engine SSANGYONG KORANDO 2012 Service Manual

[x] Cancel search | Manufacturer: SSANGYONG, Model Year: 2012, Model line: KORANDO, Model: SSANGYONG KORANDO 2012Pages: 1082, PDF Size: 96.1 MB

Page 459 of 1082

12-58530-00

2. CONFIGURATION

1) Circuit Diagram

The engine ECU detects the operating conditions of cruise control system, and monitors the braking

performance, vehicle speed, road conditions and ESP system operation. If the engine ECU determines

that there are not any problem to drive in cruise control mode, the vehicle can be operated by cruise

switch signals (decelerating, accelerating, cruising).

Page 461 of 1082

12-78530-00

3. OPERATION

1) Setting a Desired Speed

To operate the cruise control, accelerate to the desired speed, which must be more than 38 km/h (24

MPH) and less than 150 km/h (90 MPH). In the vehicle equipped with manual transaxle, the gear shift

lever should be in 3rd or higher gear position.

Diesel engine equipped vehicle: When the desired speed is reached, press CRUISE ON (3) switch of

cruise control lever.

Gasoline engine equipped vehicle: When the desired speed is reached, press CRUISE ON (3) switch

of cruise control lever. The system is ready to activate the cruise control function. To activate the cruise

control function, push up (1) the ACCEL switch of the cruise control lever or push down (2) the DECEL

switch.

Now, the vehicle is cruised by this system with the set speed.

And you can set to other vehicle speeds again with above steps after an accelerator pedal intervention

during the cruise control running. 1.

2.

3.

4.

Never use the cruise control system until you get used to it.

Improper use or not fully aware of this function could result in collision and/or personal injuries.

Page 465 of 1082

12-118530-00

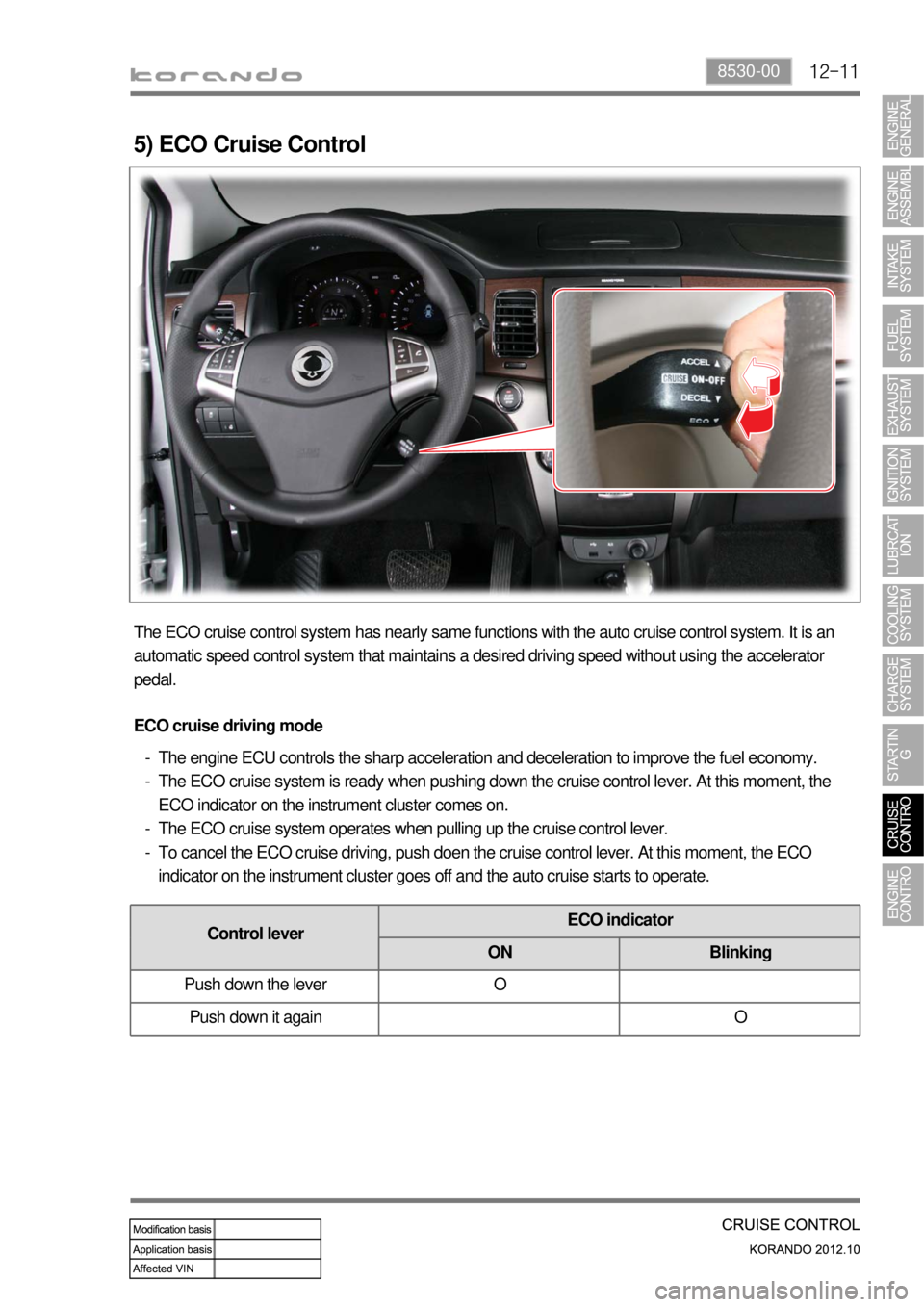

5) ECO Cruise Control

The ECO cruise control system has nearly same functions with the auto cruise control system. It is an

automatic speed control system that maintains a desired driving speed without using the accelerator

pedal.

ECO cruise driving mode

The engine ECU controls the sharp acceleration and deceleration to improve the fuel economy.

The ECO cruise system is ready when pushing down the cruise control lever. At this moment, the

ECO indicator on the instrument cluster comes on.

The ECO cruise system operates when pulling up the cruise control lever.

To cancel the ECO cruise driving, push doen the cruise control lever. At this moment, the ECO

indicator on the instrument cluster goes off and the auto cruise starts to operate. -

-

-

-

Control leverECO indicator

ON Blinking

Push down the lever O

Push down it again O

Page 467 of 1082

12-138530-00

Do not move the shift lever to Neutral position while driving with the cruise control turned on.

Otherwise, it may result in system malfunction or accidents.

Always be prepared to use the brake or accelerator pedal for safe driving while the cruise control

system is running.

The actual speed can be different from the set speed momentarily when driving on a uphill or

downhill. So, it is recommended to disable the cruise control function on a uphill or downhill. hen

driving on a steep hill use the engine brake and foot brake properly to protect the vehicle system

and for a safe driving.

Ensure that the safe distance is maintained and use the brake pedal if needed. 1.

2.

3.

4.

(1) Abnormal Cancellation of the Cruise Control

Sharp acceleration or deceleration

- 50 km/h faster than set speed

- 25 km/h faster than set speed for one minute

- 70 km/h slower than set speed

- 65 km/h slower than set speed for 3 minutes

When the cruise control lever is faulty.

When the brake switch and the brake light switch input signal are implausible. 1.

2.

3.

When the cruise control function is cancelled abnormally or intermittent problems occur, stop the vehicle

and turn off the ignition switch and remove the key to reset the system. After a while, turn on the ignition

switch again to operate the cruise control system.

Page 468 of 1082

15-31490-00

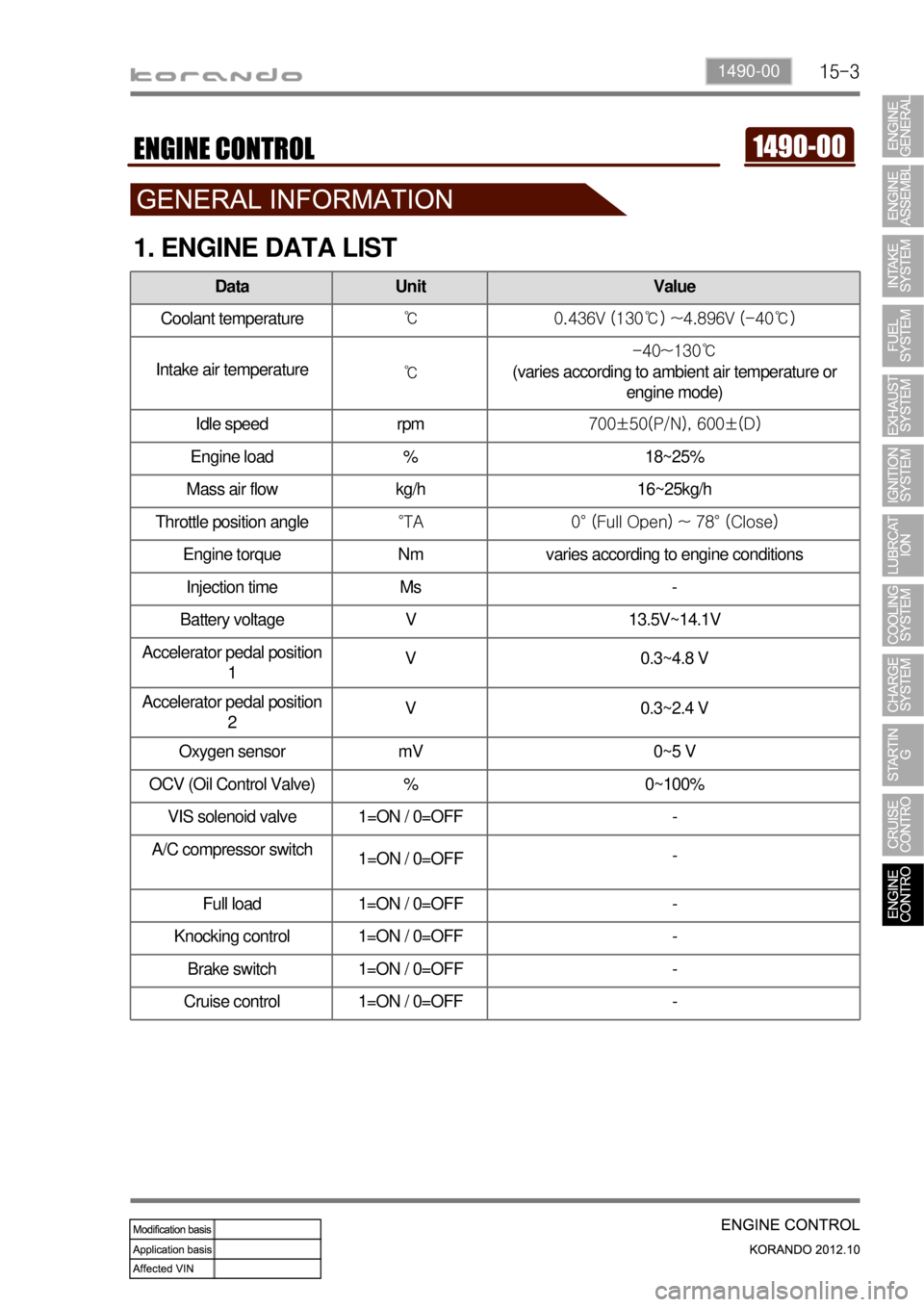

1. ENGINE DATA LIST

Data Unit Value

Coolant temperature℃ 0.436V (130℃) ~4.896V (-40℃)

Intake air temperature

℃-40~130℃

(varies according to ambient air temperature or

engine mode)

Idle speed rpm700±50(P/N), 600±(D)

Engine load % 18~25%

Mass air flow kg/h 16~25kg/h

Throttle position angle°TA 0° (Full Open) ~ 78° (Close)

Engine torque Nm varies according to engine conditions

Injection time Ms -

Battery voltage V 13.5V~14.1V

Accelerator pedal position

1V 0.3~4.8 V

Accelerator pedal position

2V 0.3~2.4 V

Oxygen sensor mV 0~5 V

OCV (Oil Control Valve) % 0~100%

VIS solenoid valve 1=ON / 0=OFF -

A/C compressor switch

1=ON / 0=OFF-

Full load 1=ON / 0=OFF -

Knocking control 1=ON / 0=OFF -

Brake switch 1=ON / 0=OFF -

Cruise control 1=ON / 0=OFF -

Page 470 of 1082

15-50000-00

Purge control

solenoid valve

G20DF engine

ECUCoolant Temp

sensorCamshaft position

sensor

Crankshaft position

sensor

T-MAP sensorVIS solenoid valveElectronic throttle

bodyMagnetic trigger

ring

Front oxygen

sensor

Page 472 of 1082

15-70000-00

Rear oxygen

sensor

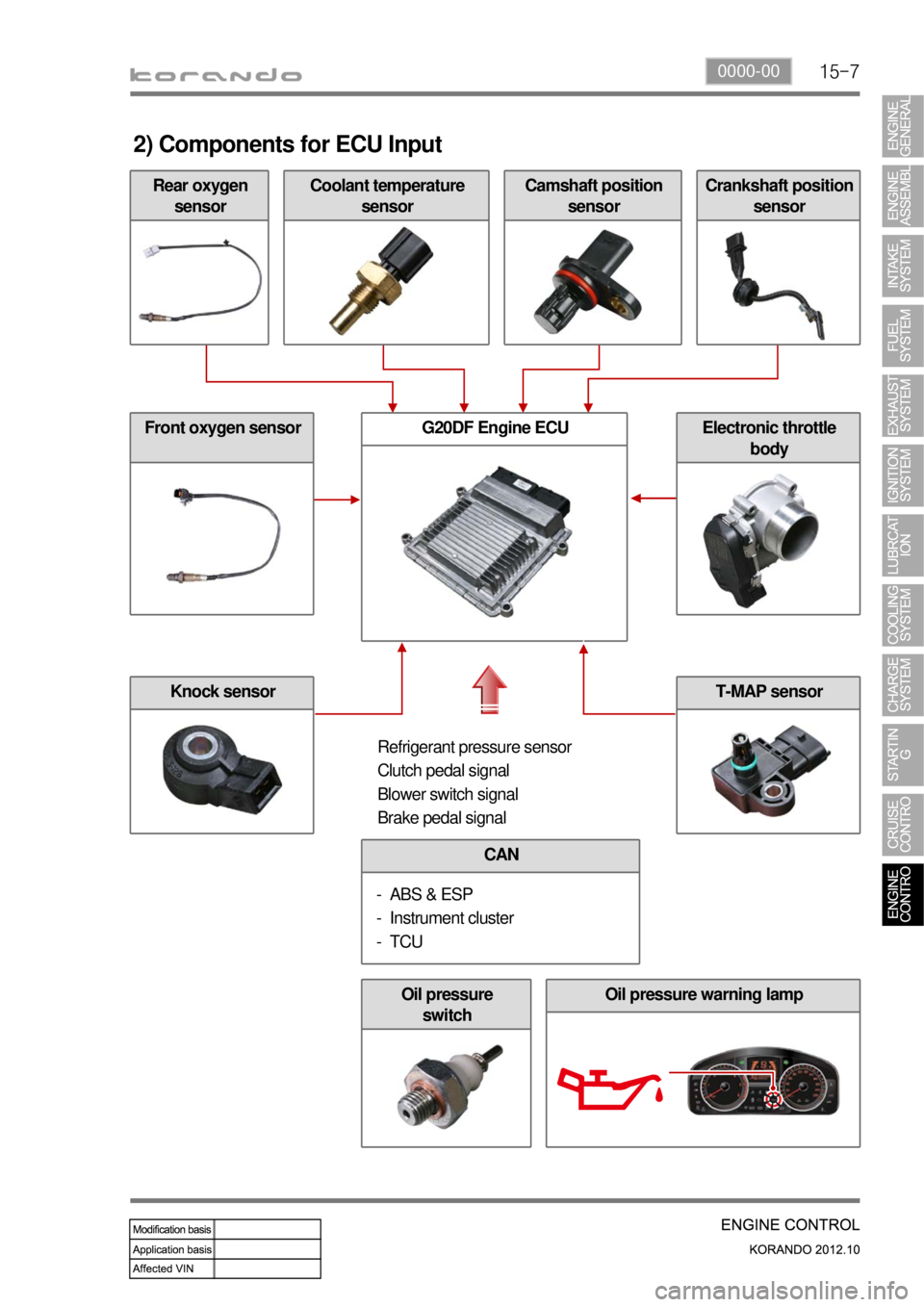

2) Components for ECU Input

Coolant temperature

sensorCamshaft position

sensorCrankshaft position

sensor

Front oxygen sensor

Knock sensor

G20DF Engine ECUElectronic throttle

body

Refrigerant pressure sensor

Clutch pedal signal

Blower switch signal

Brake pedal signal

CAN

ABS & ESP

Instrument cluster

TCU -

-

-

Oil pressure

switchOil pressure warning lamp

T-MAP sensor

Page 473 of 1082

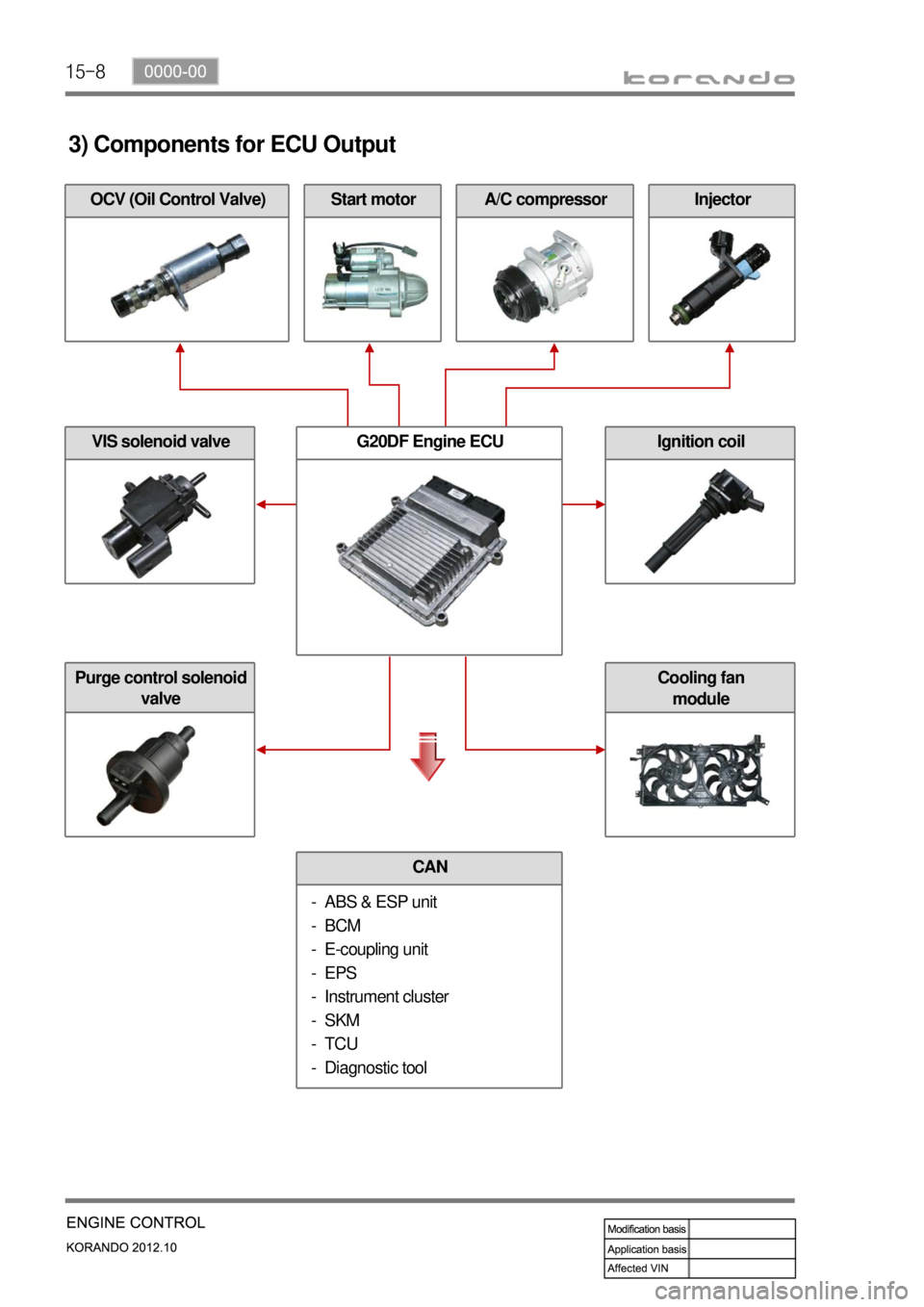

15-8

A/C compressorOCV (Oil Control Valve)

3) Components for ECU Output

Start motorInjector

VIS solenoid valve

Purge control solenoid

valve

G20DF Engine ECUIgnition coil

CAN

ABS & ESP unit

BCM

E-coupling unit

EPS

Instrument cluster

SKM

TCU

Diagnostic tool -

-

-

-

-

-

-

-

Cooling fan

module

Page 474 of 1082

15-91490-00

3. ECU CONTROL

1) Functions

ECU receives and analyzes signals from various sensors and then modifies those signals into

permissible voltage levels and analyzes to control respective actuators.

ECU microprocessor calculates injection period and injection timing proper for engine piston speed and

crankshaft angle based on input data and stored specific map to control the engine power and emission

gas.

Output signal of the ECU microprocessor activates the injector solenoid valve to control the fuel injection

period and injection timing; so controls various actuators in response to engine changes.

Auxiliary function of ECU has adopted to reduce emission gas, improve fuel economy and enhance

safety, comforts and conveniences. For example, there are autocruise and immobilizer and adopted

CAN communication to exchange data among electrical systems (automatic T/M and brake system) in

the vehicle fluently. And the diagnostic tool can be used to diagnose vehicle status and defectives.

<00760097008c00990088009b00900095008e0047009b008c00940097008c00990088009b009c0099008c0047009900880095008e008c00470096008d0047006c006a007c00470090009a0047009500960099009400880093009300a000470054005b005700

47009b009600470052005f005c00b6006a004700880095008b> protected from factors like oil,

water and electromagnetism and there should be no mechanical shocks.

2) Control Functions

Controls by operating stages:

To make optimum combustion under every operating stage, ECU should calculate proper injection

volume in each stage by considering various factors.

Starting injection volume control:

During initial starting, injecting fuel volume will be calculated by function of temperature and engine

cranking speed. Starting injection continues from when the ignition switch is turned to ignition

position to till the engine reaches to allowable minimum speed.

Driving mode control:

If the vehicle runs normally, fuel injection volume will be calculated by accelerator pedal travel and

engine rpm and the drive map will be used to match the drivers inputs with optimum engine power. -

-

-

Page 475 of 1082

15-10

3) Injection Volume Control

(1) Overview

To keep the best engine conditions and to reduce the emission gas, ECU determines the injection

volume and timing.

(2) Components

Input Components ▶

Accelerator pedal

position sensorFront oxygen

sensorCoolant temperature

sensorCrankshaft position

sensor

Camshaft position

sensorKnock sensorT-MAP sensorElectronic throttle

body

Output Components ▶