SSANGYONG KORANDO 1997 Service Repair Manual

Manufacturer: SSANGYONG, Model Year: 1997, Model line: KORANDO, Model: SSANGYONG KORANDO 1997Pages: 2053, PDF Size: 88.33 MB

Page 1381 of 2053

TRANSFER CASE 5D1-11

SSANGYONG MY2002

DIAGNOSIS

While the transfer case control unit (TCCU) is active it

periodically monitors its inputs and outputs. If a fault

is detected the 4WD CHECK lamp is illuminated and a

fault code is stored in the TCCU memory.

When requested, fault codes are downloaded to scan

tool through a diagnostic connector (K-line) serial com

munication.

SELF-DIAGNOSTIC TESTS

TCCU Internal Function

When the ignition is turned on the TCCU tests its read

only memory (ROM) and random access memory

(RAM). If there is a fault, the TCCU immediately resets

itself and re-tests the ROM and RAM. If the fault

persists the TCCU continues to reset and re-test until

the fault is corrected or the ignition is turned off. All

TCCU functions are inhibited until the fault is corrected.

The 4WD CHECK lamp is not illuminated if there is a

ROM or RAM fault.

If the ROM/RAM passes the electronically erasable

programmable read only memory (EEPROM) is tested.

If there is a fault the 4WD CHECK lamp is illuminated

and the TCCU continues to operate using the default

calibration data stored in ROM. Fault codes are not

stored when there is an EEPROM fault.

An EEPROM fault can only be cleared by cycling

ignition OFF-ON.

Shift Motor Assembly Test

If the TCCU detects a shift motor or position encoder

fault continuously for one second the 4WD CHECK

lamp is turned on and the appropriate fault code is

stored in memory.

1. A shift motor fault when the motor is off is defined

as follows:

Motor HI-LO circuits are shorted to ground.

Motor LO-HI circuits are shorted to ground.

Motor circuits are open.

2. A shift motor fault when the motor is energized is

defined as follows:

Motor HI-LO circuits are shorted to ground.

Motor LO-HI circuits are shorted to ground.

Motor HI-LO circuits are shorted to motor LO

HI circuits.

Motor circuits are open.

3. A position encoder fault is defined as follows:

Any position code which does not correspond

to the valid 9 codes.

A short to ground on any of the encoder lines.

4. If no shifts are in progress when a failure occurs

the TCCU will not respond to any shift commands.5. If a shift command has been received but not

acted upon when a failure occurred the TCCU

would cancel the command and not respond to

any subsequent shift commands.

6. If a shift command is in progress when an invalid

position code is confirmed it will be halted and

the TCCU will turn the motor toward the high

position. Afterwards the TCCU will not respond to

any shift commands.

7. If the shift motor or position encoder assembly

failures, other than a motor failure which occurs

when the motor is energized, recovers continuously

for one second the TCCU will function normally.

The 4WD CHECK lamp is turned off but the fault

code will remain in memory.

8. A motor failure (i.e. open or short circuit) which

occurs when the motor is energized can only be

cleared by cycling the ignition OFF-ON.

Front Speed Sensor Test

If a front speed sensor fault is detected continuously

for 0.5 second the 4WD CHECK lamp is illuminated.

The TCCU then responds as follows:

1. If the system is in high range the TCCU uses the

rear speed sensor to determine the EMC touch off

level and wheel slip control is suspended.

2. If the system is in low range, the EMC duty cycle

is set to maximum, independent of vehicle speed,

until the system is shifted out of low range.

3. All electric shift activity is halted until the Ignition

is cycled. If a shift is in progress it will be

completed.

If the front speed sensor recovers continuously for O.5

second the TCCU will function normally. The 4WD

CHECK lamp is turned off but the fault code will remain

in memory.

Rear Speed Sensor Test

If a rear speed sensor fault is detected continuously

for 0.5 second the 4WD CHECK lamp is illuminated.

The TCCU then responds as follows:

1. If the system is in high range the TCCU uses the

front speed sensor to determine the EMC touch

off level and wheel slip control is suspended.

2. If the system is in low range, the EMC duty cycle

is set to maximum independent of vehicle speed

until the system is shifted out of low range.

3. All electric shift activity is halted until the Ignition

is cycled. If a shift is in progress it will be

completed.

4. If the rear speed sensor recovers continuously for

0.5 second the TCCU will function normally. The

4WD CHECK lamp is turned off but the fault code

will remain in memory.

Page 1382 of 2053

SSANGYONG MY2002

5D1-12 TRANSFER CASE

Both Speed Sensor Faulty

If both the front and rear speed sensors are faulty con

tinuously for 0.5 seconds the 4WD CHECK lamp is

illuminated. The TCCU then responds as follows:

1. If the system is in high range the TCCU sets the

EMC touch off level based on a vehicle speed of

0 and wheel slip control is suspended.

2. If the system is in low range, the EMC duty cycle

is set to maximum until the system is shifted out

of low range.

3. All electric shift activity is halted until the Ignition

is cycled. If a shift is in progress it will be

completed.

If both speed sensors recover continuously for 0.5 sec-

ond the TCCU will function normally. The 4WD CHECK

lamp is turned off but the fault code will remain in

memory.

Electro-Magnetic Clutch Test

The electromagnetic clutch (EMC) is tested for open

circuit or short circuit to ground. If a fault is detected

continuously for 0.8 second the 4WD CHECK lamp is

turned on and all TODTM activity is halted.

If the EMC recovers continuously for 0.8 second the

TCCU will function normally. The 4WD CHECK lamp is

turned off but the fault code will remain in memory.

DIAGNOSTIC TROUBLE CODES

(DTCS)

When a fault is detected a diagnostic trouble code

(DTC) is stored in the TCCU and illuminates the 4WD

CHECK indicator. This DTC will remain in memory until

the TCCU is instructed to erase DTCs by scan tool.

Notice: DTCs can not be erased by disconnecting of

power supply to the TCCU.

Diagnostic Trouble Codes Table

CLEARING DIAGNOSTIC

TROUBLE CODES

When diagnose by scan tool, it is required that you

make adequate service on defects against all fault

codes. And then you should delete the memorized fault

codes in transfer case control unit (TCCU) using scan

tool as follows;

1. Connect a scan tool with dada link connector

(DLC).

2. Select TROUBLE CODE CLEAR in scan tool.

3. In TROUBLE CODE CLEAR screen, press ENTER

key to erase the fault code.

Description

EEPROM Checksum Fault

TP Sensor Loss of Signal

TP Sensor Out of Range

Electro-Magnetic Clutch Open / Short

to Battery

Electro-Magnetic Clutch Short to

Ground

Front Speed Sensor Voltage Low

Front Speed Sensor Voltage High

Rear Speed Sensor Voltage Low

Rear Speed Sensor Voltage High

Speed Sensor Reference Voltage Low

Speed Sensor Reference Voltage

High DTC

1714

1715

1716

1721

1722

1731

1732

1733

1735

1736

1741

Description

Motor Open / Shorted to Battery

Motor Output Shorted to Ground

Shift System Timeout

General Position Encoder Fault (In-

validCode)

Position 1 Shorted to Ground

Position 2 Shorted to Ground

Position 3 Shorted to Ground

Position 4 Shorted to Ground DTC

1742

1714

1743

1750

1751

1752

1753

1754

Page 1383 of 2053

TRANSFER CASE 5D1-13

SSANGYONG MY2002

BLANK

Page 1384 of 2053

SSANGYONG MY2002

5D1-14 TRANSFER CASE

4WD CHECK INDICATOR STAYS ON WITH IGNITION SWITCH ON

KAA5D040

Circuit Description

When the ignition switch turns to ON the transfer case

control unit (TCCU) illuminates 4WD CHECK and 4WD

LOWindicator to check bulb operation and turns off

after 0.6 seconds. Then TCCU starts self-diagnosis

and illuminate 4WD CHECK indicator when TCCU

detects any fault.

Diagnostic Aids

If the 4WD CHECK indicator illuminates steadily the

TCCU may detect some fault. TCCU should be

checked by scan tool to solve the problem.

The 4WD CHECK indicator also illuminates steadily

if the terminal B2 of TCCU connector is shorted to

ground. The shorted wire or terminals should be re-

paired.

Test Description

The number(s) below refer to step(s) on the diagnostic

table.

2. This step, along with step 4, checks the short to

ground condition of the wire or terminals

Step

1

ABS INDICATOR LAMP ILLUMINATED CONTINUOUSLY, NO DTCs STORED

Action Yes

Go to the

specific DTC

diagnostic tableNo

Go to Step 2 Value(s)

1. Turn the ignition switch to OFF.

2. Connect the scan tool to the data link connector

(DLC).

3. Turn the ignition switch to ON and request the DTC.

Does the scan tool display any DTC?

Page 1385 of 2053

TRANSFER CASE 5D1-15

SSANGYONG MY2002

Step

2

3

4

5Action

Yes

Go to Step 3

System OK

Go to Step 5

System OKNo

Go to Step 4

-

System OK

- Value(s)

1. Turn the ignition switch to OFF.

2. Disconnect the 18-pin connector from transfer case

control unit (TCCU).

3. Turn the ignition switch to ON and check the 4WD

CHECK bulb operation.

Does the 4WD CHECK indicator come on steadily?

Repair any short to ground circuit between terminal

B2 of TCCU connector and terminal A4 of cluster.

Is the repair complete?

1. Turn the ignition OFF.

2. Check the pin or terminals for damage or improper

connection.

3. Reconnect all the connectors.

4. Turn the ignition ON.

Does the 4WD CHECK indicator come on steadily?

Replace the TCCU.

Is the repair complete?

Page 1386 of 2053

SSANGYONG MY2002

5D1-16 TRANSFER CASE

KAA5D040

NO 4WD LOW INDICATOR STAYS ON WITH IGNITION SWITCH ON

Circuit Description

When the ignition switch turns to ON the transfer case

control unit (TCCU) illuminates 4WD CHECK and 4WD

LOWindicator to check bulb operation and turns off

after 0.6 seconds. Then TCCU starts self-diagnosis

and illuminate 4WD CHECK indicator when TCCU

detects any fault.

Diagnostic Aids

If the 4WD LOW indicator illuminates steadily the

transfer case in 4 wheel drive low range and 4H/4L

switch set to 4L. It is normal condition.

The 4WD LOW indicator also illuminates steadily if

the terminal B9 of TCCU connector is shorted to

ground. The shorted wire or terminals should be re-

paired.

Test Description

The number(s) below refer to step(s) on the diagnostic

table.

2. This step checks for the normal bulb operation.

Step

1

2

Action Yes

Go to Step 2

System OKNo

Go to Step 3

- Value(s)

Check the position of 4H/4L switch.

Does the 4H/4L switch set on 4L.

1. Turn the ignition switch to ON.

2. Set the shift lever to N (neutral).

3. Turn the 4H/4L switch to 4H.

Does the 4WD LOWindicator go off?

Page 1387 of 2053

TRANSFER CASE 5D1-17

SSANGYONG MY2002

Step

3

4

5

6

7ActionYes

Go to Step 4

System OK

Go to Step 6

System OK

System OKNo

Go to Step 5

-

System OK

Go to Step-7

- Value(s)

1. Turn the ignition switch to ON.

2. Set the shift lever to N (neutral).

3. Turn the 4H/4L switch to 4L.

Does the 4WD LOWindicator go off?

The wiring of 4H/4L switch is reversed. Repair the

wiring.

Is the repair complete?

1. Turn the ignition OFF.

2. Check the pin or terminals for damage or improper

connection.

3. Reconnect all the connectors.

4. Turn the ignition ON.

Does the 4WD LOW indicator come on steadily?

Repair any short to ground circuit between terminal B9

of TCCU connector and terminal A8 of cluster.

Is the repair complete?

Replace the TCCU.

Is the repair complete?

Page 1388 of 2053

SSANGYONG MY2002

5D1-66 TRANSFER CASE

KAA5D240

KAA5D250

ON-VEHICLE SERVICE

OIL REPLACEMENT

Important: Use only recommended oil or not the trans-

fer case will be severely damaged. Inspect every

10,000 km and replace every 60,000 km.

Specified Oil Level

The oil level should be just under the filler hole.

REPAIR INSTRUCTIONS

Oil Replacement

1. Lift the vehicle and make sure safety.

2. Prepare a vessel to drain transfer case oil.

3. Remove the planner damper, if equipped.

4. Remove the drain plug and filler plug, and drain

the oil completely.

5. Install and tighten the drain plug.

Installation Notice

6. Replenish recommended transfer case oil to speci-

fied oil level through the filler plughole.

7. Install and tighten the filler plug.

Installation Notice

8. Check oil leakage.

9. Install the planner damper.

Installation Notice

Tightening Torque19 - 30 Nm

(14 - 22 lb-ft)

Tightening Torque4 - 6 Nm

(35 - 53 lb-in)

Tightening Torque29 - 41 Nm

(21 - 30 lb-ft)

Page 1389 of 2053

TRANSFER CASE 5D1-67

SSANGYONG MY2002

KAA5D260

KAA5D270

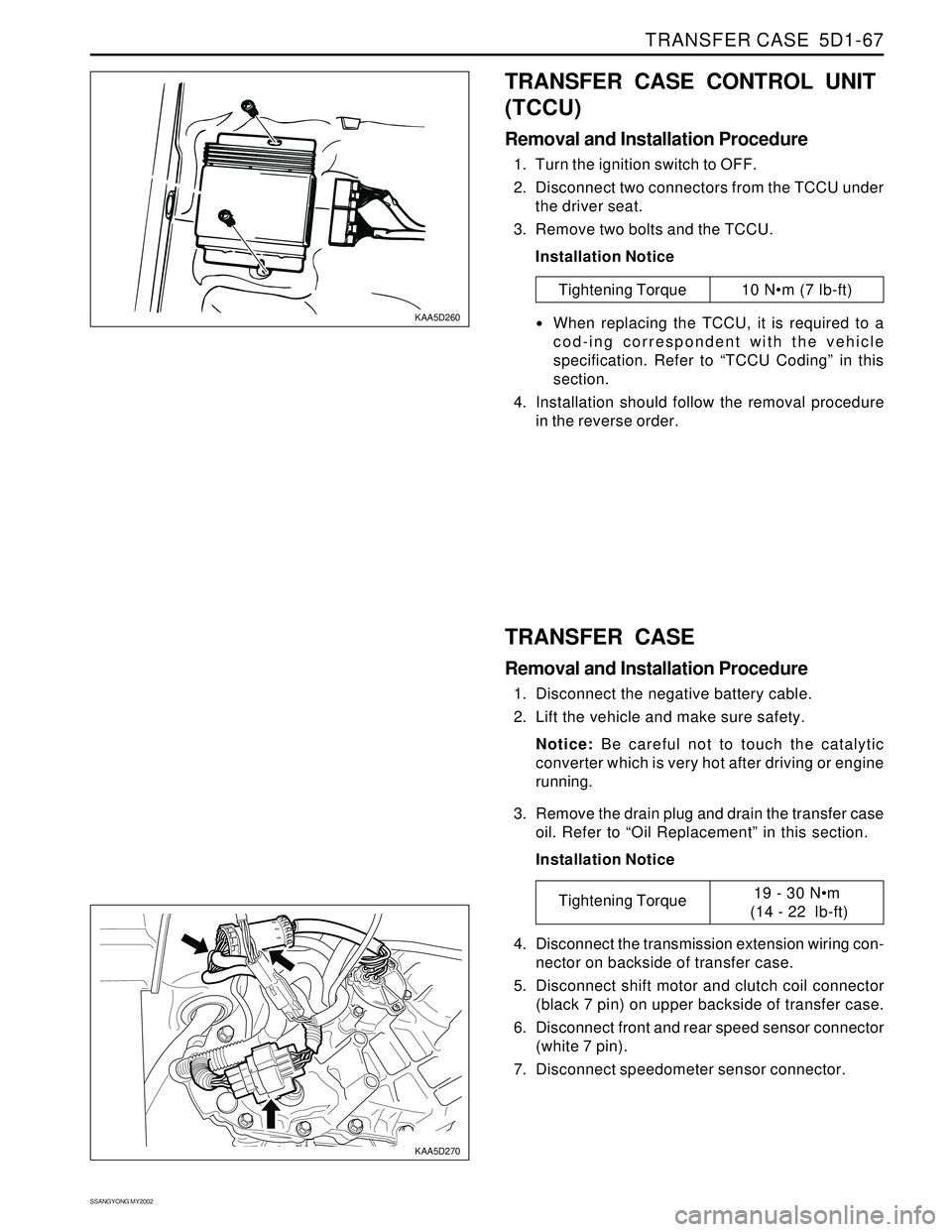

TRANSFER CASE CONTROL UNIT

(TCCU)

Removal and Installation Procedure

1. Turn the ignition switch to OFF.

2. Disconnect two connectors from the TCCU under

the driver seat.

3. Remove two bolts and the TCCU.

Installation Notice

Tightening Torque 10 Nm (7 lb-ft)

When replacing the TCCU, it is required to a

cod-ing correspondent with the vehicle

specification. Refer to “TCCU Coding” in this

section.

4. Installation should follow the removal procedure

in the reverse order.

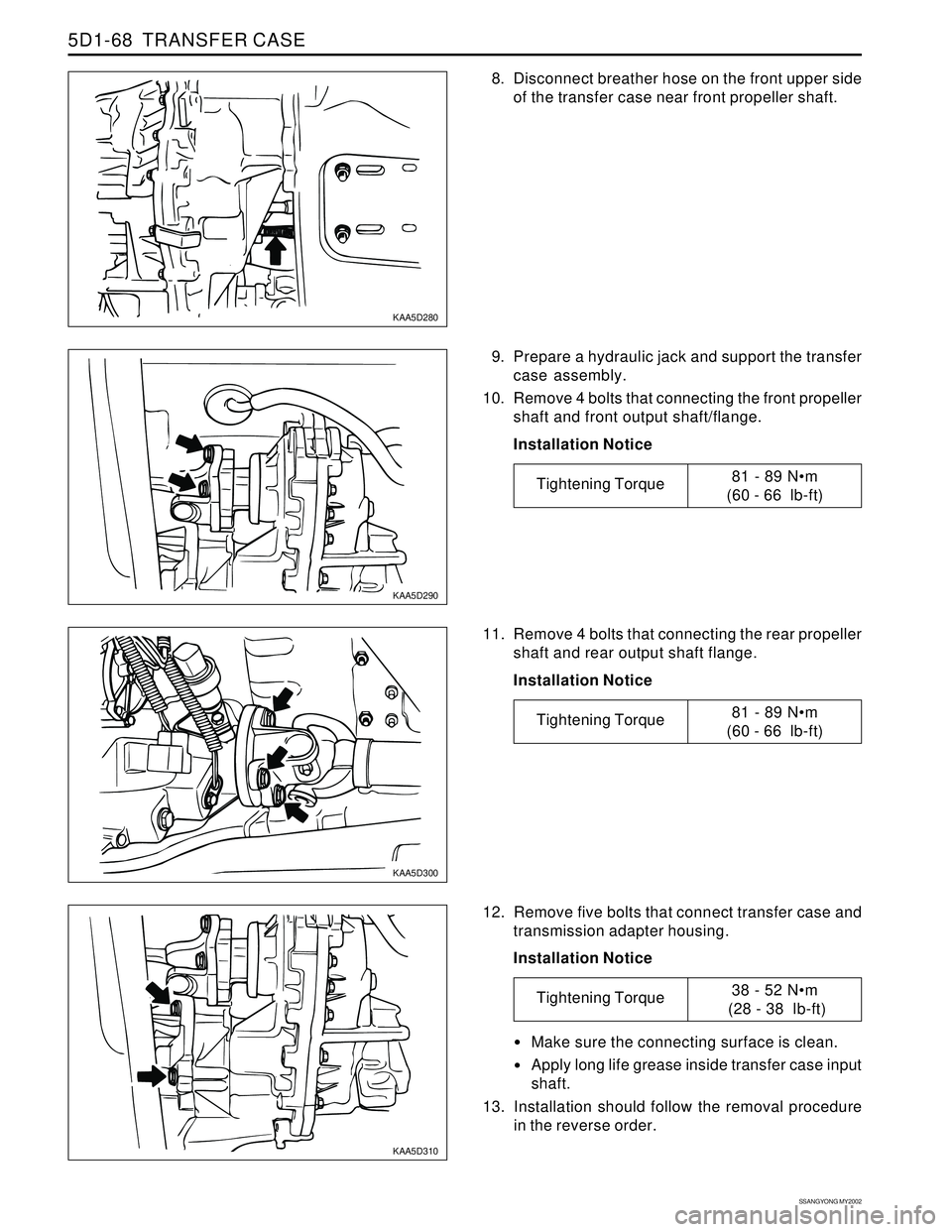

TRANSFER CASE

Removal and Installation Procedure

1. Disconnect the negative battery cable.

2. Lift the vehicle and make sure safety.

Notice: Be careful not to touch the catalytic

converter which is very hot after driving or engine

running.

3. Remove the drain plug and drain the transfer case

oil. Refer to “Oil Replacement” in this section.

Installation Notice

4. Disconnect the transmission extension wiring con-

nector on backside of transfer case.

5. Disconnect shift motor and clutch coil connector

(black 7 pin) on upper backside of transfer case.

6. Disconnect front and rear speed sensor connector

(white 7 pin).

7. Disconnect speedometer sensor connector.

Tightening Torque19 - 30 Nm

(14 - 22 lb-ft)

Page 1390 of 2053

SSANGYONG MY2002

5D1-68 TRANSFER CASE

KAA5D280

KAA5D290

KAA5D300

KAA5D310

8. Disconnect breather hose on the front upper side

of the transfer case near front propeller shaft.

12. Remove five bolts that connect transfer case and

transmission adapter housing.

Installation Notice 11. Remove 4 bolts that connecting the rear propeller

shaft and rear output shaft flange.

Installation Notice 9. Prepare a hydraulic jack and support the transfer

case assembly.

10. Remove 4 bolts that connecting the front propeller

shaft and front output shaft/flange.

Installation Notice

Make sure the connecting surface is clean.

Apply long life grease inside transfer case input

shaft.

13. Installation should follow the removal procedure

in the reverse order.

Tightening Torque81 - 89 Nm

(60 - 66 lb-ft)

Tightening Torque81 - 89 Nm

(60 - 66 lb-ft)

Tightening Torque38 - 52 Nm

(28 - 38 lb-ft)