diagram SSANGYONG KORANDO 1997 Service Repair Manual

[x] Cancel search | Manufacturer: SSANGYONG, Model Year: 1997, Model line: KORANDO, Model: SSANGYONG KORANDO 1997Pages: 2053, PDF Size: 88.33 MB

Page 28 of 2053

1A1 -- 8 GENERAL ENGINE INFORMATION

D AEW OO M Y_2000

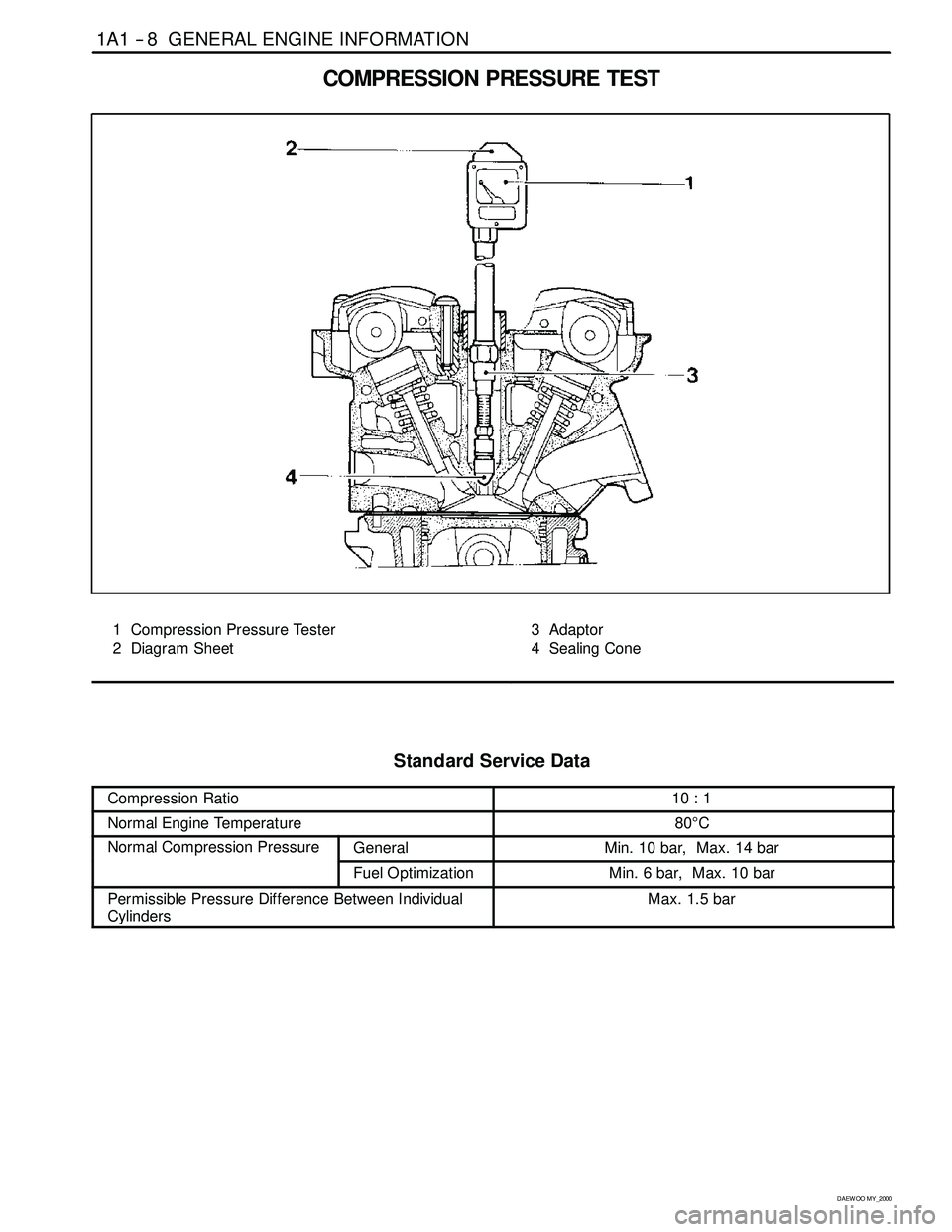

COMPRESSION PRESSURE TEST

1 Compression Pressure Tester

2 Diagram Sheet3 Adaptor

4 Sealing Cone

Standard Service Data

Compression Ratio10 : 1

Normal Engine Temperature80°C

Normal Compression PressureGeneralMin. 10 bar, Max. 14 barp

Fuel OptimizationMin. 6 bar, Max. 10 bar

Permissible Pressure Difference Between Individual

CylindersMax. 1.5 bar

Page 29 of 2053

GENERAL ENGINE INFORMATION 1A1 -- 9

D AEW OO M Y_2000

Measuring Procedure

1. Warm the engine up to normal operating tempera-

ture.

2. Remove the spark plugs.

3. Place the diagram sheet to compression pressure

tester.

4. Connect the adaptor to compression pressure tester

and install it into the spark plug hole.

5. Crank the engine approx. eight revolutions by using

the start motor.6. Compare the measurements of compression pres-

sure tester with the specifications.

7. Measure the compression pressure of the other cylin-

ders in the same way.

8. If measured value is not within the specifications, per-

form the cylinder pressure leakage test.

Notice

DDischarge the combustion residues in the cylinders

before testing the compression pressure.

DApply the parking brake before cranking the engine.

Page 162 of 2053

1E 1 -- 10 M162 ENGINE ELECTRICAL

D AEW OO M Y_2000

Circuit Diagram

Inspection & Maintenance Procedure (for

MSE)

1. While the ignition switch is in ’OFF’ position, remove

the wiring connectors (1 and 15) from ignition coil and

measure the primary resistance between terminal

No.1 and No.15.

Specified Value

0.9 -- 1.6Ω(20°C)

Notice:If out of specified value, replace the ignition coil.

2. During engine cranking, measure primary voltage

(T1/1) between ECU terminal No. 71 and No. 69.

Specified Value

200 -- 350 V

Notice

DMeasure remaining cables.

-- T1/2 : No. 72 and 69.

-- T1/3 : No. 70 and 69.

DIf out of specified value, check ignition cable and

ECU.

3. Using a multi-- tester, measure the secondary coil re-

sistance between 5a and 5b.

Specified Value

6--8.5kΩ

Page 164 of 2053

D AEW OO M Y_2000

SECTION 1F1

ENGINE CONTROLS

CAUTION: Disconnect the negative battery cable before removing or installing any electrical unit or when a

tool or equipment could easily come in contact with exposed electrical terminals. Disconnecting this cable

will help prevent personal injury and damage to the vehicle. The ignition must also be in LOCK unless other -

wise noted.

TABLE OF CONTENTS

Engine and ECM Problem Check Report 1F1 -- 2....

Specifications 1F1 -- 3............................

Engine Data Display Table 1F1 -- 3.................

Fastener Tightening Specifications 1F1 -- 4..........

Fuel System Specification 1F1 -- 5.................

Temperature vs Resistance 1F1 -- 5................

Special Tools and Equipment 1F1 -- 6..............

Special Tools Table 1F1 -- 6.......................

Schematic and Routing Diagrams 1F1 -- 7..........

ECM Wiring Diagram

(3.2L DOHC -- MSE 3.62S) 1F1 -- 7..............

Diagnosis 1F1 -- 14................................

Failure Code Diagnosis 1F1 -- 14.....................

Clearing Failure Codes 1F1 -- 14...................

Failure Codes Table 1F1 -- 14.....................

Ignition System 1F1 -- 18...........................

Ignition Coil 1F1 -- 20.............................

Crankshaft Position (CKP) Sensor 1F1 -- 22.........

Camshaft Position (CMP) Sensor 1F1 -- 26..........

Camshaft Actuator 1F1 -- 30......................

Knock Sensor (KS) 1F1 -- 32......................

Spark Plug 1F1 -- 34.............................

System Voltage 1F1 -- 38.........................

Ignition Switch 1F1 -- 39..........................

Fuel System 1F1 -- 40..............................

Fuel Pump 1F1 -- 42.............................

Fuel Injector 1F1 -- 46............................

Purge Control Valve 1F1 -- 50.....................

Fuel Rail 1F1 -- 52...............................

Fuel Pressure Regulator 1F1 -- 54.................

Induction System 1F1 -- 56..........................

Throttle Valve Actuator 1F1 -- 56...................

Hot Film Air Mass (HFM) Sensor 1F1 -- 60..........

Engine Coolant Temperature (ECT) Sensor 1F1 -- 64.

Accelerator Pedal Module 1F1 -- 68................

Clutch Switch 1F1 -- 71...........................Cooling Fan 1F1 -- 72............................

A/C Compressor Relay 1F1 -- 73...................

Cruise Control Switch 1F1 -- 74....................

Traction Control System (TCS) 1F1 -- 75............

Resonance Flap 1F1 -- 76.........................

Stop Lamp Switch 1F1 -- 77.......................

Engine RPM 1F1 -- 78............................

Exhaust System 1F1 -- 79...........................

Catalytic Converter 1F1 -- 79......................

Oxygen Sensor 1F1 -- 80.........................

Engine Control Module 1F1 -- 86.....................

Serial Data Communication 1F1--88...............

Internal Failure 1F1 -- 90..........................

Electronic Throttle Controller Safety

Malfunction 1F1 -- 92...........................

Immobilizer 1F1 -- 94.............................

Maintenance and Repair 1F1 -- 95..................

On -- Vehicle Service 1F1 -- 95........................

Discharging the Pressure in Fuel System 1F1 -- 95...

Fuel Pump 1F1 -- 95.............................

Fuel Filter 1F1 -- 96..............................

Fuel Tank 1F1 -- 97..............................

Fuel Pressure Regulator 1F1 -- 98.................

Fuel Rail and Injector 1F1 -- 99....................

Engine Coolant Temperature Sensor 1F1 -- 100......

Throttle Body (Integrated with the

Actuator) 1F1 -- 101............................

Hot Film Air Mass (HFM) Sensor 1F1 -- 102.........

Knock Sensor 1F1 -- 102..........................

Pedal Position Sensor 1F1 -- 103...................

Oxygen Sensor 1F1 -- 103........................

Purge Control Valve 1F1 -- 104....................

Canister 1F1 -- 104...............................

Camshaft Position Sensor 1F1 -- 104...............

Crankshaft Position Sensor 1F1 -- 105..............

Engine Control Module 1F1 -- 105..................

Page 170 of 2053

M162 ENGINE CONTROLS 1F1 -- 7

D AEW OO M Y_2000

SCHEMATIC AND ROUTING DIAGRAMS

KAB1F010

ECM WIRING DIAGRAM (3.2L DOHC -- 1OF 7) (MSE 3.62S)

Page 171 of 2053

1F1 -- 8 M162 ENGINE CONTROLS

D AEW OO M Y_2000

KAB1F020

ECM WIRING DIAGRAM (3.2L DOHC -- 2 OF 7) (MSE 3.62S)

Page 172 of 2053

M162 ENGINE CONTROLS 1F1 -- 9

D AEW OO M Y_2000

KAB1F030

ECM WIRING DIAGRAM (3.2L DOHC -- 3 OF 7) (MSE 3.62S)

Page 173 of 2053

1F1 -- 10 M162 ENGINE CONTROLS

D AEW OO M Y_2000

KAB1F040

ECM WIRING DIAGRAM (3.2L DOHC -- 4 OF 7) (MSE 3.62S)

Page 174 of 2053

M162 ENGINE CONTROLS 1F1 -- 11

D AEW OO M Y_2000

KAB1F050

ECM WIRING DIAGRAM (3.2L DOHC -- 5 OF 7) (MSE 3.62S)

Page 175 of 2053

1F1 -- 12 M162 ENGINE CONTROLS

D AEW OO M Y_2000

KAB1F060

ECM WIRING DIAGRAM (3.2L DOHC -- 6 OF 7) (MSE 3.62S)