section 2c SSANGYONG KORANDO 1997 Service Repair Manual

[x] Cancel search | Manufacturer: SSANGYONG, Model Year: 1997, Model line: KORANDO, Model: SSANGYONG KORANDO 1997Pages: 2053, PDF Size: 88.33 MB

Page 1555 of 2053

SECTION 7D

FULL AUTOMATIC TEMPERATURE

CONTROL HEATING, VENTILATION AND

AIR CONDITIONING SYSTEM

FATC (Full Automatic Temperature Control) is full automatic heater and airconditioning system that detects

incar temperature, ambient temperature, sun load and coolant temperature and controls airconditioner

system blowing capacity, outlet temperature and intaking/outlet mode to maintain interior comfort.

TABLE OF CONTENTS

Specifications.......................................................7D-2

Refrigerant..........................................................7D-2

Evaporator Unit....................................................7D-2

Blower Unit..........................................................7D-2

Compressor.........................................................7D-2

Condenser...........................................................7D-2

Receiver Drier......................................................7D-2

Pressure Switch...................................................7D-3

Air Filter...............................................................7D-3

Heater Unit..........................................................7D-3

Service Specifications ..........................................7D-4

Fastener Tightening Specifications.......................7D-4Schematic and Routing Diagrams.......................7D-5

Circuit Diagram....................................................7D-5

FATC Block Diagram...........................................7D-6

Component Locator.............................................7D-7

Ventilation System...............................................7D-7

Function Description............................................7D-8

Diagnosis..............................................................7D-9

Diagnosis Test.....................................................7D-9

Maintenance and Repair................................... 7D-13

FATC Control Panel............................................ 7D-13

Air Filter............................................................. 7D-16

Troubleshooting................................................. 7D-17

Page 1558 of 2053

SSANGYONG MY2002

7D-4 FATC-HAVC

SERVICE SPECIFICATIONS

Input Section

Incar Sensor

Ambient Sensor

Coolant Temperature SensorApplicationDescriptionResistance (25°C)

Voltage Rating

Current Rating

Resistance (25°C)

Voltage Rating

Current Rating

Resistance (25°C)

Voltage Rating

Current Rating

Evaporator Unit

2.186 kΩ ± 0.07 kΩ

5 V

3 mA

1.0 kΩ ± 0.03 kΩ

5 V

3 mA

0.55 kΩ ± 0.02 kΩ

5 V

3 mA

Intake Actuator

Mode Actuator

Mix Actuator

Power TR

Blower Motor Power ConsumptionApplicationDescriptionCurrent Rating (at 12 V)

LOCK Current

Current Rating (at 12 V)

LOCK Current

Current Rating (at 12 V)

LOCK Current

Ic

Pc70 ± 30 mA

Less than 500 mA

100 ± 40 mA

Less than 500 mA

100 ± 40 mA

Less than 500 mA

30 A

200 W

220 W

FASTENER TIGHTENING SPECIFICATIONS

N•m

4 - 6

4 - 6

4 - 6

5 - 8

4 - 6

20 - 30

20 - 26Lb-Ft

2.9 - 4.4

2.9 - 4.4

2.9 - 4.4

3.7 - 5.9

2.9 - 4.4

14.7 - 22.1

14.7 - 19.1 Condenser Bolt

Condenser Fan Nut

Condenser Bolt

Receiver Drier Pipe Bolt

Receiver Drier Pipe Bolt (Condenser)

Pressure Pipe Bolt

Pressure Mounting BoltLb-In

35.4 - 53.1

35.4 - 53.1

35.4 - 53.1

44.2 - 70.8

35.4 - 53.1

177.0 - 265.5

177.0 - 230.1Application

Page 1577 of 2053

SECTION 8A

SEAT BELTS

CAUTION: Disconnect the negative battery cable before removing or installing any electrical unit or when a

tool or equipment could easily come in contact with exposed electrical terminals. Disconnecting this cable

will help prevent personal injury and damage to the vehicle. The ignition must be in B unless otherwise

noted.

TABLE OF CONTENTS

Description and Operation...................................8A-2

Driver Seat Belt Warning......................................8A-2

Three-Point Front Seat Belt With Pretensioner.......8A-2

Three-Point Rear Outboard Seat Belt....................8A-2

Two-Point Lap Rear Center Seat Belt....................8A-2

Operational and Functional Checks......................8A-2

Child Seat Tether Anchor.....................................8A-2

Component Locator.............................................8A-3

Front Seat Belt.....................................................8A-3

Rear Seat Belt.....................................................8A-4Repair Procedures...............................................8A-5

On-Vehicle Service.................................................8A-5

Three-Point Front Seat Belt With Pretensioner.......8A-5

Front Seat Belt Height Adjuster............................8A-6

Three-Point Rear Outboard Seat Belt....................8A-6

Two-Point Lap Rear Center Seat Belt....................8A-7

Child Seat Tether Anchor.....................................8A-7

Specifications.......................................................8A-8

Fastener Tightening Specifications.......................8A-8

Schematic and Routing Diagrams.......................8A-9

Seat Belt & Tension Reducer...............................8A-9

Page 1578 of 2053

SSANGYONG MY2002

8A-2 SEAT BELTS

DESCRIPTION AND OPERATION

DRIVER SEAT BELT WARNING

The driver’s seat belt incorporates a seat belt warning

lamp in the instrument cluster to remind the driver if

the seat belt is not fastened when the ignition is turned

ON. The warning lamp blinks for eight seconds with

chime and goes out.

THREE-POINT FRONT SEAT BELT

WITH PRETENSIONER

The front seat belt contains an electronically controlled

pyrotechnic retractor, pretensioner, which reduces seat

belt slack when it activated in a head-on or angled

front collision. The front seat belt must be replaced

after an accident that causes its activation. At normal

condition the driver’s seat belt operates as emergency

locking retractor (ELR).

Emergency Locking Retractor (ELR)

The ELR seat belt is always unlocked, allowing the

passenger freedom of movement, except in

emergencies such as rapid deceleration, rapid

acceleration, or hard cornering maneuvers.

THREE-POINT REAR OUTBOARD

SEAT BELT

The rear outboard seating position uses the emergency

locking retractor (ELR). Refer to Three-point front seat

belt with pretensioner in this section for details.

TWO-POINT LAP REAR CENTER

SEAT BELT

The two-point lap rear center seat belt is a single contin-

uous length of webbing. The webbing is routed from

the anchor through plate and into a single retractor.

OPERATIONAL AND FUNCTIONAL

CHECKS

Caution:

Keep sharp objects and potentially damaged ob

jects away from seat belts.

Avoid bending or damaging any portion of

buckle or the latch plate

Do not breach or dye the belt webbing. Use only

mild soap and water in order to clean the belts.

When installing the seat belt anchor bolts and

screws, start the bolts and screws by hand in or-

der to prevent cross-threading.

Do not attempt any repairs on the retractor mech-

anisms or covers. Replace any defective assem-

blies with new assemblies.

Replace any belts that are cut or damaged in any

way.

1. Inspect all seat anchor bolts and screws in order to

verify that they are secure.

2. Inspect the seat belt buckle. The buckle must lock

and unlock easily.

3. After inserting the latch into the buckle, tug sharply

on the belt. The buckle must remain locked.

4. Fully extend the shoulder belt portion to make sure

that there is no twisting or tears in the belt.

5. Let the shoulder belt retract fully. The belt should

retract easily.

CHILD SEAT TETHER ANCHOR

There are three child seat tether anchors to hold the

child seat firmly. One is located rear center of ceiling

and two are located on the rear corner of floor.

Page 1582 of 2053

SSANGYONG MY2002

8A-6 SEAT BELTS

KAA8A070

KAA8A060

KAA8A050

7. Remove the plastic cap to reveal the upper B-

pillar seat belt anchor.

8. Remove the bolt and B-pillar seat belt anchor.

Installation Notice

9. Installation should follow the removal procedure

in the reverse order.

Tightening Torque 45 Nm (33 lb-ft)

FRONT SEAT BELT HEIGHT

ADJUSTER

Removal and installation Procedure

1. Remove the front seat belt upper B-pillar anchor

bolt.

Installation Notice

2. Remove the rear seat belt upper anchor bolt.

Installation Notice

3. Remove the rear upper quarter trim panel. Refer

to Section 9G, Interior Trim.

4. Remove the bolts and seat belt height adjuster.

Installation Notice

5. Installation should follow the removal procedure

in the reverse order.

THREE-POINT REAR OUTBOARD

SEAT BELT

Removal and installation Procedure

1. Remove the plastic cap to reveal the seat belt

lower anchor bolt.

2. Remove the lower anchor bolt.

Installation Notice

Tightening Torque 45 Nm (33 lb-ft)

Tightening Torque 45 Nm (33 lb-ft)

Tightening Torque 45 Nm (33 lb-ft)

Tightening Torque 45 Nm (33 lb-ft)

Page 1586 of 2053

SECTION 8B

SUPPLEMENTAL RESTRAINTS SYSTEM

CAUTION: Disconnect the negative battery cable before removing or installing any electrical unit or when a

tool or equipment could easily come in contact with exposed electrical terminals. Disconnecting this cable

will help prevent personal injury and damage to the vehicle. The ignition must also be in LOCK unless

other-wise noted.

TABLE OF CONTENTS

Description and Operation...................................8B-3

Supplemental Restraint System (SRS)..................8B-3

Airbag Modules...................................................8B-3

Front Seat Belt Pretensioners...............................8B-4

Sensing and Diagnostic Module (SDM)................8B-4

Airbag Warning Lamp ..........................................8B-5

Clock Spring........................................................8B-5

Wiring Harness Connectors..................................8B-5

Components Locator............................................8B-6

SRS Component and Wiring Location View...........8B-6

Diagnostic Information and Procedures..............8B-7

Diagnostic Trouble Codes (DTC)..........................8B-7

Scan Tool Diagnostics.........................................8B-7

Use of Special Tools............................................8B-7

Diagnostic Trouble Code Table............................8B-7

SRS Diagnostic System Check..........................8B-10

Sensing and Diagnostic Module (SDM)

Integrity Check...............................................8B-12

Airbag Warning Lamp Stays on with Ignition

Switch ON......................................................8B-14

DTCs - Internal Fault..........................................8B-16

DTCs 01 Driver Deployment Loop Shorted to

Voltage...........................................................8B-18

DTC 02 Passenger Deployment Loop Shorted to

Voltage...........................................................8B-20

DTC 03 Driver Seat Belt Pretensioner Shorted to

Voltage...........................................................8B-22

DTC 04 Passenger Seat Belt Pretensioner

Shorted to Voltage..........................................8B-24

DTC 05 Driver Deployment Loop Shorted to

Ground...........................................................8B-26

DTC 06 Passenger Deployment Loop Shorted to

Ground...........................................................8B-28

DTC 07 Driver Seat Belt Pretensioner Shorted to

Ground...........................................................8B-30DTC 08 Passenger Seat Belt Pretensioner

Shorted to Ground ..........................................8B-32

DTC 17 Driver Deployment Loop

Resistance High.............................................8B-34

DTC 18 Passenger Deployment Loop

Resistance High.............................................8B-38

DTC 19 Driver Seat Belt Pretensioner

Deployment Loop resistance High...................8B-40

DTC 20 Passenger Seat Belt Pretensioner

Deployment Loop Resistance High.................8B-42

DTC 21 Driver Airbag Deployment Loop

Resistance Low..............................................8B-44

DTC 22 Passenger Airbag Deployment Loop

Resistance Low..............................................8B-48

DTC 23 Driver Seat Belt Pretensioner

Deployment Loop resistance Low....................8B-50

DTC 24 Passenger Seat Belt Pretensioner

Deployment Loop Resistance Low..................8B-52

DTC 46 Airbag Warning Lamp Circuit Open or

Short to Ground/Battery..................................8B-54

DTC 47 Battery Voltage is Out of

Specification...................................................8B-56

Repair Instruction...............................................8B-58

On-Vehicle Service...............................................8B-58

Service Precaution.............................................8B-58

Disabling the Supplemental Restraint

System (SRS).................................................8B-58

Enabling the Supplemental Restraint

System (SRS).................................................8B-58

Handling, Installation and Diagnosis..................8B-58

Repairs and Inspections Required After an

Accident ........................................................8B-58

Accident with Deployment - Components

Replacement..................................................8B-58

Accident without Deployment - Component

Inspection......................................................8B-59

Page 1592 of 2053

SUPPLEMENTAL RESTRAINTS SYSTEM 8B-7

SSANGYONG MY2002

Driver Deployment Loop Shorted to Voltage

Passenger Deployment Loop Shorted to Voltage

Driver Seat Belt Pretensioner Shorted to Voltage

Passenger Seat Belt Pretensioner Shorted to Voltage

Driver Deployment Loop Shorted to Ground

Passenger Deployment Loop Shorted to Ground

Driver Seat Belt Pretensioner Shorted to Ground

Passenger Seat Belt Pretensioner Shorted to Ground

Driver Energy Shutdown Switch Error

Passenger Energy Shutdown Switch Error

Driver Seat Belt Pretensioner Energy Shutdown Switch Error

Passenger Seat Belt Pretensioner Energy Shutdown

Switch Error

Driver Ignition Switch Fault Internal

Passenger Ignition Switch Fault Internal

Driver Seat Belt Pretensioner Ignition Switch Fault

Passenger Seat Belt Pretensioner Ignition Switch Fault 01

02

03

04

05

06

07

08

09

10

11

12

13

14

15

16

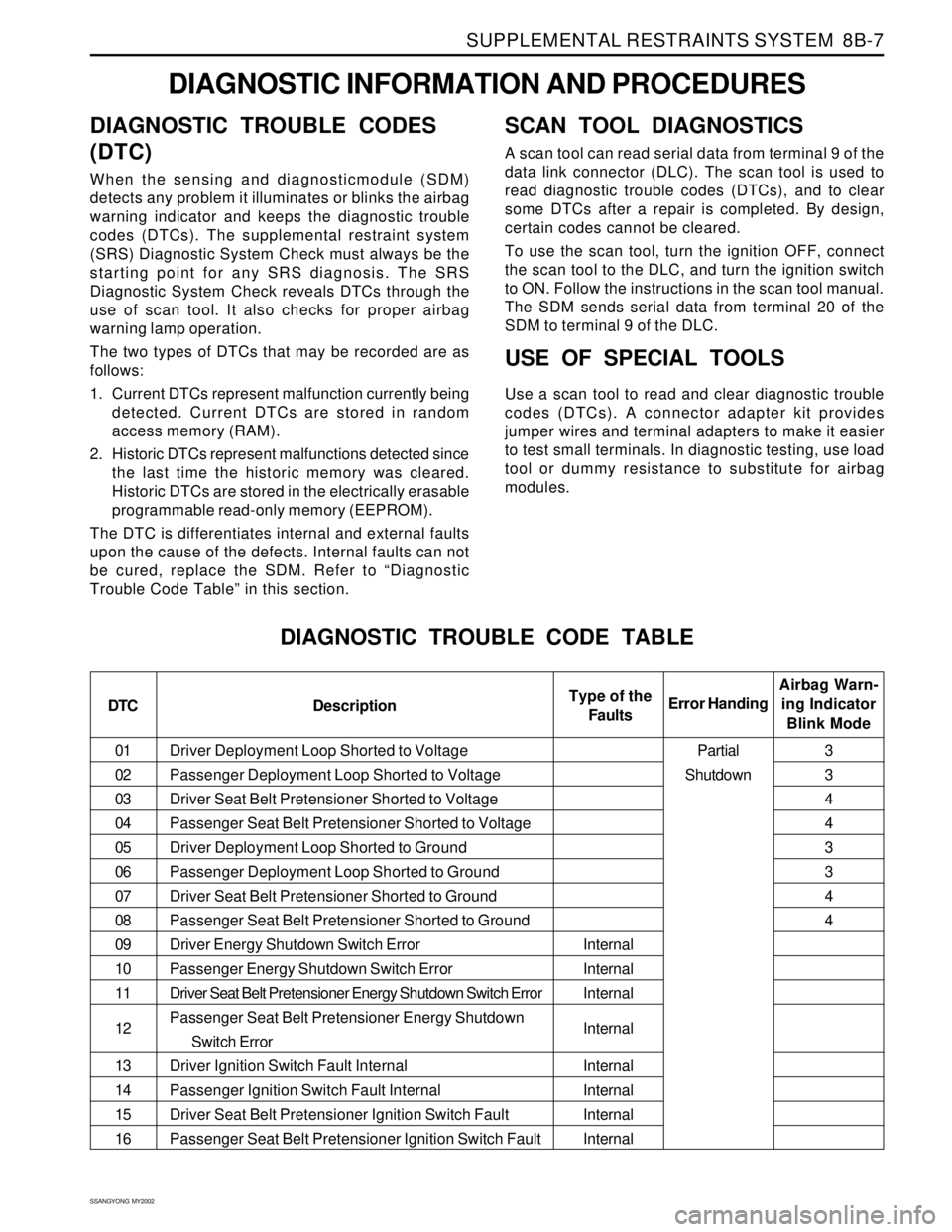

DIAGNOSTIC INFORMATION AND PROCEDURES

DIAGNOSTIC TROUBLE CODES

(DTC)

When the sensing and diagnosticmodule (SDM)

detects any problem it illuminates or blinks the airbag

warning indicator and keeps the diagnostic trouble

codes (DTCs). The supplemental restraint system

(SRS) Diagnostic System Check must always be the

starting point for any SRS diagnosis. The SRS

Diagnostic System Check reveals DTCs through the

use of scan tool. It also checks for proper airbag

warning lamp operation.

The two types of DTCs that may be recorded are as

follows:

1. Current DTCs represent malfunction currently being

detected. Current DTCs are stored in random

access memory (RAM).

2. Historic DTCs represent malfunctions detected since

the last time the historic memory was cleared.

Historic DTCs are stored in the electrically erasable

programmable read-only memory (EEPROM).

The DTC is differentiates internal and external faults

upon the cause of the defects. Internal faults can not

be cured, replace the SDM. Refer to “Diagnostic

Trouble Code Table” in this section.

SCAN TOOL DIAGNOSTICS

A scan tool can read serial data from terminal 9 of the

data link connector (DLC). The scan tool is used to

read diagnostic trouble codes (DTCs), and to clear

some DTCs after a repair is completed. By design,

certain codes cannot be cleared.

To use the scan tool, turn the ignition OFF, connect

the scan tool to the DLC, and turn the ignition switch

to ON. Follow the instructions in the scan tool manual.

The SDM sends serial data from terminal 20 of the

SDM to terminal 9 of the DLC.

USE OF SPECIAL TOOLS

Use a scan tool to read and clear diagnostic trouble

codes (DTCs). A connector adapter kit provides

jumper wires and terminal adapters to make it easier

to test small terminals. In diagnostic testing, use load

tool or dummy resistance to substitute for airbag

modules.

DIAGNOSTIC TROUBLE CODE TABLE

DTC DescriptionAirbag Warn-

ing Indicator

Blink Mode Error HandingType of the

Faults

Internal

Internal

Internal

Internal

Internal

Internal

Internal

Internal3

3

4

4

3

3

4

4

Partial

Shutdown

Page 1595 of 2053

SSANGYONG MY2002

8B-10 SUPPLEMENTAL RESTRAINTS SYSTEM

SRS DIAGNOSTIC SYSTEM CHECK

Notice: If the vehicle interior has been exposed to

extensive water intrusion such as water leaks, driving

through high water, flooding, or other caucuses, the

sensing and diagnostic module (SDM) and SDM

connector may be need to be replaced. With ignition

OFF, inspect the area around the SDM, including the

carpet. If any significant soaking or evidence of previous

soaking is detected, the water must be removed, water

damage repaired, and the SDM and SDM connector must

be replaced. Before attempting any of these repairs, the

supplemental restraint system (SRS) must be disabled.

Refer to “Disabling the SRS” and “Sensing and

Diagnostic Module (SDM)” in this section.

The SRS Diagnostic System Check must always be

the starting point for any SRS system diagnosis. The

SRS Diagnostic System Check reveals diagnostic

trouble codes (DTCs) through the use of scan tool.

The diagnostic procedures used in this section are

designed to find and repair SRS conditions. To get

the best results, it is important to use the diagnostic

charts and follow the sequence listed below.

1. Perform the SRS Diagnostic System Check, which

reveals diagnostic trouble codes (DTCs) through

the use of scan tool. It also checks for proper airbag

indicator operation.

2. Refer to the proper diagnostic chart as directed by

SRS Diagnostic System Check. Bypassing these

procedures may result in extended diagnostic time,

incorrect diagnosis, and incorrect parts

replacement.3. Repeat the SRS Diagnostic System Check after any

repair or diagnostic procedures have been

performed to ensure that the repair has beenmade

correctly and that no other malfunction exists.

Circuit Description

When the ignitions witch is first turned to ON, ignition

voltage is supplied from airbag fuse to the SDM at

input terminal 5. The SDM responds by turning on the

airbag indicator for 4.5 seconds and then turning it off

while the SDM performs tests on the SRS system.

Diagnostic Aids

The order in which DTCs are diagnosed is very

important. Failure to diagnose the DTCs in the order

specified may result in extended diagnostic time,

incorrect diagnosis, and incorrect parts replacement.

Test Description

The numbers below refer to steps on the diagnostic

table.

2. This test differentiates between an indicator that

will not come on and an indicator that stays on when

it should be off.

3. Refer to the first caution below

5. This test, along with step 6, differentiates internal

or external faults of SDM.

9. Refer to the cautions below.

Page 1601 of 2053

SSANGYONG MY2002

8B-16 SUPPLEMENTAL RESTRAINTS SYSTEM

Yes

Go to Step 2

Go to specific

DTC chart.

Go to “SRS

Diagnostic

System

Check”No

-

Go to Step 2

- Value

-

-Step

1

2

3Action

Perform the SRS Diagnostic System Check.

Is the SRS Diagnostic System Check complete?

Check for any DTCs that is not internal fault.

Is there any DTCs that set except internal DTC?

1. Disable the supplemental restraint system (SRS) in

this section.

2. Replace SDM.

3. Enable the SRS.

4. Make sure all the components are properly mounted.

Is the repair complete?

Circuit Description

When the ignition switch is turned to ON, the sensing

and diagnostic module (SDM) will perform tests to

diagnose critical malfunctions within SDM itself. Internal

fault DTC will set when any of the malfunctions detected

by SDM itself. Refer to “Diagnostic Trouble Code

Table” in this section.

DIAGNOSTIC TROUBLE CODES (DTCS) - INTERNAL FAULT

Action Taken

The SDM will turn on the airbag indicator and set

diagnostic trouble code.

The SDM will shutdown its function partially or totally.

Diagnostic Trouble Code (DTC) - Internal Fault

Caution: The sensing and diagnosis module (SDM)

can maintain sufficient voltage to deploy the airbags

and pretensioners for 0.15 seconds after the ignition

is OFF and the fuse has been removed. If the airbags

or pretensioners are not disconnected, do not begin

service until one minute has passed after

disconnecting power to the SDM. Otherwise, injury

could result.Caution: During service procedure, be very careful

when handling the SDM. Never strike or jar the

SDM. Never power the supplemental restraints

system (SRS) when the SDM is not rigidly attached

to the vehicle. Also SDM mounting nuts must be

carefully tightened to ensure proper operation of

the SRS. The SDM could be activated if it is powered

when it is not rigidly attached to the vehicle,

resulting in unexpected deployment and possible

injury.

Page 1603 of 2053

SUPPLEMENTAL RESTRAINTS SYSTEM 8B-19

SSANGYONG MY2002

1. Disable the Supplemental Restraint System (SRS).

Refer to “Disabling the Supplemental Restraint

System (SRS)” in this section.

2. Virtually inspect the driver airbag circuit and

connectors, especially at the SDM.

Is there any evidence of rubbing, damage or chafing?

1. Repair the damaged wires or connectors.

2. Connect all the SRS components.

Is the repair complete?

1. Disconnect the SDM connector.

2. Disconnect driver airbag.

3. Turn the ignition ON.

4. Measure the voltage between terminal 1 (or 2) of

the driver airbag connector and ground.

Is the voltage within the specified value?

1. Disconnect C203.

2. Measure the voltage between terminal 1 (or 2) of

the driver airbag connector and ground.

Is the voltage within the specified value?

1. Repair short to voltage in clock spring or replace

the clock spring as needed.

2. Connect all SRS components.

Is the repair complete?

1. Repair short to voltage between SDM and C203.

2. Connect all SRS components.

Is the repair complete?

1. Connect dummy resistance (2.15 ± 0.35 Ω) to

driver airbag connector instead of driver airbag.

2. Enable the SRS.

3. Connect the scan tool to the data link connector

(DLC).

4. Clear DTC and request DTC.

Is the DTC 01 still present?

Replace driver airbag.

Is the repair complete?

1. Replace SDM.

2. Connect all SRS components.

Is the repair complete?

StepAction Value(s) Yes No

2

4

5

6

- Go to Step 3 Go to Step 4

3

-Go to “SRS

Diagnostic

System Check” -

≈ 0 v Go to Step 8 Go to Step 5

≈ 0 v Go to Step 7 Go to Step 6

-Go to “SRS

Diagnostic

System Check” -

-Go to “SRS

Diagnostic

System Check” -

-Go to “SRS

Diagnostic

System Check” -

-Go to “SRS

Diagnostic

System Check” -

- Go to Step 10 Go to Step 9 7

8

9

10