technical data SKODA YETI 2011 1.G / 5L Owner's Manual

[x] Cancel search | Manufacturer: SKODA, Model Year: 2011, Model line: YETI, Model: SKODA YETI 2011 1.G / 5LPages: 252, PDF Size: 3.61 MB

Page 215 of 252

WARNING (Continued)

● Secure the base plate of the lifting jack with suitable means to prevent

possible moving. A soft and slippery ground under the base plate may move

the lifting jack, causing the vehicle to fall down. It is therefore always neces-

sary to place the lifting jack on a solid surface or use a wide and stable base.

Use a non-slip base (e.g. a rubber foot mat) if the

surface is smooth, such as

cobbled stones, a tiled floor, etc.

● Attach the lifting jack only at the attachment points provided for this pur-

pose.

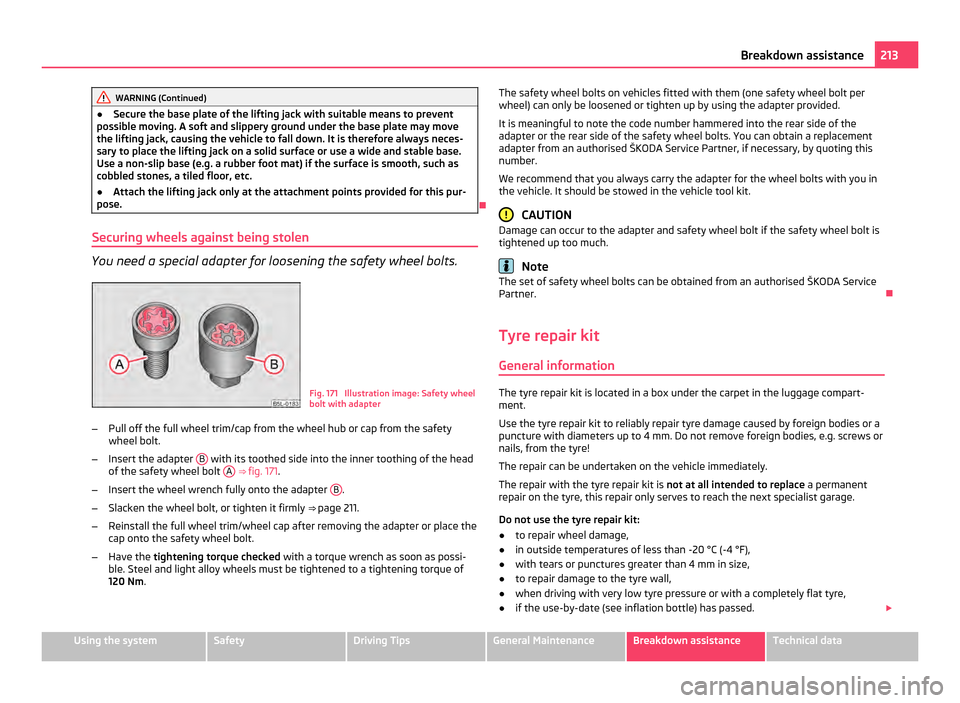

Securing wheels against being stolen You need a special adapter for loosening the safety wheel bolts.

Fig. 171 Illustration image: Safety wheel

bolt with adapter

– Pull off the full wheel trim/cap from the wheel hub or cap from the safety

wheel bolt.

– Insert the adapter B with its toothed side into the inner toothing of the head

of the safety wheel bolt A

⇒

fig. 171 .

– Insert the wheel wrench fully onto the adapter B .

– Slacken the wheel bolt, or tighten it firmly ⇒ page 211.

– Reinstall the full wheel trim/wheel cap after removing the adapter or place the

cap onto the safety wheel bolt.

– Have the tightening torque checked with a torque wrench as soon as possi-

ble. Steel and light alloy wheels must be tightened to a tightening torque of

120

Nm. The safety wheel bolts on vehicles fitted with them (one safety wheel bolt per

wheel) can only be loosened or tighten up by using the adapter provided.

It is meaningful to note the code number hammered into the rear side of the

adapter or the rear side of the safety wheel bolts. You can obtain a replacement

adapter from an authorised

ŠKODA Service Partner, if necessary, by quoting this

number.

We recommend that you always carry the adapter for the wheel bolts with you in

the vehicle. It should be stowed in the vehicle tool kit. CAUTION

Damage can occur to the adapter and safety wheel bolt if the safety wheel bolt is

tightened up too much. Note

The set of safety wheel bolts can be obtained from an authorised ŠKODA Service

Partner.

Tyre repair kit General information The tyre repair kit is located in a box under the carpet in the luggage compart-

ment.

Use the tyre repair kit to reliably repair tyre damage caused by foreign bodies or a

puncture with diameters up to 4 mm. Do not remove foreign bodies, e.g. screws or

nails, from the tyre!

The repair can be undertaken on the vehicle immediately.

The repair with the tyre repair kit is not at all intended to replace a permanent

repair on the tyre, this repair only serves to reach the next specialist garage.

Do not use the tyre repair kit:

● to repair wheel damage,

● in outside temperatures of less than -20 °C (-4 °F),

● with tears or punctures greater than 4 mm in size,

● to repair damage to the tyre wall,

● when driving with very low tyre pressure or with a completely flat tyre,

● if the use-by-date (see inflation bottle) has passed. £ 213

Breakdown assistance Using the system Safety Driving Tips General Maintenance Breakdown assistance Technical data

Page 217 of 252

–

Have all the occupants get out. While changing a tyre, the occupants of the

vehicle should not stand on the road (instead they should remain behind a

crash barrier, for example).

– Switch off the engine and engage 1st gear or if your vehicle is fitted with an

automatic gearbox, position the selector lever into position P .

– Apply the handbrake firmly.

– Check whether you can carry out the repairs with the tyre repair kit

⇒ page 213, General information.

– If a trailer is coupled, uncouple it.

– Remove the tyre repair kit from the luggage compartment.

– Stick the sticker 2

⇒

fig. 172 on the dash panel in view of the driver.

– Do not remove the foreign body, e.g. screw or nail, from the tyre.

– Unscrew the valve cap.

– Use the valve remover 1 to remove the valve core and place it down on a

clean surface.

Seal and inflate tyres Sealing tyres

–

Forcefully shake the tyre inflator bottle 10

⇒ fig. 172 several times.

– Firmly screw inflation hose 3 onto the tyre inflator bottle in a clockwise direc-

tion 10 . The film on the cap is pierced automatically.

– Remove the plug from the inflation hose 3 and plug the open end fully into

the tyre valve.

– Hold the bottle 10 with the floor facing upwards and fill the whole sealing

agent in the tyre inflator bottle into the tyres.

– Remove the empty tyre inflator bottle from the valve.

– Screw the valve core back into the tyre valve using the valve remover 1 .

Pumping up the tyres

– Screw the tyre inflation hose 5

⇒

fig. 172 of the air compressor firmly onto the

tyre valve.

– Check whether the air release valve 7 is closed.–

On vehicles fitted with a manual gearbox, move the gearshift lever into Neu-

tral.

– Start the engine and run it in idle.

– Insert the plug 9 into the 12 Volt socket. ⇒

page 79

– Switch on the air compressor with the ON and OFF switch 8 .

– Allow the air compressor to run until reaching a pressure of 2.0 - 2.5 bar. Maxi-

mum run time of 8 minutes ⇒ !

– Switch off the air compressor with the ON and OFF switch.

– If you cannot reach an air pressure of 2.0 – 2.5 bar, unscrew the tyre inflation

hose 5 from the tyre valve.

– Drive the vehicle approx. 10 metres forwards or backwards to allow the sealing

agent to distribute in the tyre.

– Screw the tyre inflation hose of the air compressor 5 firmly back onto the

tyre valve and repeat the inflation procedure.

– If you cannot reach the required tyre inflation pressure here either, this means

the tyre has sustained too much damage. You cannot seal with tyre with the

breakdown kit ⇒ .

– Switch off the air compressor with the ON and OFF switch.

– Remove the tyre inflation hose 5 from the tyre valve.

After reaching a tyre inflation pressure of 2.0 – 2.5 bar, drive at a maximum speed

of 80 km/h (50

mph).

Check the tyre inflation pressure after driving 10 minutes ⇒ page 216, Check after

driving for 10 minutes. WARNING

● During inflation, the tyre inflation hose and air compressor may get hot-

risk of injury!

● Do not place hot tyre inflation hoses or hot air compressors on flammable

materials - risk of fire!

● If you cannot inflate the tyre to at least 2.0 bar, this means the damage

sustained was too serious. The sealing agent cannot be used to seal the tyre.

Do not drive the vehicle. Get professional assistance. £ 215

Breakdown assistance Using the system Safety Driving Tips General Maintenance Breakdown assistance Technical data

Page 219 of 252

Connecting negative terminal and engine block

– Attach one end 3 to the negative terminal of the battery supplying the power

B .

– Attach the other end 4 to a solid metal part which is connected firmly to the

engine block, or to the engine block itself.

Starting engine

– Start the engine of the vehicle providing current and run the engine at idling

speed.

– Now start the engine of the vehicle with the discharged battery.

– Interrupt the attempt at starting an engine after 10 seconds if it does not start

right away and wait for about 30 seconds before repeating the attempt.

– Disconnect the cables in exactly the reverse order they were connected.WARNING

● The non-insulated parts of the terminal clamps must never make contact

with each other. In addition, the jump-start cable connected to the positive

terminal of the battery must not come into contact with electrically conduct-

ing parts of the vehicle - risk of short circuit!

● Do not affix the jump starting cables to the negative terminal of the dis-

charged battery. There is the risk of detonating gas seeping out the battery

being ignited by the strong spark which results from the engine being started.

● Run the jump-start cables so that they cannot be caught by any rotating

parts in the engine compartment.

● Do not bend over the batteries - risk of caustic burns!

● The vent screws of the battery cells must be tightened firmly.

● Keep any sources of ignition (naked flame, smouldering cigarettes etc.)

away from the battery - risk of an explosion!

● Never jump-start the batteries which have a too low electrolyte level - risk

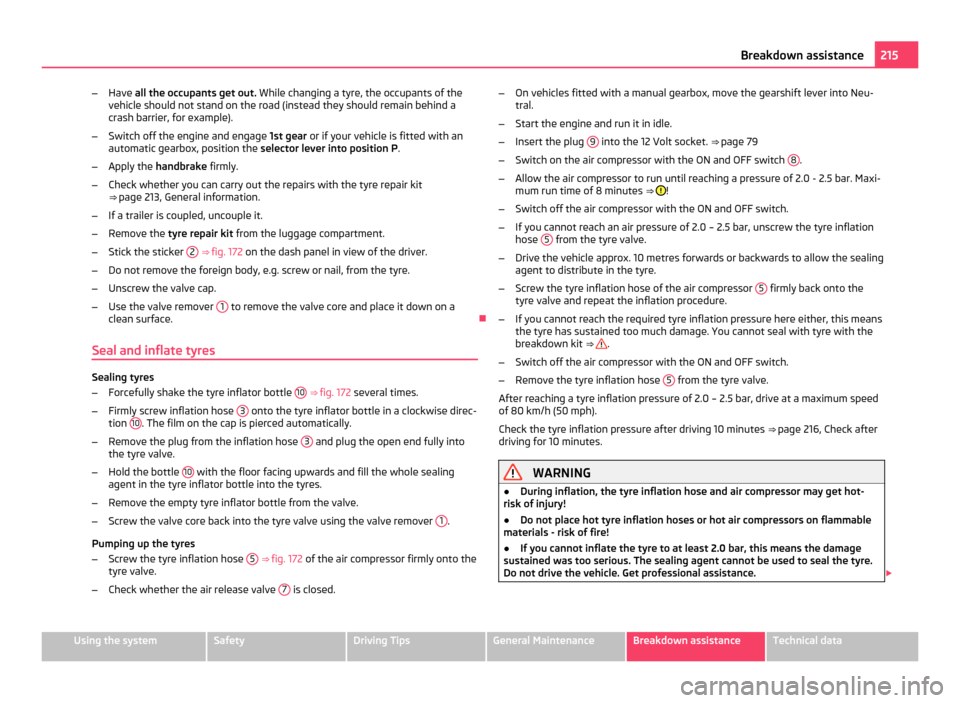

of explosion and caustic burns! Jump-starting on vehicles with the “START-STOP” system Fig. 174 Jump-starting on vehicles with

the START-STOP system

One vehicles with the “START STOP” system, the negative cable of the charger

must never be connected directly to the negative pole of the vehicle battery, but

only to the engine earth ⇒ fig. 174.

The vehicle General Vehicles with manual transmission can be towed in with a tow bar or a tow rope

or with the front or rear wheels raised.

Vehicles with automatic transmission can be towed in with a tow bar or a tow

rope or with the front wheels raised. If the vehicle is raised at rear, the automatic gearbox is damaged!

Vehicles with four-wheel drive can be towed in with a tow bar or a tow rope or

with the front wheels raised.

A tow bar is safest way of towing a vehicle and also minimizes any shocks. You

can use a tow rope only if a suitable tow bar is not available.

Refer to the following guidelines when towing:

Driver of the towing vehicle

– Release the clutch particularly gently when starting off or depress the acceler-

ator particularly gently if your vehicle is fitted with an automatic gearbox.

– On vehicles with manual transmission, only push down on the accelerator ped-

al once the rope is taught. £ 217

Breakdown assistance Using the system Safety Driving Tips General Maintenance Breakdown assistance Technical data

Page 221 of 252

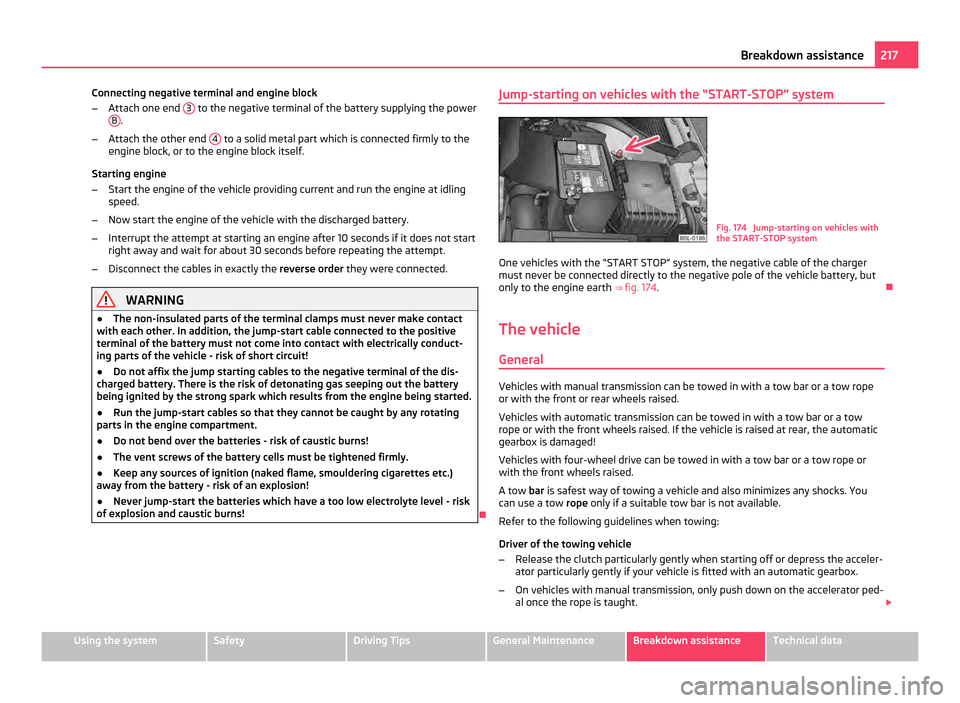

CAUTION

The towing eye must always be screwed in fully and firmly tightened, otherwise

the towing eye can tear when towing in or tow-starting!

Rear towing eye Fig. 176 Rear bumper: Removing the cover/installing the towing eye

–

Press on the upper half of the cover in direction of arrow 1

⇒ fig. 176 .

– Take the cover out of the rear bumper ⇒ fig. 176 - left.

– Screw in the towing eye by hand to the left up to the stop ⇒ fig. 176 - right and

tighten it as much as possible. For tightening, we recommend that you use for

example the wheel wrench, the lashing eye of another vehicle or a similar ob-

ject which you can push through the eye.

– In order to reinstall the cover after screwing out the towing eye, first of all in-

sert the upper part of the cover and then press in the lower part. The cover

must engage firmly. CAUTION

The towing eye must always be screwed in fully and firmly tightened, otherwise

the towing eye can tear when towing in or tow-starting! 219

Breakdown assistance Using the system Safety Driving Tips General Maintenance Breakdown assistance Technical data

Page 223 of 252

On some vehicles, the battery cover must be removed before removing the fuse

cover ⇒ page 197.

Removing fuse cover

–

Move the circlips A ⇒

fig. 178 as far as the stop, the symbol appears behind

the circlip and remove the cover.

Installing fuse cover

– Position the fuse cover on the fuse box and push the circlips A as far as the

stop - the symbol is visible behind the circlip.CAUTION

● When unlocking and locking the fuse cover, it must be pressed on the sides to

the box, otherwise damage can occur to the locking mechanism.

● Carefully position the fuse cover in the engine compartment. If the cover was

not correctly positioned, water can get into the fuses and this results in a damage

to the vehicle!

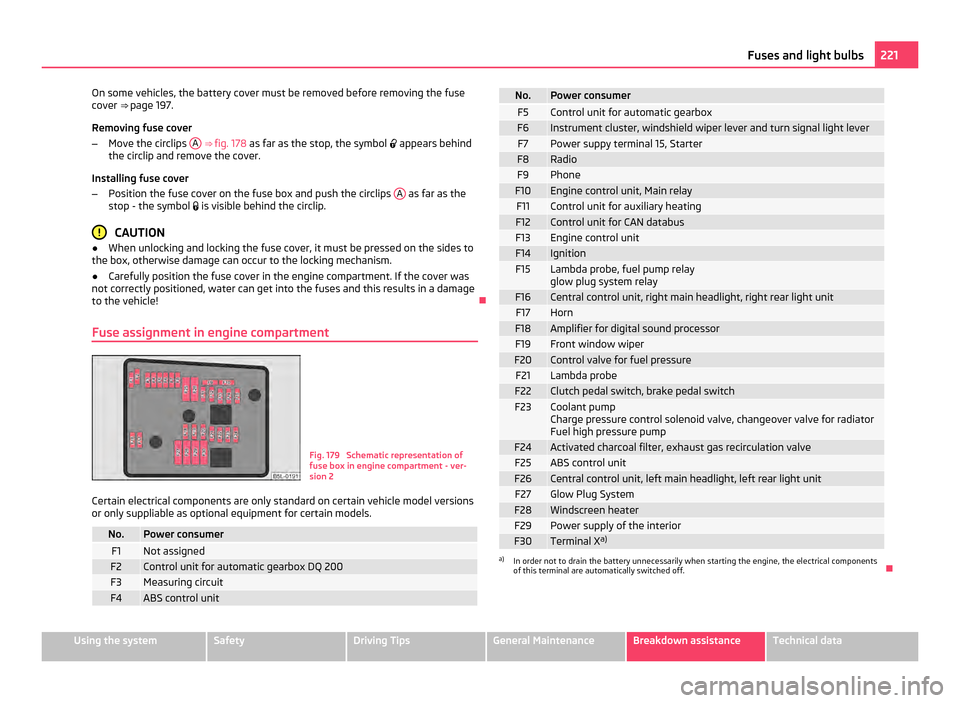

Fuse assignment in engine compartment Fig. 179 Schematic representation of

fuse box in engine compartment - ver-

sion 2

Certain electrical components are only standard on certain vehicle model versions

or only suppliable as optional equipment for certain models. No. Power consumer

F1 Not assigned

F2 Control unit for automatic gearbox DQ 200

F3 Measuring circuit

F4 ABS control unit No. Power consumer

F5 Control unit for automatic gearbox

F6 Instrument cluster, windshield wiper lever and turn signal light lever

F7 Power suppy terminal 15, Starter

F8 Radio

F9 Phone

F10 Engine control unit, Main relay

F11 Control unit for auxiliary heating

F12 Control unit for CAN databus

F13 Engine control unit

F14 Ignition

F15 Lambda probe, fuel pump relay

glow plug system relay

F16 Central control unit, right main headlight, right rear light unit

F17 Horn

F18 Amplifier for digital sound processor

F19 Front window wiper

F20 Control valve for fuel pressure

F21 Lambda probe

F22 Clutch pedal switch, brake pedal switch

F23 Coolant pump

Charge pressure control solenoid valve, changeover valve for radiator

Fuel high pressure pump

F24 Activated charcoal filter, exhaust gas recirculation valve

F25 ABS control unit

F26 Central control unit, left main headlight, left rear light unit

F27 Glow Plug System

F28 Windscreen heater

F29 Power supply of the interior

F30 Terminal X

a) a)

In order not to drain the battery unnecessarily when starting the engine, the electrical components

of this terminal are automatically switched off. 221

Fuses and light bulbs Using the system Safety Driving Tips General Maintenance Breakdown assistance Technical data

Page 225 of 252

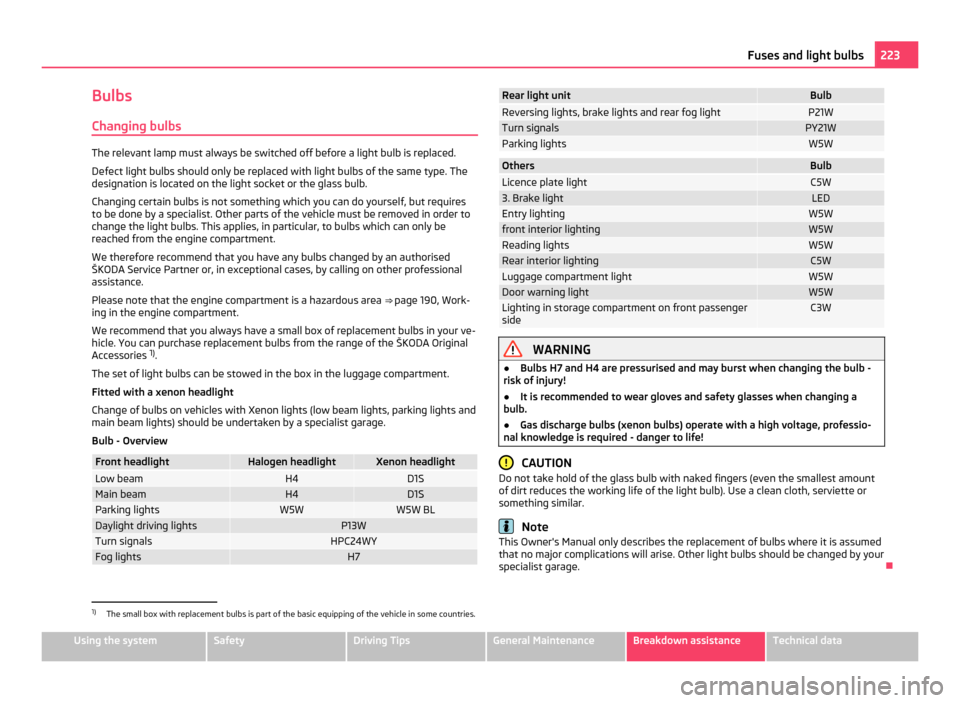

Bulbs

Changing bulbs The relevant lamp must always be switched off before a light bulb is replaced.

Defect light bulbs should only be replaced with light bulbs of the same type. The

designation is located on the light socket or the glass bulb.

Changing certain bulbs is not something which you can do yourself, but requires

to be done by a specialist. Other parts of the vehicle must be removed in order to

change the light bulbs. This applies, in particular, to bulbs which can only be

reached from the engine compartment.

We therefore recommend that you have any bulbs changed by an authorised

ŠKODA Service Partner or, in exceptional cases, by calling on other professional

assistance.

Please note that the engine compartment is a hazardous area ⇒

page 190, Work-

ing in the engine compartment.

We recommend that you always have a small box of replacement bulbs in your ve-

hicle. You can purchase replacement bulbs from the range of the ŠKODA Original

Accessories 1)

.

The set of light bulbs can be stowed in the box in the luggage compartment.

Fitted with a xenon headlight

Change of bulbs on vehicles with Xenon lights (low beam lights, parking lights and

main beam lights) should be undertaken by a specialist garage.

Bulb - Overview Front headlight Halogen headlight Xenon headlight

Low beam H4 D1S

Main beam H4 D1S

Parking lights W5W W5W BL

Daylight driving lights P13W

Turn signals HPC24WY

Fog lights H7 Rear light unit Bulb

Reversing lights, brake lights and rear fog light P21W

Turn signals PY21W

Parking lights W5W

Others Bulb

Licence plate light C5W

3. Brake light LED

Entry lighting W5W

front interior lighting W5W

Reading lights W5W

Rear interior lighting C5W

Luggage compartment light W5W

Door warning light W5W

Lighting in storage compartment on front passenger

side C3W

WARNING

● Bulbs H7 and H4 are pressurised and may burst when changing the bulb -

risk of injury!

● It is recommended to wear gloves and safety glasses when changing a

bulb.

● Gas discharge bulbs (xenon bulbs) operate with a high voltage, professio-

nal knowledge is required - danger to life! CAUTION

Do not take hold of the glass bulb with naked fingers (even the smallest amount

of dirt reduces the working life of the light bulb). Use a clean cloth, serviette or

something similar. Note

This Owner's Manual only describes the replacement of bulbs where it is assumed

that no major complications will arise. Other light bulbs should be changed by your

specialist garage. 1)

The small box with replacement bulbs is part of the basic equipping of the vehicle in some countries. 223

Fuses and light bulbs Using the system Safety Driving Tips General Maintenance Breakdown assistance Technical data

Page 227 of 252

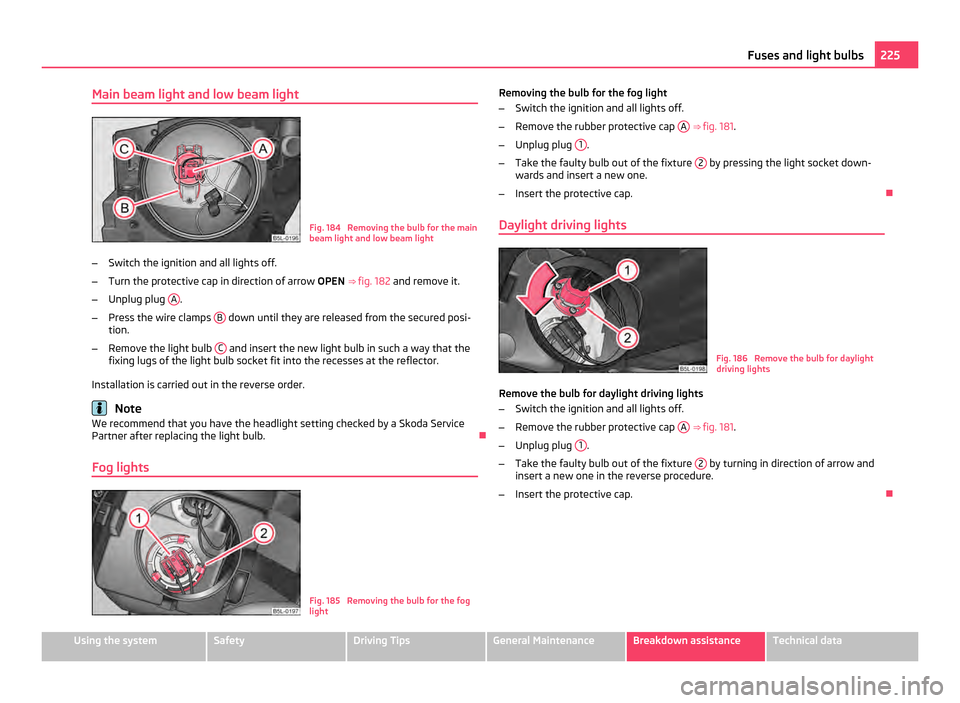

Main beam light and low beam light

Fig. 184 Removing the bulb for the main

beam light and low beam light

– Switch the ignition and all lights off.

– Turn the protective cap in direction of arrow OPEN ⇒ fig. 182 and remove it.

– Unplug plug A .

– Press the wire clamps B down until they are released from the secured posi-

tion.

– Remove the light bulb C and insert the new light bulb in such a way that the

fixing lugs of the light bulb socket fit into the recesses at the reflector.

Installation is carried out in the reverse order. Note

We recommend that you have the headlight setting checked by a Skoda Service

Partner after replacing the light bulb.

Fog lights Fig. 185 Removing the bulb for the fog

light Removing the bulb for the fog light

–

Switch the ignition and all lights off.

– Remove the rubber protective cap A ⇒ fig. 181

.

– Unplug plug 1 .

– Take the faulty bulb out of the fixture 2 by pressing the light socket down-

wards and insert a new one.

– Insert the protective cap.

Daylight driving lights Fig. 186 Remove the bulb for daylight

driving lights

Remove the bulb for daylight driving lights

– Switch the ignition and all lights off.

– Remove the rubber protective cap A

⇒ fig. 181 .

– Unplug plug 1 .

– Take the faulty bulb out of the fixture 2 by turning in direction of arrow and

insert a new one in the reverse procedure.

– Insert the protective cap. 225

Fuses and light bulbs Using the system Safety Driving Tips General Maintenance Breakdown assistance Technical data

Page 229 of 252

–

Replace the the glass cover of the light and press it down to the stop - ensure

that the glass cover is correctly installed.

– Screw the glass cover tight. 227

Fuses and light bulbs Using the system Safety Driving Tips General Maintenance Breakdown assistance Technical data

Page 230 of 252

Technical data

Technical data General information The details given in the official vehicle registration documents always take prece-

dence over the details in the Owner's Manual. Please refer to the official vehicle

registration documents or consult a specialist garage concerning the engine with

which your vehicle is equipped.

Used abbreviations Abbreviation Importance

kW Kilowatt, measuring unit for the engine output

rpm Engine revolutions per minute

Nm Newton meter, measuring unit for the engine torque

CO

2 in g/km discharged quantity of carbon dioxide in grams per driven

kilometre

TSI Petrol engine with a turbocharger and a direct fuel injec-

tion system TDI CR Diesel engine with turbocharger and injection system

Common Rail

M5/M6 5-speed/6-speed manual gearbox

DQ6/DQ7 6 speed-/7 speed automatic gearbox DSG

N1 The vehicles of this category are designed and construc-

ted for conveying goods with a maximum weight of

3.5

tons DPF Diesel particle filter

Performances The listed performance values were determined without performance-reducing

equipment, e.g. air conditioning system.

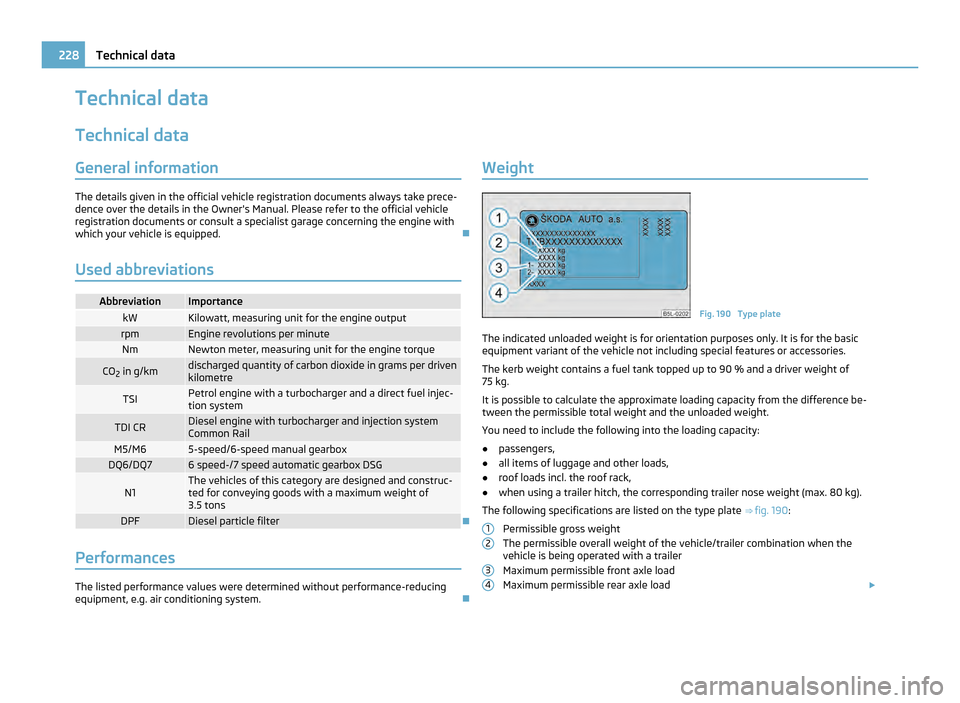

Weight

Fig. 190 Type plate

The indicated unloaded weight is for orientation purposes only. It is for the basic

equipment variant of the vehicle not including special features or accessories.

The kerb weight contains a fuel tank topped up to 90 % and a driver weight of

75 kg.

It is possible to calculate the approximate loading capacity from the difference be-

tween the permissible total weight and the unloaded weight.

You need to include the following into the loading capacity:

● passengers,

● all items of luggage and other loads,

● roof loads incl. the roof rack,

● when using a trailer hitch, the corresponding trailer nose weight (max. 80 kg).

The following specifications are listed on the type plate ⇒

fig. 190 :

Permissible gross weight

The permissible overall weight of the vehicle/trailer combination when the

vehicle is being operated with a trailer

Maximum permissible front axle load

Maximum permissible rear axle load £

1 2

3

4228

Technical data

Page 231 of 252

The identification plate is affixed to the lower part of the column between the

front and rear doors on the front passenger side.

WARNING

Do not exceed the permissible overall weight - risk of accident and damage to

the vehicle.

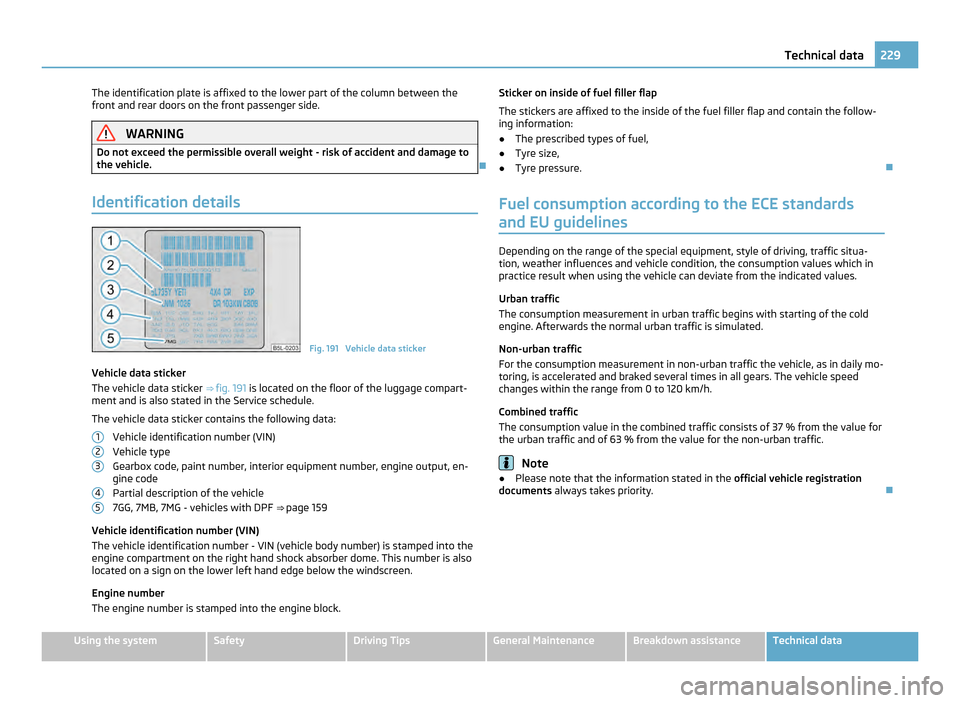

Identification details Fig. 191 Vehicle data sticker

Vehicle data sticker

The vehicle data sticker ⇒ fig. 191 is located on the floor of the luggage compart-

ment and is also stated in the Service schedule.

The vehicle data sticker contains the following data:

Vehicle identification number (VIN)

Vehicle type

Gearbox code, paint number, interior equipment number, engine output, en-

gine code

Partial description of the vehicle

7GG, 7MB, 7MG - vehicles with DPF ⇒ page 159

Vehicle identification number (VIN)

The vehicle identification number - VIN (vehicle body number) is stamped into the

engine compartment on the right hand shock absorber dome. This number is also

located on a sign on the lower left hand edge below the windscreen.

Engine number

The engine number is stamped into the engine block. 1 2

3

4

5 Sticker on inside of fuel filler flap

The stickers are affixed to the inside of the fuel filler flap and contain the follow-

ing information:

● The prescribed types of fuel,

● Tyre size,

● Tyre pressure.

Fuel consumption according to the ECE standards

and EU guidelines Depending on the range of the special equipment, style of driving, traffic situa-

tion, weather influences and vehicle condition, the consumption values which in

practice result when using the vehicle can deviate from the indicated values.

Urban traffic

The consumption measurement in urban traffic begins with starting of the cold

engine. Afterwards the normal urban traffic is simulated.

Non-urban traffic

For the consumption measurement in non-urban traffic the vehicle, as in daily mo-

toring, is accelerated and braked several times in all gears. The vehicle speed

changes within the range from 0 to 120 km/h.

Combined traffic

The consumption value in the combined traffic consists of 37 % from the value for

the urban traffic and of 63 % from the value for the non-urban traffic. Note

● Please note that the information stated in the official vehicle registration

documents always takes priority. 229

Technical data Using the system Safety Driving Tips General Maintenance Breakdown assistance Technical data