steering SSANGYONG KORANDO 1997 Service Repair Manual

[x] Cancel search | Manufacturer: SSANGYONG, Model Year: 1997, Model line: KORANDO, Model: SSANGYONG KORANDO 1997Pages: 2053, PDF Size: 88.33 MB

Page 1501 of 2053

POWER STEERING AND COLUMN 6E-15

SSANGYONG MY2002

SPECIAL TOOLS AND EQUIPMENT

SPECIAL TOOLS TABLE

661 589 00 33 00

Steering Wheel Puller

KAA6E150

Page 1588 of 2053

SUPPLEMENTAL RESTRAINTS SYSTEM 8B-3

SSANGYONG MY2002

SUPPLEMENTAL RESTRAINT

SYSTEM (SRS)

The supplemental restraint system (SRS) is safety de-

vice used in conjunction with the seat belts.

The air bag does not replace the function of the

seatbelt. The driver and the passengers must always

fasten their seat belts adjust them for a proper fit.

The SRS is designed to protect the driver and the front

seat passenger in the event of a significant frontal im-

pact to the vehicle. The airbags deploy if the force is

applied from a direction within about 30 degrees of

the vehicle’s centerline.

The SRS system consists of the following components:

Driver side airbag module.

Passenger airbag module.

Driver’s and passengers front seat belt pretension-

ers.

Sensing and diagnostic module (SDM).

Clock spring.

Wire harness and connectors.

Airbag warning lamp on the instrument cluster.

There are there are for separate four separate deploy-

ment loops in the SRS system. The term “loop” is

used because current leaves the SDM and returns to

the SDM during deployment or testing. First loop is

the circuit from SDM to the driver airbag and back to

the SDM. Second loop is the circuit from the SDM to

the passenger airbag and back to the SDM. The third

and forth loops are for right and left pretensioners.

DESCRIPTION AND OPERATION

KAA8B010

deployment, the system will enter overall or partial

shutdown status and the airbag will not inflate. The

Diagnostic System Check reveals diagnostic trouble

codes (DTCs) through the use of scan tool. It also

checks for proper airbag warning lamp operation.

Battery Voltage Check

The SDM checks the battery voltage continuously and

if the voltage is out of normal operating range (9-16

volts), all system diagnosis stops and turns on the

warning warning lamp.

Deployment Line Check

The SDM checks not only low or high resistance in the

deployment loop but also short to battery or ground

condition to indicates defects in deployment loop. It

indicates the defects by blinking the airbag warning

warning lamp.

Safety Function Check

The SDM checks the operation of arming sensor. If

the arming sensor is shorted more than 2 seconds,

the SDM will enter overall shutdown mode.

AIRBAG MODULES

Driver Airbag Module

Caution: Tampering with driver side airbag module

creates the risk of an injury from unexpected de-

ployment. Therefore, the passenger airbag module

should never be disassembled.

The passenger airbag module is under the center pad

of the steering wheel. The driver airbag module contains

an igniter charge and a gas generator to inflate the

folded airbag.

The airbag contains a shorting bar, which short-circuit

the driver high circuit to driver low circuit when the

connector is disconnected. The shorting bar prevents

current from traveling through the driver airbag module

during servicing. The shorting bar is disengaged when

the connector is connected.

System Control

The sensing and diagnostic module (SDM) continuously

monitors and controls the supplemental restraint

system (SRS) function during ignition ON or driving.

When SDM detects any problem it turns on or blink

the airbag warning lamp and keeps the diagnostic

trouble codes (DTCs). If there is a danger of improper

KAA8B020

Page 1590 of 2053

SUPPLEMENTAL RESTRAINTS SYSTEM 8B-5

SSANGYONG MY2002

KAA8B060

AIRBAG WARNING LAMP

The instrument cluster contains an airbag warning indi-

cator bulb to verify the operation of the airbag indicator

and sensing and diagnostic module (SDM). The SDM

performs a start-up test when the ignition is turned ON

and turns the airbag indicator on for 4.5 seconds by

supplying an internal ground to the indicator lamp

circuit. After 4.5 seconds, the airbag indicator will turn

off if no more malfunctions have been detected.

If the SDM has detected malfunctions, which could

potentially affect the operation of the supplemental

restraint system (SRS) it turns on or blinks the airbag

warning indicator. The airbag indicator stays on for

the malfunction of internal system and blinks for

external circuit problem such as short to battery or

ground. The airbag indicator blinks four different modes

according to the fault.

Some malfunctions could result in non-deployment

when necessary or deployment under conditions which

would no normally result in deployment.

When the SDM is not properly attached to its connector

the airbag circuit is shorted to ground because there

is a shorting bar within the SDM electronic connector.

The shorting bar is disengaged when proper connection

is made, but if a poor connection exists the SDM

connector supplies a ground to the airbag indicator in

dependently of the SDM, and the airbag indicator turns

on.

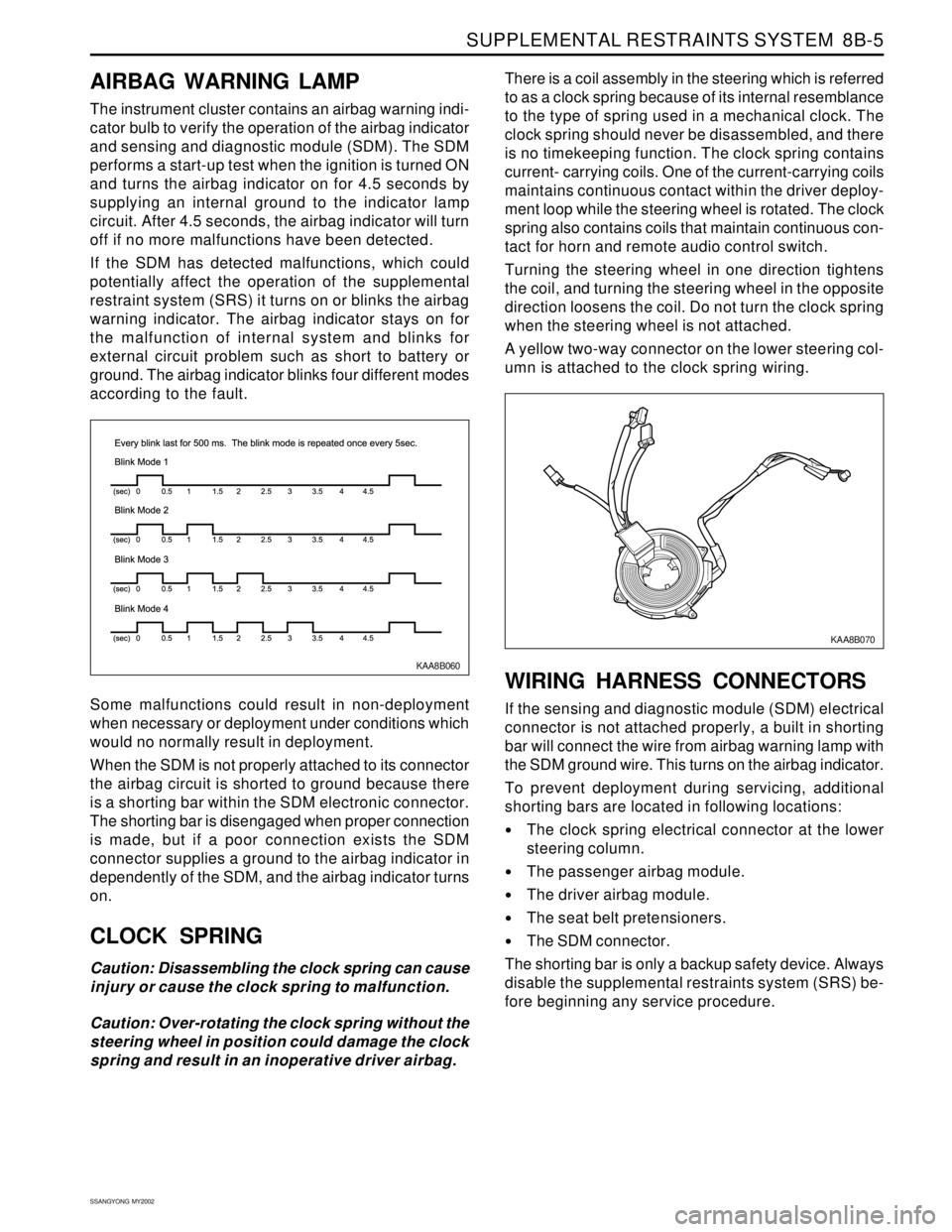

CLOCK SPRING

Caution: Disassembling the clock spring can cause

injury or cause the clock spring to malfunction.

Caution: Over-rotating the clock spring without the

steering wheel in position could damage the clock

spring and result in an inoperative driver airbag.There is a coil assembly in the steering which is referred

to as a clock spring because of its internal resemblance

to the type of spring used in a mechanical clock. The

clock spring should never be disassembled, and there

is no timekeeping function. The clock spring contains

current- carrying coils. One of the current-carrying coils

maintains continuous contact within the driver deploy-

ment loop while the steering wheel is rotated. The clock

spring also contains coils that maintain continuous con-

tact for horn and remote audio control switch.

Turning the steering wheel in one direction tightens

the coil, and turning the steering wheel in the opposite

direction loosens the coil. Do not turn the clock spring

when the steering wheel is not attached.

A yellow two-way connector on the lower steering col-

umn is attached to the clock spring wiring.

WIRING HARNESS CONNECTORS

If the sensing and diagnostic module (SDM) electrical

connector is not attached properly, a built in shorting

bar will connect the wire from airbag warning lamp with

the SDM ground wire. This turns on the airbag indicator.

To prevent deployment during servicing, additional

shorting bars are located in following locations:

The clock spring electrical connector at the lower

steering column.

The passenger airbag module.

The driver airbag module.

The seat belt pretensioners.

The SDM connector.

The shorting bar is only a backup safety device. Always

disable the supplemental restraints system (SRS) be-

fore beginning any service procedure.

KAA8B070

Page 1619 of 2053

SUPPLEMENTAL RESTRAINTS SYSTEM 8B-35

SSANGYONG MY2002

Perform the SRS Diagnostic System Check.

Is the SRS Diagnostic System Check complete?

1. Disable the Supplemental Restraint System (SRS).

Refer to “Disabling the Supplemental Restraint

System (SRS)” in this section.

2. Inspect the yellow clock spring connector at the

lower steering column.

Is a faulty connector or terminal or loose wire de-

tected?

1. Repair or Replace the faulty connector, terminal, or

wire.

2. Connect all the SRS components.

Is the repair complete?

1. Disconnect the SDM connector.

2. Check terminals 13 and 14 for loose terminals or

wire.

Is a problem found?

Replace the loose terminals or wires at SDM connec-

tor.

Is the repair complete?

1. Reconnect the SDM.

2. Connect dummy resistance (2.15 ± 0.35 Ω) to

driver airbag connector instead of driver airbag.

3. Connect other SRS components.

4. Enable the SRS.

5. Turn the ignition switch to ON and check for DTCs

with scan tool.

Is DTC 17 still current?

Replace driver airbag.

Is the repair complete?

1. Disable the SRS.

2. Disconnect C203.

3. Connect dummy resistance (2.15 ± 0.35 Ω) to SDM

side terminal of C203.

4. Enable the SRS.

5. Turn the ignition switch to ON and check for DTCs

with scan tool.

Is DTC 17 still current?

1. Disconnect the SDM.

2. Measure resistance between terminal 1 or 2 of

C203 and ground.

Is the resistance equal to specified value?

3. Measure the voltage between terminal 1 or 2 of

C203 and ground.

Is the voltage within the specified value?

1. Repair short to ground or short to voltage circuit

between SDM and C203.

2. Connect all SRS components.

Is the repair complete?

StepAction Value(s) Yes No

2

4

5

6

- Go to Step 3 Go to Step 4

3

-Go to “SRS

Diagnostic

System Check” -

- Go to Step 5 Go to Step 6

-Go to “SRS

Diagnostic

System Check” -

-Go to “SRS

Diagnostic

System Check” -

- Go to Step 9 Go to Step 12 7

8

9

10

-Go to “SRS

Diagnostic

System Check” - 1

- Go to Step 2 -

≈ 0 v Go to Step 11 Go to Step 10∞

- Go to Step 8 Go to Step 7

Page 1628 of 2053

SUPPLEMENTAL RESTRAINTS SYSTEM 8B-45

SSANGYONG MY2002

Perform the SRS Diagnostic System Check.

Is the SRS Diagnostic System Check complete?

1. Disable the Supplemental Restraint System (SRS).

Refer to “Disabling the Supplemental Restraint

System (SRS)” in this section.

2. Inspect the yellow clock spring connector at the

lower steering column.

Is a faulty connector or terminal or loose wire de-

tected?

1. Repair or Replace the faulty connector, terminal, or

wire.

2. Connect all the SRS components.

Is the repair complete?

1. Disconnect the SDM connector.

2. Check terminals 13 and 14 for loose terminals or

wire.

Is a problem found?

Replace the loose terminals or wires at SDM connec-

tor.

Is the repair complete?

1. Reconnect the SDM.

2. Connect dummy resistance (2.15 ± 0.35 Ω) to

driver airbag connector instead of driver airbag.

3. Connect other SRS components.

4. Enable the SRS.

5. Turn the ignition switch to ON and check for DTCs

with scan tool.

Is DTC 21 still current?

Replace driver airbag.

Is the repair complete?

1. Disable the SRS.

2. Disconnect C203.

3. Connect dummy resistance (2.15 ± 0.35 Ω) to SDM

side terminal of C203.

4. Enable the SRS.

5. Turn the ignition switch to ON and check for DTCs

with scan tool.

Is DTC 21 still current?

Measure resistance between terminal 1 and 2 of

connector C203.

Is the resistance within the specified value?

Repair open circuit between C203 and SDM.

Is the repair complete?

1. Disconnect the SDM.

2. Measure resistance between terminal 1 or 2 of

C203 and ground.

Is the resistance equal to specified value?

3. Measure the voltage between terminal 1 or 2 of the

driver airbag module and ground.

Is the voltage within the specified value?

StepAction Value(s) Yes No

2

4

5

6

- Go to Step 3 Go to Step 4

3

-Go to “SRS

Diagnostic

System Check” -

- Go to Step 5 Go to Step 6

-Go to “SRS

Diagnostic

System Check” -

7

8

9

10

-Go to “SRS

Diagnostic

System Check” - 1

- Go to Step 2 -

∞

- Go to Step 8 Go to Step 7

-Go to “SRS

Diagnostic

System Check” -

11

- Go to Step 9 Go to Step 14

≈ 0 v Go to Step 11 Go to Step 10

≈ 0 v Go to Step 10 Go to Step 9

Page 1640 of 2053

SSANGYONG MY2002

8B-58 SUPPLEMENTAL RESTRAINTS SYSTEM

REPAIR INSTRUCTION

ON-VEHICLE SERVICE

SERVICE PRECAUTION

Caution: The sensing and diagnosis module (SDM)

can maintain sufficient voltage to deploy the airbags

and pretensioner for 0.15 seconds after the ignition

is OFF and the airbag fuse has been removed. If the

airbags or pretensioners are not disconnected, do

not begin service until one minute has passed after

disconnecting power to the SDM. If the airbag are

disconnected, service can begin immediately without

waiting for one-minute time period to expire. Failure

to temporarily disable the SRS during service can

result in unexpected deployment, personal injury,

and otherwise unneeded SRS repairs.

DISABLING THE SUPPLEMENTAL

RESTRAINT SYSTEM (SRS)

1. Turn the steering wheel to the straight-ahead

position.

2. Turn the ignition switch to LOCK and remove the key.

3. Remove the airbag fuse F31 in the I/P fuse block

and wait more than one minute for SRS capacitor to

discharge.

ENABLING THE SUPPLEMENTAL

RESTRAINT SYSTEM (SRS)

Enabling the supplemental restraint system (SRS) is

reverse order of “Disabling the Supplemental Restraint

System (SRS)”.

Caution: Staying well away from the inflator

modules, turn the ignition key switch to ON, and

verify that the airbag indicator illuminates for 4.5

seconds and turns OFF. If it does not operate as

described, perform the “SRS Diagnostic System

Check” referring in this section.

HANDLING, INSTALLATION AND

DIAGNOSIS

Airbag modules should not be subjected to

temperature above 65°C (149°F)

An airbag module or sensing and diagnostic module

(SDM) should not be used if it has been dropped

from height of 0.9 meters (3 feet) or greater.

It is very important for the SDM to be installed flat

on the mounting surface, parallel to the vehicle’s

longitudinal axis.

To avoid setting diagnostic trouble codes (DTCs),

do not apply power to the SRS unless all components

are connected or a diagnostic chart request it.

The SRS Diagnostic System Check must be the

starting point of any SRS diagnostics. The SRS

Diagnostic System Check will verify proper airbag

indicator operation and will lead you to correct chart

to diagnose any SRS malfunctions. Bypassing

these procedures may result in extended diagnostic

time and incorrect parts replacements.

REPAIRS AND INSPECTIONS

REQUIRED AFTER AN ACCIDENT

Caution: any repairs to the vehicle’s structure must

return it to the original production configuration.

Deployment requires replacement of SDM, the

inflator modules, and a dimensional inspection of

the steering column.

If any SRS components are damaged, they must

be replaced. If SRS components mounting points

are damaged, they must be repaired or replaced.

Never use SRS parts from another vehicle. This does

not include remanufactured parts purchased from

an authorized source.

Do not attempt to service the SDM, the clock spring,

or other airbag modules, these items must be

replaced if they are defective.

Verify the part number of replacement airbag

modules. Some inflator modules look identical but

contain different internal components.

ACCIDENT WITH DEPLOYMENT -

COMPONENTS REPLACEMENT

All SRS components must be replaced after frontal crash

involving airbag deployment. After deployment, a

powdery residue may be on the surface of the airbag.

The powder consists primarily of cornstarch (used to

lubricate the bag as it inflates) and by-products of the

chemical reaction. Sodium hydroxide dust (similar to

lye soap) is produced as a by-product of the deployment

reaction. The sodium hydroxide then quickly reacts with

atmospheric moisture and is converted to sodium

carbonate and sodium bicarbonate (also known as

baking soda). Therefore, it is unlikely that sodium

hydroxide will be present after deployment. Replace

the following SRS components.

Caution: Wear gloves and safety glasses during the

disposal procedure. Refer to “Deployed Airbag

Module Disposal Procedure” in this section.

The SDM.

Airbag modules and pretensioners

SRS wiring

Clock spring

Page 1641 of 2053

SUPPLEMENTAL RESTRAINTS SYSTEM 8B-59

SSANGYONG MY2002

KAA8B130

ACCIDENT WITHOUT DEPLOYMENT

- COMPONENT INSPECTION

Certain inspection must be performed after any crash,

whether the airbag has deployed or not:

The steering column must be dimensionally

inspected.

Inspect the knee bolsters and mounting points for

distortion, bending, cracking, or other damage.

Inspect the instrument panel (I/P) and steering

column reinforcement plate for distortion, bending,

cracking, or other damage.

Inspect the I/P braces for distortion, bending,

cracking, or other damage.

Inspect seat belt and mounting points. Refer to

Section 8A, Seat Belts.

SENSING AND DIAGNOSTIC

MODULE (SDM)

Caution: during service procedures, be very careful

when handling the SDM. Never strike or jar the SDM.

Never power up the SRS when the SDM is not rigidly

attached to the vehicle. All SDM mounting nuts must

carefully tightened, to ensure proper operation of

the SRS. The SDM could be activated if it is powered

while not rigidly attached to the vehicle, resulting

in unexpected deployment and possible injury.

Important: If the vehicle interior has been exposed to

extensive water intrusion such as water leaks, driving

through high water, flooding, or other causes, the sensing

and diagnostic module (SDM) and SDM connector may

need to be replaced. With the ignition OFF, inspect the

area around the SDM, including the carpet. If any

significant soaking or evidence of previous soaking is

detected, the water must be removed, the water damage

repaired, and the SDM and SDM connector must be

replaced. Before attempting any of these repairs, the

supplemental restraint system (SRS) must be disabled.

Refer to”Disabling the Supplemental Restraint System

(SRS)” in this section.

Removal and installation Procedure

1. Disable the supplemental restraint system (SRS).

Refer to “Disabling the SRS” in this section.

2. Remove the connector position assurance lock,

which is tethered to the SDM connector.

3. Disconnect the SDM electrical connector.

4. Remove the SDM mounting nuts and grounding nut.

Installation Notice

5. Remove the SDM.

6. Installation should follow the removal procedure

in the reverse order.

Notice: Enable the SRS. Refer to “Enabling the SRS”

in this section.

Tightening Torque 12 Nm (106 lb-in)

Page 1642 of 2053

SSANGYONG MY2002

8B-60 SUPPLEMENTAL RESTRAINTS SYSTEM

KAA8B140

DRIVER AIRBAG MODULE

Removal and installation Procedure

1. Disconnect the negative battery cable.

Caution: The SDM can maintain sufficient

voltage to deploy the airbags for 0.15 seconds

after the Ignition is OFF and the airbag fuse has

been removed. If the airbags are not

disconnected, service cannot begin until one

minute has passed after disconnecting power

to the SDM. If the airbags are disconnected,

service can begin immediately without waiting

for one-minute time period to expire. Failure to

temporarily disable the SRS during service

result in unexpected deployment, personal

injury, and otherwise unneeded SRS repair.

2. Disable the supplemental restraint system (SRS).

Refer to “Disabling the SRS” in this section.

3. Position the steering wheel straight ahead.

4. Remove the driver airbag module mounting bolts.

Installation Notice

Caution: When handling an airbag module,

always keeps the top of the unit facing upward.

This leaves room for the airbag to expand if the

module unexpectedly deploys. Without room

for expansion, a module suddenly propelled

toward a person or object can cause injury or

vehicle damage.

5. Remove the connector from the horn terminal and

the driver airbag module.

6. Remove the driver airbag module.

7. Installation should follow the removal procedure

in the reverse order.

Tightening Torque 8 Nm (71 lb-in)

Page 1643 of 2053

SUPPLEMENTAL RESTRAINTS SYSTEM 8B-61

SSANGYONG MY2002

KAA8B050

CLOCK SPRING

Removal and installation Procedure

Caution: The SDM can maintain sufficient voltage

to deploy the airbags for 0.15 seconds after the

Ignition is OFF and the airbag fuse has been

removed. If the airbags are not disconnected, service

cannot begin until one minute has passed after

disconnecting power to the SDM. If the airbags are

disconnected, service can begin immediately

without waiting for one-minute time period to

expire. Failure to temporarily disable the SRS

during service result in unexpected deployment,

personal injury, and otherwise unneeded SRS repair.

1. Disconnect the negative battery cable.

2. Remove the driver airbag module. Refer to “Driver

Airbag Module” in this section.

3. Remove the steering wheel. Refer to Section 6E,

Steering Wheel and Column.

4. Remove the steering column cover. Refer to

Section 6E, Steering Wheel and Column.

5. Carefully full the instrument panel lower cover.

6. Remove driver side knee bolster.

7. Disconnect the clock spring, horn and remote

audio control connectors at the lower steering

column.

8. Remove the screws and the clock spring from the

steering shaft.

Installation Notice

Turning the clock spring more than three turns

clockwise or counterclockwise can damage the

spring.

Align the clock spring before installation. Turn

the lobe of the clock spring clockwise to lock

but do not force. Then turn the lobe of clock

spring count clockwise approximately three

turns to the neutral position, with the front of

the wheels straight ahead. Properly align the

pointed marks on the components of the clock

spring.

9. Installation should follow the removal procedure

in the reverse order.

Caution: If the clock spring is not properly

aligned, the steering wheel may not be able to

rotate completely during a turn. Restricted

turning ability can cause the vehicle to crash.

Improper alignment of the clock spring also may

make the supplemental restraint system (SRS)

inoperative, preventing the airbag from

deploying during crash. Both of the out comes

can result in injury.

Tightening Torque 4 Nm (35 lb-in)

Page 1645 of 2053

SUPPLEMENTAL RESTRAINTS SYSTEM 8B-63

SSANGYONG MY2002

KAA8B170

AIRBAG MODULE DEPLOYMENT

(IN VEHICLE)

Deploy airbags before disposing of them. If a vehicle to be

scraped, the airbag may be deployed inside the vehicle.

Caution: To avoid injury while deploying an airbag

or a pretensioner in the vehicle, observe the

following precaution:

Before deploying the airbags, remove all loose

objects from the airbag’s expansion area.

Deploy the airbags with the vehicle doors closed

and the side windows open.

Deploy the airbags only in an evacuated area.

Service personnel who must be present during

the deployment should be at least 10 meters (33

feet) in front of the vehicle.

Do not connect the voltage source until after

having completed all other preparations for the

deployment of the airbags.

Allow a deployed airbag module or pretensioner

to cool for at least 30 minutes before handling.

Wear gloves and eye protection during the

disposal procedure.

If the deployment fails, disconnect the voltage

source and wait 5 minutes before approaching

the vehicle.

Deployment Procedure

Caution: The SDM can maintain sufficient voltage

to deploy the airbags for 0.15 seconds after the

Ignition is OFF and the airbag fuse has been

removed. If the airbags are not disconnected, service

cannot begin until one minute has passed after

disconnecting power to the SDM. If the airbags are

disconnected, service can begin immediately

without waiting for one-minute time period to

expire. Failure to temporarily disable the SRS

during service result in unexpected deployment,

personal injury, and otherwise unneeded SRS repair.

1. Disconnect both battery cables and place the

battery at least 10 meters (33 feet) from the vehicle.

2. Remove the knee bolster from the steering column.

Refer to Section 9G, Interior Trim.

3. At the lower steering column, cut the two wires

leading from the supplemental restraint system

(SRS) harness to the clock spring.

4. Strip 13 mm (0.5 inch) of the insulation from the

end of the wires leading to the clock spring.

5. Use two additional wires, each at least 10 meters

(33 feet) long, to reach from the deployment battery

to the inflator module.

6. Strip 13 mm (0.5 inch) of the insulation from the

ends of these two additional wires.