Never completely empty the tank! An irreg-

ular fuel supply can cause ignition faults,

which can result in damage to a substantial

amount of engine parts and the exhaust sys-

tem.

● If any fuel is spilt onto the paintwork of the

vehicle, it should be removed immediately.

Risk of damage to paintwork! Refuelling

Fig. 107

Vehicle as seen from the rear right:

fuel tank flap/fuel tank flap with tank un-

screwed cap attached. Vehicles with a fuel cap with key

–

Press the flap in the direction of the arrow

1

››› Fig. 107 .

– Open the c o

ver in the direction indicated

by the arrow 2 .–

Hold onto the fuel tank cap with one hand

and unlock it using the ignition key, turning

it anti-clockwise.

– Unscrew the tank cap anti-clockwise and

place it on top of the tank flap ››› Fig. 107

.

– Inser

t the pump nozzle into the fuel feed

tube as far as it will go.

The fuel tank is full as soon as the automatic

filler nozzle cuts out ››› .

– Remove the pump nozzle from the fuel feed

tube and place it back on the pump.

– Screw the tank cap clockwise until it clicks

into place.

– Hold onto the fuel tank cap with one hand

and lock it using the ignition key, turning it

clockwise.

– Press the tank flap with your hand to close

it.

– Check that the fuel flap is correctly closed.

Vehicles with a keyless fuel cap (the side

flap will unlock using the central locking

system)

– Once the vehicle has been unlocked using

the central locking button, press the fuel

flap in the direction of the arrow 1 ›››

Fig. 107 .

– Open the c o

ver in the direction indicated

by the arrow 2 .

»

129

Technical specifications

Advice

Operation

Safety

Page 132 of 200

Advice

– Unscrew the tank cap anti-clockwise and

place it on top of the tank flap ››› Fig. 107

.

– Insert the pump nozzle into the fuel feed

tube as far as it will go.

The fuel tank is full as soon as the automatic

filler nozzle cuts out ››› .

– Remove the pump nozzle from the fuel feed

tube and place it back on the pump.

– Screw the tank cap clockwise until it clicks

into place.

– Close the tank flap. Make sure you hear it

click into place.

– Check that the fuel flap is properly closed. CAUTION

● Switch off the auxiliary heater (heater and

independent heater) before filling the tank.

● The fuel tank is full as soon as the automat-

ic filler nozzle cuts out. Do not continue fill-

ing, as this will fill the expansion chamber. Note

The fuel tank capacity is around 55 litres, of

which 7 litres are the reserve. Unleaded petrol

Your vehicle must only be run on

unleaded

petrol that complies with the Standard EN

228 (in Germany, also DIN 51626 – 1, or E10

for unleaded petrol with 95 and 91 octane

rating (RON) or DIN 51626 – 2, or E5 for un-

leaded petrol with 95 and 98 RON).

Prescribed fuel – unleaded petrol (95/91

RON)

Use unleaded petrol with 95

RON. Unleaded

petrol with 91 RON can also be used, al-

though thi s

will result in a slight loss of pow-

er.

If, as an emergency measure, you have to fill

the tank with petrol with a lower RON to that

prescribed, use only moderate engine

speeds and light throttle. High engine speed

and full throttle can seriously damage the en-

gine! Fill up with petrol with the correct RON

as soon as possible.

Prescribed fuel – unleaded petrol (min. 95

RON)

Use unleaded petrol with 95 RON.

If u

nleaded petrol with 95 RON is not availa-

bl

e, you can fill up with petrol with 91 RON as

an emerg

ency measure. In this case, use only

moderate engine speeds and a light throttle.

High engine speed and full throttle can seri- ously damage the engine! Fill up with petrol

with the correct RON as soon as possible.

Petrol with a RON below

91 cannot be used,

even a

s an emergency measure. Risk of seri-

ously damaging the engine!

Unleaded petrol with higher RON

Unleaded petrol with a higher RON to that

prescribed can be used without limits.

In vehicles running on prescribed unleaded

petrol with 95/91 RON

, there is no notable

increase in power or lower fuel consumption

when petrol with a RON higher than 95

is

used.

In vehicles running on prescribed unleaded

petrol with min. 95 RON

, there is an increase

in power and a lower fuel consumption when

petrol with a RON higher than 95

is used.

Prescribed fuel – unleaded petrol (98/(95)

RON)

Use unleaded petrol with 98

RON. Unleaded

petrol with 95 RON can also be used, al-

though this will result in a slight loss of pow-

er.

If unleaded petrol with 98

or 95 RON is not

available, you can fill up with petrol with 91

RON as an emergency measure. In this case,

use only moderate engine speeds and a light

throttle. High engine speed and full throttle

can seriously damage the engine! Fill up with

130

Page 135 of 200

Checking and refilling levels

CAUTION

● When topping up fluids, make sure the cor-

rect fluid is put into the correct filler opening.

Otherwise this can cause serious malfunc-

tions or engine damage!

● Never open the bonnet using the release

catch. Risk of damage! For the sake of the environment

Due to the environmentally-friendly disposal

of fluids, the equipment necessary and the

knowledge required, let an authorised SEAT

dealer change fluids during service inspec-

tions of the vehicle. Note

● Please contact an authorised SEAT dealer

with any doubts regarding fluids.

● Fluids of the correct specifications can be

acquired from the selection of SEAT Original

Accessories. Opening and closing the bonnet

Fig. 108

Unlocking the bonnet. Fig. 109

Locking the bonnet. Opening the bonnet

–

Open the front left door.

– Pull the lever 1

››› Fig. 108 under the dash

p anel

in the direction indicated by the ar-

row.

Before opening

the bonnet, make sure that

the windscreen wiper arms are not lifted »

133

Technical specifications

Advice

Operation

Safety

Page 141 of 200

Checking and refilling levels

Brake fluid Checking brake fluid level Fig. 113

Engine compartment: brake fluid

reservoir. The brake fluid reservoir is located in the en-

gine compartment of the vehicle.

– Switch the ignition off.

– Open the bonnet ››› page 132.

– Check the brake fluid level in the reservoir

››› Fig. 113 . It should be between the “MIN”

and “MAX” m ark

s.

The fluid level drops slightly after a period of

time due to automatic compensation for

brake pad wear. This is quite normal.

However, if the level goes down noticeably in

a short time, or drops below the “MIN” mark,

there may be a leak in the brake system. If

the brake fluid level in the reservoir is too low, this will be indicated by the warning

lamp illuminating on the instrument panel

››› page 33, Brake system . WARNING

If the fluid level has dropped below the MIN

mark, do not continue driving. Risk of acci-

dent! Go t

o a technical service. Changing the brake fluid

Brake fluid absorbs moisture. Therefore, it

gradually absorbs moisture from the atmos-

phere. If the water content in the brake fluid

is too high, the brake system could corrode.

The water content also reduces the boiling

point of the brake fluid.

The brake fluid must comply with one of the

following standards or specifications:

● VW 50114

● FMVSS 116 DOT4 WARNING

Heavy use of the brakes may cause a vapour

lock if the brake fluid is left in the brake sys-

tem for too long. This would seriously affect

the efficiency of the brakes and the safety of

the vehicle. CAUTION

Brake fluid damages the vehicle paintwork. Windscreen washer

Fig. 114

Engine compartment: windscreen

washer reservoir. The container for the windscreen washer con-

tains the cleaning fluid for the windscreen or

rear window and the headlight washer sys-

tem. The container is located in the engine

compartment.

»

139Technical specifications

Advice

Operation

Safety

Page 145 of 200

Checking and refilling levels

CAUTION

In vehicles fitted with the “Start-Stop” sys-

tem, the charger cable cannot be directly con-

nected to the negative terminal of the vehicle

battery but must be attached to the engine

ground point ››› page 158. Disconnecting and connecting the

battery

The following functions will either be inoper-

ative or will not work properly after discon-

necting and reconnecting the battery:FunctionInstallation

Setting the clock›››

page 32

The multifunction display data

is deleted››› page 39 Note

We recommend having the vehicle checked by

an authorised SEAT dealer to guarantee the

correct working order of all electrical sys-

tems. Changing the battery

A replacement battery must have the same

capacity, voltage, current rating and size as

the original. The appropriate types of battery can be acquired from authorised SEAT deal-

ers.

We recommend having the battery changed

by an authorised SEAT dealer, where the new

battery will be correctly installed and the

original disposed of in line with regulations.

Automatic disconnection of electrical

equipment When heavily-charging a battery, the pro-

gramme selected by the electrical system

control unit prevents the battery from auto-

matically discharging. This may result in the

following:

● Increase in idling speed so that the alterna-

tor can supply more current to the electrical

system.

● The performance of certain electrical com-

ponents could be limited or some may switch

off temporarily, e.g. the heated seats, the

heated rear window, the 12 V power socket. Note

Despite any measures taken by the control

unit, the battery could drain. e.g. with the en-

gine is switched off, the key is turned in the

ignition for a long period or the side lights or

parking lights are switched on. The switching

off of certain electrical components does not

impair driving comfort and often the driver

will not even notice. 143

Technical specifications

Advice

Operation

Safety

Page 151 of 200

Emergencies

Snow chains Snow chains must only be used on the front

wheels.

In winter road conditions, snow chains not

only help to improve grip but also improve

the braking capacity.

For technical reasons snow chains may only

be used on tyres with the following wheel

rim/tyre combinations.Rim sizeRim offsetTyre size

5J x 14

a)35 mm175/70

6J x 15b)38 mm185/60

6J x 15b)38 mm195/55

a)

Only use snow chains with fine-pitch links and lock no greater

than 9 mm.

b) Only use snow chains with fine-pitch links and lock no greater

than 13 mm.

Remove the wheel trims before fitting snow

chains. CAUTION

Chains must be removed when roads are free

of snow. Otherwise they will impair handling,

damage the tyres and wear out very quickly. Emergencies

Emergency equipment First-aid kit and warning triangle* Fig. 121

Location of the warning triangle. The warning triangle, measuring max.

436 x 45 x 32 mm, can be secured to the lin-

ing on the rear of the luggage compartment

with rubber straps

››› Fig. 121. WARNING

The first-aid kit and fire extinguisher must be

properly secured so that they are not catapul-

ted through the vehicle during driving and

braking manoeuvres or in the event of an ac-

cident. Risk of injury. Note

● Observe the expiry date of the contents of

the first aid kit.

● We recommend you use the first-aid kit and

the warning triangle from the SEAT Original

Accessories programme available in author-

ised SEAT dealers. Fire extinguisher*

Read the instructions given on the fire extin-

guisher carefully.

The fire extinguisher must be checked once a

year by an authorised person (take the appli-

cable legal regulations into account).

WARNING

The fire extinguisher must be properly se-

cured so that it is not catapulted through the

vehicle, causing injuries, during driving and

braking manoeuvres or in the event of an ac-

cident. Note

● The fire extinguisher must comply with lo-

cal legal requirements.

● Observe the expiry date of the fire extin-

guisher. The fire extinguisher may not work

properly if used after the expiry date. 149

Technical specifications

Advice

Operation

Safety

Page 152 of 200

Advice

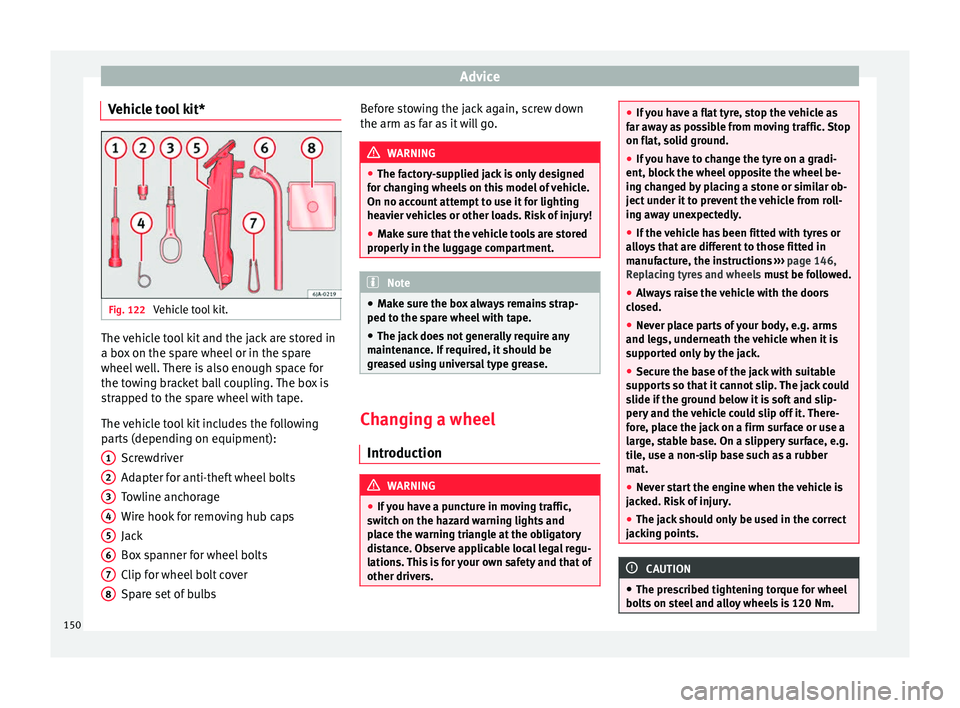

Vehicle tool kit* Fig. 122

Vehicle tool kit. The vehicle tool kit and the jack are stored in

a box on the spare wheel or in the spare

wheel well. There is also enough space for

the towing bracket ball coupling. The box is

strapped to the spare wheel with tape.

The vehicle tool kit includes the following

parts (depending on equipment):

Screwdriver

Adapter for anti-theft wheel bolts

Towline anchorage

Wire hook for removing hub caps

Jack

Box spanner for wheel bolts

Clip for wheel bolt cover

Spare set of bulbs

1 2

3

4

5

6

7

8 Before stowing the jack again, screw down

the arm as far as it will go.

WARNING

● The factory-supplied jack is only designed

for changing wheels on this model of vehicle.

On no account attempt to use it for lighting

heavier vehicles or other loads. Risk of injury!

● Make sure that the vehicle tools are stored

properly in the luggage compartment. Note

● Make sure the box always remains strap-

ped to the spare wheel with tape.

● The jack does not generally require any

maintenance. If required, it should be

greased using universal type grease. Changing a wheel

Introduction WARNING

● If you have a puncture in moving traffic,

switch on the hazard warning lights and

place the warning triangle at the obligatory

distance. Observe applicable local legal regu-

lations. This is for your own safety and that of

other drivers. ●

If you have a flat tyre, stop the vehicle as

far away as possible from moving traffic. Stop

on flat, solid ground.

● If you have to change the tyre on a gradi-

ent, block the wheel opposite the wheel be-

ing changed by placing a stone or similar ob-

ject under it to prevent the vehicle from roll-

ing away unexpectedly.

● If the vehicle has been fitted with tyres or

alloys that are different to those fitted in

manufacture, the instructions ››› page 146,

Replacing tyres and wheels must be followed.

● Always raise the vehicle with the doors

closed.

● Never place parts of your body, e.g. arms

and legs, underneath the vehicle when it is

supported only by the jack.

● Secure the base of the jack with suitable

supports so that it cannot slip. The jack could

slide if the ground below it is soft and slip-

pery and the vehicle could slip off it. There-

fore, place the jack on a firm surface or use a

large, stable base. On a slippery surface, e.g.

tile, use a non-slip base such as a rubber

mat.

● Never start the engine when the vehicle is

jacked. Risk of injury.

● The jack should only be used in the correct

jacking points. CAUTION

● The prescribed tightening torque for wheel

bolts on steel and alloy wheels is 120 Nm. 150

Page 155 of 200

Emergencies

Loosening wheel bolts – Fit the box spanner as far as it will go over

the wheel bolt 1)

.

– Grip the end of the box spanner and turn

the wheel bolt about one turn anti-clock-

w i

se ››› Fig. 124.

Tightening wheel bolts – Fit the box spanner as far as it will go over

the wheel bolt 1)

.

– Grip the box spanner as close to the end as

possible and tighten the bolt firmly by turn-

ing clockwise. WARNING

The wheel bolts should only be loosened

slightly (about one turn) before raising the

vehicle with the jack. Risk of accident! Note

If the wheel bolt is very tight, it may be pos-

sible to loosen it by pushing down the end of

the box spanner carefully with your foot. Hold

on to the vehicle for support and take care

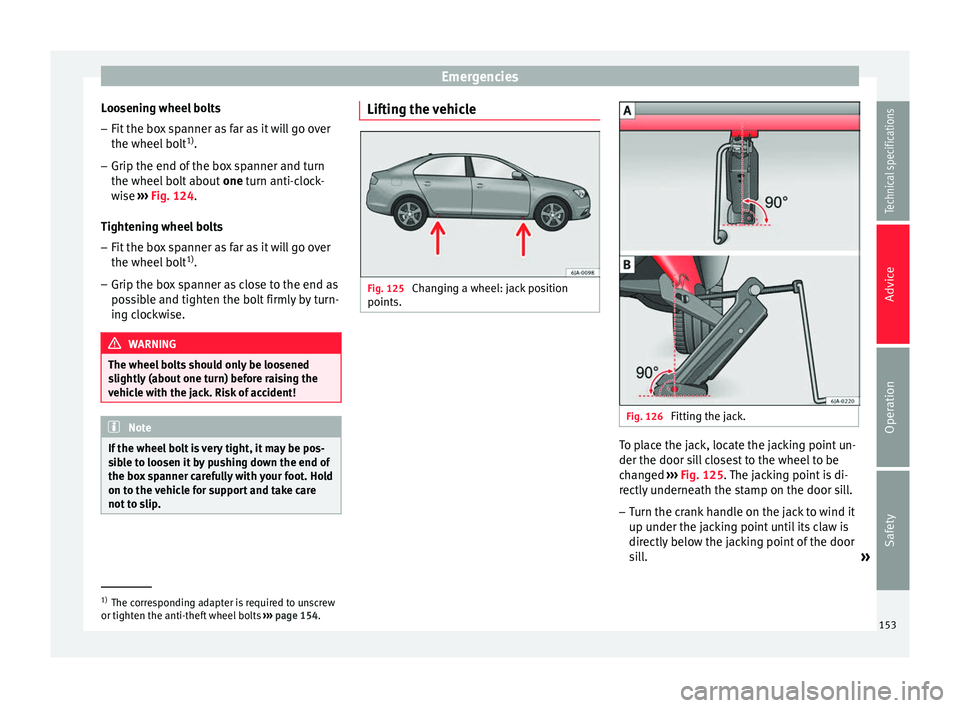

not to slip. Lifting the vehicle

Fig. 125

Changing a wheel: jack position

points. Fig. 126

Fitting the jack. To place the jack, locate the jacking point un-

der the door sill closest to the wheel to be

changed

››› Fig. 125 . The jacking point is di-

r ectly

underneath the stamp on the door sill.

– Turn the crank handle on the jack to wind it

up under the jacking point until its claw is

directly below the jacking point of the door

sill.

»1)

The corresponding adapter is required to unscrew

or tighten the anti-theft wheel bolts ››› page 154.

153

Technical specifications

Advice

Operation

Safety

Page 160 of 200

Advice

How to jump start: description Fig. 129

Diagram of connections for vehicles

without Start Stop system Fig. 130

Diagram of connections for vehicles

with Start Stop system Jump lead terminal connections

1. Switch off the ignition of both vehicles

››› . 2. Connect one end of the

red jump lead to

the po s

itive + terminal of the vehicle

with the flat battery A

››› Fig. 129 .

3. C

onnect the other end of the red

jump

lead to the positive terminal + in the ve-

hicle providing assistance B .

4. For vehicles without Start-Stop system:

connect one end of the black jump lead to

the negative terminal – of the vehicle

providing the current B

››› Fig. 129 .

– For

vehicles with Start-Stop system: con-

nect one end of the black jump lead X to a

suitable ground terminal, to a solid piece of

metal in the engine block, or to the engine

block itself ››› Fig. 130 .

5. C

onnect the other end of the black jump

lead X to a solid metal component bolted

to the engine block or to the engine block

itself of the vehicle with the flat battery.

Do not connect it to a point near the bat-

tery A .

6. Position the leads in such a way that they cannot come into contact with any moving

parts in the engine compartment.

Starting

7. Start the engine of the vehicle with the boosting battery and let it run at idling

speed. 8. Start the engine of the vehicle with the flat

battery and wait 2 or 3 minutes until the

engine is “running”.

Removing the jump leads

9. Before you remove the jump leads, switch off the dipped beam headlights (if they

are switched on).

10.Turn on the heater blower and heated rear window in the vehicle with the flat battery.

This helps minimise voltage peaks which

are generated when the leads are discon-

nected.

11. When the engine is running, disconnect

the l e

ads in reverse order to the details

given above.

Connect the battery clamps so they have

good metal-to-metal contact with the battery

terminals.

If the engine fails to start, switch off the start-

er after about 10 seconds and try again after

about 1 minute. WARNING

● Please note the safety warnings referring to

working in the engine compartment

››› page 132.

● The b att

ery providing assistance must have

the same voltage as the flat battery (12V) and

approximately the same capacity (see imprint 158