height SSANGYONG KORANDO 1997 Service Owner's Manual

[x] Cancel search | Manufacturer: SSANGYONG, Model Year: 1997, Model line: KORANDO, Model: SSANGYONG KORANDO 1997Pages: 2053, PDF Size: 88.33 MB

Page 817 of 2053

SUSPENSION DIAGNOSIS 2A-5

SSANGYONG MY2002

Action Checks

Replace the dampeners.

Maintain the proper load weight.

Replace the spring. Inspect for worn dampeners.

Check for an overloaded vehicle.

Inspect for a broken or a sagging spring.Tighten the stabilizer link.

Maintain the proper load weight.

Replace the spring. Inspect for a loose stabilizer link.

Check for an overloaded vehicle.

Inspect for a broken or a sagging spring.Action ChecksAction Checks

Replace the dampeners.

Replace the spring. Inspect for incorrect dampeners.

Inspect for an incorrect spring. Inspect for worn dampeners.

Inspect for a broken or a sagging spring.Replace the dampeners.

Replace the spring.Action ChecksReplace the spring.

Maintain the proper load weight.

Replace the spring. Inspect for a broken or a sagging spring.

Check for an overloaded vehicle.

Inspect for an incorrect or weak spring.Action Checks Inspect for worn or loose front wheel bearings.

Inspect for a broken or a sagging spring.

Inspect for a leaking wheel cylinder or caliper.

Inspect for warped rotors.

Inspect for an incorrect or an uneven caster.Replace the front wheel bearings.

Replace the spring.

Replace the wheel cylinder or the caliper.

Replace the rotors.

If the caster is beyond specifications, check the frame

and repair it, as needed.Action Checks

Low or Uneven Trim Height

Ride Too Soft

Ride Too Harsh

Body Leans or Sways in Corners

Suspension Bottoms

Erratic Steering when Braking

Page 820 of 2053

SECTION 2B

WHEEL ALIGNMENT

TABLE OF CONTENTS

Description and Operation....................................2B-2

Four Wheel Alignment ..........................................2B-2

Toe-in..................................................................2B-2

Caster.................................................................2B-2

Camber...............................................................2B-2

Diagnostic Information and Procedures...............2B-3

Tire Diagnosis......................................................2B-3

Radial Tire Lead/Pull............................................2B-4Vibration Diagnosis..............................................2B-6

Vehicle Height......................................................2B-7

Front Toe-in Adjustment .......................................2B-7

Front Camber Check............................................2B-8

Front Caster Check..............................................2B-8

Specifications.......................................................2B-9

Wheel Alignment Specifications...........................2B-9

Fastener Tightening Specifications.......................2B-9

Page 825 of 2053

SSANGYONG MY2002

2B-6 WHEEL ALIGNMENT

VIBRATION DIAGNOSIS

Wheel imbalance causes most highway speed vibration

problems. A vibration can remain after dynamic balanc-

ing because:

A tire is out of round

A rim is out of round

A tire stiffness variation exists

Measuring tire and wheel free runout will uncover only

part of the problem. All three causes, known as loaded

radial runout, must be checked using method of substi-

tuting known good tire and wheel assemblies on the

problem vehicle.

Tire Balancing

Balance is the easiest procedure to perform and should

be done first if the vibration occurs at high speeds. Do

an off-vehicle, two-plane dynamic balance first to

correct any imbalance in the tire and wheel assembly.

An on-vehicle finish balance will correct any brake drum,

rotor, or wheel cover imbalance, If balancing does not

correct the high-speed vibration, or if the vibration oc-

curs at low speeds, runout is the probable cause.

Preliminary Checks

Prior to performing any work, always road test the car

and perform a careful visual inspection for:

Obvious tire and wheel runout.

Obvious drive axle runout.

Improper tire inflation.

Incorrect trim height.

Bent or damaged wheels.

Debris build-up on the tire or the wheel.

Irregular or excessive tire wear.

Improper tire bead seating on the rim,

Imperfections in the tires, including: tread deforma-

tions, separations, or bulges from impact damage.

Slight sidewall indentations are normal and will not

affect ride quality.

KAA2B040

Page 826 of 2053

WHEEL ALIGNMENT 2B-7

SSANGYONG MY2002

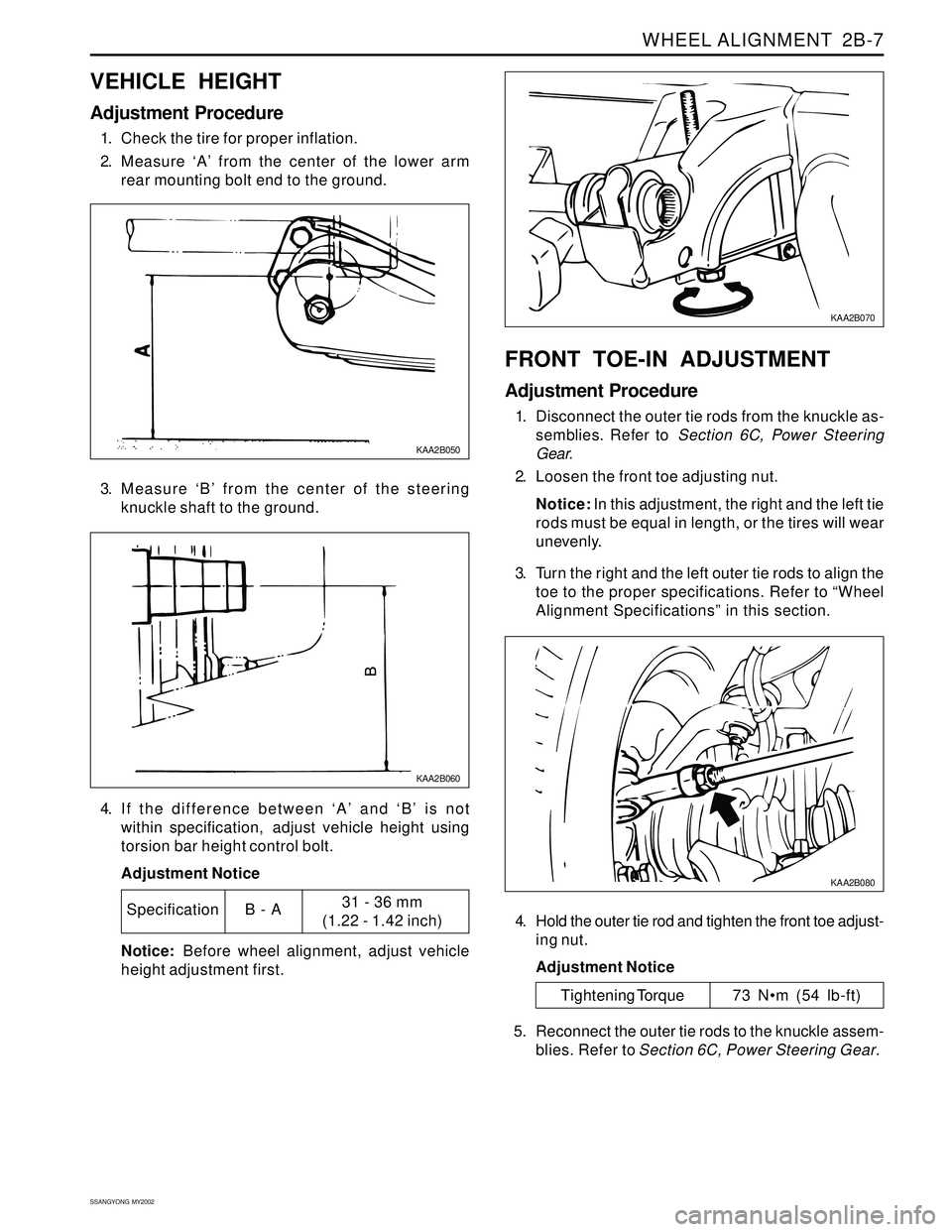

VEHICLE HEIGHT

Adjustment Procedure

1. Check the tire for proper inflation.

2. Measure ‘A’ from the center of the lower arm

rear mounting bolt end to the ground.

KAA2B050

3. Measure ‘B’ from the center of the steering

knuckle shaft to the ground.

KAA2B060

4. If the difference between ‘A’ and ‘B’ is not

within specification, adjust vehicle height using

torsion bar height control bolt.

Adjustment Notice

Specification31 - 36 mm

(1.22 - 1.42 inch)B - A

Notice: Before wheel alignment, adjust vehicle

height adjustment first.

KAA2B070

FRONT TOE-IN ADJUSTMENT

Adjustment Procedure

1. Disconnect the outer tie rods from the knuckle as-

semblies. Refer to Section 6C, Power Steering

Gear.

2. Loosen the front toe adjusting nut.

Notice: In this adjustment, the right and the left tie

rods must be equal in length, or the tires will wear

unevenly.

3. Turn the right and the left outer tie rods to align the

toe to the proper specifications. Refer to “Wheel

Alignment Specifications” in this section.

KAA2B080

4. Hold the outer tie rod and tighten the front toe adjust-

ing nut.

Adjustment Notice

Tightening Torque 73 Nm (54 lb-ft)

5. Reconnect the outer tie rods to the knuckle assem-

blies. Refer to Section 6C, Power Steering Gear.

Page 835 of 2053

FRONT SUSPENSION 2C-7

SSANGYONG MY2002

TORSION BAR

Removal and Installation Procedure

1. Raise and suitably support the vehicle.

2. Remove the height control bolt.

Notice:

Install the torsion bar and adjust the distance

be tween the end of the height control blot and

piece end of the bolt to be 50 - 55 mm (1.97 -

2.17 inch). Adjust the vehicle height.

KAA2C110

KAA2C120

KAA2C130

3. Remove the torsion bar fixing nuts and bolts and

then withdraw the torsion bar.

Installation Notice

Check and adjust the wheel alignment.

4. Installation should follow the removal procedure

in the reverse order.

LOWER CONTROL ARM

Tools Required

661 589 13 33 00 Ball Joint Remover

Removal and Installation Procedure

1. Raise and suitably support the vehicle.

2. Remove the front wheels. Refer to Section 2E,

Tires and Wheels.

3. Remove the torsion bar. Refer to “Torsion Bar” in

this section.

4. Remove the front shock absorber lower mounting

bolt and nut.

Installation Notice

Tightening Torque 70 Nm (52 lb-ft)

Tightening

TorqueM10

M1250 Nm (37 lb-ft)

70 Nm (52 lb-ft)

Page 848 of 2053

REAR SUSPENSION 2D-3

SSANGYONG MY2002

DIAGNOSTIC INFORMATION AND PROCEDURES

EXCESSIVE FRICTION CHECK

Ball Joint Inspection

Check excessive friction in the rear suspension as fol-

lows:

1. With the aid of a helper, lift up on the rear bumper

and raise the vehicle as high as possible. Slow

release the bumper and allow the car to assume

normal trim height.

2. Measure the distance from the floor to the center

of the bumper.3. Push down on the bumper, release slowly, and

allow the car to assume normal trim height.

4. Measure the distance from the floor to the center

of the bumper.

The distance between the two measurements should

be less than 12.7 mm (0.50 inch). If the difference

exceeds this limit, inspect the control arms for damage

or wear.

Page 928 of 2053

SSAMGYONG MY2002

4A-8 HYDRAULIC BRAKES

YAD4A170

YAD4A180

LCRV (LOAD CONSCIOUS

REDUCING VALVE)

LCRV consists of sensing part and hydraulic control

part.

1. Sensing Part

It detects the changes of vehicle height caused

by vehicle load. It consists of load sensing spring

and control lever which change according to

vehicle load.

2. Hydraulic Control Part

It consists of valve stem devices which controls

hydraulic pressure according to load detected by

sensing part.

YAD4A190

4. Place alignment marks between the lock nut (b)

and adjusting screw (c) after the valve setting.

5. LCRV setting should be performed with unloaded

vehicle condition.

Setting Method

1. Install the connecting rod (a) to the No.1 hole.

2. Adjust the clearance “X” to be 0mm and tighten

the bolt (c) using the lock nut (b).

Installation Notice

Tightening Torque14 - 18 Nm

(10 - 13 lb-ft)

3. Remove the connecting rod (a) from the No.1 hole

and reinstall it to the No.2 hole.

Installation Notice

Tightening Torque14 - 18 Nm

(10 - 13 lb-ft)

Page 1363 of 2053

SSAMGYONG MY2002

5C-8 CLUTCH

5. Unscrew the bolts and remove the clutch cover,

pressure plate and clutch disc.

Notice: Be careful not to drop the pressure plate

and clutch disc.

Installation Notice

6. Installation should follow the removal procedure

in the reverse order.

Notice:

Before installation, clean oil and grease on the

flywheel surface.

Do not clean the clutch disc and release bearing

in solvent.

2. Clutch Disc

Check the facing for rivet looseness, excessive

runout, sticks, oil and grease.

Measure the rivet head depth.

If out limit, replace the disc.

Inspection Procedure

1. Clutch Cover

Check the diaphragm spring tip for wear and

height unevenness.

Check the pressure plate surface for wear, crack

and discoloration.

Check the strap plate rivet for looseness and

replace the clutch cover if loosened.

KAA5C090

KAA5C100

KAA5C110

Tightening Torque21 - 27 Nm

(15 - 20 lb-ft)

Wear Limit 0.3 mm

Unevenness Limit 0.8 mm

Page 1368 of 2053

CLUTCH 5C-13

SSANGYONG MY2002

Inspection Procedure

1. Pedal Stroke (A).

Installation Notice

Notice: To adjust the pedal stroke, loosen the lock

nut (H) of the interlock switch (G) and turn the two

lock auto until the stroke is correct.

2. Pedal Height (B).

Installation Notice

Notice: To adjust the pedal height, loosen the lock

nut (C) of the stopper bolt (D) and turn the stopper

bolt until the height is correct.

3. Pedal Free Play (E).

Installation Notice

Notice: To adjust the pedal free play, loosen the

lock nut (F) of the master cylinder and turn the

push rod until the free play is correct.

4. Check the fulcrum pin and the bushing for wear,

the pedal for bending and the spring for damage.

KAA5C160

Max. Stroke 158 mm

Height

(From the Floor Carpet)147 - 187 mm

Free Play 5 - 10 mm

Page 1577 of 2053

SECTION 8A

SEAT BELTS

CAUTION: Disconnect the negative battery cable before removing or installing any electrical unit or when a

tool or equipment could easily come in contact with exposed electrical terminals. Disconnecting this cable

will help prevent personal injury and damage to the vehicle. The ignition must be in B unless otherwise

noted.

TABLE OF CONTENTS

Description and Operation...................................8A-2

Driver Seat Belt Warning......................................8A-2

Three-Point Front Seat Belt With Pretensioner.......8A-2

Three-Point Rear Outboard Seat Belt....................8A-2

Two-Point Lap Rear Center Seat Belt....................8A-2

Operational and Functional Checks......................8A-2

Child Seat Tether Anchor.....................................8A-2

Component Locator.............................................8A-3

Front Seat Belt.....................................................8A-3

Rear Seat Belt.....................................................8A-4Repair Procedures...............................................8A-5

On-Vehicle Service.................................................8A-5

Three-Point Front Seat Belt With Pretensioner.......8A-5

Front Seat Belt Height Adjuster............................8A-6

Three-Point Rear Outboard Seat Belt....................8A-6

Two-Point Lap Rear Center Seat Belt....................8A-7

Child Seat Tether Anchor.....................................8A-7

Specifications.......................................................8A-8

Fastener Tightening Specifications.......................8A-8

Schematic and Routing Diagrams.......................8A-9

Seat Belt & Tension Reducer...............................8A-9