engine SSANGYONG KORANDO 1997 Service Repair Manual

[x] Cancel search | Manufacturer: SSANGYONG, Model Year: 1997, Model line: KORANDO, Model: SSANGYONG KORANDO 1997Pages: 2053, PDF Size: 88.33 MB

Page 500 of 2053

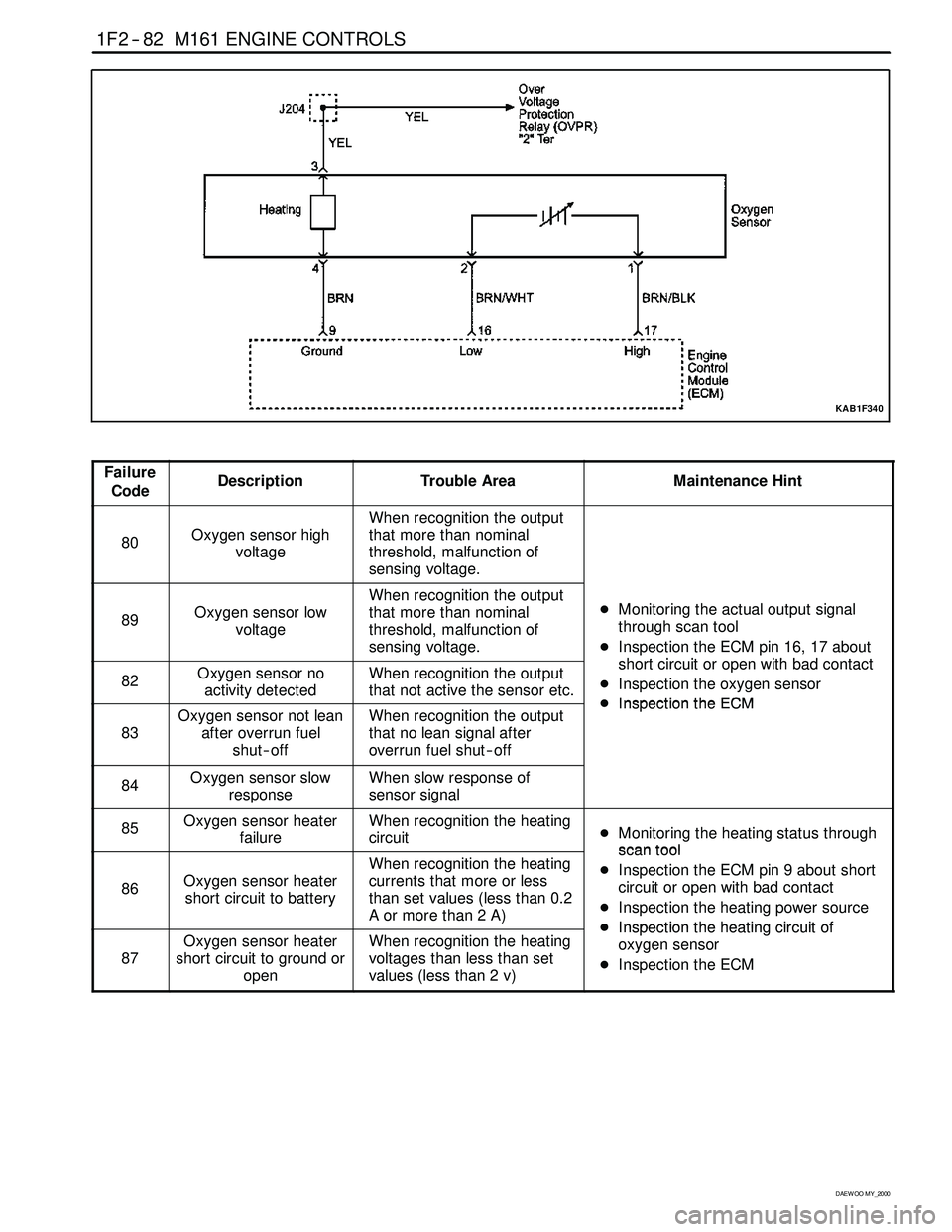

1F2 -- 82 M161 ENGINE CONTROLS

D AEW OO M Y_2000

KAB1F340

Failure

CodeDescriptionTrouble AreaMaintenance Hint

80Oxygen sensor high

voltage

When recognition the output

that more than nominal

threshold, malfunction of

sensing voltage.

89Oxygen sensor low

voltage

When recognition the output

that more than nominal

threshold, malfunction of

sensing voltage.DMonitoring the actual output signal

through scan tool

DInspection the ECM pin 16, 17 about

htiitithbdtt

82Oxygen sensor no

activity detectedWhen recognition the output

that not active the sensor etc.short circuit or open with bad contact

DInspection the oxygen sensor

DInspectiontheECM

83

Oxygen sensor not lean

after overrun fuel

shut -- offWhen recognition the output

that no lean signal after

overrun fuel shut -- offDInspectiontheECM

84Oxygen sensor slow

responseWhen slow response of

sensor signal

85Oxygen sensor heater

failureWhen recognition the heating

circuitDMonitoring the heating status through

scantool

86Oxygen sensor heater

short circuit to battery

When recognition the heating

currents that more or less

than set values (less than 0.2

Aormorethan2A)scantool

DInspection the ECM pin 9 about short

circuit or open with bad contact

DInspection the heating power source

DInspectiontheheatingcircuitof

87

Oxygen sensor heater

short circuit to ground or

openWhen recognition the heating

voltages than less than set

values (less than 2 v)DInspectiontheheating circuitof

oxygen sensor

DInspection the ECM

Page 501 of 2053

M161 ENGINE CONTROLS 1F2 -- 83

D AEW OO M Y_2000

Failure

CodeDescriptionTrouble AreaMaintenance Hint

81

Bank 1 system short

term fuel trim adaptation

below lean threshold

When recognition the value

less than nominal control

threshold, it means that when

big deviation in control range

of adaptation values through

fuel and air mixture formation

93

Bank 1 system short

term fuel trim adaptation

above rich threshold

When recognition the value

more than nominal control

threshold, it means that when

big deviation in control range

of adaptation values through

fuel and air mixture formation

96

Bank 1 system short

term fuel trim at rich

stopWhen recognition the short

term fuel trim that more than

nominal threshold

97

Bank1 system short

term fuel trim at lean

stopWhen recognition the short

term fuel trim that less than

nominal threshold

DInspection the intake air leakage

DIns

pection the injectionquantities with

98

Bank 1 system idle

adaptation failure (above

rich threshold)When recognition the long

term fuel trim exceeds rich

threshold

DInspectiontheinjectionquantitieswith

injector block or leakage

DInspection the exhaust leakage

DInspection the ECM

99

Bank 1 system idle

adaptation failure (below

rich threshold)When recognition the long

term fuel trim exceeds lean

threshold

p

100

Bank 1 system learning

control failure (rich, low

load)When recognition the long

term fuel trim exceeds rich

threshold

101

Bank 1 system learning

control failure (lean, low

load)When recognition the long

term fuel trim exceeds lean

threshold

102

Bank 1 system learning

control failure (rich, high

load)When recognition the long

term fuel trim exceeds rich

threshold

103

Bank 1 system learning

control failure (rich, low

load)When recognition the long

term fuel trim exceeds lean

threshold

Circuit Description

In order to control emissions, a catalytic converter is used to covert harmful emissions into harmless water vapor and

carbon dioxide. The ECM has the ability to monitor this process by using a oxygen sensor. The oxygen sensor pro-

duces and output signal which indicates the storage capacity of the catalyst. This in turn indicates the catalyst’s ability

to convert exhaust emission effectively. If the oxygen sensor pigtail wiring, connector, or terminal is damaged. Do not

attempt to repair the wiring, connector, or terminals. In order for the sensor to function properly, it must have a clean air

reference provided to it. This clean air reference is obtained by way of the oxygen sensor wire(s). Any attempt to repair

the wires, connector, or terminal and degrade the oxygen sensor performance.

Page 502 of 2053

1F2 -- 84 M161 ENGINE CONTROLS

D AEW OO M Y_2000

Oxygen Sensor Signal Voltage Inspection

1. Maintain the engine speed is at idle while the coolant temperature is over 80°C.

2. Measure the oxygen sensor signal voltage between the ECM terminal No. 16 and No. 17.

Specified Value

-- 0.2 ~ 1.0 v

Notice:If the measured value is not within the specified value, the possible cause may be in cable, oxygen sensor or

ECM

Oxygen Sensor Heating Voltage Inspection

1. Maintain the engine speed is at idle while the coolant temperature is over 80°C.

2. Measure the oxygen sensor signal voltage between the ECM terminal No. 11 and No. 9.

Specified Value

11 ~ 14 v

Notice:If the measured value is not within the specified value, the possible cause may be in cable, oxygen sensor or

ECM

Oxygen sensor Heating Current Consumption Inspection

1. Turn the ignition switch to “ON” position.

2. Measure the oxygen sensor heating current consumption between the ECM terminal No. 9 and No. 5.

Specified Value

0.2~2.0A

Notice:If the measured value is not within the specified value, the possible cause may be in cable, oxygen sensor or

ECM

Page 503 of 2053

M161 ENGINE CONTROLS 1F2 -- 85

D AEW OO M Y_2000

BLANK

Page 504 of 2053

1F2 -- 86 M161 ENGINE CONTROLS

D AEW OO M Y_2000

ENGINE CONTROL MODULE

YAA1F830

The Engine Control Module (ECM), located inside the right side kick panel, is the control center of the fuel injection

system. It constantly looks at the information from various sensors and controls the systems that affect the vehicle’s

performance. Engine rpm and air mass are used to measure the air intake quantity resulting in fuel injection metering.

The ECM also performs the diagnostic functions of the system. It can recognize operational problems, store failure

code(s) which identify the problem areas to aid the technician in making repairs.

There are no serviceable parts in the ECM. The calibrations are stored in the ECM in the Programmable Read Only

Memory (PROM).

The ECM supplies either 5 or 12 volts to power the sensors or switches. This is done through resistance in the ECM

which are so high in value that a test light will not come ON when connected to the circuit. In some cases, even an

ordinary shop voltmeter will not give and accurate reading because its resistance is too low. You must use a digital

voltmeter with a 10 Mohm input impedance to get accurate voltage readings. The ECM controls output circuits such as

the ignition coils, the fuel injectors, the fuel pump relay, the camshaft actuator, the canister purge valve, etc., by con-

trolling the ground circuit.

Page 505 of 2053

M161 ENGINE CONTROLS 1F2 -- 87

D AEW OO M Y_2000

BLANK

Page 506 of 2053

1F2 -- 88 M161 ENGINE CONTROLS

D AEW OO M Y_2000

SERIAL DATA COMMUNICATION

KAB1F350

Failure

CodeDescriptionTrouble AreaMaintenance Hint

23CAN communication

failure: ASR/MSR

When CAN signal message

missing or implausibility for

ASR/MSR unit or not

initialized condition

DInspection the ASR unit with CAN

connection

DInspection the Engine Control Module

(ECM) pin 38, 37 about short circuit or

open with bad contact

DInspection the ECM

24CAN communication

failure: ABS

When CAN signal message

missing or implausibility for

ABS unit or not initialized

conditionDInspection the ABS unit with CAN

connection

DInspection the ECM pin 38, 37 about

short circuit or open with bad contact

DInspection the ECM

26CAN communication

failure: TCU (A/T only)

When CAN signal message

missing or implausibility for

TCU unit or not initialized

conditionDInspection the TCM unit with CAN

connection

DInspection the ECM pin 38, 37 about

short circuit or open with bad contact

DInspection the ECM

Page 507 of 2053

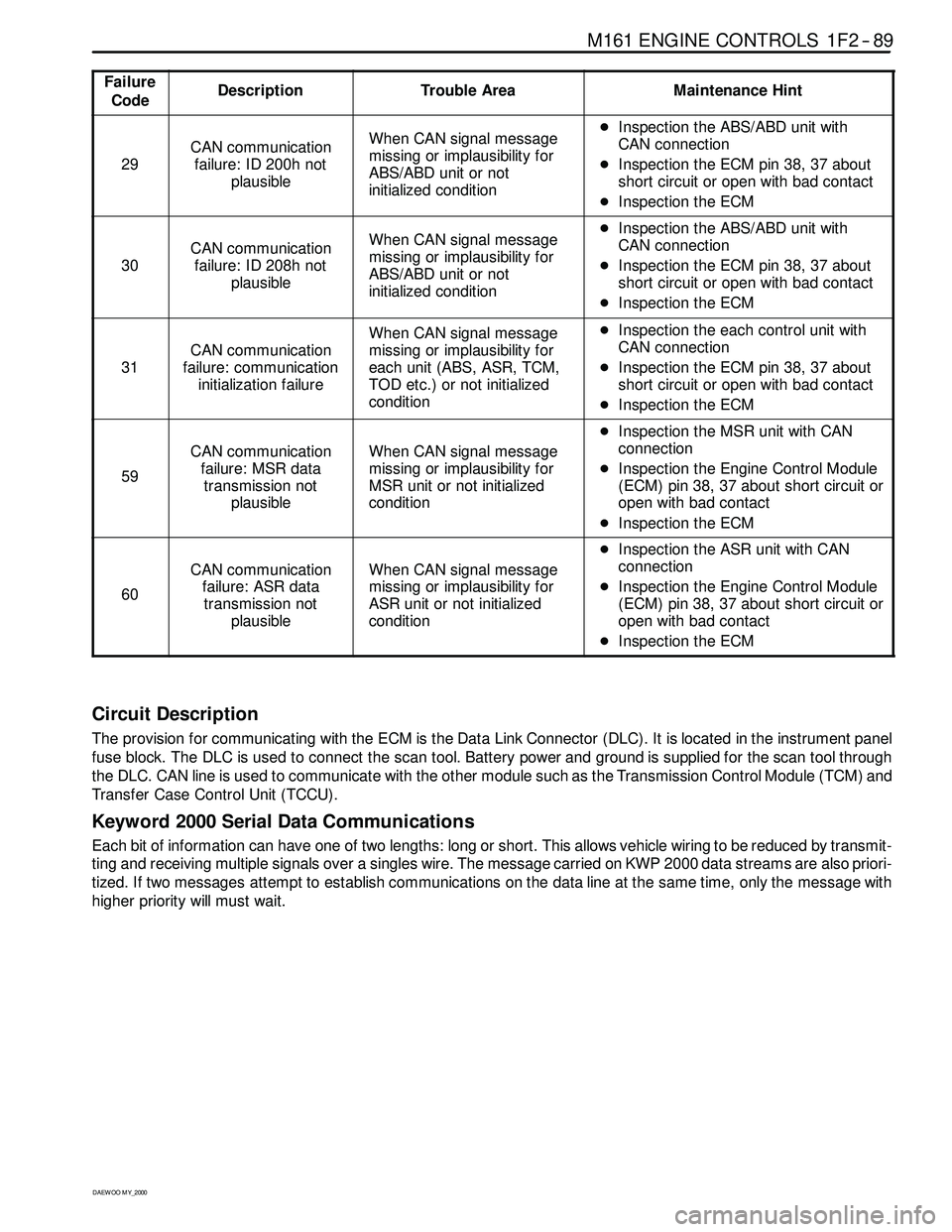

M161 ENGINE CONTROLS 1F2 -- 89

D AEW OO M Y_2000

Failure

CodeDescriptionTrouble AreaMaintenance Hint

29

CAN communication

failure: ID 200h not

plausibleWhen CAN signal message

missing or implausibility for

ABS/ABD unit or not

initialized conditionDInspection the ABS/ABD unit with

CAN connection

DInspection the ECM pin 38, 37 about

short circuit or open with bad contact

DInspection the ECM

30

CAN communication

failure: ID 208h not

plausibleWhen CAN signal message

missing or implausibility for

ABS/ABD unit or not

initialized conditionDInspection the ABS/ABD unit with

CAN connection

DInspection the ECM pin 38, 37 about

short circuit or open with bad contact

DInspection the ECM

31

CAN communication

failure: communication

initialization failure

When CAN signal message

missing or implausibility for

each unit (ABS, ASR, TCM,

TOD etc.) or not initialized

conditionDInspection the each control unit with

CAN connection

DInspection the ECM pin 38, 37 about

short circuit or open with bad contact

DInspection the ECM

59

CAN communication

failure: MSR data

transmission not

plausibleWhen CAN signal message

missing or implausibility for

MSR unit or not initialized

condition

DInspection the MSR unit with CAN

connection

DInspection the Engine Control Module

(ECM) pin 38, 37 about short circuit or

open with bad contact

DInspection the ECM

60

CAN communication

failure: ASR data

transmission not

plausibleWhen CAN signal message

missing or implausibility for

ASR unit or not initialized

condition

DInspection the ASR unit with CAN

connection

DInspection the Engine Control Module

(ECM) pin 38, 37 about short circuit or

open with bad contact

DInspection the ECM

Circuit Description

The provision for communicating with the ECM is the Data Link Connector (DLC). It is located in the instrument panel

fuse block. The DLC is used to connect the scan tool. Battery power and ground is supplied for the scan tool through

the DLC. CAN line is used to communicate with the other module such as the Transmission Control Module (TCM) and

Transfer Case Control Unit (TCCU).

Keyword 2000 Serial Data Communications

Each bit of information can have one of two lengths: long or short. This allows vehicle wiring to be reduced by transmit-

ting and receiving multiple signals over a singles wire. The message carried on KWP 2000 data streams are also priori-

tized. If two messages attempt to establish communications on the data line at the same time, only the message with

higher prioritywill must wait.

Page 508 of 2053

1F2 -- 90 M161 ENGINE CONTROLS

D AEW OO M Y_2000

INTERNAL FAILURE

Failure

CodeDescriptionTrouble AreaMaintenance Hint

21Transmission coding

failureWhen faulty of variant coding

of transmission

DInspection the coding condition

through scan tool

DInspection the Engine Control Module

(ECM)

DInspection the CAN line

DInspection the TCM

136ECM failure (RAM)

When malfunction of random

access memory -- ECM

internal error

DInspection the ECM

142Uncoded/ unprogramed

ECMWhen malfunction of ECM

coding-- required ECM

encoding

DFulfill the ECM variant coding

137ECM failure (EPROM)

143

ECM failure

(EEPROM/Flash -- EPPOM

checksum failure)

144ECM failure (coding ID

checksum failure)When malfunction of ECM

internalDInspection the ECM

145ECM failure (coding

checksum failure)

146ECM failure (programming

checksum failure)

Page 509 of 2053

M161 ENGINE CONTROLS 1F2 -- 91

D AEW OO M Y_2000

BLANK