wheel torque SKODA FABIA 2014 2.G / 5J Owner's Manual

[x] Cancel search | Manufacturer: SKODA, Model Year: 2014, Model line: FABIA, Model: SKODA FABIA 2014 2.G / 5JPages: 197, PDF Size: 13.56 MB

Page 152 of 197

WARNING (Continued)■Unusual vibrations or pulling of the vehicle to one side could be a sign of

tyre damage. If there is any doubt that a wheel is damaged, immediately re-

duce your speed and stop! If no external damage is evident, drive slowly

and carefully to the nearest specialist garage to have the vehicle checked.■

Only use those tyres or wheel rims which have been approved by ŠKODA

for your model of vehicle. Failure to observe this instruction will adversely

affect the road safety of your vehicle – there is the risk of an accident.

WARNINGInformation regarding tyre damage or wear■Never use tyres if you do not know anything about the condition and age.■

Never drive with damaged tyres – there is the risk of an accident.

■

Immediately replace damaged wheel rims or tyres.

■

You must have your tyres replaced with new ones at the latest when the

wear indicators have been worn down.

■

Worn tyres do not provide the necessary grip particularly at high speeds

on wet roads. “Aquaplaning” (uncontrolled movements of the vehicle –

“swimming” on a wet road surface) could be the result.

WARNINGInformation on tyre pressure■The tyre control display does not absolve the driver of the responsibility

to ensure the correct tyre inflation pressure. Check the tyre pressure at

regular intervals.■

Pressures that are too low or too high impair handling – there is the risk

of an accident.

■

If the pressure is too low, the tyre must overcome a greater rolling resist-

ance. This will heat the tyre up, especially at higher speeds. This can result

in tread separation and a tyre blowout.

WARNINGInformation on the wheel bolts■The wheel bolts must be clean and must turn easily. Never treat them

with grease or oil.■

The prescribed tightening torque of the wheel bolts for steel and light al-

loy wheels is 120 Nm.

WARNING (Continued)■ If the wheel bolts are tightened to a too low tightening torque, the rim

can come loose when the car is moving – risk of accident! A tightening tor-

que which is too high can damage the bolts and threads and this can result

in permanent deformation of the contact surfaces on the rim.■

In case of incorrect treatment of the wheel bolts, the wheel can loosen

when the car is moving – risk of accident!

WARNINGInformation on the spare wheel■Only use the spare wheel while absolutely necessary.■

Never drive with more than one spare wheel mounted.

■

The snow chains cannot be used on the spare wheel.

CAUTION

■ If a spare wheel is used that is not identical to the fitted tyres, the following

must be observed » page 155, Spare and back-up wheel .■

Protect the tyres from contact with oil, grease and fuel.

■

Replace lost dust caps.

■

If, in the event of a puncture, it is necessary to fit a spare wheel with a tyre

without a dedicated running direction or the opposite running direction, drive

carefully as the optimum characteristics of the tyre are no longer applicable in

this situation.

For the sake of the environment

Tyres which are insufficiently inflated increase your fuel consumption.

Note

■ We recommend that any work on the wheels or tyres is carried out by a spe-

cialist garage.■

We recommend that you use wheel rims, tyres, full wheel trims and snow

chains from ŠKODA Original Accessories.

150General Maintenance

Page 162 of 197

WARNING (Continued)■Secure the base plate of the lifting jack with suitable means to prevent

possible moving. A soft and slippery ground under the base plate may move

the lifting jack, causing the vehicle to fall down. It is therefore always nec-

essary to place the lifting jack on a solid surface or use a wide and stable

base. Use a non-slip base (e.g. a rubber foot mat) if the surface is smooth,

such as cobbled stones, tiled floor, etc.■

Only attach the lifting jack to the attachment points provided for this pur-

pose.

■

Always raise the vehicle with the doors closed.

■

Never position any body parts, such as arms or legs under the vehicle,

while the vehicle is raised with a lifting jack.

■

Never start the engine with the vehicle sitting on the raised jack – there

is a risk of injury.

WARNINGInformation on the wheel bolts■The wheel bolts must be clean and must turn easily. Never treat them

with grease or oil.■

The prescribed tightening torque of the wheel bolts for steel and light al-

loy wheels is 120 Nm.

■

If the wheel bolts are tightened to a too low tightening torque, the rim

can come loose when the car is moving – risk of accident! A tightening tor-

que which is too high can damage the bolts and threads and this can result

in permanent deformation of the contact surfaces on the rim.

■

In case of incorrect treatment of the wheel bolts, the wheel can loosen

when the car is moving – risk of accident!

Note

The national legal requirements must be observed when changing a wheel.

Preparation

Read and observe

on page 159 first.

Always change a wheel on a level surface as far as possible.

The following steps must be carried out before actually changing the wheel:

›

Have all the occupants get out. The passengers should not stand on the

road (instead they should remain behind a crash barrier, for instance) while

the wheel is being changed.

› Switch off the engine.›Move the gearshift lever into

Neutral or move the selector lever for the auto-

matic gearbox into position P.›

Apply the handbrake firmly.

›

Uncouple any trailer.

›

Remove the vehicle tool kit » page 159 and the spare wheel » page 155 ,

Spare and back-up wheel from the boot.

Changing a wheel

Read and observe

on page 159 first.

›

Remove the full wheel trim » page 156 or caps » page 156 .

›

First of all slacken the anti-theft wheel bolt and then the other wheel

bolts » page 161 .

›

Jack up the vehicle until the wheel that needs changing is clear of the

ground » page 161 .

›

Unscrew the wheel bolts and place them on a clean surface (cloth, paper,

etc.).

›

Remove the wheel carefully.

›

Attach the spare wheel and slightly screw on the wheel bolts.

›

Lower the vehicle.

›

Tighten the opposite wheel bolts alternately (cross-wise) with the wheelwrench. Tighten the anti-theft wheel bolt last » page 161.

›

Reinstall the wheel trim/wheel trim cap or the caps.

Note

■

All bolts must be clean and must turn easily.■Under no circumstances grease or oil the wheel bolts!■

When fitting unidirectional tyres, ensure that the direction of rotation is cor-

rect » page 154 , Unidirectional tyres .

Subsequent steps

Read and observe

on page 159 first.

The following steps must also be performed after changing the wheel.

›

Stow and attach the replaced wheel in the spare wheel well using a special

screw » page 155 , Spare and back-up wheel .

›

Stow the tool kit in the space provided and secure using the strap.

›

Check the tyre pressure on the installed spare wheel as soon as possible.

160Do-it-yourself

Page 163 of 197

›Have the

tightening torque of the wheel bolts checked with a torque

wrench as soon as possible.›

Change the damaged wheel or consult a specialist garage about repair possi-

bilities.

Note

■ If it is determined that the wheel bolts are corroded and difficult to turn

when changing the wheel, the bolts must be replaced before checking the

tightening torque.■

Drive cautiously and only at a moderate speed until the tightening torque

has been checked.

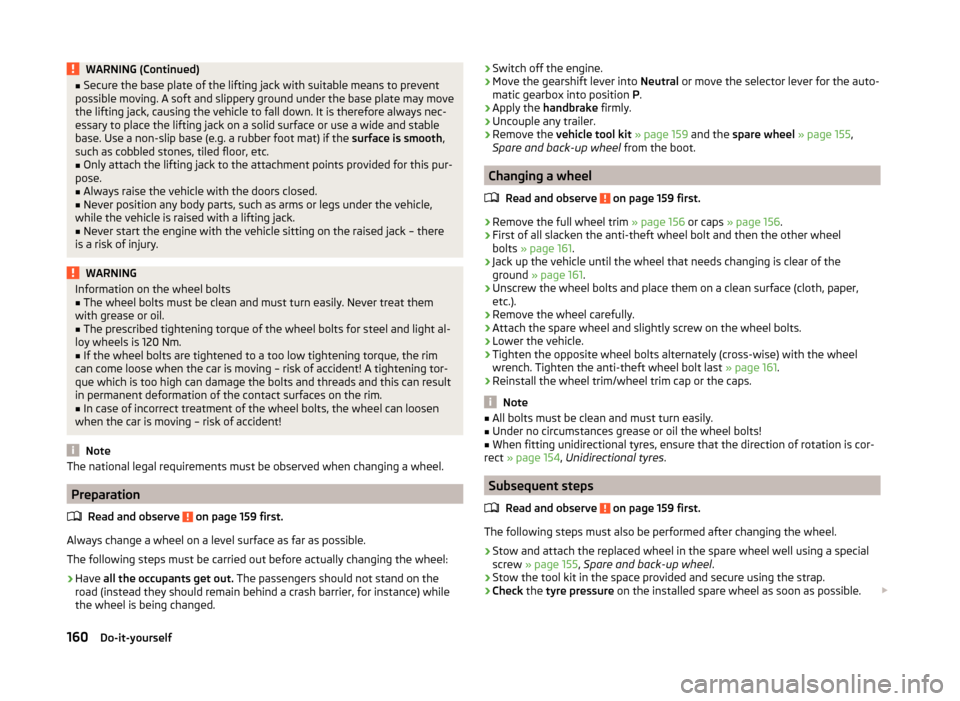

Loosening/tightening wheel bolts

Fig. 141

Changing a wheel: Loosening the

wheel bolts

Read and observe on page 159 first.

Undoing

›

Push the wheel wrench onto the wheel bolt as far as the stop 1)

.

›

Grip the wrench at its end and turn the bolt about one turn in the direction of

the arrow » Fig. 141.

Tightening

›

Push the wheel wrench onto the wheel bolt as far as the stop 1)

.

›

Grip the wrench at its end and turn the bolt against the direction of the ar-

row » Fig. 141 until it is tight.

WARNINGUndo the wheel bolts only a little (about one turn) until the vehicle has

been jacked up. Otherwise the wheel could come off and fall down – there

is a risk of injury.NoteIf it proves difficult to undo the bolts, carefully apply pressure to the end of the

wrench with your foodt. Keep hold of the vehicle when doing so, and make

sure you keep your footing.

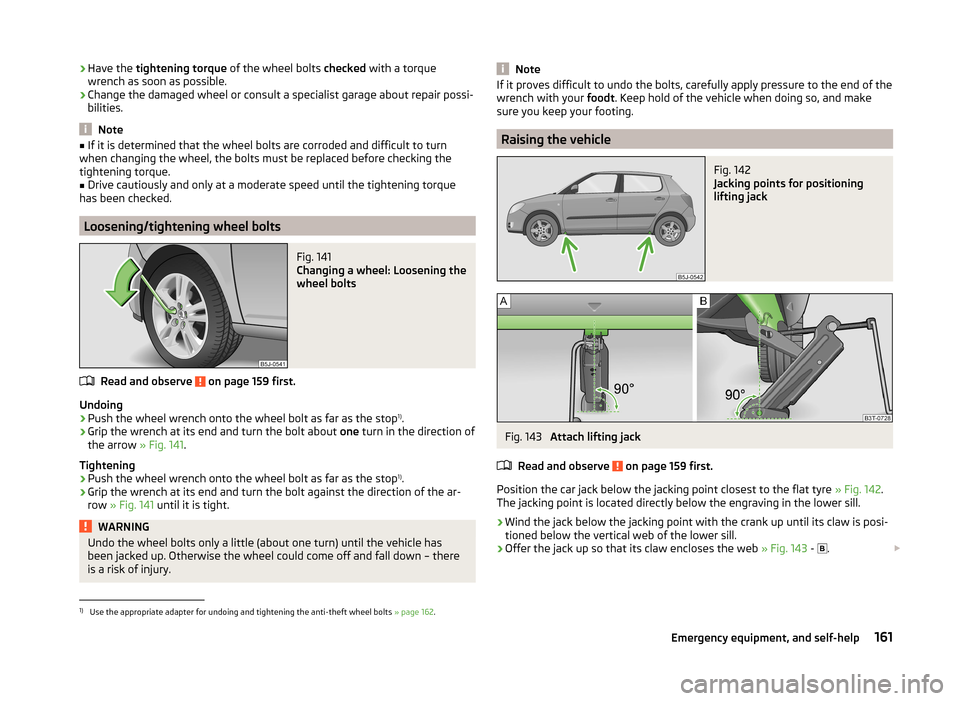

Raising the vehicle

Fig. 142

Jacking points for positioning

lifting jack

Fig. 143

Attach lifting jack

Read and observe

on page 159 first.

Position the car jack below the jacking point closest to the flat tyre » Fig. 142.

The jacking point is located directly below the engraving in the lower sill.

›

Wind the jack below the jacking point with the crank up until its claw is posi-

tioned below the vertical web of the lower sill.

›

Offer the jack up so that its claw encloses the web » Fig. 143 -

.

1)

Use the appropriate adapter for undoing and tightening the anti-theft wheel bolts

» page 162.

161Emergency equipment, and self-help

Page 164 of 197

›Support the base plate of the jack with its full area resting on level ground

and ensure that the jack is located in a vertical position at the point where

the claw encloses the web » Fig. 143 -

.›

Continue turning up the jack until the wheel is just about lifted off the

ground.

WARNING■ Only raise the vehicle at the jacking points.■Choose a flat and firm surface for jacking the vehicle.

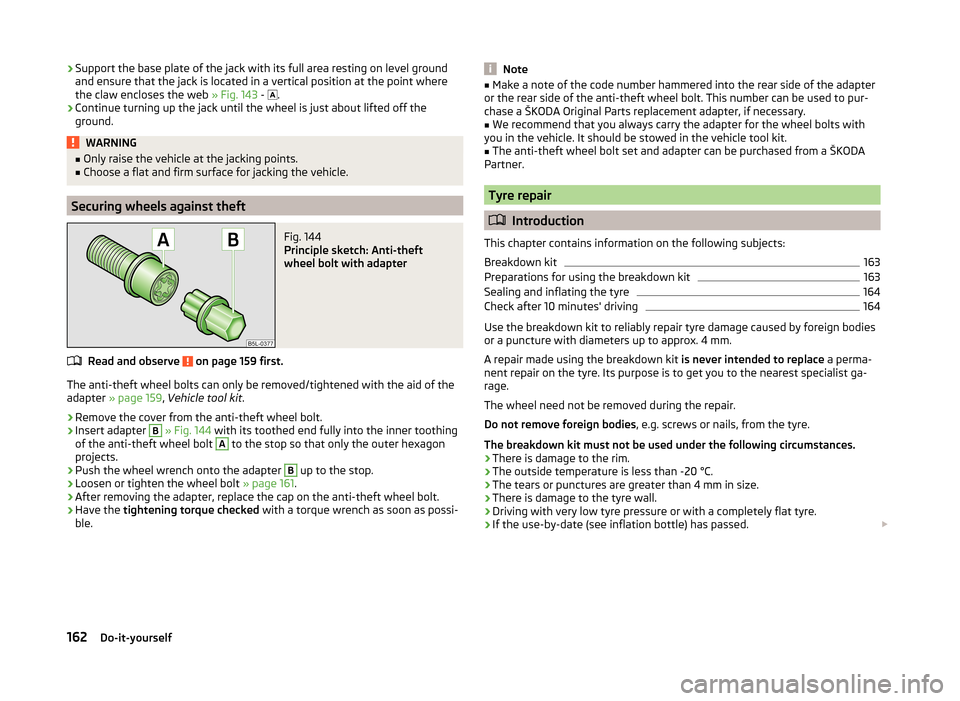

Securing wheels against theft

Fig. 144

Principle sketch: Anti-theft

wheel bolt with adapter

Read and observe on page 159 first.

The anti-theft wheel bolts can only be removed/tightened with the aid of the

adapter » page 159 , Vehicle tool kit .

›

Remove the cover from the anti-theft wheel bolt.

›

Insert adapter

B

» Fig. 144 with its toothed end fully into the inner toothing

of the anti-theft wheel bolt

A

to the stop so that only the outer hexagon

projects.

›

Push the wheel wrench onto the adapter

B

up to the stop.

›

Loosen or tighten the wheel bolt » page 161.

›

After removing the adapter, replace the cap on the anti-theft wheel bolt.

›

Have the tightening torque checked with a torque wrench as soon as possi-

ble.

Note■ Make a note of the code number hammered into the rear side of the adapter

or the rear side of the anti-theft wheel bolt. This number can be used to pur-

chase a ŠKODA Original Parts replacement adapter, if necessary.■

We recommend that you always carry the adapter for the wheel bolts with

you in the vehicle. It should be stowed in the vehicle tool kit.

■

The anti-theft wheel bolt set and adapter can be purchased from a ŠKODA

Partner.

Tyre repair

Introduction

This chapter contains information on the following subjects:

Breakdown kit

163

Preparations for using the breakdown kit

163

Sealing and inflating the tyre

164

Check after 10 minutes' driving

164

Use the breakdown kit to reliably repair tyre damage caused by foreign bodies

or a puncture with diameters up to approx. 4 mm.

A repair made using the breakdown kit is never intended to replace a perma-

nent repair on the tyre. Its purpose is to get you to the nearest specialist ga-

rage.

The wheel need not be removed during the repair.

Do not remove foreign bodies , e.g. screws or nails, from the tyre.

The breakdown kit must not be used under the following circumstances. › There is damage to the rim.

› The outside temperature is less than -20 °C.

› The tears or punctures are greater than 4 mm in size.

› There is damage to the tyre wall.

› Driving with very low tyre pressure or with a completely flat tyre.

› If the use-by-date (see inflation bottle) has passed.

162Do-it-yourself