torque SSANGYONG KORANDO 1997 Service Repair Manual

[x] Cancel search | Manufacturer: SSANGYONG, Model Year: 1997, Model line: KORANDO, Model: SSANGYONG KORANDO 1997Pages: 2053, PDF Size: 88.33 MB

Page 1766 of 2053

SSANGYONG MY2002

9H-8 SEATS

50/50 SPLIT REAR SEAT CUSHION

LOCK STRIKER

Removal and Installation Procedure

1. Remove the bolts and rear seat cushion lock

striker.

Installation Notice

Dissimilar metals in direct contact with each

other may corrode rapidly. Make sure to use

the correct fasteners to prevent premature

corrosion.

2. Installation should follow the removal procedure

in the reverse order.

KAA9H200

2. Remove the child seat anchorage bolt.

Installation Notice

Dissimilar metals in direct contact with each

other may corrode rapidly. Make sure to use

the correct fasteners to prevent premature

corrosion.

3. Installation should follow the removal procedure

in the reverse order.

KAA9H190

CHILD SEAT ANCHORAGE

Removal and Installation Procedure

1. Remove the child seat anchorage cover.

Tightening Torque34.3 - 53.9 Nm

(25 - 39 lb-ft)

KAA9H170

Tightening Torque 19 Nm (14 lb-ft)

Page 1791 of 2053

GLASS AND MIRRORS 9L-9

SSANGYONG MY2002

KAA9L160

KAA9L170

FRONT DOOR GLASS

Removal Procedure

1. Remove the door seal trim. Refer to Section 9P,

Doors.

2. Remove the screws that secure the glass to the

window regulator.

3. Remove the glass from the door.

4. Removal procedure should follow the installation

procedure in the reverse order.

Installation Procedure

1. Install the glass in the door and position the glass

within the window regulator.

Notice: Dissimilar metals in direct contact with

each other may corrode rapidly. Make sure to use

the correct fasteners to prevent premature

corrosion.

2. Install the glass to the window regulator with the

screws.

Installation Notice

3. Install the door seal trim. Refer to Section 9P,

Doors.

4. Removal procedure should follow the installation

procedure in the reverse order.

Tightening Torque1.96 - 2.94 Nm

(17.50 - 26.25 lb-in)

KAA9L180

FIXED GLASS

Removal and Installation Procedure

1. Remove the exterior B-pillar molding. Refer to

Section 9M, Exterior Trim.

2. Remove the screws that secure the glass to the

window regulator.

3. Remove the glass from the door.

Installation Notice

Dissimilar metals in direct contact with each

other may corrode rapidly. Make sure to use

the correct fasteners to prevent premature

corrosion.

4. Installation should follow the removal procedure

in the reverse order.

Tightening Torque 7 Nm (62 lb-in)

Page 1792 of 2053

SSANGYONG MY2002

9L-10 GLASS AND MIRRORS

KAA9L190

KAA9L200

OUTSIDE REARVIEW MIRROR

Removal and Installation Procedure

1. Remove the tweeter inner cover.

2. Remove the screws with the outside rearview

mirror.

Installation Notice

Dissimilar metals in direct contact with each

other may corrode rapidly. Make sure to use

the correct fasteners to prevent premature

corrosion.

3. Installation should follow the removal procedure

in the reverse order.

INSIDE REARVIEW MIRROR

Removal and Installation Procedure

1. Remove the screw with the inside rearview mirror.

Installation Notice

Dissimilar metals in direct contact with each

other may corrode rapidly. Make sure to use

the correct fasteners to prevent premature

corrosion.

2. Installation should follow the removal procedure

in the reverse order.

Tightening Torque1.4 - 1.7 Nm

(9 lb-in)

Tightening Torque3 - 5 Nm

(27 - 44 lb-in)

Page 1801 of 2053

SSANGYONG MY2002

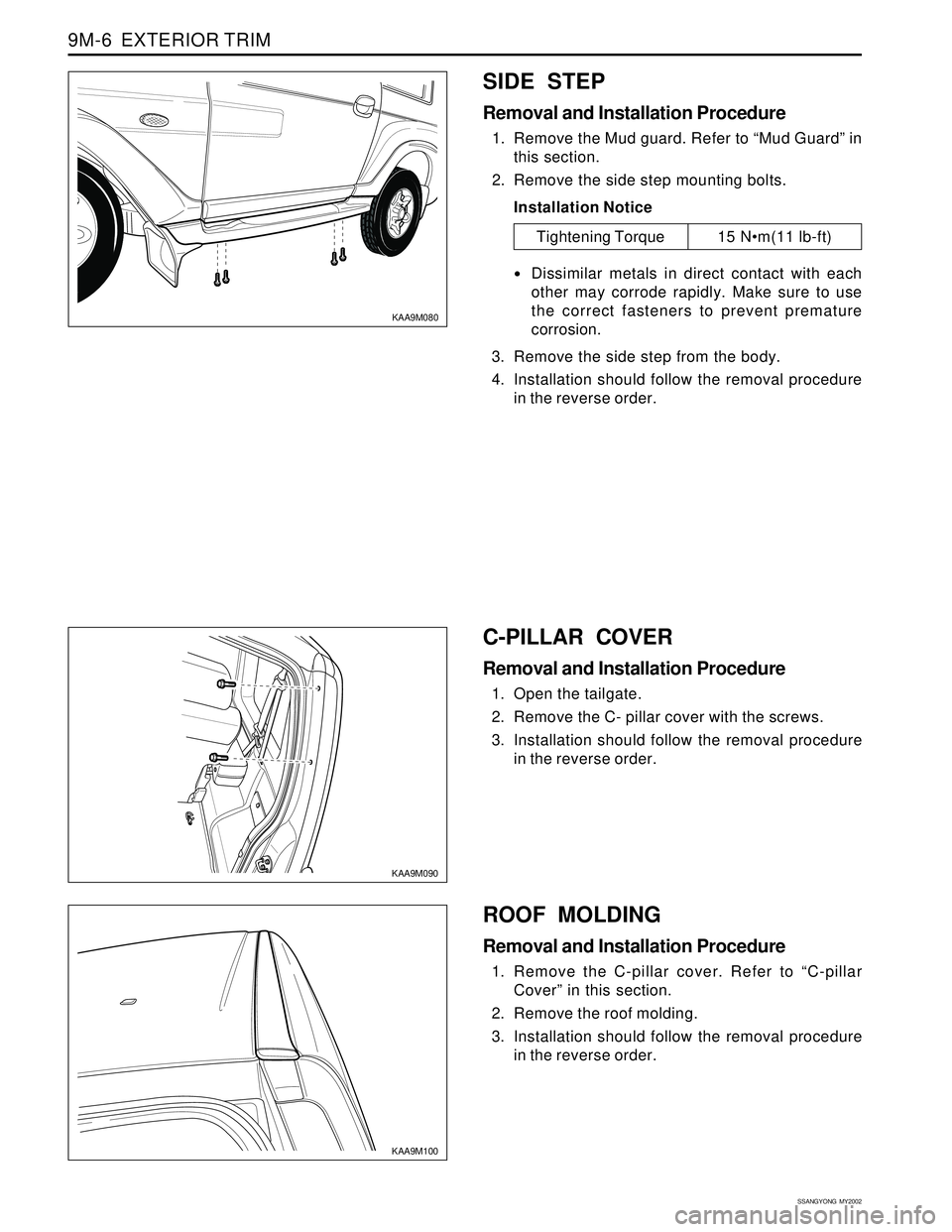

9M-6 EXTERIOR TRIM

KAA9M090

KAA9M100

C-PILLAR COVER

Removal and Installation Procedure

1. Open the tailgate.

2. Remove the C- pillar cover with the screws.

3. Installation should follow the removal procedure

in the reverse order. 3. Remove the side step from the body.

4. Installation should follow the removal procedure

in the reverse order.

ROOF MOLDING

Removal and Installation Procedure

1. Remove the C-pillar cover. Refer to “C-pillar

Cover” in this section.

2. Remove the roof molding.

3. Installation should follow the removal procedure

in the reverse order.

SIDE STEP

Removal and Installation Procedure

1. Remove the Mud guard. Refer to “Mud Guard” in

this section.

2. Remove the side step mounting bolts.

Installation Notice

Dissimilar metals in direct contact with each

other may corrode rapidly. Make sure to use

the correct fasteners to prevent premature

corrosion.

KAA9M080

Tightening Torque 15 Nm(11 lb-ft)

Page 1810 of 2053

SSANGYONG MY2002

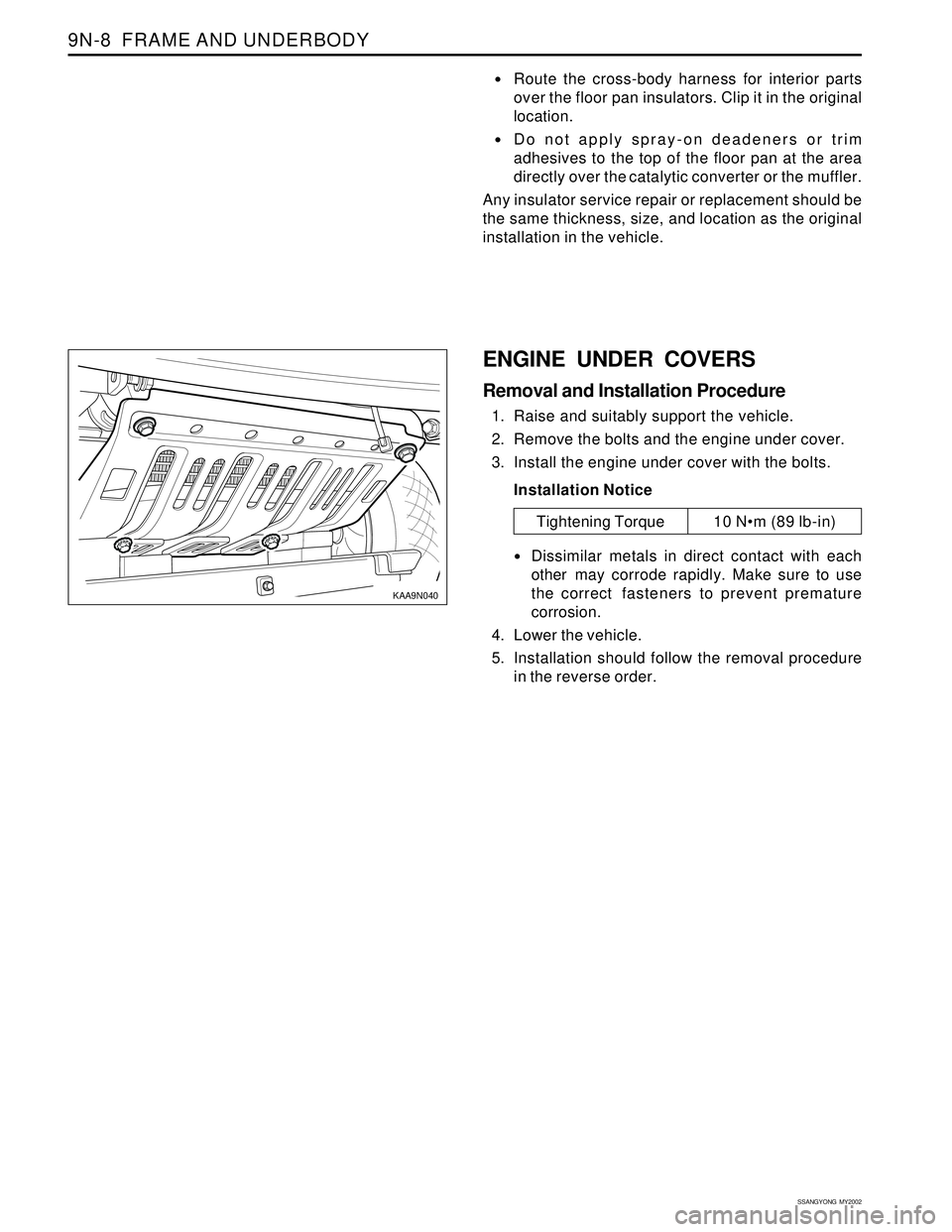

9N-8 FRAME AND UNDERBODY

KAA9N040

Route the cross-body harness for interior parts

over the floor pan insulators. Clip it in the original

location.

Do not apply spray-on deadeners or trim

adhesives to the top of the floor pan at the area

directly over the catalytic converter or the muffler.

Any insulator service repair or replacement should be

the same thickness, size, and location as the original

installation in the vehicle.

ENGINE UNDER COVERS

Removal and Installation Procedure

1. Raise and suitably support the vehicle.

2. Remove the bolts and the engine under cover.

3. Install the engine under cover with the bolts.

Installation Notice

Dissimilar metals in direct contact with each

other may corrode rapidly. Make sure to use

the correct fasteners to prevent premature

corrosion.

4. Lower the vehicle.

5. Installation should follow the removal procedure

in the reverse order.

Tightening Torque 10 Nm (89 lb-in)

Page 1816 of 2053

SSANGYONG MY2002

9O-4 BUMPERS AND FASCIAS

KAA9O030

KAA9O040

2. Remove the front bumper with the bolts.

Installation Notice

•Dissimilar metals in direct contact with each

other may corrode rapidly. Make sure to use

the correct fasteners to prevent premature

corrosion.

3. Remove the front bumper fascia.

4. Installation should follow the removal procedure

in the reverse order.

KAA9O020

ON-VEHICLE SERVICE

UNIT REPAIR

FRONT BUMPER FASCIA

Removal and Installation Procedure

1. Remove the side support bracket nuts.

Installation Notice

Dissimilar metals in direct contact with each

other may corrode rapidly. Make sure to use

the correct fasteners to prevent premature

corrosion.

REPAIR INSTRUCTIONS

Tightening Torque 11 Nm (97 lb-in)

Tightening Torque117 Nm (154 lb-ft)

Page 1817 of 2053

BUMPERS AND FASCIAS 9O-5

SSANGYONG MY2002

KAA9O050

REAR BUMPER FASCIA

Removal and Installation Procedure

1. Remove the mud guard. Refer to Section 9M,

Exterior Trim.

2. Remove the rear bumper with the bolts.

3. Remove the rear bumper fascia from the rear

bumper.

Installation Notice

Dissimilar metals in direct contact with each

other may corrode rapidly. Make sure to use

the correct fasteners to prevent premature

corrosion.

4. Installation should follow the removal procedure

in the reverse order.

KAA9O060

FRONT BUMPER IMPACT BAR

Removal and Installation Procedure

1. Remove the front bumper fascia. Refer to Front

Bumper Fascia in this section.

2. Remove the nuts with the front bumper impact bar.

Installation Notice

Dissimilar metals in direct contact with each

other may corrode rapidly. Make sure to use

the correct fasteners to prevent premature

corrosion.

3. Installation should follow the removal procedure

in the reverse order.

Tightening Torque 29 Nm (21 lb-ft)

Tightening Torque117 Nm (154 lb-ft)

Page 1821 of 2053

SSANGYONG MY2002

9P-4 DOORS

DOOR LOCK STRIKER

Removal and Installation Procedure

1. Remove the screws and the door lock striker.

Installation Notice

Dissimilar metals in direct contact with each

other may corrode rapidly. Make sure to use

the correct fasteners to prevent premature

corrosion.

2. Installation should follow the removal procedure

in the reverse order.

KAA9P020

ON-VEHICLE SERVICE

UNIT REPAIR

DOOR GLASS RUN

Removal and Installation Procedure

1. Lower the window.

2. Remove the glass from the door.

3. Remove the front door glass run.

4. Installation should follow the removal procedure

in the reverse order.

REPAIR INSTRUCTIONS

KAA9P030

DOOR SIDE OPENING

WEATHERSTRIP

Removal and Installation Procedure

1. Remove the side opening weatherstrip.

2. Installation should follow the removal procedure

in the reverse order.

Tightening Torque9.8 - 18.62 Nm

(7.23 - 13.74 lb-ft)

KAA9P040

Page 1822 of 2053

DOORS 9P-5

SSANGYONG MY2002

DOOR LOCK STRIKER

ADJUSTMENT

Installation Notice:

The door lock striker is an important attaching part

that can affect the performance of vital components

and systems and can cause major repair expenses. If

replacement becomes necessary, the door lock striker

must be replaced by one with the same part number

or with an equivalent part. Do not use a replacement

part of lesser quality or of a substitute design. The

specified torque values must be used during

reassembly in order to ensure the proper retention of

the part.

The door lock striker consists of a striker with two screws

that are threaded into a tapped, floating cage plate

located in the appropriate body pillar. This floating

cage plate allows the striker to be easily adjusted in

or out and up or down. The door is secured in the closed

position when the door lock fork snaps over and

engages the striker.

Fore/Aft Adjustment

1. The door must be properly aligned.

2. Close the door until the lock fork contacts the

striker.

3. Stand next to the door opening and move the door

slowly in and out, just touching the striker each

time.

4. The alignment of the lock fork and the striker can

be easily seen. The lock fork should be

perpendicular to and fall near the middle of the

striker between the B-pillar and the end of the

striker.

5. If a fore or aft adjustment is required, use the

following steps:

5.1 Remove the striker screws.

5.2 Remove the spacer in order to move the striker

toward the front of the vehicle.

5.3 Add a 2 mm (0.8 inch) spacer in order to move

the striker toward the front of the vehicle.

5.4 Install the striker screws.

6. Perform the up/down or the in/out adjustment.

Refer to “up/down or in/out Adjustment” in this

section.

Page 1823 of 2053

SSANGYONG MY2002

9P-6 DOORS

KAA9P050

FRONT DOOR LOCK

Removal and Installation Procedure

1. Disconnect the negative battery cable.

2. Remove the inside door handle. Refer to “Inside

door Handle” in this section.

3. Disconnect the inside door handle and the lock

rods.

4. Remove the screws and the guide rail.

5. Remove the screws and the front door lock.

Installation Notice

Dissimilar metals in direct contact with each

other may corrode rapidly. Make sure to use

the correct fasteners to prevent premature

corrosion.

6. Installation should follow the removal procedure

in the reverse order.

Up/Down or In/Out Adjustment

An adjustment of the striker in the up/down or in/out

directions may be necessary for a number of reasons:

Vehicle frame damage as the result of a collision.

Installation of new door weather stripping.

Customer complaints of excessive wind noise.

Difficulty in opening or closing the door.

In order to adjust the door striker in an up/down or in/

out direction, perform the following procedure:

1. The door must be properly aligned.

2. Loosen the striker screws.

3. The floating cage plate can be moved slightly

using the ends of the striker screws. Move the

floating cage plate to the desired position.

Notice: It is important to use a flat-end rotary file in

order not to damage the tapped floating cage plate.

The striker screws and the tapped floating cage plate

are important attaching parts that could affect the

performance of vital components and systems.

4. If proper adjustment requires that the floating cage

plate be moved more than is possible, use an

electric hand drill and a 3/8-inch rotary file with a

flat head in order to enlarge the body opening in

the direction required.

5. Tighten the striker screws to the correct position.

Tightening Torque6.86 - 9.8 Nm

(5.06 - 7.23 lb-ft)