engine SSANGYONG KORANDO 1997 Service Repair Manual

[x] Cancel search | Manufacturer: SSANGYONG, Model Year: 1997, Model line: KORANDO, Model: SSANGYONG KORANDO 1997Pages: 2053, PDF Size: 88.33 MB

Page 520 of 2053

1F2 -- 102 M161 ENGINE CONTROLS

D AEW OO M Y_2000

KAA1F190

HOT FILM AIR MASS (HFM) SENSOR

Removal and Installation Procedure

1. Disconnect the negative battery cable.

2. Disconnect the Hot Film Air Mass (HFM) sensor

electrical connector.

3. Remove the HFM sensor retaining screws.

4. Turn the HFM sensor coupling in the direction

shown in the figure in the left so that it gets sepa-

rated from the contact surface.

Notice:Make sure the HFM sensor coupling connects

completely with the contact surface installation.

5. Remove the HFM sensor.

6. Installation should follow the removal procedure in

the reverse order.

KAA1F180

KNOCK SENSOR

Removal and installation Procedure

1. Disconnect the negative battery cable.

2. Disconnect the knock sensor electrical connector

from the intake manifold bracket.

3. Remove the knock sensor mounting bolt from the

knock sensor installed on the cylinder block.

Installation Notice

Tightening Torque

25 NSm (18 Ib-ft)

4. Remove the knock sensor.

5. Installation should follow the removal procedure in

the reverse order.

Page 521 of 2053

M161 ENGINE CONTROLS 1F2 -- 103

D AEW OO M Y_2000

KAA1F410

PEDAL POSITION SENSOR

Removal and installation Procedure

1. Disconnect the negative battery cable.

2. Disconnect the pedal position sensor connector.

3. Unscrew the bolts and nut.

Installation Notice

Tightening Torque

6NSm (53 lb-in)

4. Remove the pedal and sensor assembly.

5. Installation should follow the removal procedure in

the reverse order.

YAA1F820

OXYGEN SENSOR

Removal and Installation Procedure

1. Disconnect the negative battery cable.

Notice:The oxygen sensor uses a permanently at-

tached pigtail and connector. This pigtail should not be

removed from the oxygen sensor. Damage or removal

of the pigtail or the connector could affect proper opera-

tion of the oxygen sensor. Do not drop the oxygen sen-

sor.

2. Disconnect the electrical connector.

3. Carefully remove the oxygen sensor from the exhaust

pipe.

Installation Notice

Tightening Torque

55 NSm (41 Ib-ft)

Important:A special anti-seize compound is used on

the oxygen sensor threads. This compound consists of

a liquid graphite and glass beads. The graphitewill burn

away, but the glass beadswill remain, making the sen-

sor easier to remove. New or serviced sensors will al-

ready have the compound applied to the threads. If a

sensor is removed from any engine and is to be rein-

stalled, the threads must have an anti-seize compound

applied before reinstallation.

4. Coat the threads of the oxygen sensor with an anti-

seize compound, if needed.

5. Installation should follow the removal procedure in

the reverse order.

Page 522 of 2053

1F2 -- 104 M161 ENGINE CONTROLS

D AEW OO M Y_2000

KAB1F400

PURGE CONTROL VALVE

Removal and Installation Procedure

1. Disconnect the negative battery cable.

2. Disconnect the purge control valve connector.

3. Disconnect the throttle body-to-purge control valve

hose from the purge control valve.

4. Disconnect the canister-to-purge control valve hose

from the purge control valve.

5. Remove the purge control valve.

6. Installation should follow the removal provedure in

the reverse order.

KAB1F410

CANISTER

Removal and Installation Procedure

Caution: Canister and vacuum hoses contain fuel

vapors. Do not smoke in the area or permit an open

flame.

1. Disconnect the fuel tank-to-canister hose form the

canister.

2. Disconnect the canister-to-purge control valve hose

form the canister.

KAB1F400

3. Remove the canister mounting bolts.

Installation Notice

Tightening Torque

6NSm (53 lb-in)

4. Remove the canister.

5. Installation should follow the removal procedure in

the reverse order.

YAA1F810

CAMSHAFT POSITION SENSOR

Removal and Installation Procedure

1. Disconnect the negative battery cable.

2. Disconnect the electrical connector from the cam-

shaft position sensor.

3. Remove the camshaft position sensor retaining bolt.

Installation Notice

Tightening Torque

10 NSm (89 Ib-in)

Page 523 of 2053

M161 ENGINE CONTROLS 1F2 -- 105

D AEW OO M Y_2000

4. Check the O-ring for damage and replace it if neces-

sary.

5. Installation should follow the removal procedure in

the reverse order.

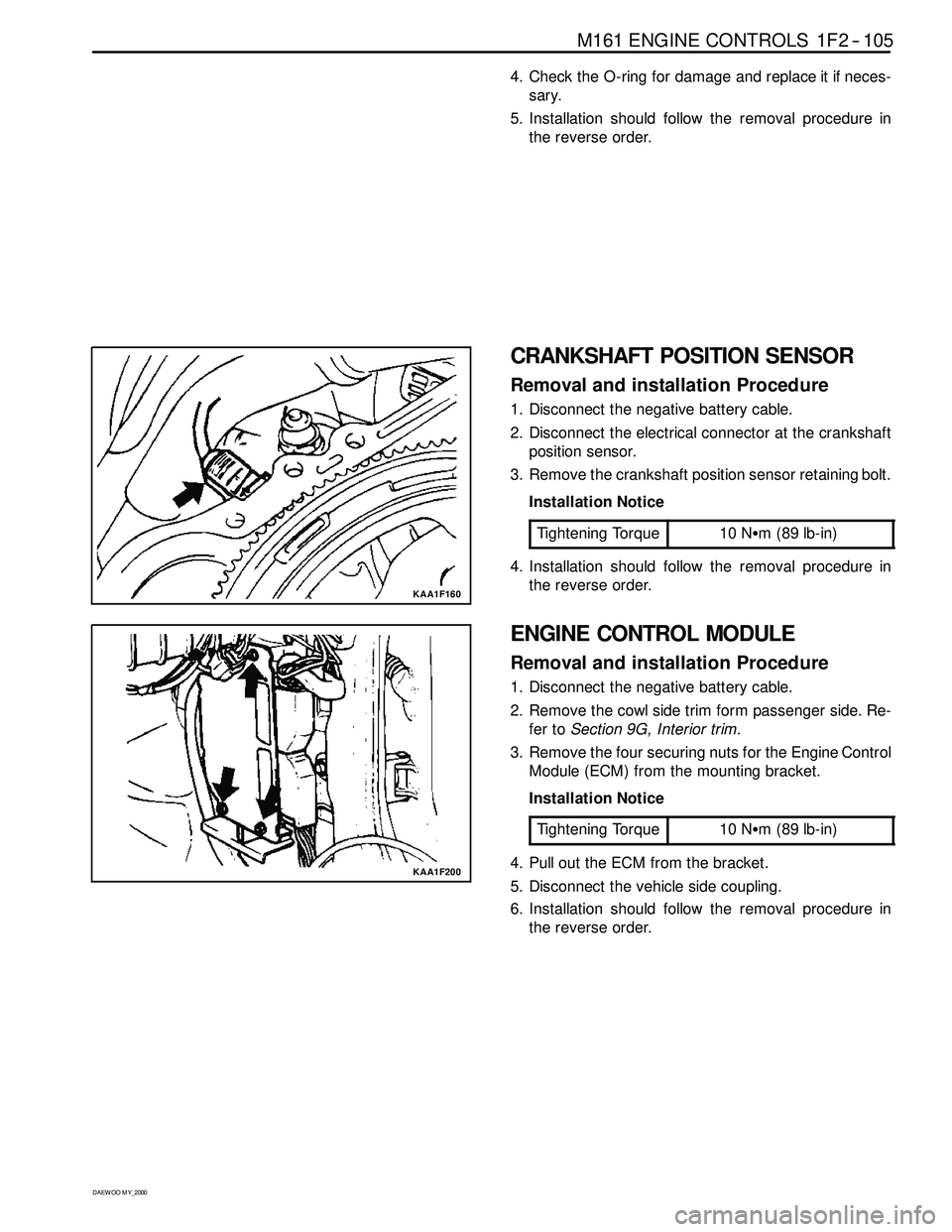

KAA1F160

CRANKSHAFT POSITION SENSOR

Removal and installation Procedure

1. Disconnect the negative battery cable.

2. Disconnect the electrical connector at the crankshaft

position sensor.

3. Remove the crankshaft position sensor retaining bolt.

Installation Notice

Tightening Torque

10 NSm (89 lb-in)

4. Installation should follow the removal procedure in

the reverse order.

KAA1F200

ENGINE CONTROL MODULE

Removal and installation Procedure

1. Disconnect the negative battery cable.

2. Remove the cowl side trim form passenger side. Re-

fer toSection 9G, Interior trim.

3. Remove the four securing nuts for the Engine Control

Module (ECM) from the mounting bracket.

Installation Notice

Tightening Torque

10 NSm (89 lb-in)

4. Pull out the ECM from the bracket.

5. Disconnect the vehicle side coupling.

6. Installation should follow the removal procedure in

the reverse order.

Page 524 of 2053

D AEW OO M Y_2000

SECTION 1G2

M161 ENGINE INTAKE & EXHAUST

CAUTION: Disconnect the negative battery cable before removing or installing any electrical unit or when a

tool or equipment could easily come in contact with exposed electrical terminals. Disconnecting this cable

will help prevent personal injury and damage to the vehicle. The ignition must also be in LOCK unless other -

wise noted.

TABLE OF CONTENTS

Specifications 1G2 -- 2...........................

Fastener Tightening Specifications 1G2 -- 2.........

Maintenance and Repair 1G2 -- 3..................

On-- Vehicle Service 1G2-- 3........................

Air Cleaner 1G2-- 3.............................

Air Intake Shield 1G2-- 5.........................Intake Air Duct 1G2--6..........................

Intake Manifold 1G2--8.........................

Exhaust Manifold 1G2-- 10.......................

Removal and Installation of Exhaust

System 1G2-- 12.............................

Page 525 of 2053

1G2 -- 2 M161 ENGINE INTAKE & EXHAUST

D AEW OO M Y_2000

SPECIFICATIONS

FASTENER TIGHTENING SPECIFICATIONS

ApplicationNSmLb-FtLb-In

Air Cleaner Mounting Bolt22.5 -- 27.516.6 -- 20.3--

Intake Manifold Mounting Bolts22.5 -- 27.516.6 -- 20.3--

Idle Regulator and Intermediate Flange Bolts22.5 -- 27.516.6 -- 20.3--

Supporting Assembly Bolts22.5 -- 27.516.6 -- 20.3--

Oxygen Sensor5541--

Connection Piece36 -- 4427 -- 33--

Exhaust Pipe Flange Bolts3022--

Exhaust Manifold Nuts31.5 -- 38.523.2 -- 28.4--

Exhaust Pipe-- to-- Catalytic Converter Flange Nuts28 -- 4721 -- 35--

Front Muffler Pipe -- to -- Catalytic Converter Flange Nuts28 -- 4721 -- 35--

Rear Muffler Pipe Flange -- to -- Front Muffler Pipe Flange

Nuts28 -- 4721 -- 35--

Page 526 of 2053

M161 ENGINE INTAKE & EXHAUST 1G2 -- 3

D AEW OO M Y_2000

MAINTENANCE AND REPAIR

ON -- VEHICLE SERVICE

AIR CLEANER

1 Air Cleaner Assembly

2 Element Assembly

3 Insulator4 Air Duct Hose

6 Bolt (M8 x 30 ) 22.5-- 27.5 NSm ...............

Page 527 of 2053

1G2 -- 4 M161 ENGINE INTAKE & EXHAUST

D AEW OO M Y_2000

Removal and Installation Procedure

1. Disconnect the HFM sensor and the air cleaner by

prying up the clamp.

2. Remove the air cleaner mounting bolt.

Installation Notice

Tightening Torque

22.5 -- 27.5 NSm

(16.6 -- 20.3 lb-ft)

3. Remove air intake shield upper cover, and then re-

move the air cleaner from rubber bearing on bracket.

Notice:For installation, exactly seat the air cleaner into

the rubber bearing.

Page 528 of 2053

M161 ENGINE INTAKE & EXHAUST 1G2 -- 5

D AEW OO M Y_2000

AIR INTAKE SHIELD

Preceding Work: Removal of air cleaner

1 Air Cleaner Assembly

3 Insulator

4 Air Duct Hose5 Air Inlet Duct

7 Bolt(M6x35) 9--11NSm ...................

Removal & Installation Procedure

1. Remove the upper cover (3) from the air intake shield

(5) upper mounting pin.

2. Remove the bolts (4 and 6).

3. Remove the air intake shield (5).

4. Installation should follow the removal procedure in

the reverse order.

Page 529 of 2053

1G2 -- 6 M161 ENGINE INTAKE & EXHAUST

D AEW OO M Y_2000

INTAKE AIR DUCT

1 Clamp

2 Sleeve

3 HFM Sensor

4 Intake Air Duct5Blow--byHose

7 Clamp(2 pieces)

8 Intake Air Duct Mounting Bracket