section 2c SSANGYONG KORANDO 1997 Service Repair Manual

[x] Cancel search | Manufacturer: SSANGYONG, Model Year: 1997, Model line: KORANDO, Model: SSANGYONG KORANDO 1997Pages: 2053, PDF Size: 88.33 MB

Page 1437 of 2053

SSANGYONG MY2002

5D2-38 TRANSFER CASE (PART TIME - 4408)

KAA5D830

KAA5D840

KAA5D850

Input Shaft

Cross Sectional View

Tightening Torque346 - 380 Nm

Front Output Shaft

1. Install the deflector on the yoke.

2. Position the output shaft in transfer case and install

the companion flange assembly, oil seal, washer

and nut.

3. Holding the companion flange, tighten the nut.

Installation Notice

Reduction Shift Parts

1. Install the new pin, roller and retainer into the

reduction shift fork.

2. Press the pin, roller and retainer into the reduction

spilt fork bore completely.

Notice: Make sure that the cam roller turns freely.

3. Install the 2 fork facing on the reduction shift fork

assembly.

4. Install the reduction shift fork onto the previously

installed reduction hub in the transfer case.

5. Install the output shaft spline into the reduction

hub and engage the output shaft end with input

shaft bearing.

Notice: For installation of the output shaft,

assemble the oil pump temporarily.

Page 1443 of 2053

SECTION 6A

POWER STEERING SYSTEM

TABLE OF CONTENTS

Description and Operation...................................6A-2

General Description.............................................6A-2

Component Locator.............................................6A-3

Diagnostic Information and Procedures..............6A-4

Power Steering System Pressure Test..................6A-4

Power Steering System Leak Test........................6A-4

Maintenance .........................................................6A-5

Bleeding the Power Steering System....................6A-5

Checking and Adding Fluid..................................6A-5Repair Instructions................................................6A-6

On-Vehicle Service.................................................6A-6

Power Steering Fluid Reservoir.............................6A-6

Power Steering Pump Hoses and Pipes................6A-7

Specifications.......................................................6A-9

General Specification...........................................6A-9

Fastener Tightening Specifications.......................6A-9

Special Tools and Equipment............................ 6A-10

Special Tools Table............................................6A-10

Page 1446 of 2053

SSANGYONG MY2002

6A-4 POWER STEERING SYSTEM

KAA6A020

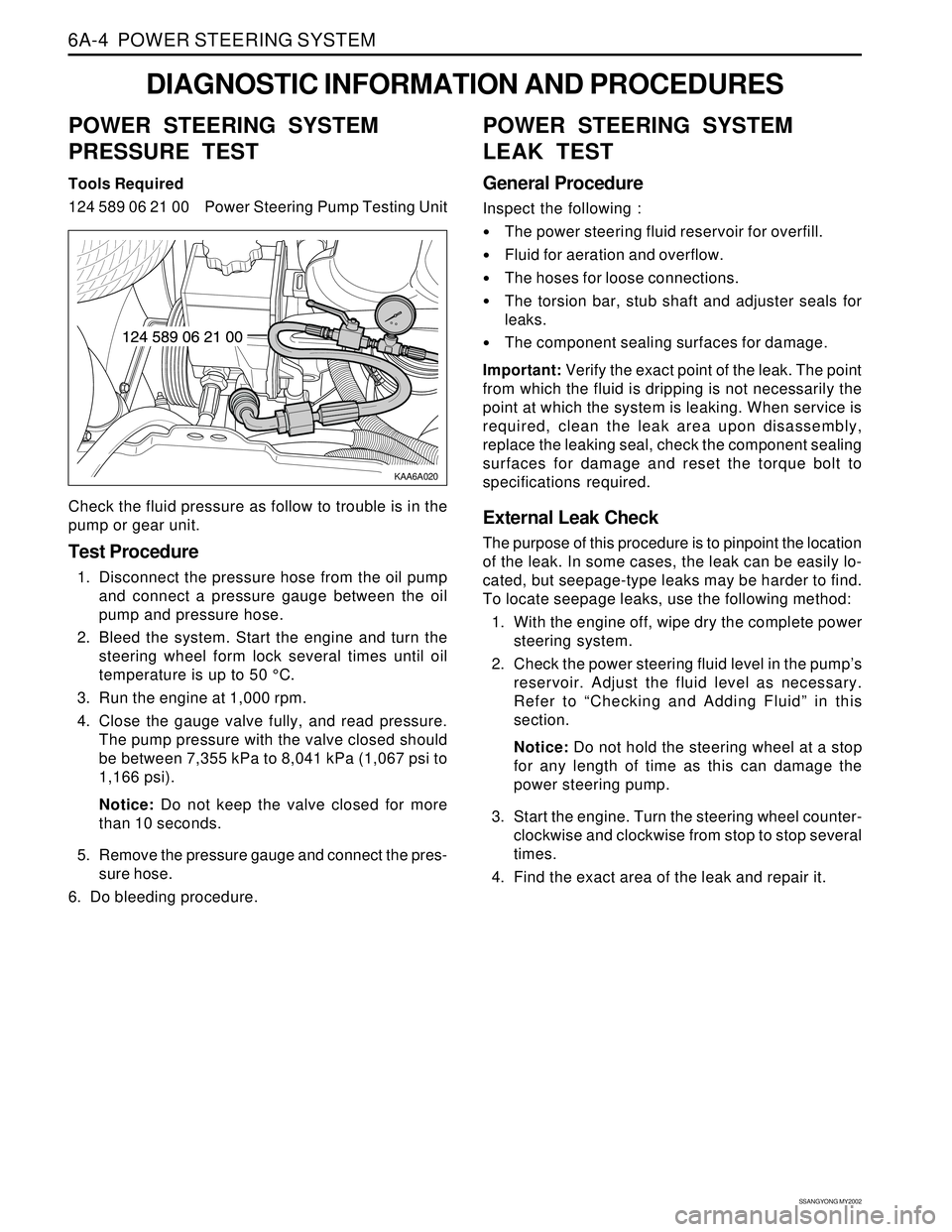

DIAGNOSTIC INFORMATION AND PROCEDURES

POWER STEERING SYSTEM

PRESSURE TEST

Tools Required

124 589 06 21 00 Power Steering Pump Testing Unit

Check the fluid pressure as follow to trouble is in the

pump or gear unit.

Test Procedure

1. Disconnect the pressure hose from the oil pump

and connect a pressure gauge between the oil

pump and pressure hose.

2. Bleed the system. Start the engine and turn the

steering wheel form lock several times until oil

temperature is up to 50 °C.

3. Run the engine at 1,000 rpm.

4. Close the gauge valve fully, and read pressure.

The pump pressure with the valve closed should

be between 7,355 kPa to 8,041 kPa (1,067 psi to

1,166 psi).

Notice: Do not keep the valve closed for more

than 10 seconds.

5. Remove the pressure gauge and connect the pres-

sure hose.

6. Do bleeding procedure.

POWER STEERING SYSTEM

LEAK TEST

General Procedure

Inspect the following :

The power steering fluid reservoir for overfill.

Fluid for aeration and overflow.

The hoses for loose connections.

The torsion bar, stub shaft and adjuster seals for

leaks.

The component sealing surfaces for damage.

Important: Verify the exact point of the leak. The point

from which the fluid is dripping is not necessarily the

point at which the system is leaking. When service is

required, clean the leak area upon disassembly,

replace the leaking seal, check the component sealing

surfaces for damage and reset the torque bolt to

specifications required.

External Leak Check

The purpose of this procedure is to pinpoint the location

of the leak. In some cases, the leak can be easily lo-

cated, but seepage-type leaks may be harder to find.

To locate seepage leaks, use the following method:

1. With the engine off, wipe dry the complete power

steering system.

2. Check the power steering fluid level in the pump’s

reservoir. Adjust the fluid level as necessary.

Refer to “Checking and Adding Fluid” in this

section.

Notice: Do not hold the steering wheel at a stop

for any length of time as this can damage the

power steering pump.

3. Start the engine. Turn the steering wheel counter-

clockwise and clockwise from stop to stop several

times.

4. Find the exact area of the leak and repair it.

Page 1448 of 2053

SSANGYONG MY2002

6A-6 POWER STEERING SYSTEM

KAA6A040

3. Remove the power steering fluid reservoir

mounting bolts (1).

Removal Notice:

One power steering fluid reservoir mounting bolt

(2) is located in the fluid reservoir.

Installation Notice

KAA6A030

ON-VEHICLE SERVICE

POWER STEERING FLUID

RESERVOIR

Tools Required

DW310-021Power Steering Pump Pulley Remover/

Installer

Removal and Installation Procedure

1. Remove the power steering pump. Refer to

Section 6B, Power Steering Pump.

2. Remove the power steering pump pulley nut, using

the power steering pump pulley remover/installer

DW310-021.

Installation Notice

REPAIR INSTRUCTIONS

Tightening Torque 61 Nm (44 lb-ft)

15 Nm (11 lb-ft)

18 Nm (13 lb-ft)

Tightening

TorqueBolts (1)

Bolt (2)

4. Remove the power steering fluid reservoir upward.

After installing the power steering fluid reservoir,

bleed the power steering system. Refer to

“Bleeding the Power Steering System” in this

section.

5. Installation should follow the removal procedure

in the reverse order.

Page 1449 of 2053

POWER STEERING SYSTEM 6A-7

SSANGYONG MY2002

KAA6A050

KAA6A060

4. Disconnect the return line pipe from the power

steering gear outlet.

Installation Notice

KAA6A070

5. Disconnect the pressure line pipe from the power

steering gear inlet.

Installation Notice

POWER STEERING PUMP HOSES

AND PIPES

Removal and Installation Procedure

1. Remove the battery. Refer to Section 1E, Engine

Electrical.

2. Siphon the power steering fluid from the fluid reser-

voir.

3. Disconnect the pressure line pipe from the outlet

connection on the power steering pump and return

hose from the inlet connection on the power

steering fluid reservoir.

Installation Notice

Tightening Torque 44 Nm (33 lb-ft)

Tightening Torque 17 Nm (13 lb-ft)

Tightening Torque 17 Nm (13 lb-ft)

Page 1450 of 2053

SSANGYONG MY2002

6A-8 POWER STEERING SYSTEM

KAA6A080

6. Remove the return line support clip from the front

frame.

Installation Notice

Tightening Torque 9 Nm (80 lb-in)

After installing the power steering fluid reservoir,

bleed the power steering system. Refer to

“Bleeding the Power Steering System” in this

section.

7. Installation should follow the removal procedure

in the reverse order.

Page 1455 of 2053

SSANGYONG MY2002

6A-4 POWER STEERING SYSTEM

KAA6A020

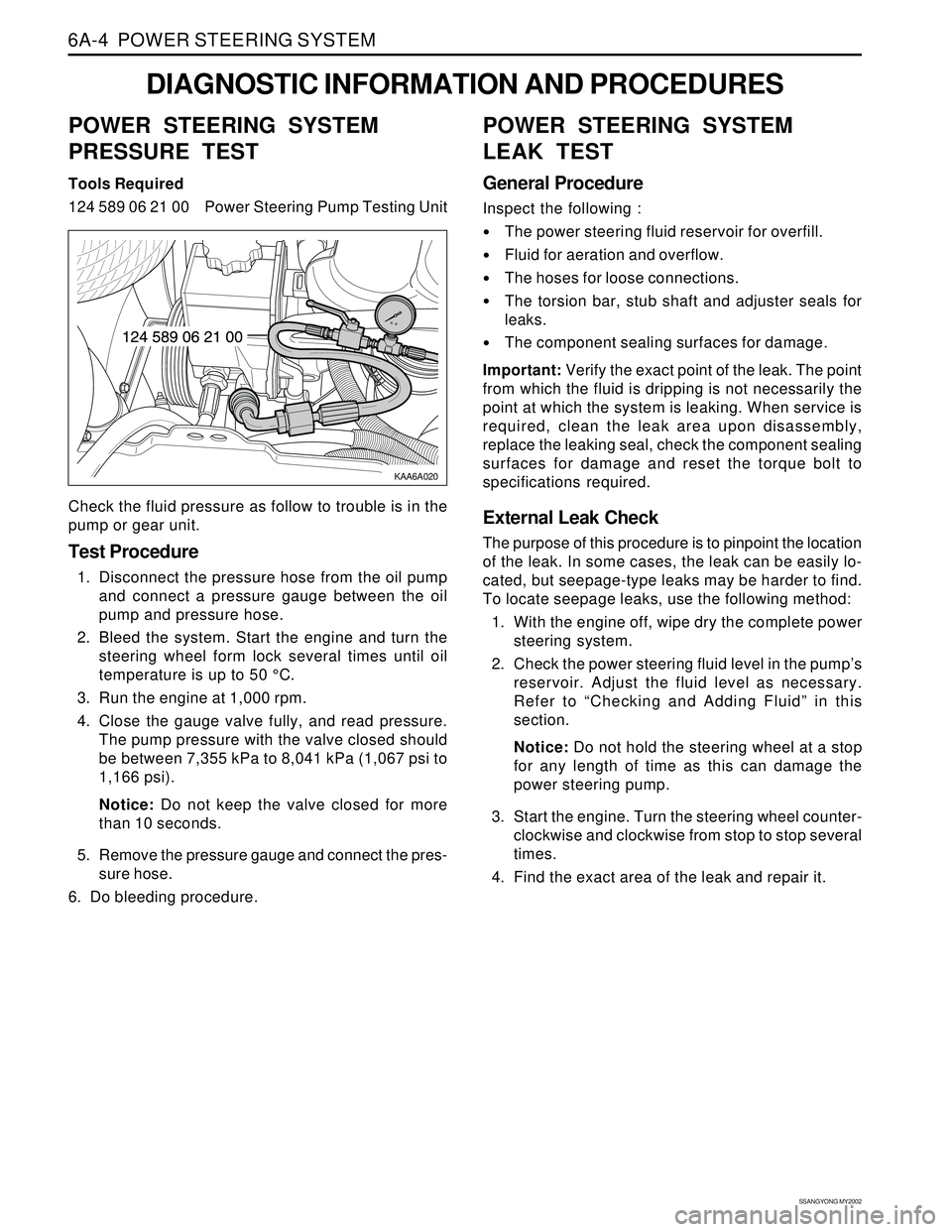

DIAGNOSTIC INFORMATION AND PROCEDURES

POWER STEERING SYSTEM

PRESSURE TEST

Tools Required

124 589 06 21 00 Power Steering Pump Testing Unit

Check the fluid pressure as follow to trouble is in the

pump or gear unit.

Test Procedure

1. Disconnect the pressure hose from the oil pump

and connect a pressure gauge between the oil

pump and pressure hose.

2. Bleed the system. Start the engine and turn the

steering wheel form lock several times until oil

temperature is up to 50 °C.

3. Run the engine at 1,000 rpm.

4. Close the gauge valve fully, and read pressure.

The pump pressure with the valve closed should

be between 7,355 kPa to 8,041 kPa (1,067 psi to

1,166 psi).

Notice: Do not keep the valve closed for more

than 10 seconds.

5. Remove the pressure gauge and connect the pres-

sure hose.

6. Do bleeding procedure.

POWER STEERING SYSTEM

LEAK TEST

General Procedure

Inspect the following :

The power steering fluid reservoir for overfill.

Fluid for aeration and overflow.

The hoses for loose connections.

The torsion bar, stub shaft and adjuster seals for

leaks.

The component sealing surfaces for damage.

Important: Verify the exact point of the leak. The point

from which the fluid is dripping is not necessarily the

point at which the system is leaking. When service is

required, clean the leak area upon disassembly,

replace the leaking seal, check the component sealing

surfaces for damage and reset the torque bolt to

specifications required.

External Leak Check

The purpose of this procedure is to pinpoint the location

of the leak. In some cases, the leak can be easily lo-

cated, but seepage-type leaks may be harder to find.

To locate seepage leaks, use the following method:

1. With the engine off, wipe dry the complete power

steering system.

2. Check the power steering fluid level in the pump’s

reservoir. Adjust the fluid level as necessary.

Refer to “Checking and Adding Fluid” in this

section.

Notice: Do not hold the steering wheel at a stop

for any length of time as this can damage the

power steering pump.

3. Start the engine. Turn the steering wheel counter-

clockwise and clockwise from stop to stop several

times.

4. Find the exact area of the leak and repair it.

Page 1457 of 2053

SSANGYONG MY2002

6A-6 POWER STEERING SYSTEM

KAA6A040

3. Remove the power steering fluid reservoir

mounting bolts (1).

Removal Notice:

One power steering fluid reservoir mounting bolt

(2) is located in the fluid reservoir.

Installation Notice

KAA6A030

ON-VEHICLE SERVICE

POWER STEERING FLUID

RESERVOIR

Tools Required

DW310-021Power Steering Pump Pulley Remover/

Installer

Removal and Installation Procedure

1. Remove the power steering pump. Refer to

Section 6B, Power Steering Pump.

2. Remove the power steering pump pulley nut, using

the power steering pump pulley remover/installer

DW310-021.

Installation Notice

REPAIR INSTRUCTIONS

Tightening Torque 61 Nm (44 lb-ft)

15 Nm (11 lb-ft)

18 Nm (13 lb-ft)

Tightening

TorqueBolts (1)

Bolt (2)

4. Remove the power steering fluid reservoir upward.

After installing the power steering fluid reservoir,

bleed the power steering system. Refer to

“Bleeding the Power Steering System” in this

section.

5. Installation should follow the removal procedure

in the reverse order.

Page 1458 of 2053

POWER STEERING SYSTEM 6A-7

SSANGYONG MY2002

KAA6A050

KAA6A060

4. Disconnect the return line pipe from the power

steering gear outlet.

Installation Notice

KAA6A070

5. Disconnect the pressure line pipe from the power

steering gear inlet.

Installation Notice

POWER STEERING PUMP HOSES

AND PIPES

Removal and Installation Procedure

1. Remove the battery. Refer to Section 1E, Engine

Electrical.

2. Siphon the power steering fluid from the fluid reser-

voir.

3. Disconnect the pressure line pipe from the outlet

connection on the power steering pump and return

hose from the inlet connection on the power

steering fluid reservoir.

Installation Notice

Tightening Torque 44 Nm (33 lb-ft)

Tightening Torque 17 Nm (13 lb-ft)

Tightening Torque 17 Nm (13 lb-ft)

Page 1459 of 2053

SSANGYONG MY2002

6A-8 POWER STEERING SYSTEM

KAA6A080

6. Remove the return line support clip from the front

frame.

Installation Notice

Tightening Torque 9 Nm (80 lb-in)

After installing the power steering fluid reservoir,

bleed the power steering system. Refer to

“Bleeding the Power Steering System” in this

section.

7. Installation should follow the removal procedure

in the reverse order.