ECU SKODA YETI 2011 1.G / 5L Owner's Guide

[x] Cancel search | Manufacturer: SKODA, Model Year: 2011, Model line: YETI, Model: SKODA YETI 2011 1.G / 5LPages: 252, PDF Size: 3.61 MB

Page 191 of 252

Inspecting and Replenishing

Engine compartment

Bonnet remote release Fig. 151 Bonnet release lever

Bonnet remote release

β Pull the unlocking lever below the dash panel on the left-hand side β βfig. 151.

The bonnet jumps out of its lock as a result of the spring force. ο

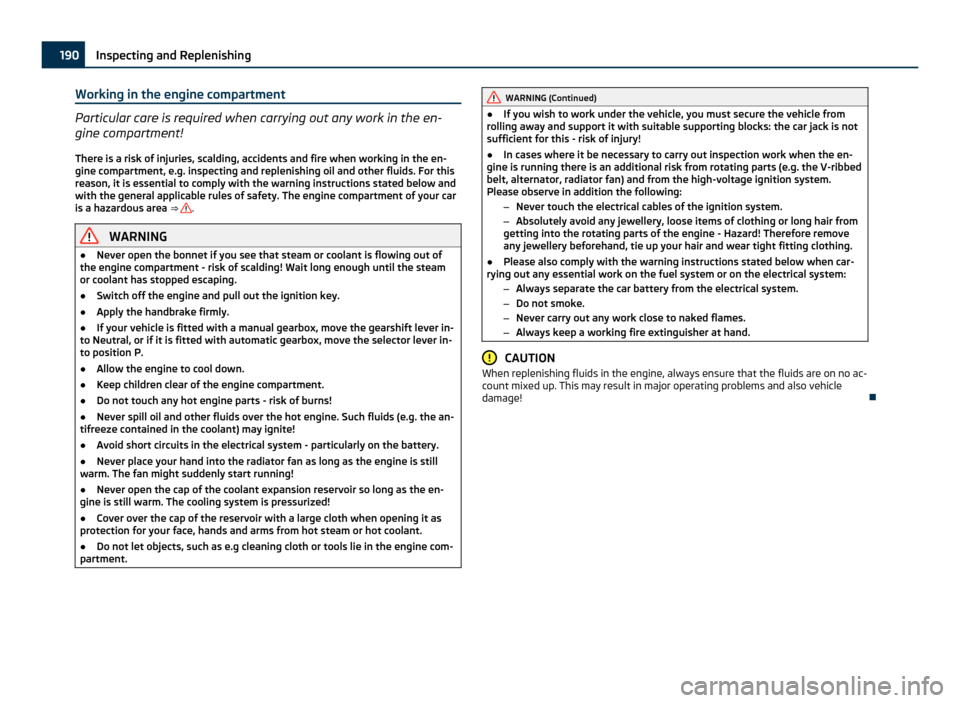

Opening and closing the bonnet. Fig. 152 Radiator grille: Locking lever/securing the bonnet with the bonnet support

Opening the bonnet

β

Unlock the bonnet β

βfig. 151. β

Ensure that the arms of the windshield wipers are correctly in place against

the windshield before opening the bonnet, otherwise damage could occur to

the paintwork.

β Pressing on the locking lever in direction of arrow 1 β

β

fig. 152 will unlock the

bonnet.

β Grasp the front part of the bonnet under the chrome trim.

β Take the bonnet support out of its holder in direction of arrow 2 and secure

the opened bonnet by inserting the end of the support in the opening 3 de-

signed for it ββfig. 152.

Closing the bonnet

β Lift the bonnet slightly and unhook the bonnet support. Press the bonnet sup-

port into the holder designed to hold it.

β Allow the bonnet to drop from a height of about 20 cm into the lock - bonnet

do not press down on it!

β Check whether the bonnet is properly closed. WARNING

β Never open the bonnet if you see that steam or coolant is flowing out of

the engine compartment - risk of scalding! Wait long enough until the steam

or coolant has stopped escaping.

β For safety reasons, the bonnet must always be properly closed when driv-

ing. One should therefore check that the lock has in fact engaged properly af-

ter closing the bonnet.

β Stop your vehicle immediately while driving if you notice that the lock is

not properly engaged and close the bonnet properly - risk of an accident! ο189

Inspecting and Replenishing Using the system Safety Driving Tips General Maintenance Breakdown assistance Technical data

Page 192 of 252

Working in the engine compartment

Particular care is required when carrying out any work in the en-

gine compartment!

There is a risk of injuries, scalding, accidents and fire when working in the en-

gine compartment, e.g. inspecting and replenishing oil and other fluids. For this

reason, it is essential to comply with the warning instructions stated below and

with the general applicable rules of safety. The engine compartment of your car

is a hazardous area β

β .

WARNING

β Never open the bonnet if you see that steam or coolant is flowing out of

the engine compartment - risk of scalding! Wait long enough until the steam

or coolant has stopped escaping.

β Switch off the engine and pull out the ignition key.

β Apply the handbrake firmly.

β If your vehicle is fitted with a manual gearbox, move the gearshift lever in-

to Neutral, or if it is fitted with automatic gearbox, move the selector lever in-

to position

P.

β Allow the engine to cool down.

β Keep children clear of the engine compartment.

β Do not touch any hot engine parts - risk of burns!

β Never spill oil and other fluids over the hot engine. Such fluids (e.g. the an-

tifreeze contained in the coolant) may ignite!

β Avoid short circuits in the electrical system - particularly on the battery.

β Never place your hand into the radiator fan as long as the engine is still

warm. The fan might suddenly start running!

β Never open the cap of the coolant expansion reservoir so long as the en-

gine is still warm. The cooling system is pressurized!

β Cover over the cap of the reservoir with a large cloth when opening it as

protection for your face, hands and arms from hot steam or hot coolant.

β Do not let objects, such as e.g cleaning cloth or tools lie in the engine com-

partment. WARNING (Continued)

β If you wish to work under the vehicle, you must secure the vehicle from

rolling away and support it with suitable supporting blocks: the car jack is not

sufficient for this - risk of injury!

β In cases where it be necessary to carry out inspection work when the en-

gine is running there is an additional risk from rotating parts (e.g. the V-ribbed

belt, alternator, radiator fan) and from the high-voltage ignition system.

Please observe in addition the following:

βNever touch the electrical cables of the ignition system.

β Absolutely avoid any jewellery, loose items of clothing or long hair from

getting into the rotating parts of the engine - Hazard! Therefore remove

any jewellery beforehand, tie up your hair and wear tight fitting clothing.

β Please also comply with the warning instructions stated below when car-

rying out any essential work on the fuel system or on the electrical system:

βAlways separate the car battery from the electrical system.

β Do not smoke.

β Never carry out any work close to naked flames.

β Always keep a working fire extinguisher at hand. CAUTION

When replenishing fluids in the engine, always ensure that the fluids are on no ac-

count mixed up. This may result in major operating problems and also vehicle

damage! ο190

Inspecting and Replenishing

Page 199 of 252

β

Do not place the battery in direct daylight in order to protect the battery hous-

ing from the effects of ultra-violet light.

β If the vehicle has not been driven for more than 3 to 4 weeks, the battery will

discharge This is because certain electrical components consume electricity (e. g.

control units) also in idle state. You can prevent the discharging of the battery by

disconnecting the negative terminal or charging the battery constantly with a very

low charging current. For the sake of the environment

A removed battery is a special type of waste which is harmful to the environment

- contact your specialist garage regarding disposing of the battery. Note

β Please also refer to the guidelines ββpage 198

, also after connecting the bat-

tery.

β You should replace batteries older than 5 years. ο

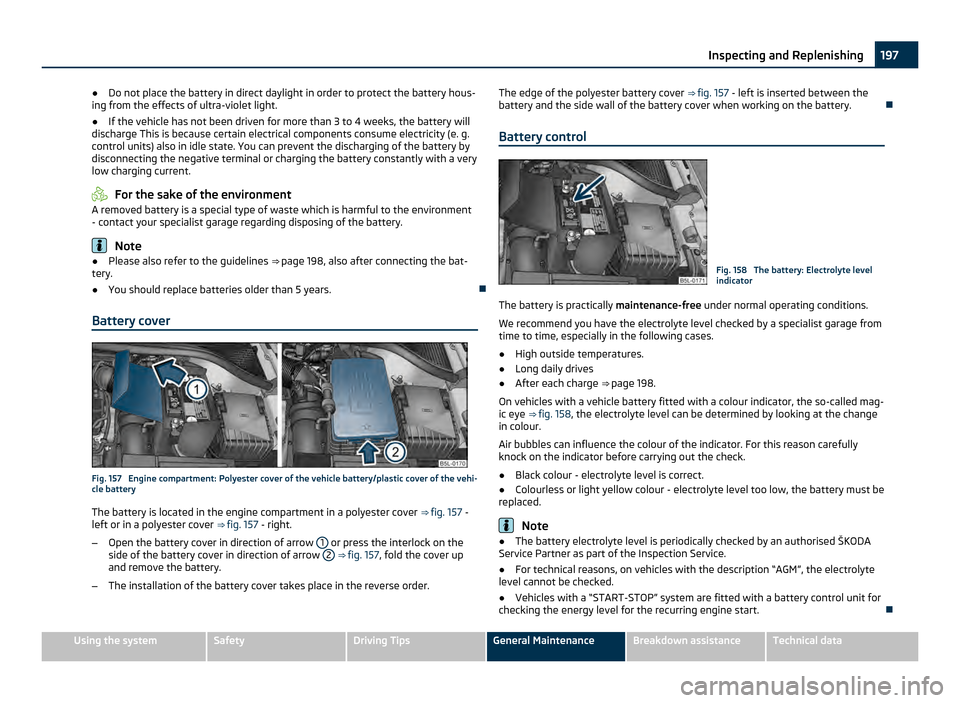

Battery cover Fig. 157 Engine compartment: Polyester cover of the vehicle battery/plastic cover of the vehi-

cle battery

The battery is located in the engine compartment in a polyester cover ββfig. 157 -

left or in a polyester cover ββfig. 157 - right.

β Open the battery cover in direction of arrow 1 or press the interlock on the

side of the battery cover in direction of arrow 2

β

βfig. 157, fold the cover up

and remove the battery.

β The installation of the battery cover takes place in the reverse order. The edge of the polyester battery cover

β

βfig. 157 - left is inserted between the

battery and the side wall of the battery cover when working on the battery. ο

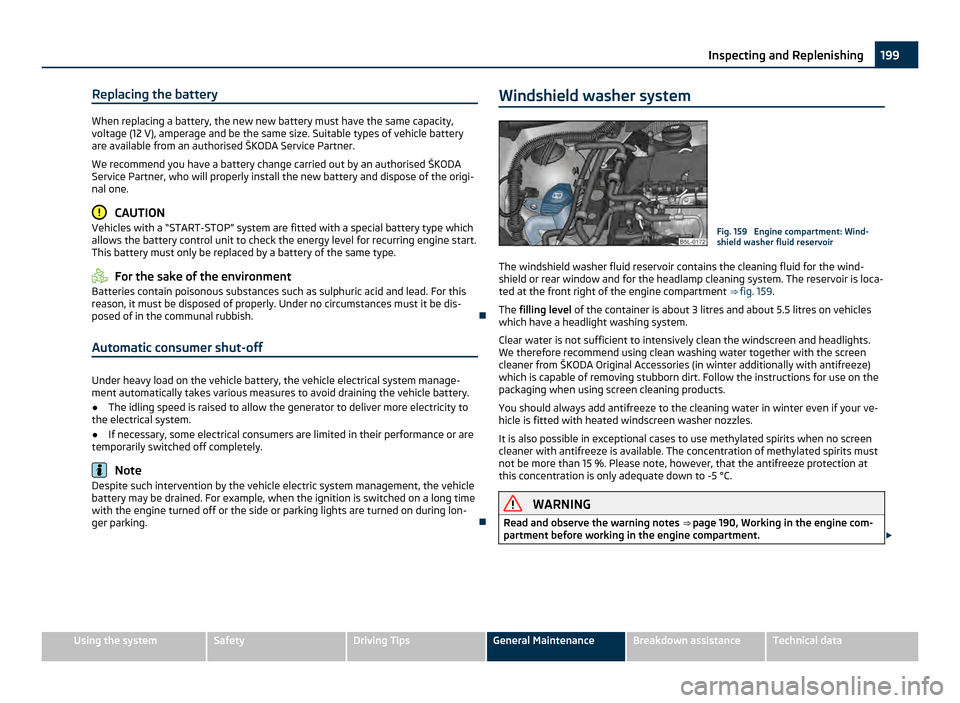

Battery control Fig. 158 The battery: Electrolyte level

indicator

The battery is practically maintenance-free under normal operating conditions.

We recommend you have the electrolyte level checked by a specialist garage from

time to time, especially in the following cases.

β High outside temperatures.

β Long daily drives

β After each charge β

βpage 198.

On vehicles with a vehicle battery fitted with a colour indicator, the so-called mag-

ic eye ββfig. 158 , the electrolyte level can be determined by looking at the change

in colour.

Air bubbles can influence the colour of the indicator. For this reason carefully

knock on the indicator before carrying out the check.

β Black colour - electrolyte level is correct.

β Colourless or light yellow colour - electrolyte level too low, the battery must be

replaced. Note

β The battery electrolyte level is periodically checked by an authorised

Ε KODA

Service Partner as part of the Inspection Service.

β For technical reasons, on vehicles with the description βAGMβ, the electrolyte

level cannot be checked.

β Vehicles with a βSTART-STOPβ system are fitted with a battery control unit for

checking the energy level for the recurring engine start. ο 197

Inspecting and Replenishing Using the system Safety Driving Tips General Maintenance Breakdown assistance Technical data

Page 201 of 252

Replacing the battery

When replacing a battery, the new new battery must have the same capacity,

voltage (12

V), amperage and be the same size. Suitable types of vehicle battery

are available from an authorised Ε KODA Service Partner.

We recommend you have a battery change carried out by an authorised Ε KODA

Service Partner, who will properly install the new battery and dispose of the origi-

nal one. CAUTION

Vehicles with a βSTART-STOPβ system are fitted with a special battery type which

allows the battery control unit to check the energy level for recurring engine start.

This battery must only be replaced by a battery of the same type. For the sake of the environment

Batteries contain poisonous substances such as sulphuric acid and lead. For this

reason, it must be disposed of properly. Under no circumstances must it be dis-

posed of in the communal rubbish. ο

Automatic consumer shut-off Under heavy load on the vehicle battery, the vehicle electrical system manage-

ment automatically takes various measures to avoid draining the vehicle battery.

β

The idling speed is raised to allow the generator to deliver more electricity to

the electrical system.

β If necessary, some electrical consumers are limited in their performance or are

temporarily switched off completely. Note

Despite such intervention by the vehicle electric system management, the vehicle

battery may be drained. For example, when the ignition is switched on a long time

with the engine turned off or the side or parking lights are turned on during lon-

ger parking. οWindshield washer system Fig. 159 Engine compartment: Wind-

shield washer fluid reservoir

The windshield washer fluid reservoir contains the cleaning fluid for the wind-

shield or rear window and for the headlamp cleaning system. The reservoir is loca-

ted at the front right of the engine compartment ββfig. 159 .

The filling level of the container is about 3 litres and about 5.5 litres on vehicles

which have a headlight washing system.

Clear water is not sufficient to intensively clean the windscreen and headlights.

We therefore recommend using clean washing water together with the screen

cleaner from

Ε KODA Original Accessories (in winter additionally with antifreeze)

which is capable of removing stubborn dirt. Follow the instructions for use on the

packaging when using screen cleaning products.

You should always add antifreeze to the cleaning water in winter even if your ve-

hicle is fitted with heated windscreen washer nozzles.

It is also possible in exceptional cases to use methylated spirits when no screen

cleaner with antifreeze is available. The concentration of methylated spirits must

not be more than 15 %. Please note, however, that the antifreeze protection at

this concentration is only adequate down to -5 Β°C. WARNING

Read and observe the warning notes ββpage 190

, Working in the engine com-

partment before working in the engine compartment. Β£ 199

Inspecting and Replenishing Using the system Safety Driving Tips General Maintenance Breakdown assistance Technical data

Page 211 of 252

The vehicle tool kit and the lifting jack, on which a sign is affixed, are stowed in a

box in the luggage compartment

β

βfig. 164; there is also space here for the de-

tachable ball head of the towing device. The box is secured with a strap. The

placement of the vehicle tool kit can vary depending on the vehicle equipment.

The vehicle tool kit contains the following parts (depending on equipment fitted):

β Tyre repair kit

β Wire clamps for removing the full wheel trims,

β Wheel wrench,

β Towing eye,

β Adapter for the wheel bolts lock,

β Replacement lamp,

β Torx screwdriver.

Before placing the lifting jack back in its storage area, screw in the arm of the lift-

ing jack fully. WARNING

β The factory-supplied lifting jack is only intended for your model of vehicle.

On no account attempt to lift a heavier vehicle or other loads - risk of injury!

β Ensure that the vehicle tool kit is safely attached in the luggage compart-

ment. Note

Ensure that the box is always secured with the strap. ο

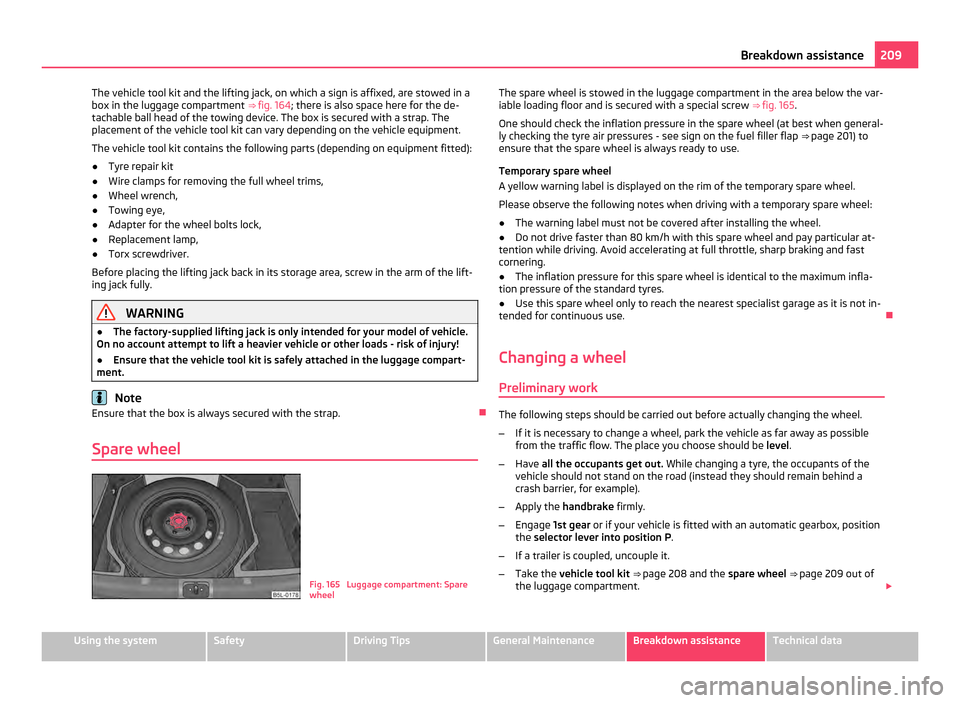

Spare wheel Fig. 165 Luggage compartment: Spare

wheelThe spare wheel is stowed in the luggage compartment in the area below the var-

iable loading floor and is secured with a special screw

ββfig. 165.

One should check the inflation pressure in the spare wheel (at best when general-

ly checking the tyre air pressures - see sign on the fuel filler flap ββpage 201) to

ensure that the spare wheel is always ready to use.

Temporary spare wheel

A yellow warning label is displayed on the rim of the temporary spare wheel.

Please observe the following notes when driving with a temporary spare wheel:

β The warning label must not be covered after installing the wheel.

β Do not drive faster than 80 km/h with this spare wheel and pay particular at-

tention while driving. Avoid accelerating at full throttle, sharp braking and fast

cornering.

β The inflation pressure for this spare wheel is identical to the maximum infla-

tion pressure of the standard tyres.

β Use this spare wheel only to reach the nearest specialist garage as it is not in-

tended for continuous use. ο

Changing a wheel Preliminary work The following steps should be carried out before actually changing the wheel.

β If it is necessary to change a wheel, park the vehicle as far away as possible

from the traffic flow. The place you choose should be level.

β Have all the occupants get out. While changing a tyre, the occupants of the

vehicle should not stand on the road (instead they should remain behind a

crash barrier, for example).

β Apply the handbrake firmly.

β Engage 1st gear or if your vehicle is fitted with an automatic gearbox, position

the selector lever into position P .

β If a trailer is coupled, uncouple it.

β Take the vehicle tool kit ββ page 208

and the spare wheel ββpage 209 out of

the luggage compartment. Β£ 209

Breakdown assistance Using the system Safety Driving Tips General Maintenance Breakdown assistance Technical data

Page 212 of 252

WARNING

β If you find yourself in flowing traffic switch on the hazard warning lights

system and place the warning triangle on the side of the road at the prescri-

bed distance from your vehicle. Comply with the national legal regulations. In

this way you are protecting not only yourself but also other road users.

β Never start the engine with the vehicle sitting on the raised jack - danger

of suffering injury. CAUTION

If you have to change a wheel on a slope first block the opposite wheel with a

stone or similar object in order to secure the vehicle from unexpectedly rolling

away. Note

Comply with the national legal regulations. ο

Changing a wheel Always change a wheel on a level surface as far as possible.

β

Take off the full wheel trim ββpage 210 or the wheel trim cap ββpage 211 or

the caps ββpage 211.

β In the case of light alloy wheels remove the wheel trim cap β

βpage 211.

β First of all slacken the safety wheel bolt and afterwards the other wheel bolts

ββ page 211.

β Jack up the vehicle until the wheel to be changed is clear of the ground

ββpage 212.

β Unscrew the wheel bolts and place them on a clean surface (cloth, paper etc.).

β Take off the wheel.

β Fit on the spare wheel and tighten the wheel bolts slightly.

β Lower the car.

β Tighten the wheel bolts firmly, alternately and diagonally using the wheel

wrench (crosswise) and lastly the wheel safety bolt β

βpage 211.

β Mount the full wheel trim/wheel trim cap or the caps. Note

β All bolts must be clean and must turn easily.

β You must never grease or oil the wheel bolts!

β When fitting on unidirectional tyres, ensure that the tyres rotate in the correct

direction ββpage 201

. ο

Subsequent steps After changing the wheel, you must perform the following steps.

β

Stow and attach the replaced wheel in the spare wheel well using a special

screw ββfig. 165 .

β Stow the vehicle tool kit in the space provided.

β Check the tyre pressure on the spare wheel just mounted as soon as possible.

β Have the tightening torque of the wheel bolts checked with a torque wrench

as soon as possible. Steel and light alloy wheels must be tightened to a tight-

ening torque of 120

Nm.

β Change the damaged wheel or consult a specialist garage about possibilities

for getting repairs done. WARNING

It is necessary to observe the guidelines given on β

βpage 203 if the vehicle is

subsequently fitted with tyres which are different to those it was fitted with

at the works. Note

β If you find, when changing the wheel, that the wheel bolts are corroded and

difficult to turn, the bolts must be replaced before checking the tightening torque.

β Drive cautiously and only at a moderate speed to a workshop where the tight-

ening torque can be checked. ο

Full wheel trim Pulling off

β

Hook the clamp found in the vehicle tool kit into the reinforced edge of the full

wheel trim. Β£210

Breakdown assistance

Page 215 of 252

WARNING (Continued)

β Secure the base plate of the lifting jack with suitable means to prevent

possible moving. A soft and slippery ground under the base plate may move

the lifting jack, causing the vehicle to fall down. It is therefore always neces-

sary to place the lifting jack on a solid surface or use a wide and stable base.

Use a non-slip base (e.g. a rubber foot mat) if the

surface is smooth, such as

cobbled stones, a tiled floor, etc.

β Attach the lifting jack only at the attachment points provided for this pur-

pose. ο

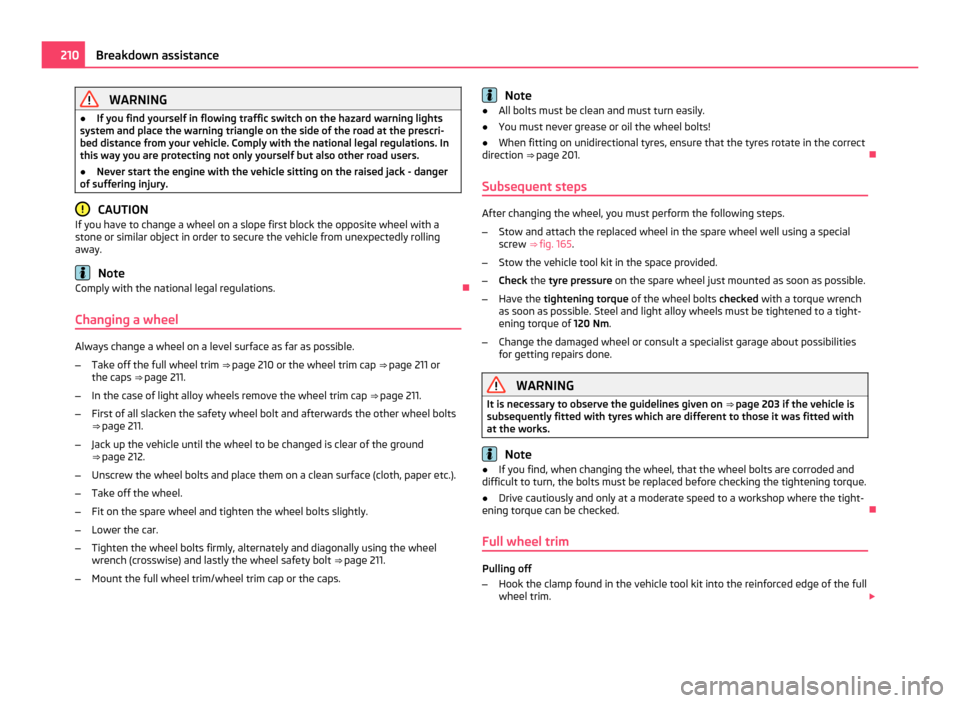

Securing wheels against being stolen You need a special adapter for loosening the safety wheel bolts.

Fig. 171 Illustration image: Safety wheel

bolt with adapter

β Pull off the full wheel trim/cap from the wheel hub or cap from the safety

wheel bolt.

β Insert the adapter B with its toothed side into the inner toothing of the head

of the safety wheel bolt A

β

βfig. 171 .

β Insert the wheel wrench fully onto the adapter B .

β Slacken the wheel bolt, or tighten it firmly ββpage 211.

β Reinstall the full wheel trim/wheel cap after removing the adapter or place the

cap onto the safety wheel bolt.

β Have the tightening torque checked with a torque wrench as soon as possi-

ble. Steel and light alloy wheels must be tightened to a tightening torque of

120

Nm. The safety wheel bolts on vehicles fitted with them (one safety wheel bolt per

wheel) can only be loosened or tighten up by using the adapter provided.

It is meaningful to note the code number hammered into the rear side of the

adapter or the rear side of the safety wheel bolts. You can obtain a replacement

adapter from an authorised

Ε KODA Service Partner, if necessary, by quoting this

number.

We recommend that you always carry the adapter for the wheel bolts with you in

the vehicle. It should be stowed in the vehicle tool kit. CAUTION

Damage can occur to the adapter and safety wheel bolt if the safety wheel bolt is

tightened up too much. Note

The set of safety wheel bolts can be obtained from an authorised Ε KODA Service

Partner. ο

Tyre repair kit General information The tyre repair kit is located in a box under the carpet in the luggage compart-

ment.

Use the tyre repair kit to reliably repair tyre damage caused by foreign bodies or a

puncture with diameters up to 4 mm. Do not remove foreign bodies, e.g. screws or

nails, from the tyre!

The repair can be undertaken on the vehicle immediately.

The repair with the tyre repair kit is not at all intended to replace a permanent

repair on the tyre, this repair only serves to reach the next specialist garage.

Do not use the tyre repair kit:

β to repair wheel damage,

β in outside temperatures of less than -20 Β°C (-4 Β°F),

β with tears or punctures greater than 4 mm in size,

β to repair damage to the tyre wall,

β when driving with very low tyre pressure or with a completely flat tyre,

β if the use-by-date (see inflation bottle) has passed. Β£ 213

Breakdown assistance Using the system Safety Driving Tips General Maintenance Breakdown assistance Technical data

Page 227 of 252

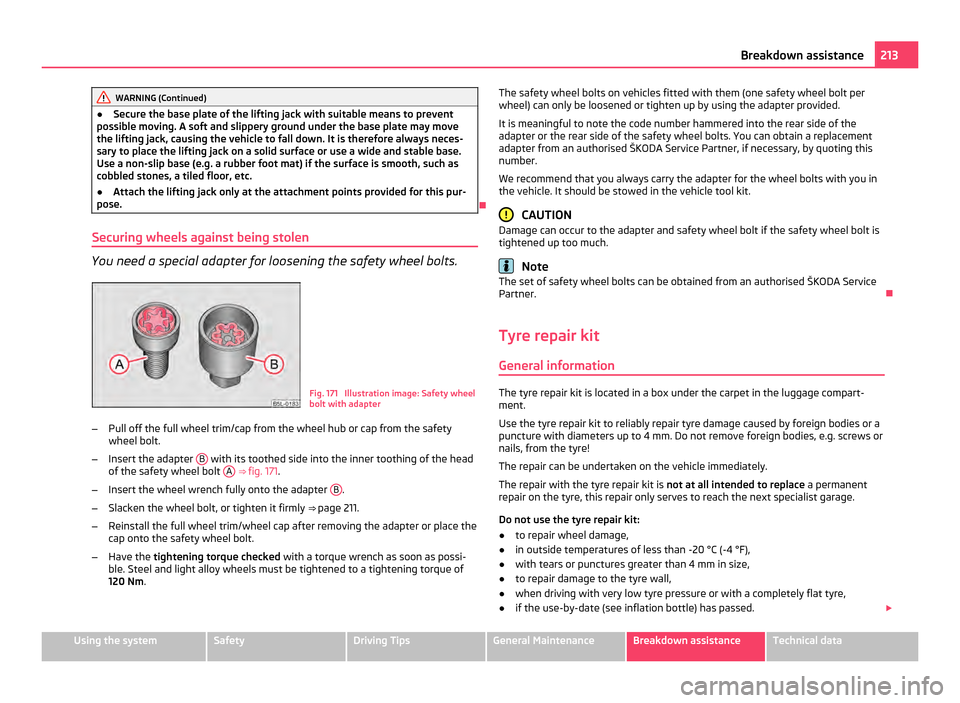

Main beam light and low beam light

Fig. 184 Removing the bulb for the main

beam light and low beam light

β Switch the ignition and all lights off.

β Turn the protective cap in direction of arrow OPEN β βfig. 182 and remove it.

β Unplug plug A .

β Press the wire clamps B down until they are released from the secured posi-

tion.

β Remove the light bulb C and insert the new light bulb in such a way that the

fixing lugs of the light bulb socket fit into the recesses at the reflector.

Installation is carried out in the reverse order. Note

We recommend that you have the headlight setting checked by a Skoda Service

Partner after replacing the light bulb. ο

Fog lights Fig. 185 Removing the bulb for the fog

light Removing the bulb for the fog light

β

Switch the ignition and all lights off.

β Remove the rubber protective cap A ββfig. 181

.

β Unplug plug 1 .

β Take the faulty bulb out of the fixture 2 by pressing the light socket down-

wards and insert a new one.

β Insert the protective cap. ο

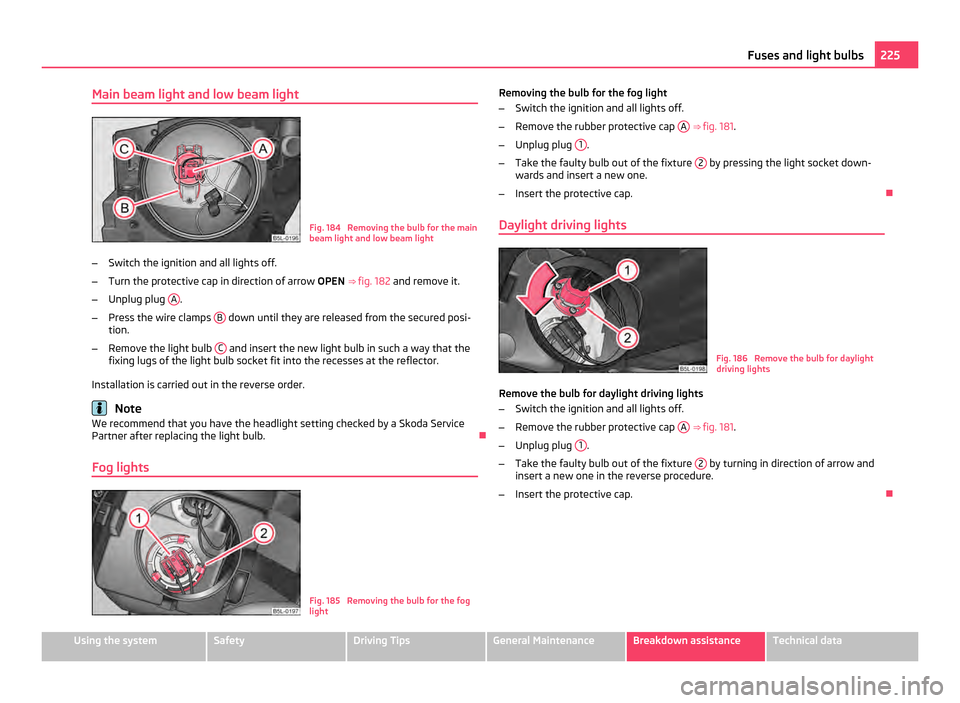

Daylight driving lights Fig. 186 Remove the bulb for daylight

driving lights

Remove the bulb for daylight driving lights

β Switch the ignition and all lights off.

β Remove the rubber protective cap A

ββ fig. 181 .

β Unplug plug 1 .

β Take the faulty bulb out of the fixture 2 by turning in direction of arrow and

insert a new one in the reverse procedure.

β Insert the protective cap. ο 225

Fuses and light bulbs Using the system Safety Driving Tips General Maintenance Breakdown assistance Technical data

Page 228 of 252

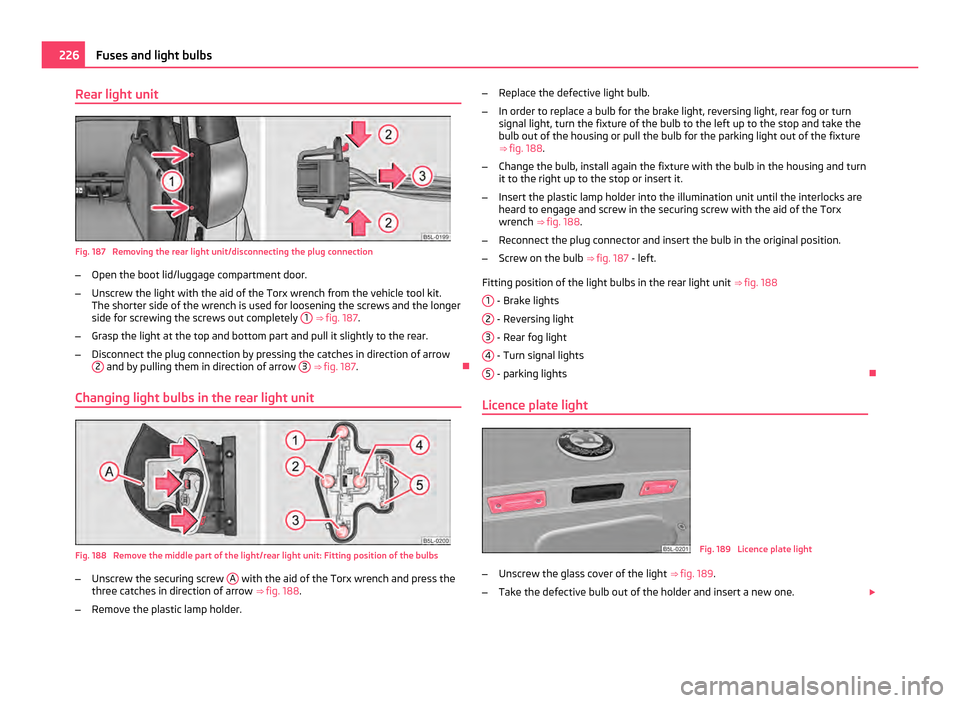

Rear light unit

Fig. 187 Removing the rear light unit/disconnecting the plug connection

β Open the boot lid/luggage compartment door.

β Unscrew the light with the aid of the Torx wrench from the vehicle tool kit.

The shorter side of the wrench is used for loosening the screws and the longer

side for screwing the screws out completely 1

β βfig. 187.

β Grasp the light at the top and bottom part and pull it slightly to the rear.

β Disconnect the plug connection by pressing the catches in direction of arrow

2 and by pulling them in direction of arrow

3

β

βfig. 187. ο

Changing light bulbs in the rear light unit Fig. 188 Remove the middle part of the light/rear light unit: Fitting position of the bulbs

β

Unscrew the securing screw A with the aid of the Torx wrench and press the

three catches in direction of arrow ββfig. 188 .

β Remove the plastic lamp holder. β

Replace the defective light bulb.

β In order to replace a bulb for the brake light, reversing light, rear fog or turn

signal light, turn the fixture of the bulb to the left up to the stop and take the

bulb out of the housing or pull the bulb for the parking light out of the fixture

ββfig. 188 .

β Change the bulb, install again the fixture with the bulb in the housing and turn

it to the right up to the stop or insert it.

β Insert the plastic lamp holder into the illumination unit until the interlocks are

heard to engage and screw in the securing screw with the aid of the Torx

wrench β

βfig. 188 .

β Reconnect the plug connector and insert the bulb in the original position.

β Screw on the bulb β

βfig. 187 - left.

Fitting position of the light bulbs in the rear light unit ββfig. 188

1 - Brake lights

2 - Reversing light

3 - Rear fog light

4 - Turn signal lights

5 - parking lights

ο

Licence plate light Fig. 189 Licence plate light

β Unscrew the glass cover of the light β

βfig. 189 .

β Take the defective bulb out of the holder and insert a new one. Β£226

Fuses and light bulbs

Page 245 of 252

Operation in winter

Battery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 198

Biodiesel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 187

De-icing windows . . . . . . . . . . . . . . . . . . . . . . . . . . . 182

Outside temperature . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Overview of the engine compartment . . . . . . . . . . . 191

P Paint . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 182

Paint damage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 182

Panoramic sliding roof . . . . . . . . . . . . . . . . . . . . . . . . . 42

Park Assist . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 105

Parking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

Parking aid Front and rear . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 104

rear . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

Parking light . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Parking the vehicle . . . . . . . . . . . . . . . . . . . . . . . . . . 103

Passive Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 128

Payload . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 228

Pedals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70, 102

Petrol . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 186

Petrol engines Starting the engine . . . . . . . . . . . . . . . . . . . . . . . . . 101

Polishing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 182

Power steering . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 158 Warning light . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Power windows . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39 Button in the driver's door . . . . . . . . . . . . . . . . . . . 39

Button in the front passenger door and in therear doors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Operational faults . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

with central locking system . . . . . . . . . . . . . . . . . . . 41

R Radiator fan . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 195 Rear-view mirror

Exterior mirror . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

Interior mirror . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

Rear armrest . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

Rear fog light . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49 Warning light . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Rear interior lighting . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Rear seats . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

Rear window Heater . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Rear window heater . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Recharge battery . . . . . . . . . . . . . . . . . . . . . . . . . . . . 198

Recommendation for changing gears . . . . . . . . . . . 14

Refuelling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 187

Remote control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37 Synchronisation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Removing seats . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

Replacement of parts . . . . . . . . . . . . . . . . . . . . . . . . 207

Replacing fuses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 220

Replacing the wiper blades . . . . . . . . . . . . . . . . . . . . 57

Roof aerial . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 181

Roof luggage rack system . . . . . . . . . . . . . . . . . . . . . 76

Running in . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 162

S

Safe securing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 128

Safety information Engine compartment . . . . . . . . . . . . . . . . . . . . . . . 190

Safety wheel bolts . . . . . . . . . . . . . . . . . . . . . . . . . . . 213

Saving electrical energy . . . . . . . . . . . . . . . . . . . . . . 163

Seat belt height adjuster Seat belts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 134

Seat belts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 132 Belt tensioners . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 135

Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 185

fastening . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 134

Safety information . . . . . . . . . . . . . . . . . . . . . . . . . . 133 taking off . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 135

Warning light . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Seat belt warning light . . . . . . . . . . . . . . . . . . . . . . . 134

Seat heating . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

Selector lever . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 113

Selector lever-emergency unlocking . . . . . . . . . . . . 116

Selector lever lock Warning light . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Selector lever positions . . . . . . . . . . . . . . . . . . . . . . . . 113

Service reminder indicator . . . . . . . . . . . . . . . . . . . . . 12

Setting temperature Heating . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

Setting the clock . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Shifting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 102

Side airbag . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 141

Side lights . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Snow chains . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 205

Spare wheel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 209

Speedometer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Stabilisation system . . . . . . . . . . . . . . . . . . . . . . . . . . 153

START-STOP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 110

Starting the engine . . . . . . . . . . . . . . . . . . . . . . . . . . 100 after fuel tank has run empty . . . . . . . . . . . . . . . . 101

Diesel engines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

Petrol engines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

Static separation net . . . . . . . . . . . . . . . . . . . . . . . . . . 73

Steering active driver-steering recommendation . . . . . . . 155

Steering force assistance . . . . . . . . . . . . . . . . . . . . . 158

Storage compartment Lighting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Storage compartments . . . . . . . . . . . . . . . . . . . . . . . . 80

Storage facilities . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

Sun . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Switching off the engine . . . . . . . . . . . . . . . . . . . . . . 101

Switch off Anti-spin regulation (ASR) Warning light . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27 243

Index Using the system Safety Driving Tips General Maintenance Breakdown assistance Technical data