engine SSANGYONG KORANDO 2012 Service Manual

[x] Cancel search | Manufacturer: SSANGYONG, Model Year: 2012, Model line: KORANDO, Model: SSANGYONG KORANDO 2012Pages: 1082, PDF Size: 96.1 MB

Page 478 of 1082

15-130000-00

Coolant temperature

sensor

4) Ignition System Control

(1) Overview

G20DF engine is equipped with the single ignition system. Each spark plug is operated independently

by the ECU and one ignition coil and spark plug are provided for each cylinder.

(2) Components

Input Components ▶

Crankshaft position

sensorAccelerator pedal position

sensor

Knock sensorCamshaft position

sensorElectronic

throttle body

Output Components ▶

Page 480 of 1082

15-150000-00

(4) Features

Determines the ignition timing according to input signal

The ECU always analyzes the following elements when determining the ignition timing. 1.

Crankshaft position sensor

Camshaft position sensor

Coolant temperature sensor

Intake air temperature/air mass -

-

-

-

Warm-up of catalytic converter

The ignition timing is retarded for about 20 seconds to operate the catalytic converter according to the

operating temperature under the following conditions: 2.

<007b008f008c0047008a00960096009300880095009b0047009b008c00940097008c00990088009b009c0099008c00470090009a00470058005c00b6006a004700a50047005b005700b6006a00470088009b0047009a009b00880099009b00900095008e00

55>

The idle speed is increased by the idle speed control to help warming up of the catalytic converter -

-

Idle speed control

<007b008f008c00470090008e00950090009b0090009600950047009b0090009400900095008e0047008a0088009500470089008c00470099008c009b00880099008b008c008b0047009c00970047009b00960047005a005d00b60047009600990047008800

8b009d00880095008a008c008b0047009c00970047009b0096> 20˚ to help idle speed control.

The ignition timing control can be performed faster than the control through the throttle valve.

Fuel cut-off in deceleration

The ignition timing is retarded temporarily to prevent abrupt increase of the torque when the

combustion is restarted.

Intake air temperature/coolant temperature

The ignition timing is retarded to prevent knocking if the intake air temperature or coolant temperature

is high. The ignition timing is retarded in the following cases. 3.

4.

5.

The intake air temperature is above 30°C.

The coolant temperature is above 105°C. -

-

The ignition timing retard for intake air temperature and for coolant temperature is added up for

correction.

ESP/ASR control mode

The ignition timing is retarded to reduce engine torque as fast as possible under the ESP/ASR

control mode.

Knocking control

If knocking occurs in the cylinder, the ignition angle of the corresponding cylinder is retarded. The

coolant temperature is 15˚C to 40˚C when starting. 6.

7.

Page 482 of 1082

15-170000-00

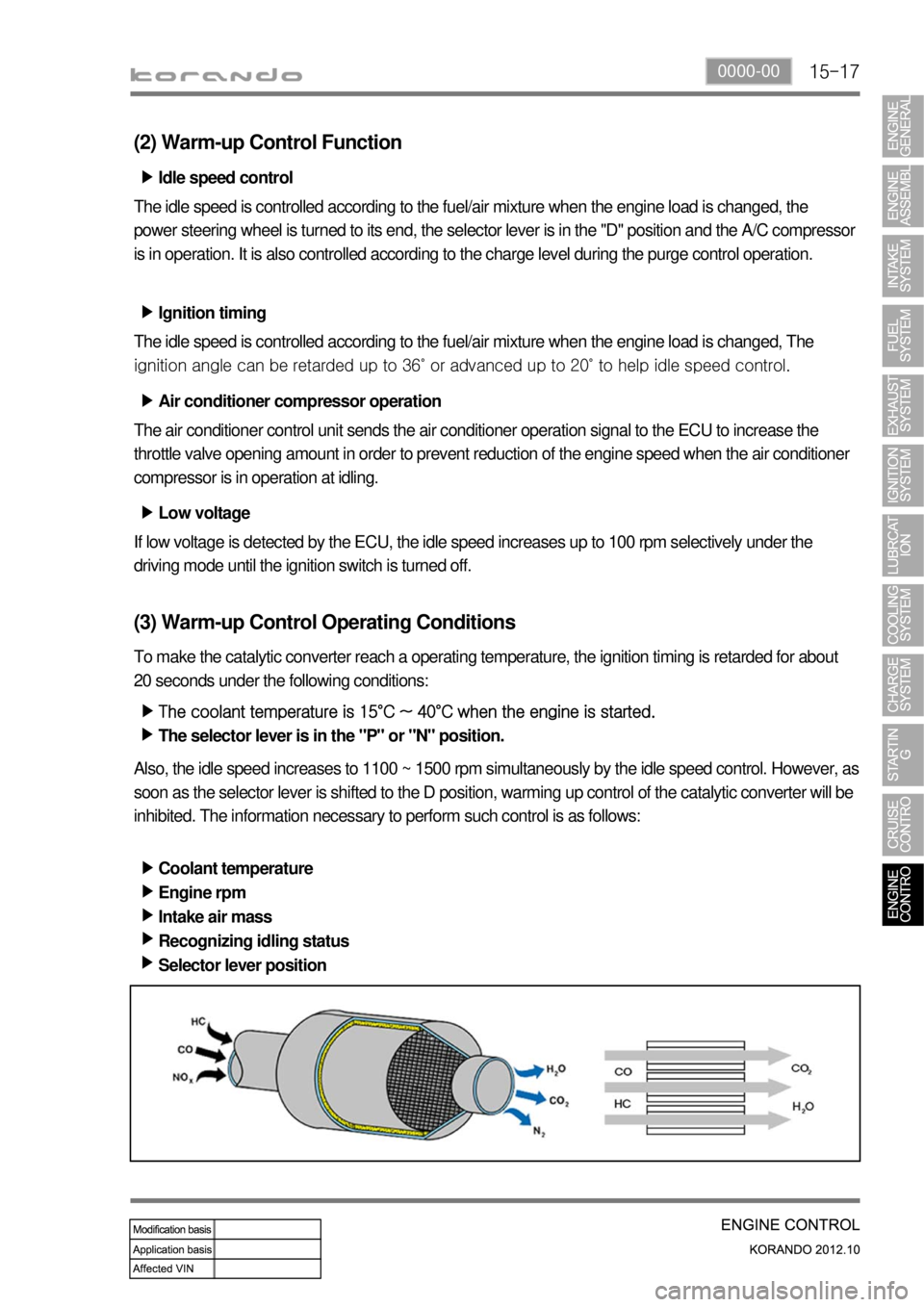

(2) Warm-up Control Function

Low voltage ▶

If low voltage is detected by the ECU, the idle speed increases up to 100 rpm selectively under the

driving mode until the ignition switch is turned off. Idle speed control ▶

The idle speed is controlled according to the fuel/air mixture when the engine load is changed, the

power steering wheel is turned to its end, the selector lever is in the "D" position and the A/C compresso

r

is in operation. It is also controlled according to the charge level during the purge control operation.

Ignition timing ▶

The idle speed is controlled according to the fuel/air mixture when the engine load is changed, The

<0090008e00950090009b009000960095004700880095008e0093008c0047008a0088009500470089008c00470099008c009b00880099008b008c008b0047009c00970047009b00960047005a005d020b00470096009900470088008b009d00880095008a00

8c008b0047009c00970047009b0096004700590057020b0047>to help idle speed control.

Air conditioner compressor operation ▶

The air conditioner control unit sends the air conditioner operation signal to the ECU to increase the

throttle valve opening amount in order to prevent reduction of the engine speed when the air conditioner

compressor is in operation at idling.

(3) Warm-up Control Operating Conditions

To make the catalytic converter reach a operating temperature, the ignition timing is retarded for about

20 seconds under the following conditions:

The coolant temperature is 15°C ~ 40°C when the engine is started.

The selector lever is in the "P" or "N" position. ▶

▶

Also, the idle speed increases to 1100 ~ 1500 rpm simultaneously by the idle speed control. However, as

soon as the selector lever is shifted to the D position, warming up control of the catalytic converter will be

inhibited. The information necessary to perform such control is as follows:

Coolant temperature

Engine rpm

Intake air mass

Recognizing idling status

Selector lever position ▶

▶

▶

▶

▶

Page 483 of 1082

15-18

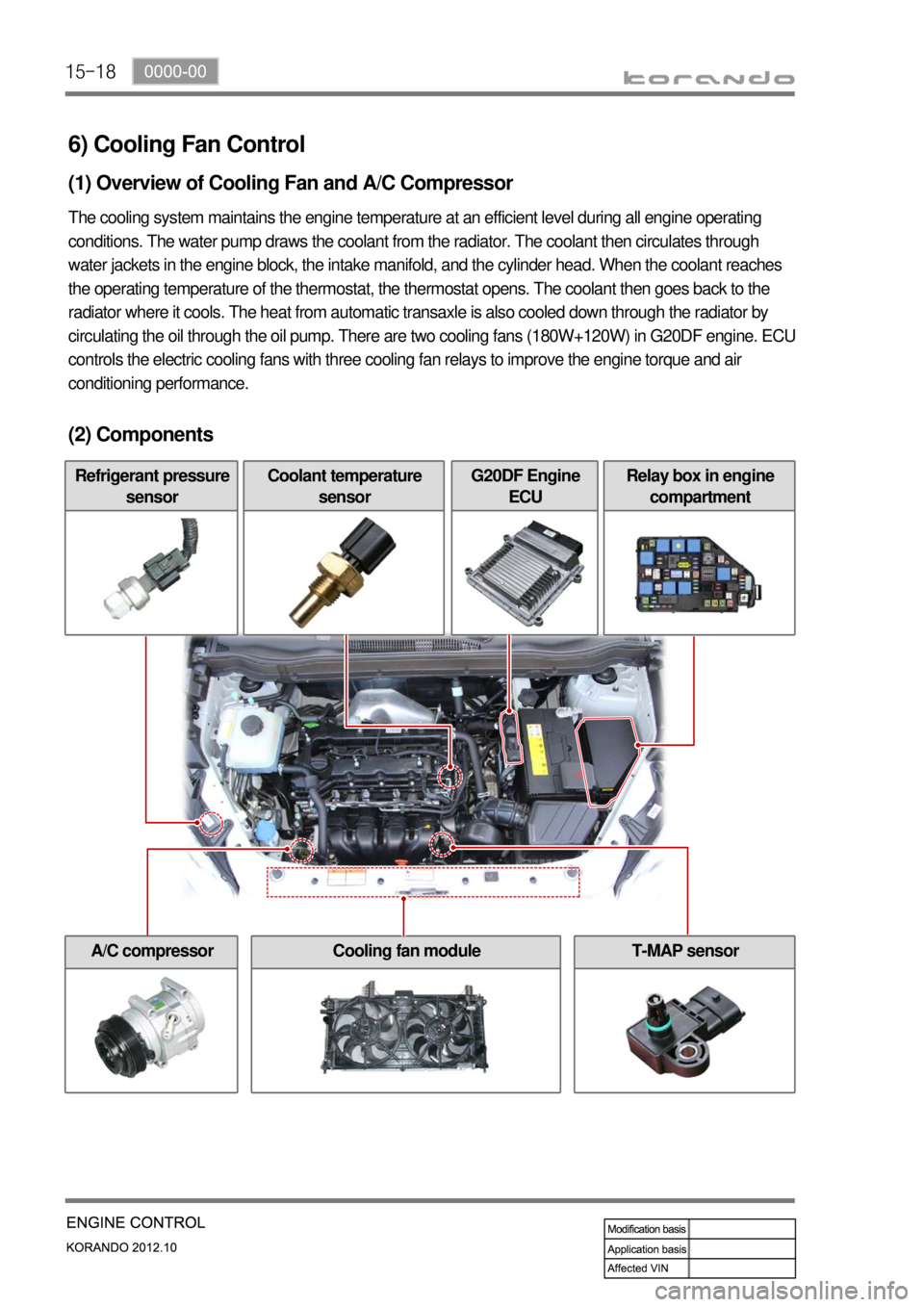

6) Cooling Fan Control

(1) Overview of Cooling Fan and A/C Compressor

The cooling system maintains the engine temperature at an efficient level during all engine operating

conditions. The water pump draws the coolant from the radiator. The coolant then circulates through

water jackets in the engine block, the intake manifold, and the cylinder head. When the coolant reaches

the operating temperature of the thermostat, the thermostat opens. The coolant then goes back to the

radiator where it cools. The heat from automatic transaxle is also cooled down through the radiator by

circulating the oil through the oil pump. There are two cooling fans (180W+120W) in G20DF engine. ECU

controls the electric cooling fans with three cooling fan relays to improve the engine torque and air

conditioning performance.

(2) Components

Refrigerant pressure

sensorCoolant temperature

sensorG20DF Engine

ECURelay box in engine

compartment

A/C compressorCooling fan moduleT-MAP sensor

Page 485 of 1082

15-20

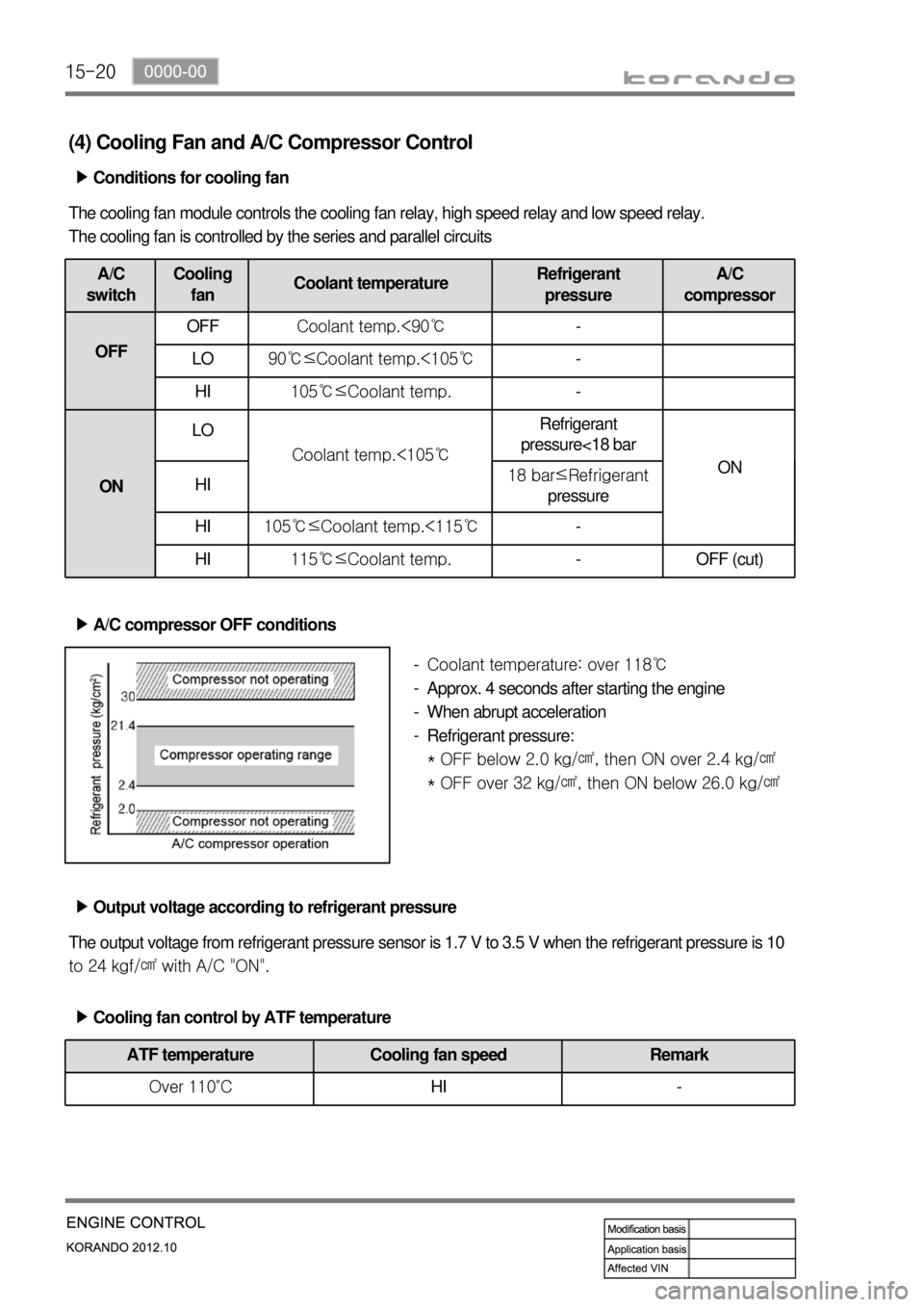

(4) Cooling Fan and A/C Compressor Control

Conditions for cooling fan ▶

The cooling fan module controls the cooling fan relay, high speed relay and low speed relay.

The cooling fan is controlled by the series and parallel circuits

A/C

switchCooling

fanCoolant temperatureRefrigerant

pressureA/C

compressor

OFFOFFCoolant temp.<90℃-

LO90℃≤Coolant temp.<105℃-

HI105℃≤Coolant temp.-

ONLO

Coolant temp.<105℃Refrigerant

pressure<18 bar

ON

HI18 bar≤Refrigerant

pressure

HI105℃≤Coolant temp.<115℃-

HI115℃≤Coolant temp.- OFF (cut)

A/C compressor OFF conditions ▶

Coolant temperature: over 118℃

Approx. 4 seconds after starting the engine

When abrupt acceleration

Refrigerant pressure:

* OFF below 2.0 kg/㎠, then ON over 2.4 kg/㎠

* OFF over 32 kg/㎠, then ON below 26.0 kg/㎠ -

-

-

-

Output voltage according to refrigerant pressure ▶

The output voltage from refrigerant pressure sensor is 1.7 V to 3.5 V when the refrigerant pressure is 10

to 24 kgf/㎠ with A/C "ON".

Cooling fan control by ATF temperature ▶

ATF temperature Cooling fan speed Remark

Over 110˚CHI -

Page 486 of 1082

15-210000-00

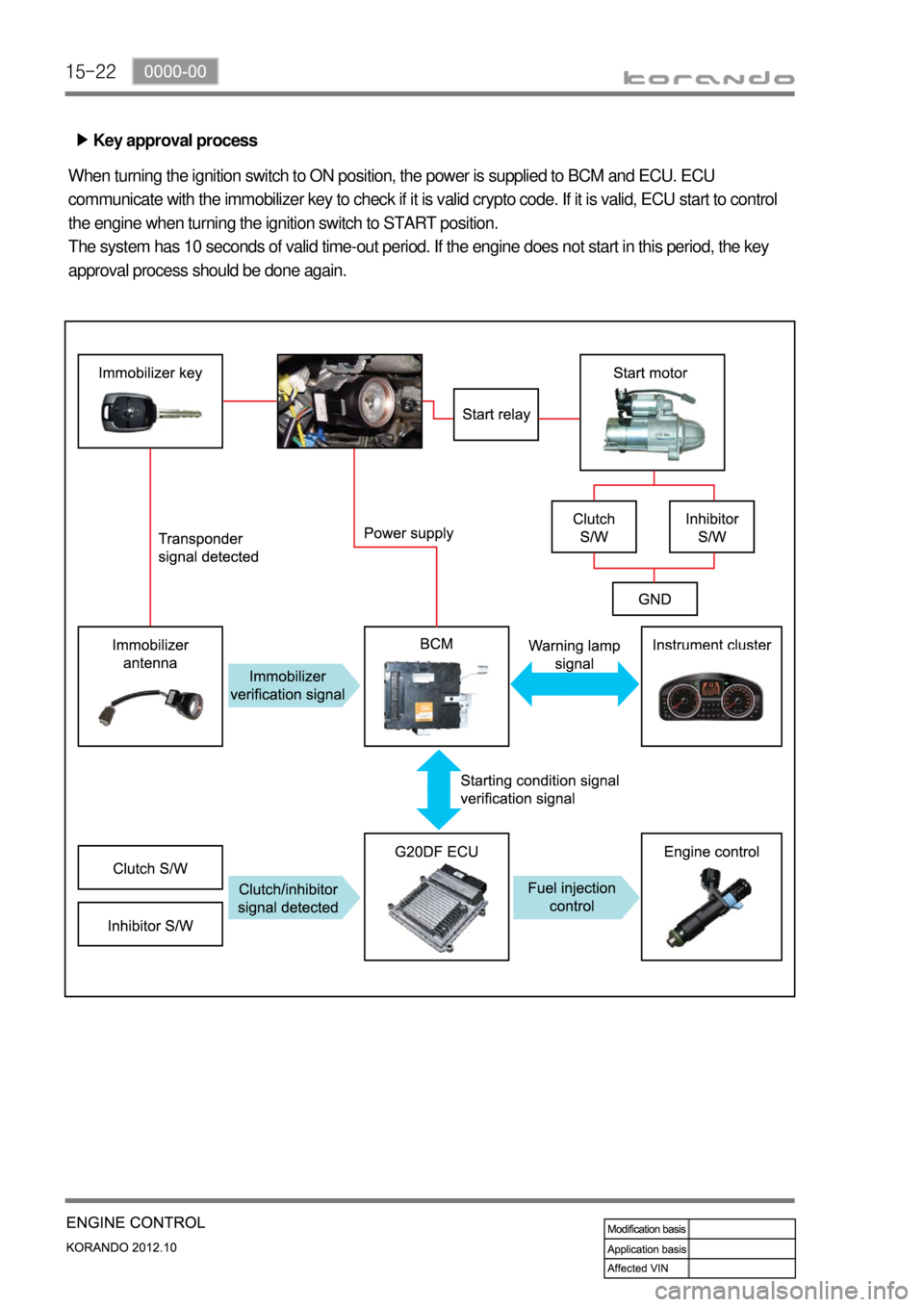

7) Immobilizer Control

(1) Overview

The Immobilizer System provides an additional theft deterrent to the vehicle in which it is installed and

prevents it from being started by unauthorized persons. The transponder integrated in the key and the

engine control unit have the same code. When the ignition key with the integrated transponder is turned

to the ON position, the ECU (Engine Control Unit) checks the crypto code of the key and, if correct,

allows the vehicle to start the engine.

For details, refer to Chapter "BCM".

(2) Components

Conditions for cooling fan ▶

Immobilizer

antenna

Immobilizer

key

Start motor

Instrument

cluster

BCM

G20DF ECU

Page 487 of 1082

15-22

Key approval process ▶

When turning the ignition switch to ON position, the power is supplied to BCM and ECU. ECU

communicate with the immobilizer key to check if it is valid crypto code. If it is valid, ECU start to control

the engine when turning the ignition switch to START position.

The system has 10 seconds of valid time-out period. If the engine does not start in this period, the key

approval process should be done again.

Page 489 of 1082

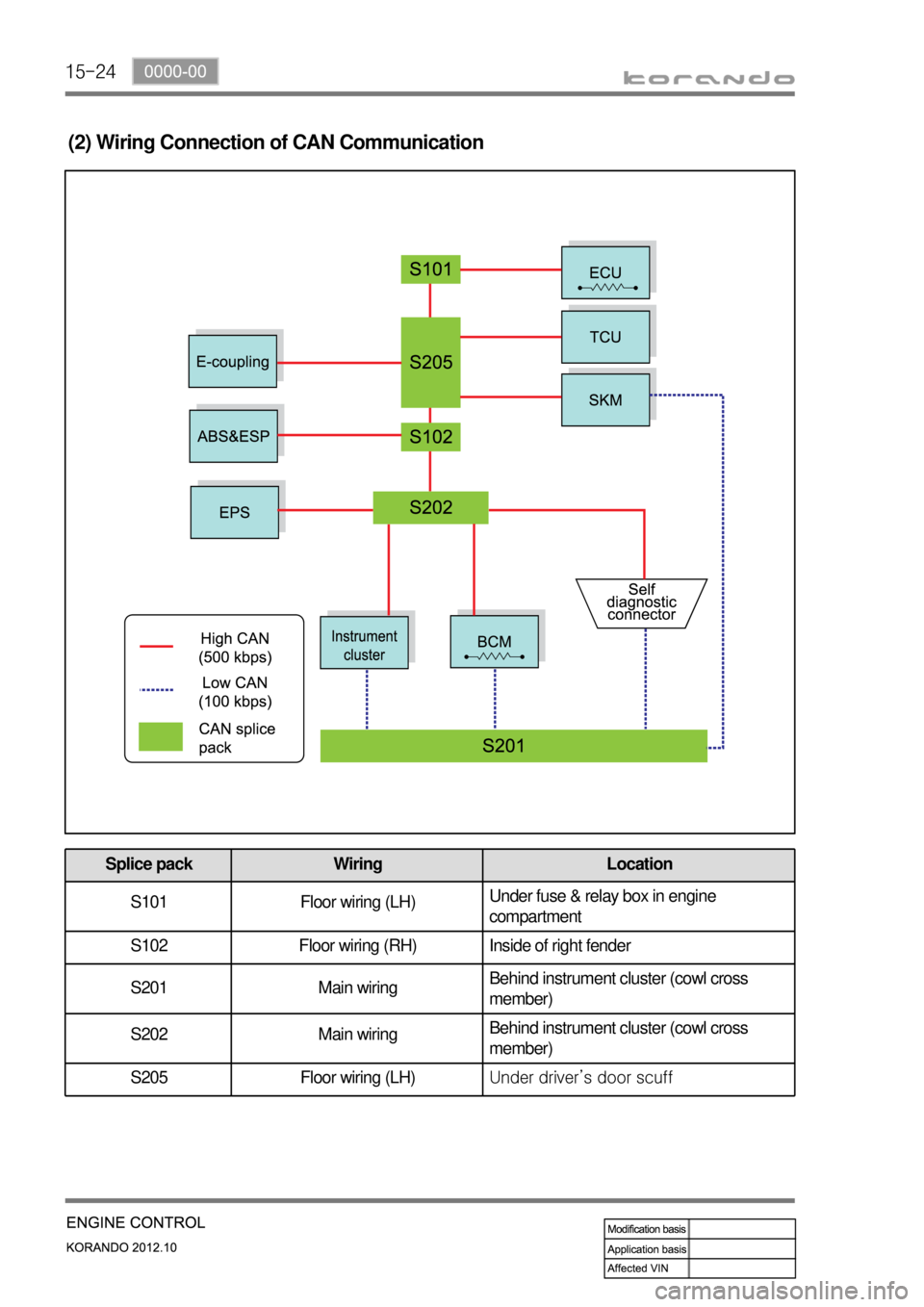

15-24

(2) Wiring Connection of CAN Communication

Splice pack Wiring Location

S101 Floor wiring (LH)Under fuse & relay box in engine

compartment

S102 Floor wiring (RH) Inside of right fender

S201 Main wiringBehind instrument cluster (cowl cross

member)

S202 Main wiringBehind instrument cluster (cowl cross

member)

S205 Floor wiring (LH)Under driver’s door scuff

Page 492 of 1082

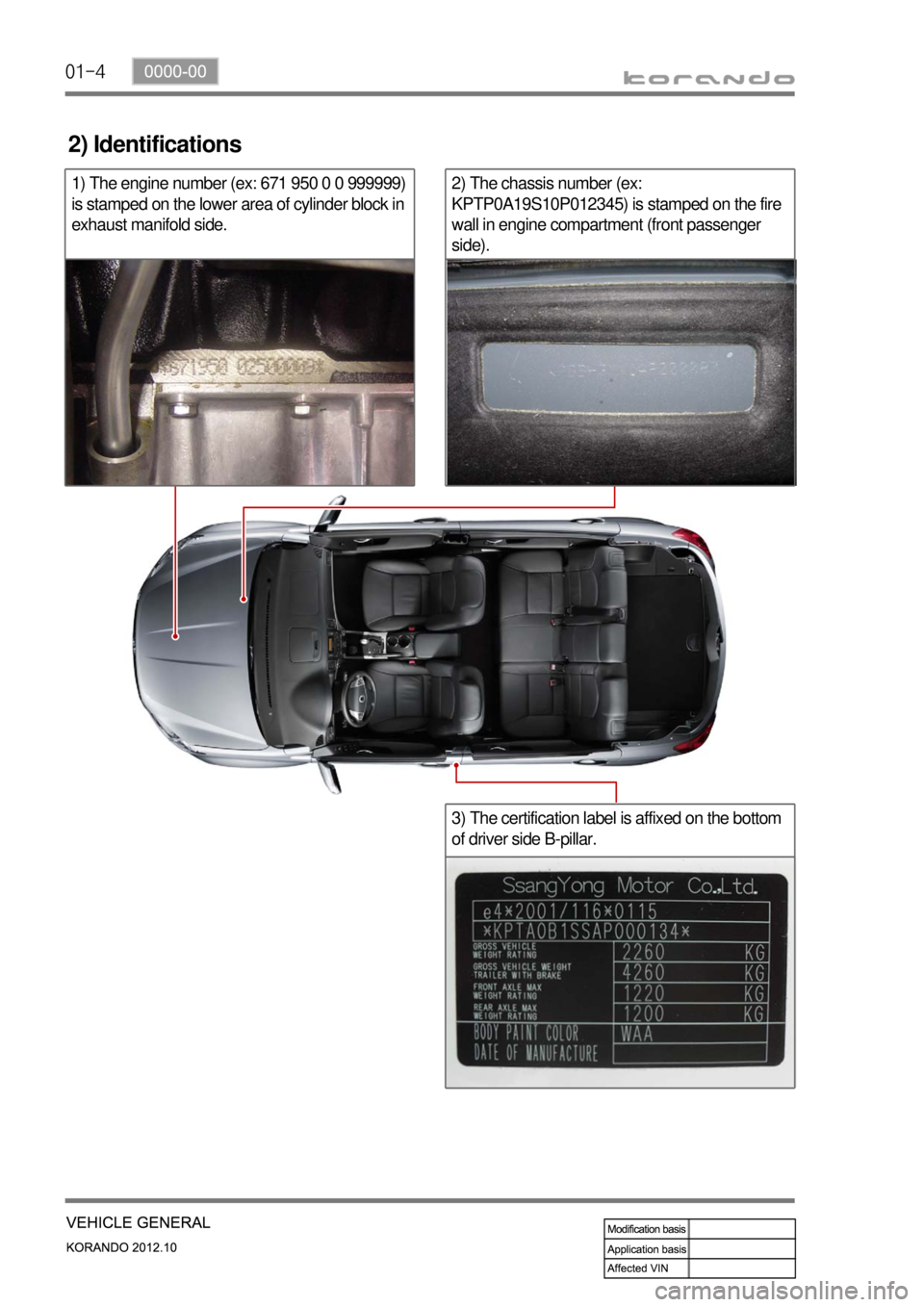

01-4

2) Identifications

2) The chassis number (ex:

KPTP0A19S10P012345) is stamped on the fire

wall in engine compartment (front passenger

side).1) The engine number (ex: 671 950 0 0 999999)

is stamped on the lower area of cylinder block in

exhaust manifold side.

3) The certification label is affixed on the bottom

of driver side B-pillar.

Page 493 of 1082

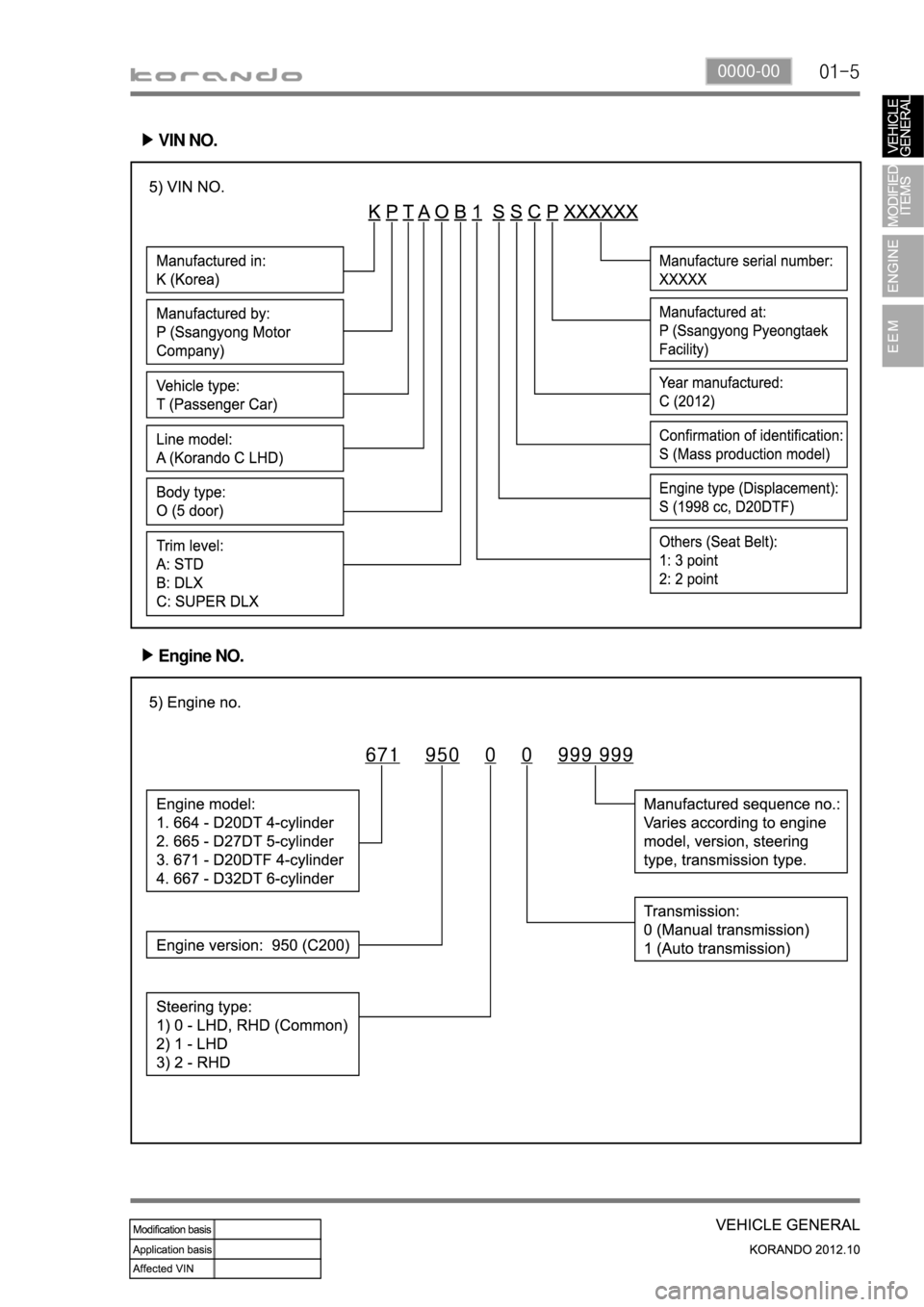

01-50000-00

VIN NO. ▶

Engine NO. ▶