Fuse SSANGYONG KORANDO 1997 Service User Guide

[x] Cancel search | Manufacturer: SSANGYONG, Model Year: 1997, Model line: KORANDO, Model: SSANGYONG KORANDO 1997Pages: 2053, PDF Size: 88.33 MB

Page 986 of 2053

EBCM Connection Fact View.............................4E-95

EBCM Connector...............................................4E-95

Hydraulic Modulator Connector..........................4E-96

Repair Instructions..............................................4E-99

On-Vehicle Service...............................................4E-99

Service Precautions...........................................4E-99

ABS 5.3 Assembly..........................................4E-100

ABS/TCS Unit..................................................4E-100

Front Wheel Speed Sensor..............................4E-101Rear Wheel Speed Sensor...............................4E-101

Acceleration Sensor .........................................4E-102

System Fuse...................................................4E-102

Indicators........................................................4E-102

Unit Repair........................................................4E-103

ABS Front Tooth Wheel....................................4E-103

Special Tools and Equipment..........................4E-104

Special Tools Table..........................................4E-104

Page 987 of 2053

ABS AND TCS 4F-3

SSANGYONG MY2002

GENERAL DESCRIPTION AND SYSTEM OPERATION

BASIC KNOWLEDGE REQUIRED

Before using this section, it is important that you have

a basic knowledge of the following items. Without this

knowledge, it will be difficult to use the diagnostic

procedures contained in this section.

•Basic Electrical Circuits - You should understand

the basic theory of electricity and know the meaning

of voltage, current (amps), and resistance (ohms).

You should understand what happens in a circuit

with an open or shorted wire. You should be able to

read and understand a wiring diagram.

Use of Circuit Testing Tools - You should know

how to use a test light and how to bypass

components to test circuits using fused jumper

wires. You should be familiar with a digital

multimeter. You should be able to measure voltage,

resistance, and current, and be familiar with the

controls and how to use them correctly.

ABS SYSTEM COMPONENTS

The ABS 5.3 Antilock Braking System (ABS) consists

of a conventional hydraulic brake system plus antilock

components. The conventional brake system includes

a vacuum booster, master cylinder, front disc brakes,

rear disc brakes, interconnecting hydraulic brake pipes

and hoses, brake fluid level switch and the BRAKE

indicator.

The ABS components include a hydraulic unit, an elec-

tronic brake control module (EBCM), two system fuses,

four wheel speed sensors (one at each wheel), intercon-

necting wiring, the ABS indicator, the EBD indicator

and the TCS indicator. See “ABS Component Locator”

in this section for the general layout of this system.

The hydraulic unit with the attached EBCM is located

between the surge tank and the bulkhead on the left

side of the vehicle.

The basic hydraulic unit configuration consists of hy-

draulic check valves, two solenoid valves for each

wheel, a hydraulic pump, and two accumulators. The

hydraulic unit controls hydraulic pressure to the front

calipers and rear calipers by modulating hydraulic

pressure to prevent wheel lockup.

Units equipped with TCS add two more valves for each

drive wheel for the purpose of applying the brake to a

wheel that is slipping. This is done with pressure from

the hydraulic pump in the unit. There is also a TCS

indicator lamp on the instrument panel to alert the driver

to the fact that the TCS system is active. The

components identified in the drawing are those added

to the basic ABS 5.3 system to provide traction control.

Nothing in the hydraulic unit or the EBCM is serviceable.

In the event of any failure, the entire ABS unit withattached EBCM must be replaced. For more

information, refer to “Base Braking Mode” and

“Antilock Braking Mode” in this section.

TRACTION CONTROL SYSTEM

(TCS) DESCRIPTION

General Information

The traction control system (TCS) is a traction system

by means of brake intervention only, available in a low

speed range (< 60kph).

It workes on µ - split roads with sidewise different friction

coefficients.

The spinning driven wheel is braked and the drive

torque can be transferred to the wheel on the high-µ

side. During TCS active, the TCS information lamp is

blinking.

The temperature of the brakes is calculated by a mathe-

matical model and TCS is switched passive if the calcu-

lated temperature is greater than a threshold value (500

°C).

TCS is permitted again, when the calculated tempera-

ture is less than 350 °C.

Control Algorithm

The input signals for the control algorithm are the

filtered wheel speed signals from the ABS speed

processing.

With the speed difference of the driven wheels, the

control deviation is calculated.

If the control deviation exceeds a certain threshold

value, the wheel with the greater slip is braked actively.

The threshold value depends on the vehicle speed:

It is reduced with increasing vehicle speed down to a

constant value.

KAA4F010

Page 1001 of 2053

SSANGYONG MY2002

4F-18 ABS AND TCS

ABS INDICATOR LAMP INOPERATIVE

KAA4F120

Circuit Description

Battery voltage is supplied to the ABS warning lamp

with the ignition switch in the ON or START positions.

The warning lamp can be activated only by the ABS

control module internally supplying ground to terminal

20 or by the shorting bar in the ABS module connector

if the connector is disconnected from the module.

Diagnosis

This procedure checks for a problem in the wiring, a

faulty ground, a voltage supply problem, a burned out

indicator lamp, or a contact problem in a connector.

Cause(s)

A fuse has blown.

The indicator lamp has burned out.

There is a corroded or broken connector terminal.

There is a faulty ground connection.

There is a broken wire in a wiring harness.

The EBCM is faulty.Test Description

The number(s) below refer to step(s) on the diagnostic

table.

1. This test checks for any DTCs that may cause

the ABS indicator lamp to be inoperative.

2. This test verifies an inoperative lamp condition.

3. This test checks for voltage on the lamp circuit.

4. This begins a series of tests of the circuit from

the indicator lamp to the EBCM and ground.

19. This begins a series of tests of the voltage supply

circuits that power the indicator lamp.

Page 1003 of 2053

SSANGYONG MY2002

4F-20 ABS AND TCS

Go to Step 15

System OK

Go to Step 17

System OK

System OK

Go to Step 20

System OK

Go to Step 22

System OK

System OK Value(s) Step

14

15

16

17

18

19

20

21

22

23

ABS Indicator Lamp Inoperative (Cont’d)

Action Yes No

Check the wiring harnesses and the connectors in

circuit Lg from the I/P cluster terminal D7 to terminal

31 of the EBCM connector.

Is the voltage equal to the specified value?

Repair the open or high resistance found.

Is the repair complete?

Check for continuity between terminal 19 of the EBCM

connector and ground G205.

Is the the continuity equal to the specified value?

Replace the ABS unit.

Is the repair complete?

Repair the continuity problem between terminal 19 of

the EBCM connector and ground G205.

Is the repair complete?

1. Turn the ignition to LOCK.

2. Check fuse F30 in the I/P fuse block.

Is fuse F30 blown?

Replace fuse F30.

Is the repair complete?

1. Turn the ignition on.

2. Check the voltage at fuse F30.

Is the voltage equal to the specified value?

Repair the power supply to fuse F30.

Is the repair complete?

1. Remove the instrument cluster.

2. Check the circuit PNK from fuse F30 to terminal A1

of the I/P cluster connector.

3. Repair any open or high resistance found in a wiring

harness, splice pack, or connector.

Is the repair complete?

∞

-

≈ 0 Ω

-

-

-

-

11 - 14 v

-

-Go to Step 16

-

Go to Step 18

-

-

Go to Step 21

-

Go to Step 23

-

-

Page 1005 of 2053

SSANGYONG MY2002

4F-22 ABS AND TCS

TRACTION CONTROL SYSTEM (TCS) INDICATOR LAMP INOPERATIVE

KAA4F120

Circuit Description

Battery voltage is supplied to the TCS warning lamp

with the ignition in ON or START. The warning lamp can

be activated only by the ABS control module internally

supplying ground to terminal 32.

Diagnosis

This procedure checks for a problem in the wiring, a

faulty ground, a voltage supply problem, a burned out

indicator lamp, or a contact problem in a connector.

Cause(s)

A fuse has blown.

The indicator lamp has burned out.

There is a corroded or broken connector terminal.

There is a faulty ground connection.

There is a broken wire in a wiring harness.

The EBCM is faulty.Test Description

The number(s) below refer to step(s) on the diagnostic

table.

1. This test checks for any DTCs that may cause

the TCS indicator lamp to be inoperative.

2. This test verifies an inoperative lamp condition.

3. This test checks for voltage on the lamp circuit.

4. This begins a series of tests of the circuit from

the indicator lamp to the EBCM and ground.

19. This begins a series of tests of the voltage supply

circuits that power the indicator lamp.

Page 1007 of 2053

SSANGYONG MY2002

4F-24 ABS AND TCS

Check the wiring harnesses and connectors in circuit

DK BLU from the I/P cluster terminal A6 to terminal 32

of the EBCM connector.

Is the voltage equal to the specified value?

Repair the open or high resistance.

Is the repair complete?

Check for continuity between terminal 19 of the ABS

connector and ground G205.

Is the continuity equal to the specified value?

Replace the ABS unit.

Is the repair complete?

Repair the continuity between terminal 19 of the EBCM

connector and ground G205.

Is the repair complete?

1. Turn the ignition to LOCK.

2. Check fuse F30 in the I/P fuse block.

Is fuse F30 blown?

Replace fuse F30.

Is the repair complete?

1. Turn the ignition ON.

2. Check the voltage at fuse F30.

Is the voltage equal to the specifies value?

Repair the power supply to fuse F30.

Is the repair complete?

1. Remove the I/P cluster.

2. Check circuit LR from fuse F30 to terminal A1 of

the I/P cluster connector.

3. Repair any open or high resistance found in a wiring

harness, a splice pack, or a connector.

Is the repair complete? Step

14

15

16

17

18

19

20

21

22

23

Traction Control System (TCS) Indicator Lamp Inoperative (Cont’d)

Action Yes NoValue(s)

≈ 0 Ω

-

≈ 0 Ω

-

-

-

-

11 - 14v

-

-Go to Step 15

System OK

Go to Step 17

System OK

System OK

Go to Step 20

System OK

Go to Step 22

System OK

System OKGo to Step 16

-

Go to Step 18

-

-

Go to Step 21

-

Go to Step 23

-

Page 1009 of 2053

SSANGYONG MY2002

4F-26 ABS AND TCS

ELECTRONIC BRAKE-FORCE DISTRIBUTION SYSTEM (EBD)

INDICATOR LAMP INOPERATIVE

KAA4F120

Circuit Description

Battery voltage is supplied to the EBD warning lamp

with the ignition in ON or START. The warning lamp can

be activated only by the ABS control module internally

supplying ground to terminal 30.

Diagnosis

This procedure checks for a problem in the wiring, a

faulty ground, a voltage supply problem, a burned out

indicator lamp, or a contact problem in a connector.

Cause(s)

A fuse has blown.

The indicator lamp has burned out.

There is a corroded or broken connector terminal.

There is a faulty ground connection.

There is a broken wire in a wiring harness.

The EBCM is faulty.Test Description

The number(s) below refer to step(s) on the diagnostic

table.

1. This test checks for any DTCs that may cause

the EBD indicator lamp to be inoperative.

2. This test verifies an inoperative lamp condition.

3. This test checks for voltage on the lamp circuit.

4. This begins a series of tests of the circuit from

the indicator lamp to the EBCM and ground.

19. This begins a series of tests of the voltage supply

circuits that power the indicator lamp.

Page 1011 of 2053

SSANGYONG MY2002

4F-28 ABS AND TCS

Check the wiring harnesses and connectors in circuit

from the I/P cluster terminal D6 to terminal 30 of the

EBCM connector.

Is the voltage equal to the specified value?

Repair the open or high resistance.

Is the repair complete?

Check for continuity between terminal 19 of the ABS

connector and ground G205.

Is the continuity equal to the specified value?

Replace the ABS unit.

Is the repair complete?

Repair the continuity between terminal 19 of the EBCM

connector and ground G205.

Is the repair complete?

1. Turn the ignition to LOCK.

2. Check fuse F30 in the I/P fuse block.

Is fuse F30 blown?

Replace fuse F30.

Is the repair complete?

1. Turn the ignition ON.

2. Check the voltage at fuse F30.

Is the voltage equal to the specifies value?

Repair the power supply to fuse F30.

Is the repair complete?

1. Remove the I/P cluster.

2. Check circuit LR from fuse F30 to terminal A1 of

the I/P cluster connector.

3. Repair any open or high resistance found in a wiring

harness, a splice pack, or a connector.

Is the repair complete? Step

14

15

16

17

18

19

20

21

22

23

Electronic Brake-Force Distribution System (EBD) Indicator Lamp Inoperative

Action

Go to Step 15

System OK

Go to Step 17

System OK

System OK

Go to Step 20

System OK

Go to Step 22

System OK

System OKGo to Step 16

-

Go to Step 18

-

-

Go to Step 21

-

Go to Step 23

-

- ∞

-

≈ 0 Ω

-

-

-

-

11 - 14v

-

-Value(s) Yes No

Page 1013 of 2053

SSANGYONG MY2002

4F-30 ABS AND TCS

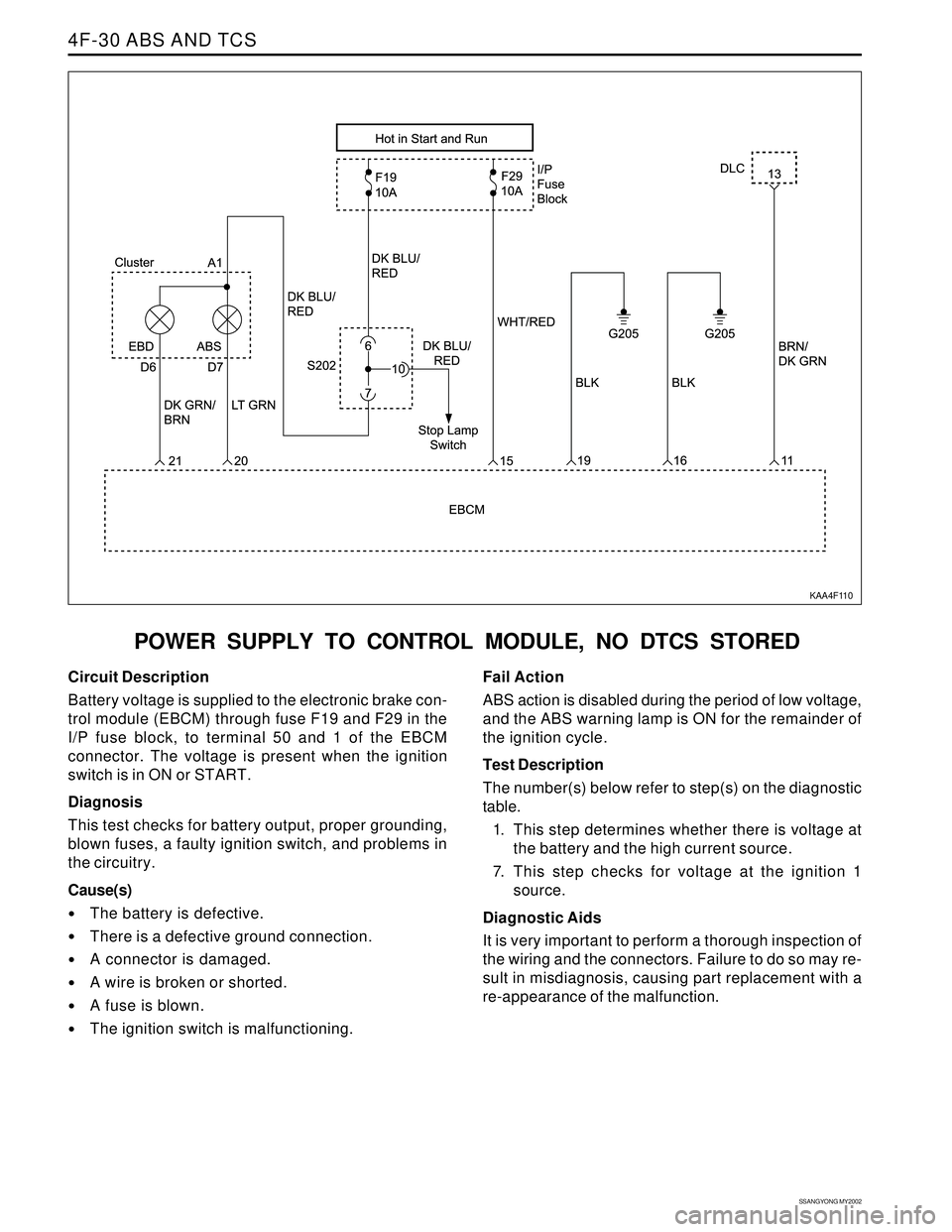

POWER SUPPLY TO CONTROL MODULE, NO DTCS STORED

KAA4F110

Circuit Description

Battery voltage is supplied to the electronic brake con-

trol module (EBCM) through fuse F19 and F29 in the

I/P fuse block, to terminal 50 and 1 of the EBCM

connector. The voltage is present when the ignition

switch is in ON or START.

Diagnosis

This test checks for battery output, proper grounding,

blown fuses, a faulty ignition switch, and problems in

the circuitry.

Cause(s)

The battery is defective.

There is a defective ground connection.

A connector is damaged.

A wire is broken or shorted.

A fuse is blown.

The ignition switch is malfunctioning.Fail Action

ABS action is disabled during the period of low voltage,

and the ABS warning lamp is ON for the remainder of

the ignition cycle.

Test Description

The number(s) below refer to step(s) on the diagnostic

table.

1. This step determines whether there is voltage at

the battery and the high current source.

7. This step checks for voltage at the ignition 1

source.

Diagnostic Aids

It is very important to perform a thorough inspection of

the wiring and the connectors. Failure to do so may re-

sult in misdiagnosis, causing part replacement with a

re-appearance of the malfunction.

Page 1014 of 2053

ABS AND TCS 4F-31

SSANGYONG MY2002

Step

1

2

3

4

5

6

7

8

9

10

11

12

13

14

Power Supply to Control Module, No DTCs Stored

Action

Go to Step 3

System OK

Go to Step 4

Go to Step 6

System OK

Go to Step 7

System OK

Go to Step 10

System OK

Go to Step 14

Go to Step 13

System OK

Go to Step 22

System OKGo to Step 2

-

Go to Step 8

Go to Step 5

-

Go to Step 25

-

Go to Step 9

-

Go to Step 18

Go to Step 12

-

Go to Step 14

- 11 - 14v

-

-

-

-

≈ 0 Ω

-

11 - 14v

-

-

-

-

≈ 0 Ω

-

Check the voltage at the battery.

Is the voltage equal to the specified value?

Charge or replace the battery, as required.

Is the repair complete?

Check fuse F30 in the I/P fuse block.

Is the fuse blown?

1. Replace fuse F30.

2. Turn the ignition to ON.

Does the fuse blow again?

Check the ABS function.

Is the repair complete?

1. Turn the ignition to OFF.

2. Remove fuse F30.

3. Disconnect the ABS connector from the EBCM.

4. Measure the resistance to ground at terminals 20

and 21.

Does the ohmmeter show the specified value?

Repair the short to ground in circuit WR between F19

and the ABS harness EBCM connector.

Is the repair complete?

1. Turn the ignition to ON.

2. Check the voltage at fuse F29.

Is the voltage equal to the specified value?

Repair the power supply to fuse F29.

Is the repair complete?

Check fuse F29 in the I/P fuse block.

Is the fuse F29 blown?

1. Replace fuse F29.

2. Turn the ignition to ON.

Does the fuse blow again?

Check the ABS function.

Is the repair complete?

1. Turn the ignition to OFF.

2. Remove fuse F29.

3. Disconnect the ABS connector from the EBCM.

4. Measure the resistance between ground and

terminal 1.

Is the resistance equal to the specified value?

Repair the short to ground in circuit WR fuse F29 of

the I/P fuse block and terminal 1 of the ABS garness

EBCM connector.

Is the repair complete?

Value(s) Yes No