SSANGYONG KORANDO 2012 Workshop Manual

KORANDO 2012

SSANGYONG

SSANGYONG

https://www.carmanualsonline.info/img/67/57504/w960_57504-0.png

SSANGYONG KORANDO 2012 Workshop Manual

Page 316 of 1082

15-40

Meter clusterImmobilizer

antenna

(10) Immobilizer control

a. Overview

The Immobilizer System provides an additional theft deterrent to the vehicle in which it is installed and

prevents it from being started by unauthorized persons. The transponder integrated in the key and the

engine control unit have the same code. When the ignition key with the integrated transponder is turned

to the ON position, the ECU (Engine Control Unit) checks the crypto code of the key and, if correct,

allows the vehicle to start the engine.

For details, refer to Chapter "BCM".

b. Components

Basic components (ignition key system) ▶

Immobilizer key

Start motor

BCM

ECU

D20DTF

Page 317 of 1082

15-410000-00

Key approval process ▶

When turning the ignition switch to ON position, the power is supplied to BCM and ECU. ECU

communicate with the immobilizer key to check if it is valid crypto code. If it is valid, ECU start to control

the engine when turning the ignition switch to START position.

The system has 10 seconds of valid time-out period. If the engine does not start in this period, the key

approval process should be done again.

Page 318 of 1082

15-42

c. Components for immobilizer with Smart key system

Components (For antenna, refer to Chapter “SKM”) ▶

Smart key slot

Smart key

Start motor

Meter

cluster

BCM

SKMD20DTF

ECU

Page 319 of 1082

15-430000-00

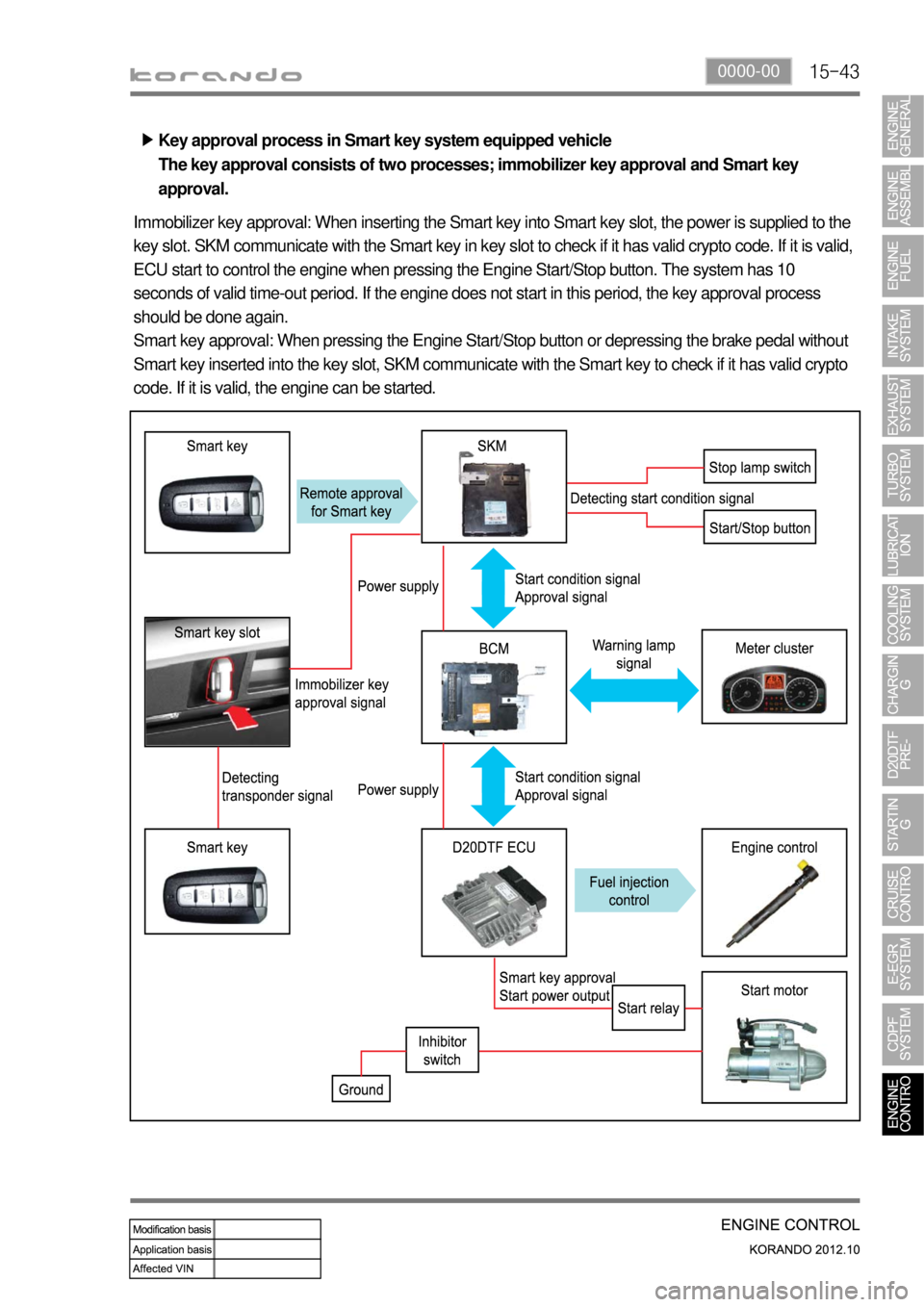

Key approval process in Smart key system equipped vehicle

The key approval consists of two processes; immobilizer key approval and Smart key

approval. ▶

Immobilizer key approval: When inserting the Smart key into Smart key slot, the power is supplied to the

key slot. SKM communicate with the Smart key in key slot to check if it has valid crypto code. If it is valid,

ECU start to control the engine when pressing the Engine Start/Stop button. The system has 10

seconds of valid time-out period. If the engine does not start in this period, the key approval process

should be done again.

Smart key approval: When pressing the Engine Start/Stop button or depressing the brake pedal without

Smart key inserted into the key slot, SKM communicate with the Smart key to check if it has valid crypto

code. If it is valid, the engine can be started.

Page 320 of 1082

15-44

Front temp. sensor

(11) CDPF control

a. Overview

As the solution for environmental regulations and PM Particle Material) of diesel engine, the low emission

vehicle is getting popular. This vehicle is equipped with an extra filter to collect the soot and burn it again

so that the amount of PM in the exhaust gas passed through the DOC (Diesel Oxidation Catalyst) is

reduced. The CDPF (Catalyst & Diesel Particulate Filter) is an integrated filter including DOC (Diesel

Oxidation Catalyst) and DPF (Diesel Particulate Filter).

For details, refer to Chapter "CDPF".

b. Components

Rear temp. sensorCDPF (DOC+DPF)

Throttle valveD20DTF ECUDifferential pres.

sensorOxygen sensor

Page 322 of 1082

15-46

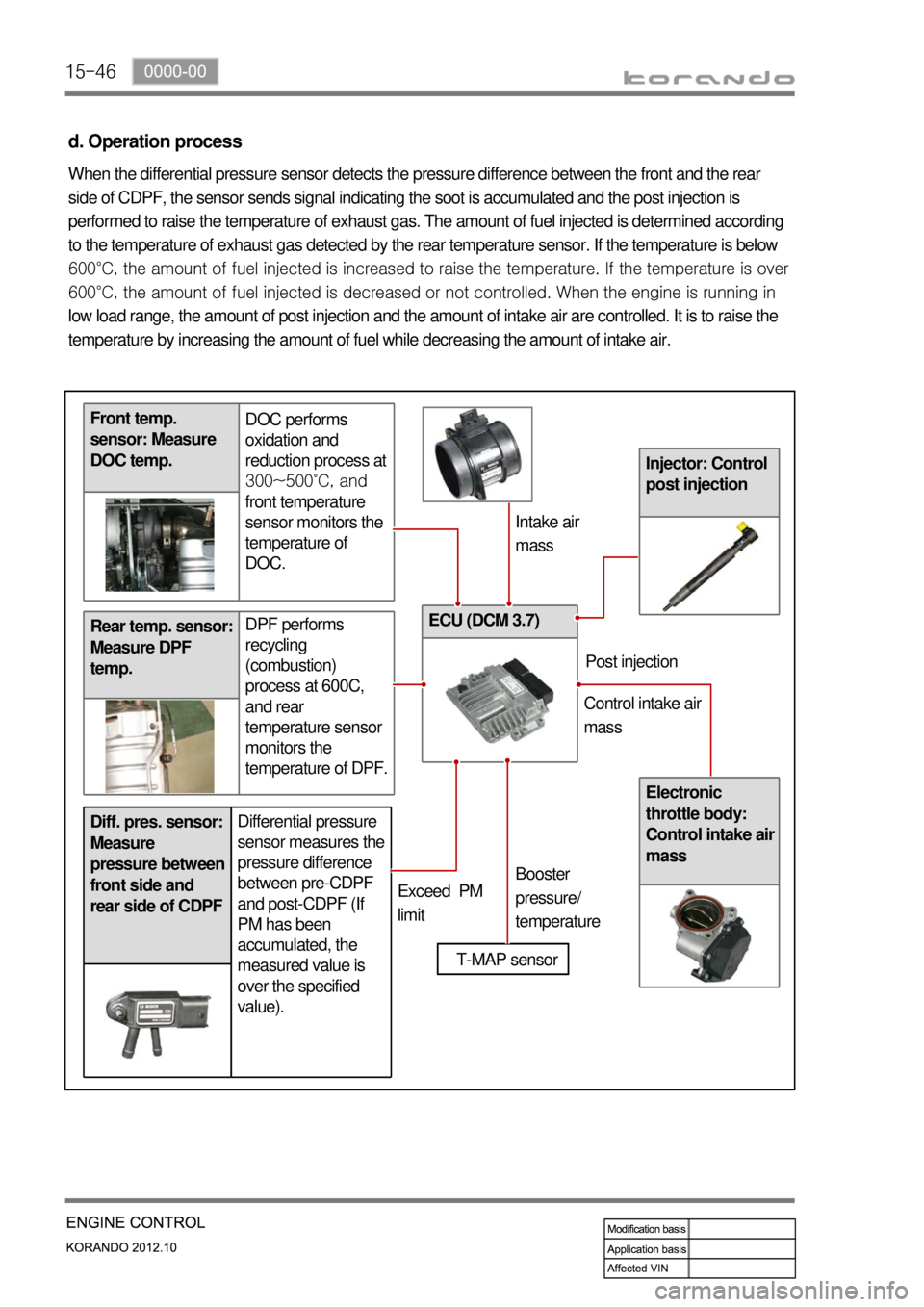

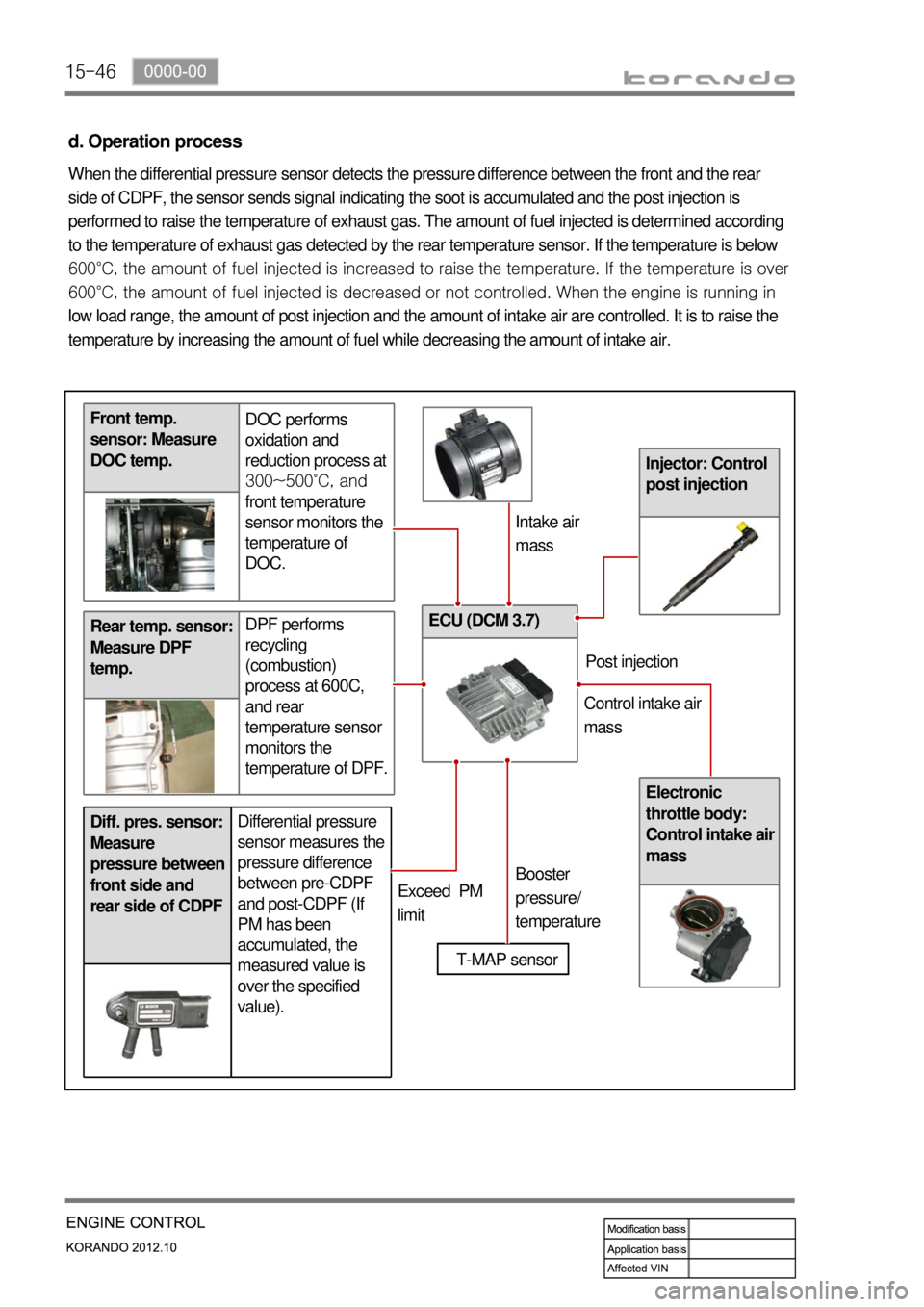

Rear temp. sensor:

Measure DPF

temp.DPF performs

recycling

(combustion)

process at 600C,

and rear

temperature sensor

monitors the

temperature of DPF.

Differential pressure

sensor measures the

pressure difference

between pre-CDPF

and post-CDPF (If

PM has been

accumulated, the

measured value is

over the specified

value).Diff. pres. sensor:

Measure

pressure between

front side and

rear side of CDPF

Injector: Control

post injection

Front temp.

sensor: Measure

DOC temp.DOC performs

oxidation and

reduction process at

300~500˚C, and

front temperature

sensor monitors the

temperature of

DOC.

Electronic

throttle body:

Control intake ai

r

mass

ECU (DCM 3.7)

d. Operation process

When the differential pressure sensor detects the pressure difference between the front and the rear

side of CDPF, the sensor sends signal indicating the soot is accumulated and the post injection is

performed to raise the temperature of exhaust gas. The amount of fuel injected is determined according

to the temperature of exhaust gas detected by the rear temperature sensor. If the temperature is below

600°C, the amount of fuel injected is increased to raise the tem

perature. If the temperature is over

600°C, the amount of fuel injected is decreased or not controlled. When the engine is running in

low load range, the amount of post injection and the amount of intake air are controlled. It is to raise the

temperature by increasing the amount of fuel while decreasing the amount of intake air.

T-MAP sensor

Intake air

mass

Exceed PM

limitBooster

pressure/

temperaturePost injection

Control intake air

mass

Page 324 of 1082

15-48

3) Input/Output for CAN communication

(1) Configuration of CAN (P-CAN/B-CAN)

CAN Topology communicate with system units. There are two types (P-CAN and B-CAN) of

communication according to the communication speed. Instrument cluster, BCM and diagnostic

connector use both types of communication. And, ECU, ABS & ESP, TCU, GCU, E-coupling and EPS

unit use P-CAN communication because it is faster than B-CAN. The terminal resistances are installed in

ECU and BCM.

Abbreviation Function

GCU Glow Control Unit

EPS Electronic Power Steering Unit

BCM Body Control Module

Page 336 of 1082

01-12

4. CODING AND SETUP

1) Engine Variant Coding

Description Coding

Vehicle speed input to ECUCAN

with ABS or ESP: CAN

WIRE

Fan3 Relays

3 Relays

PWM fan

Auto cruiseNO

with Auto cruise system: YES

YES

Engine level controlNO

without Engine level control system: NO

(Korando)

YES

G-sensorNO

with 2WD ABS and non-ABS: NO

with 4WD ABS and ESP: YES

YES

Smart keyNO

with Smart key: YES

YES

Page 337 of 1082

01-130000-00

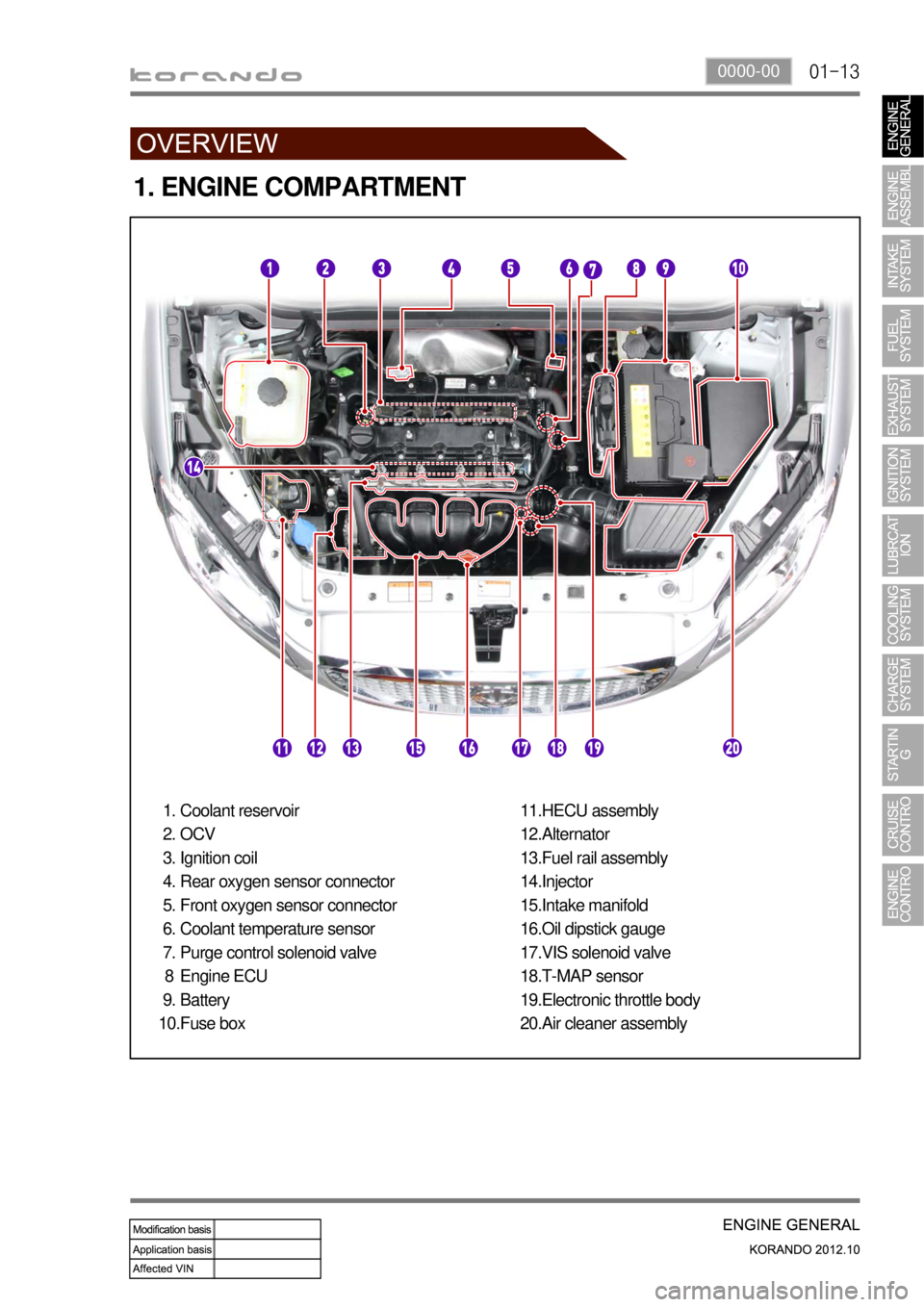

1. ENGINE COMPARTMENT

Coolant reservoir

OCV

Ignition coil

Rear oxygen sensor connector

Front oxygen sensor connector

Coolant temperature sensor

Purge control solenoid valve

Engine ECU

Battery

Fuse box 1.

2.

3.

4.

5.

6.

7.

8

9.

10.HECU assembly

Alternator

Fuel rail assembly

Injector

Intake manifold

Oil dipstick gauge

VIS solenoid valve

T-MAP sensor

Electronic throttle body

Air cleaner assembly 11.

12.

13.

14.

15.

16.

17.

18.

19.

20.

Page 338 of 1082

01-14

Engine ECU

2. FUEL SYSTEM

Engine compartment

Purge control solenoid

valveFuel railInjector