ECU SSANGYONG KORANDO 2012 Manual PDF

[x] Cancel search | Manufacturer: SSANGYONG, Model Year: 2012, Model line: KORANDO, Model: SSANGYONG KORANDO 2012Pages: 1082, PDF Size: 96.1 MB

Page 482 of 1082

15-170000-00

(2) Warm-up Control Function

Low voltage ▶

If low voltage is detected by the ECU, the idle speed increases up to 100 rpm selectively under the

driving mode until the ignition switch is turned off. Idle speed control ▶

The idle speed is controlled according to the fuel/air mixture when the engine load is changed, the

power steering wheel is turned to its end, the selector lever is in the "D" position and the A/C compresso

r

is in operation. It is also controlled according to the charge level during the purge control operation.

Ignition timing ▶

The idle speed is controlled according to the fuel/air mixture when the engine load is changed, The

<0090008e00950090009b009000960095004700880095008e0093008c0047008a0088009500470089008c00470099008c009b00880099008b008c008b0047009c00970047009b00960047005a005d020b00470096009900470088008b009d00880095008a00

8c008b0047009c00970047009b0096004700590057020b0047>to help idle speed control.

Air conditioner compressor operation ▶

The air conditioner control unit sends the air conditioner operation signal to the ECU to increase the

throttle valve opening amount in order to prevent reduction of the engine speed when the air conditioner

compressor is in operation at idling.

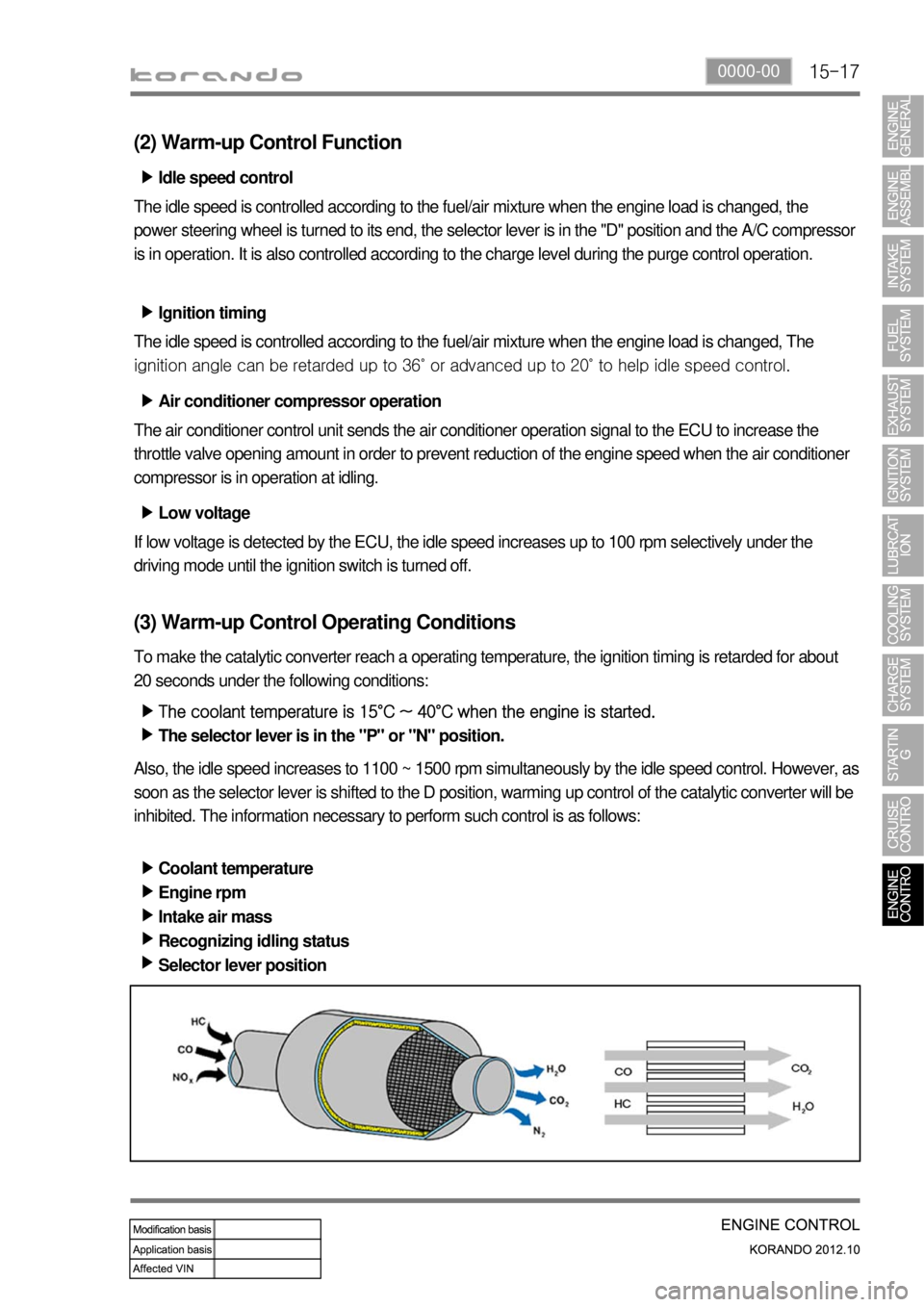

(3) Warm-up Control Operating Conditions

To make the catalytic converter reach a operating temperature, the ignition timing is retarded for about

20 seconds under the following conditions:

The coolant temperature is 15°C ~ 40°C when the engine is started.

The selector lever is in the "P" or "N" position. ▶

▶

Also, the idle speed increases to 1100 ~ 1500 rpm simultaneously by the idle speed control. However, as

soon as the selector lever is shifted to the D position, warming up control of the catalytic converter will be

inhibited. The information necessary to perform such control is as follows:

Coolant temperature

Engine rpm

Intake air mass

Recognizing idling status

Selector lever position ▶

▶

▶

▶

▶

Page 483 of 1082

15-18

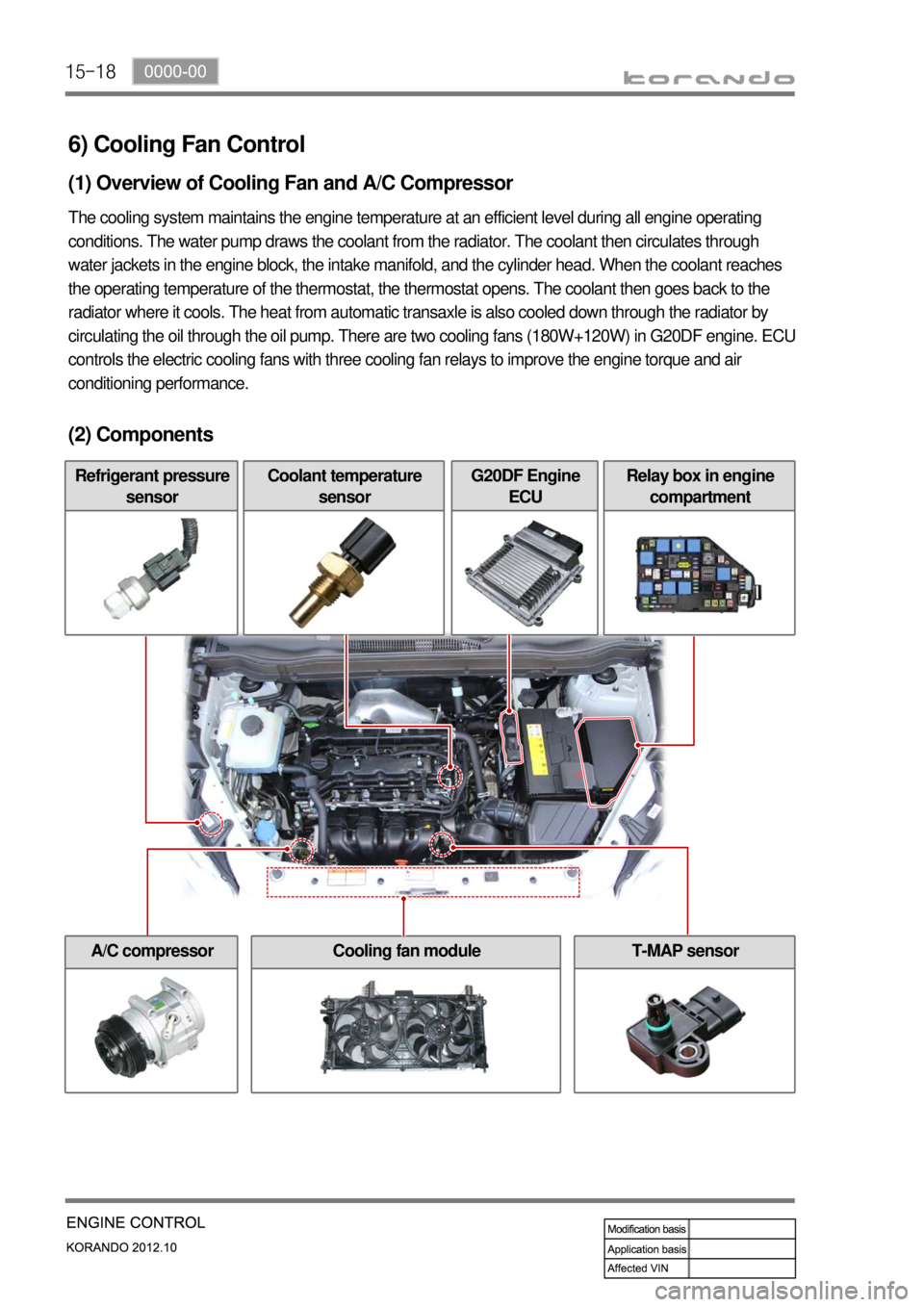

6) Cooling Fan Control

(1) Overview of Cooling Fan and A/C Compressor

The cooling system maintains the engine temperature at an efficient level during all engine operating

conditions. The water pump draws the coolant from the radiator. The coolant then circulates through

water jackets in the engine block, the intake manifold, and the cylinder head. When the coolant reaches

the operating temperature of the thermostat, the thermostat opens. The coolant then goes back to the

radiator where it cools. The heat from automatic transaxle is also cooled down through the radiator by

circulating the oil through the oil pump. There are two cooling fans (180W+120W) in G20DF engine. ECU

controls the electric cooling fans with three cooling fan relays to improve the engine torque and air

conditioning performance.

(2) Components

Refrigerant pressure

sensorCoolant temperature

sensorG20DF Engine

ECURelay box in engine

compartment

A/C compressorCooling fan moduleT-MAP sensor

Page 486 of 1082

15-210000-00

7) Immobilizer Control

(1) Overview

The Immobilizer System provides an additional theft deterrent to the vehicle in which it is installed and

prevents it from being started by unauthorized persons. The transponder integrated in the key and the

engine control unit have the same code. When the ignition key with the integrated transponder is turned

to the ON position, the ECU (Engine Control Unit) checks the crypto code of the key and, if correct,

allows the vehicle to start the engine.

For details, refer to Chapter "BCM".

(2) Components

Conditions for cooling fan ▶

Immobilizer

antenna

Immobilizer

key

Start motor

Instrument

cluster

BCM

G20DF ECU

Page 487 of 1082

15-22

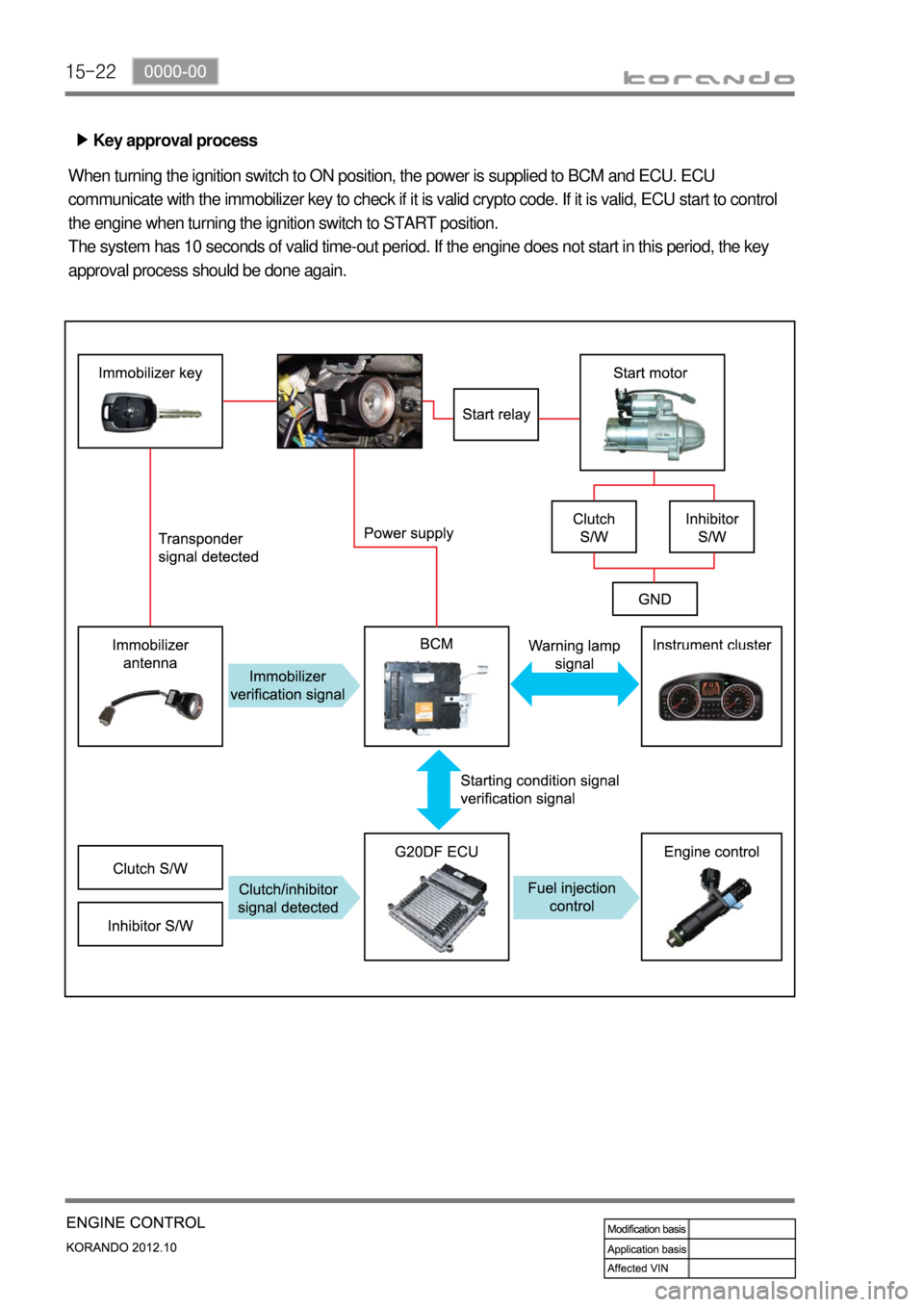

Key approval process ▶

When turning the ignition switch to ON position, the power is supplied to BCM and ECU. ECU

communicate with the immobilizer key to check if it is valid crypto code. If it is valid, ECU start to control

the engine when turning the ignition switch to START position.

The system has 10 seconds of valid time-out period. If the engine does not start in this period, the key

approval process should be done again.

Page 488 of 1082

15-230000-00

8) CAN Configuration (P-CAN/B-CAN)

(1) CAN Configuration (P-CAN/B-CAN)

Name Function

ECUElectronic Control Unit

TCUTransmission Control Unit

EPSElectronic Power Steering Unit

BCMBody Control Moudule

SKMSmart Key Moudule

CAN system communicates with the system units in vehicle. It consists of P-CAN and B-CAN according

to the communication speed.

P-CAN & B-CAN: SKM, Instrument cluster, BCM, Disgnostic connector

P-CAN: ECU, ABS & ESP, TCU, E-coupling, EPS unit

Terminal resistance: installed on ECU and BCM

Page 504 of 1082

02-50000-00

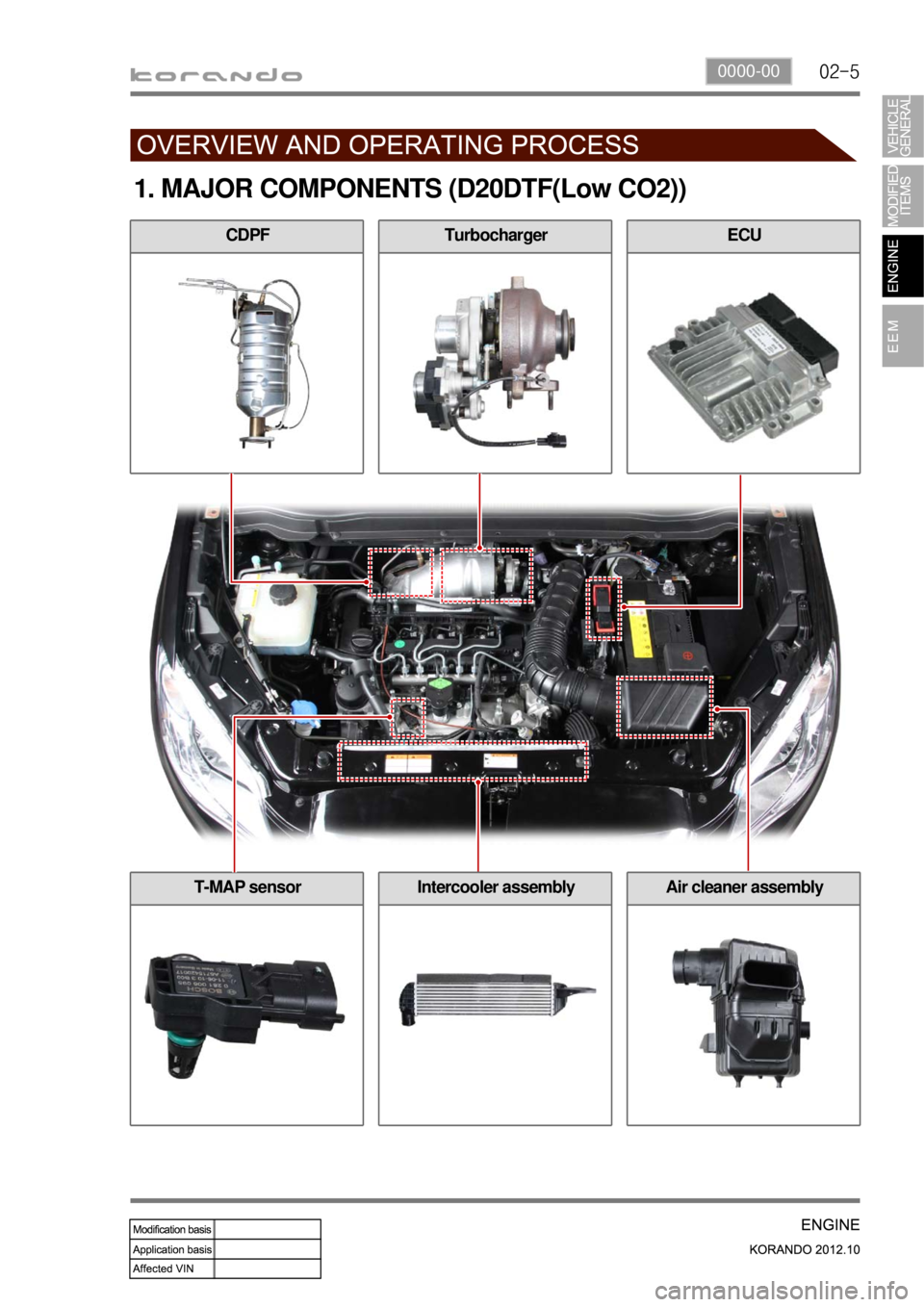

T-MAP sensor

TurbochargerCDPF

1. MAJOR COMPONENTS (D20DTF(Low CO2))

ECU

Intercooler assemblyAir cleaner assembly

Page 510 of 1082

14-4

2. COMPARISON

ItemDescription

D20DTF D20DTF (Low CO2)

Effective date From March, 2012

Applied engine D20DTF

Battery capacity 12V 90Ah

Alternator capacity Delphi 120A Delphi 140A

AlternatorChanged the diameter of belt pulley (Front view)

Changed the regulator and control logic (Rear view)

ECU Without EEM logic With EEM logic

EBS NoneMonitoring the battery conditions (voltage,

current, temperature and SOC)

Page 511 of 1082

14-50000-00

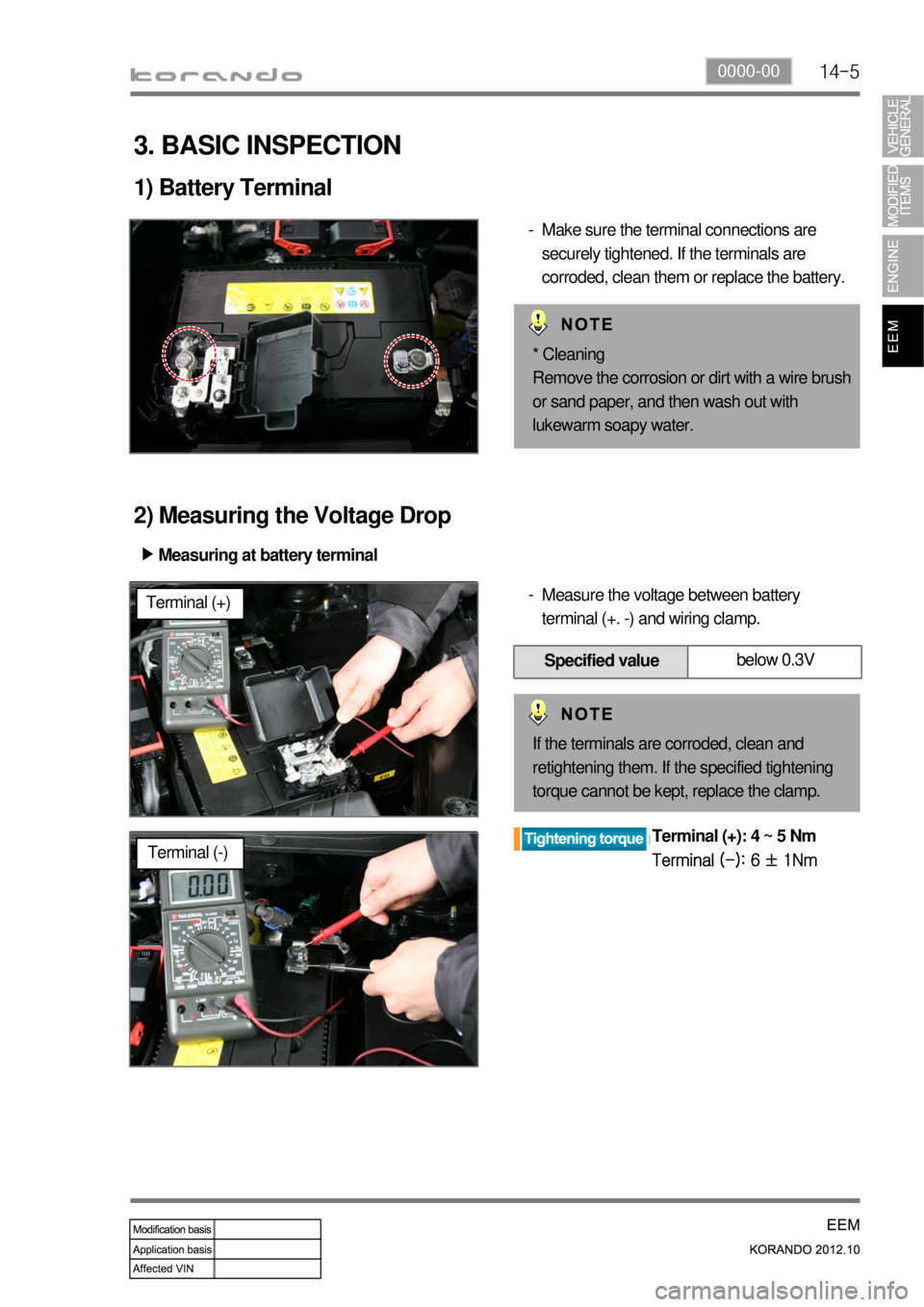

3. BASIC INSPECTION

1) Battery Terminal

Make sure the terminal connections are

securely tightened. If the terminals are

corroded, clean them or replace the battery. -

* Cleaning

Remove the corrosion or dirt with a wire brush

or sand paper, and then wash out with

lukewarm soapy water.

2) Measuring the Voltage Drop

Measuring at battery terminal ▶

Measure the voltage between battery

terminal (+. -) and wiring clamp. -

Specified valuebelow 0.3V

If the terminals are corroded, clean and

retightening them. If the specified tightening

torque cannot be kept, replace the clamp.

Terminal (+)

Terminal (-)

Terminal (+): 4 ~ 5 Nm

Terminal (-): 6 ± 1Nm

Page 522 of 1082

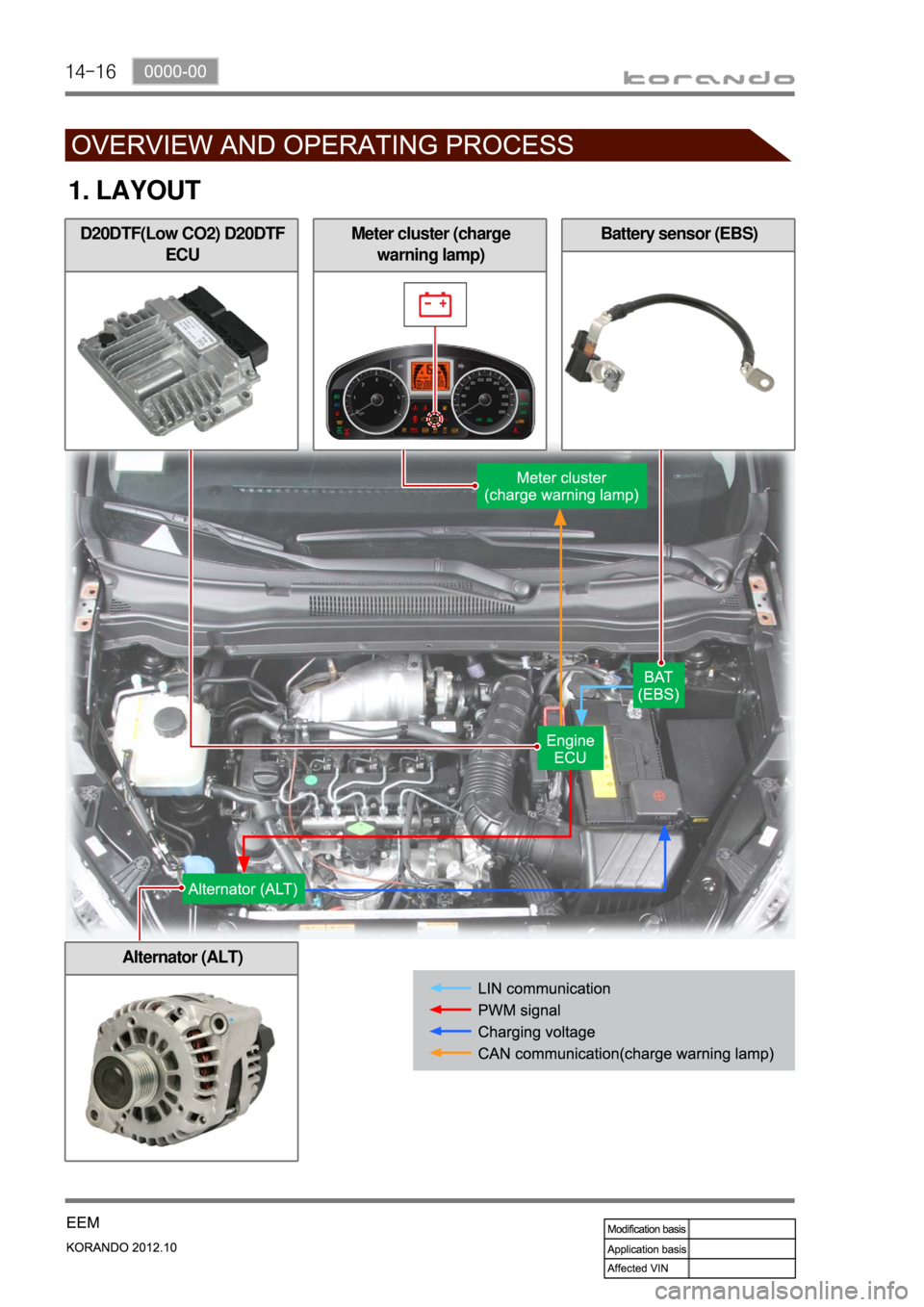

14-16

1. LAYOUT

D20DTF(Low CO2) D20DTF

ECUBattery sensor (EBS)

Alternator (ALT)

Meter cluster (charge

warning lamp)

Page 523 of 1082

14-170000-00

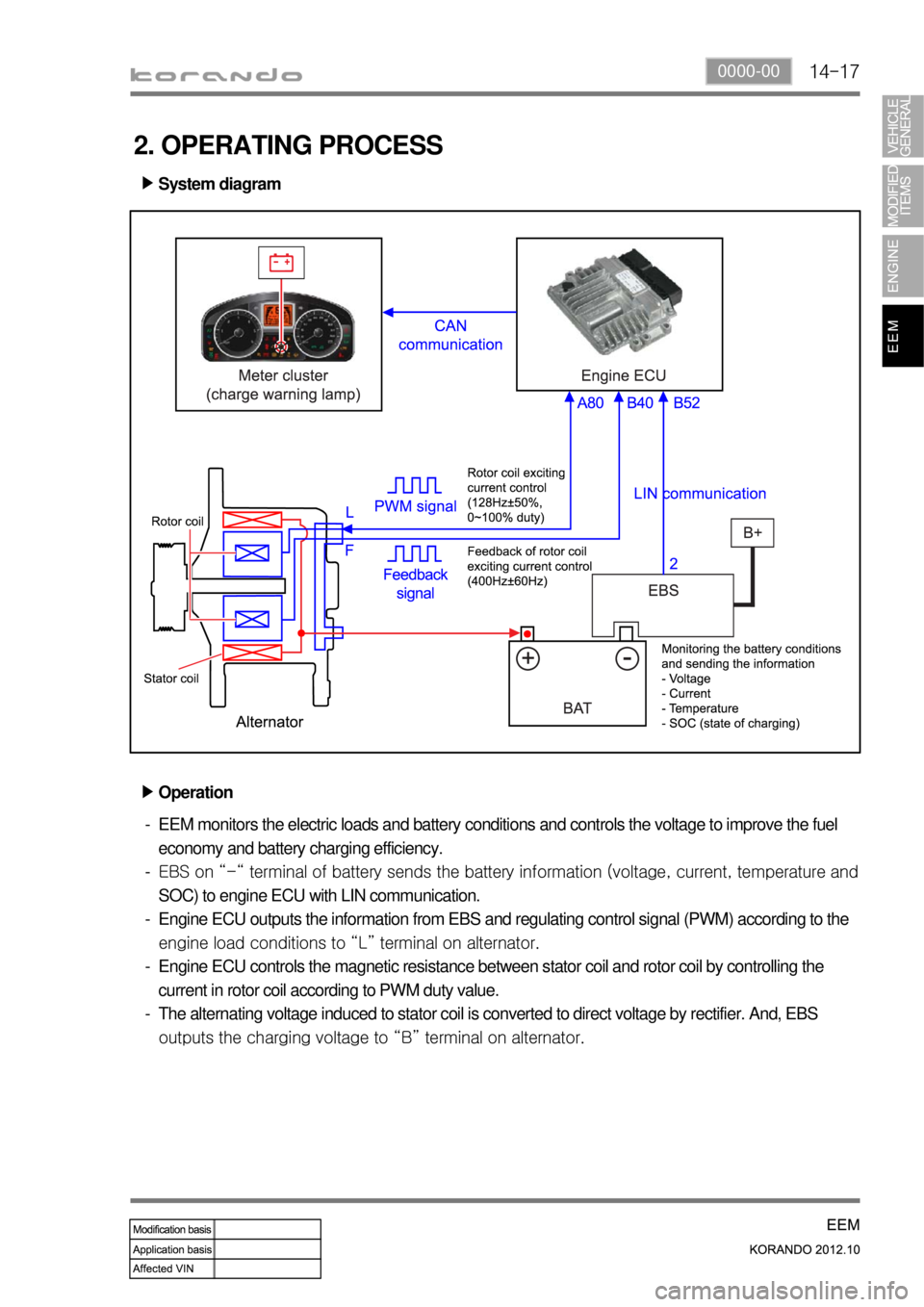

2. OPERATING PROCESS

System diagram ▶

Operation ▶

EEM monitors the electric loads and battery conditions and controls the voltage to improve the fuel

economy and battery charging efficiency.

EBS on “-“ terminal of battery sends the battery information (voltage, current, tem

perature and

SOC) to engine ECU with LIN communication.

Engine ECU outputs the information from EBS and regulating control signal (PWM) according to the

<008c0095008e00900095008c0047009300960088008b0047008a00960095008b0090009b009000960095009a0047009b0096004702c8007302c90047009b008c009900940090009500880093004700960095004700880093009b008c009900950088009b00

9600990055>

Engine ECU controls the magnetic resistance between stator coil and rotor coil by controlling the

current in rotor coil according to PWM duty value.

The alternating voltage induced to stator coil is converted to direct voltage by rectifier. And, EBS

<0096009c009b0097009c009b009a0047009b008f008c0047008a008f00880099008e00900095008e0047009d00960093009b0088008e008c0047009b0096004702c8006902c90047009b008c00990094009000950088009300470096009500470088009300

9b008c009900950088009b009600990055> -

-

-

-

-