rear wheel SSANGYONG KORANDO 2012 Service Manual

[x] Cancel search | Manufacturer: SSANGYONG, Model Year: 2012, Model line: KORANDO, Model: SSANGYONG KORANDO 2012Pages: 1082, PDF Size: 96.1 MB

Page 104 of 1082

01-8

4) Basic Inspection

(1) Horn operation

Listen for the horn sound when pressing the horn pad on the steering wheel. -

(2) Brake operation

Check if there is any abnormal noise, unusually long braking distance, or uneven braking force. If the

brake warning lamp does not go out even after starting the engien or are flashing during driving,

have the brake system checked immediately.

Check the brake pipes and hoses for connection, oil leak, crack or interference after changing the

position of tires. When replacing the tires, check the brake disc for surface condition and wear.

Check the parking brake cable and brake operation. Shorten the checking interval if the parking

brake is used frequently. -

-

-

(3) Exhaust system

Be aware to any changes in sound or smell from the exhaust system. These may be caused by leak or

overheat. Have the exhaust system checked and repaired immediately.

Inspect the exhaust system including catalytic converter. Inspect all the components and body frame

near the exhaust system. -

-

(4) Tires

Unusual vibration of the steering wheel and seats or pulling to one side on the straight and level roads

may indicates the uneven tire inflation pressure or poor wheel balance. -

(5) Steering and suspension system

Inspect the front and rear suspension and the steering system for damage, looseness or missing

parts, signs of wear or lack of lubrication. Inspect the power steering line and the hoses for

connection, leak, crack and chafing. Inspect the drive axle boot and seals for damage, tear or leak.

Replace or repair the system if necessary. -

(6) Engine oil

Check the oil level when the engine is still warm and add the specified engine oil if necessary. -

(7) Coolant

Check the coolant level in the coolant reservoir, coolant conditions (contamination, foreign material),

and hoses for damage and leak. Replace or add the Ssangyong genuine coolant, if needed. -

(8) Engine drive belt

Check all drive belts on the engine for wear, crack and looseness. Retighten or replace the belt, if

needed. -

Page 111 of 1082

02-4

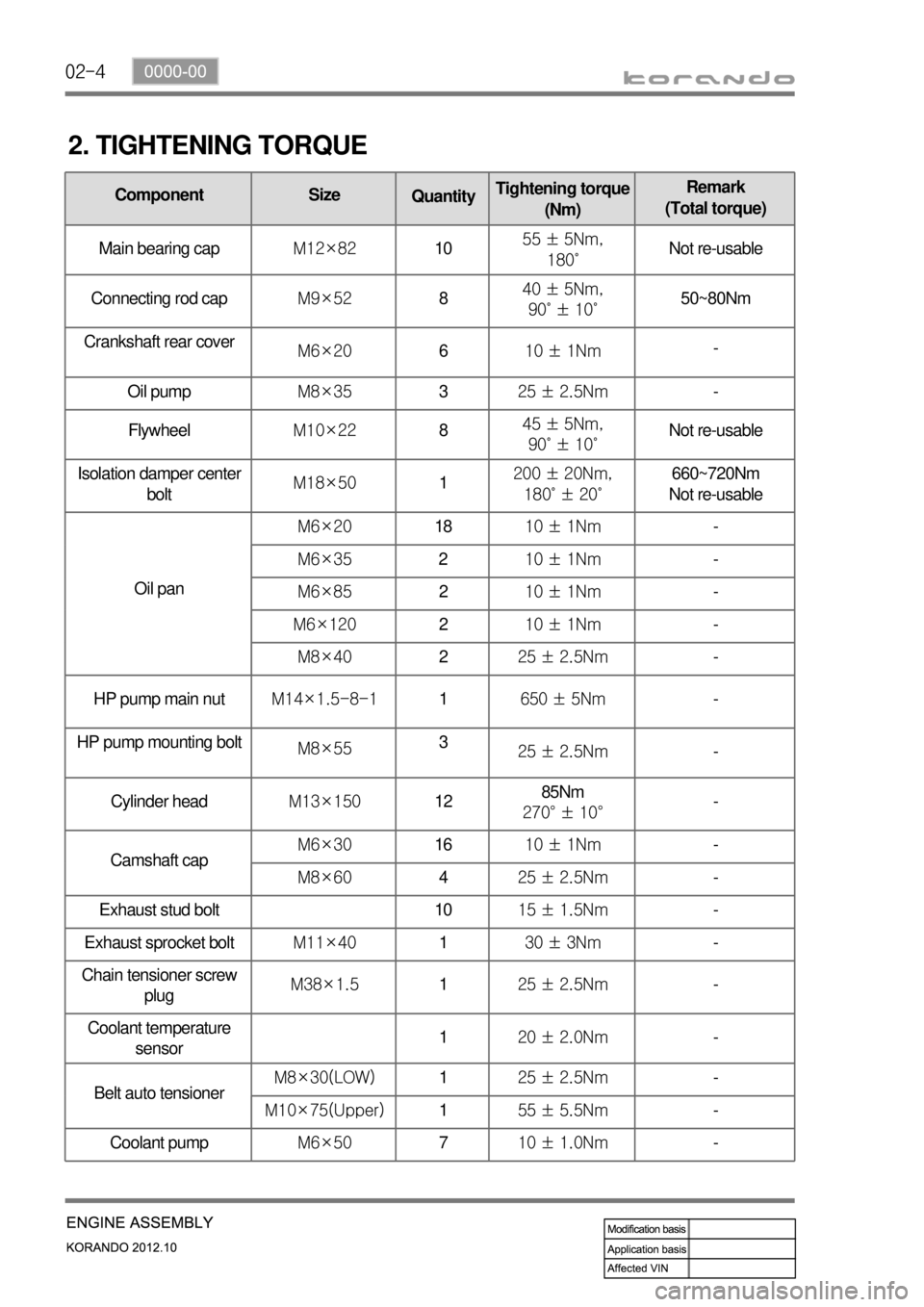

2. TIGHTENING TORQUE

Component Size

QuantityTightening torque

(Nm)Remark

(Total torque)

Main bearing capM12×821055 ± 5Nm,

180˚Not re-usable

Connecting rod capM9×52840 ± 5Nm,

90˚ ± 10˚50~80Nm

Crankshaft rear cover

M6×20610 ± 1Nm-

Oil pumpM8×35325 ± 2.5Nm-

FlywheelM10×22845 ± 5Nm,

90˚ ± 10˚Not re-usable

Isolation damper center

boltM18×501200 ± 20Nm,

180˚ ± 20˚660~720Nm

Not re-usable

Oil panM6×201810 ± 1Nm-

M6×35210 ± 1Nm-

M6×85210 ± 1Nm-

M6×120210 ± 1Nm-

M8×40225 ± 2.5Nm-

HP pump main nutM14×1.5-8-11650 ± 5Nm-

HP pump mounting bolt

M8×553

25 ± 2.5Nm-

Cylinder headM13×1501285Nm

270° ± 10°-

Camshaft capM6×301610 ± 1Nm-

M8×60425 ± 2.5Nm-

Exhaust stud bolt 1015 ± 1.5Nm-

Exhaust sprocket boltM11×40130 ± 3Nm-

Chain tensioner screw

plugM38×1.5125 ± 2.5Nm

-

Coolant temperature

sensor120 ± 2.0Nm-

Belt auto tensionerM8×30(LOW)125 ± 2.5Nm-

M10×75(Upper)155 ± 5.5Nm-

Coolant pumpM6×50710 ± 1.0Nm-

Page 328 of 1082

01-4

Engine mounting bracket

2. MAJOR COMPONENTS

Front View ▶

Cylinder head front cover

Timing gear case cover

EPS idler pulley

Alternator

Water pump pulley

A/C compressor

Crankshaft pulley

Oil pan assembly

Rear View ▶

Camshaft position sensor

Breather nipple

Purge control solenoid valveCoolant temperature sensor

Electronic throttle body

T-MAP sensor

MCC complete

VIS solenoid valve Cylinder head cover

Dual mass flywheel

Crankshaft position sensor

Hydraulic tensioner assembly

Page 332 of 1082

01-8

4) Basic Inspection

(1) Horn operation

Listen for the horn sound when pressing the horn pad on the steering wheel. -

(2) Brake operation

Check if there is any abnormal noise, unusually long braking distance, or uneven braking force. If the

brake warning lamp does not go out even after starting the engien or are flashing during driving,

have the brake system checked immediately.

Check the brake pipes and hoses for connection, oil leak, crack or interference after changing the

position of tires. When replacing the tires, check the brake disc for surface condition and wear.

Check the parking brake cable and brake operation. Shorten the checking interval if the parking

brake is used frequently. -

-

-

(3) Exhaust system

Be aware to any changes in sound or smell from the exhaust system. These may be caused by leak or

overheat. Have the exhaust system checked and repaired immediately.

Inspect the exhaust system including catalytic converter. Inspect all the components and body frame

near the exhaust system. -

-

(4) Tires

Unusual vibration of the steering wheel and seats or pulling to one side on the straight and level roads

may indicates the uneven tire inflation pressure or poor wheel balance. -

(5) Steering and suspension system

Inspect the front and rear suspension and the steering system for damage, looseness or missing

parts, signs of wear or lack of lubrication. Inspect the power steering line and the hoses for

connection, leak, crack and chafing. Inspect the drive axle boot and seals for damage, tear or leak.

Replace or repair the system if necessary. -

(6) Engine oil

Check the oil level when the engine is still warm and add the specified engine oil if necessary. -

(7) Coolant

Check the coolant level in the coolant reservoir, coolant conditions (contamination, foreign material),

and hoses for damage and leak. Replace or add the Ssangyong genuine coolant, if needed. -

(8) Engine drive belt

Check all drive belts on the engine for wear, crack and looseness. Retighten or replace the belt, if

needed. -

Page 495 of 1082

01-70000-00

Brake Master cylinder type Tandem type

Booster type Vacuum assisted booster type

Brake type Front wheel Disc

Rear wheel Disc

Parking brake Mechanical type

Suspension Front suspension MacPherson + Coil spring

Rear suspension Multi-link + Coil spring

Air

ConditionerRefrigerant (capacity)

R-134a(430 ± 30g)

Electrical Battery type / Capacity (V-AH) MF / 12 - 90

Starter capacity (V-KW) 12 - 2.3

Alternator capacity (V-A) 14V-140A (EPS), 14V-120A (NPS)

* ( ) option

DescriptionDiesel 2.0 Engine

(D20DTF(Low CO2))

Manual

TransaxleOperating type Floor change type

Gear ratio 1st 3.385

2nd 1.708

3rd 1.033

4th 0.786

5th 0.730

6th 0.595

Reverse 3.747

Transfer Case Model 4WD

Type Electronic control type

Clutch Operating type Hydraulic type

Disc type Dry single diaphragm type

Power

SteeringType Rack and pinion

Steering angle Inner39.0°

Outer31.24°

Rear Axle Drive shaft type Independent

suspensionBall joint type (4WD)

Axle housing type Build-up type (4WD)

Page 532 of 1082

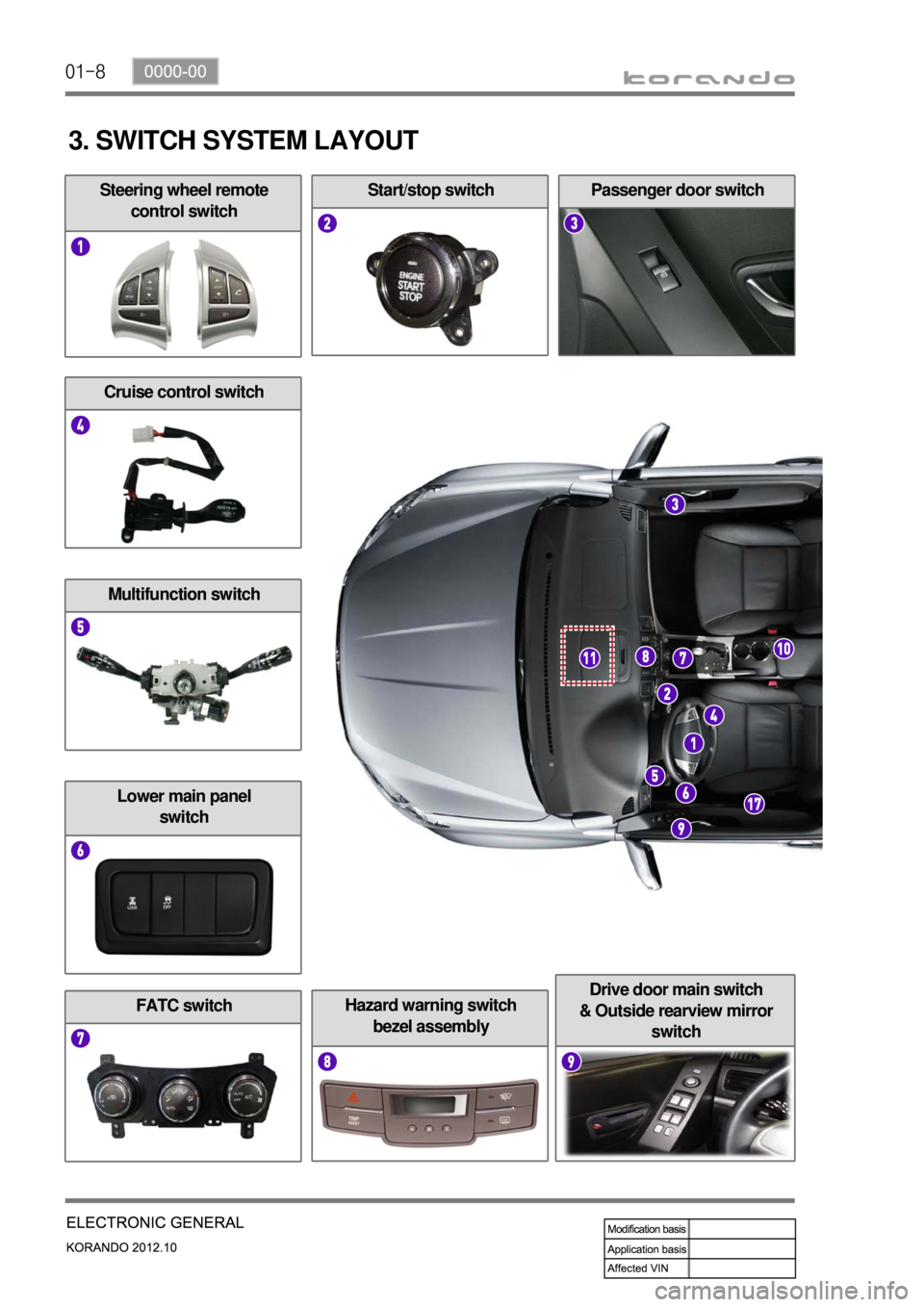

01-8

Steering wheel remote

control switchPassenger door switch

Lower main panel

switch

Start/stop switch

Cruise control switch

Hazard warning switch

bezel assembly

Multifunction switch

FATC switch

Drive door main switch

& Outside rearview mirror

switch

3. SWITCH SYSTEM LAYOUT

Page 667 of 1082

05-4

2. MAJOR CHANGES

SVC class

Previous Current

Rearranged pre-warning indicator which comes on and goes off when turning ignition on.

1) Steering wheel heating indicator added

2) Pre-warning indicator rearranged

3) Winter mode indicator added(DSL only)

STD class

Previous Current

Winter mode indicator added (one green LED)

SVC class

Previous Current

One indicator added since steering wheel heating function is equipped.

Page 716 of 1082

06-58510-00

1. OVERVIEW

Door panel switch (driver)

Door panel switch (passenger)

Door panel switch (rear)

IP panel switch

Steering wheel switch

Front console switch

Trunk switch

Headlining switch 1.

2.

3.

4.

5.

6.

7.

8.

1) Mounting Locations

Page 737 of 1082

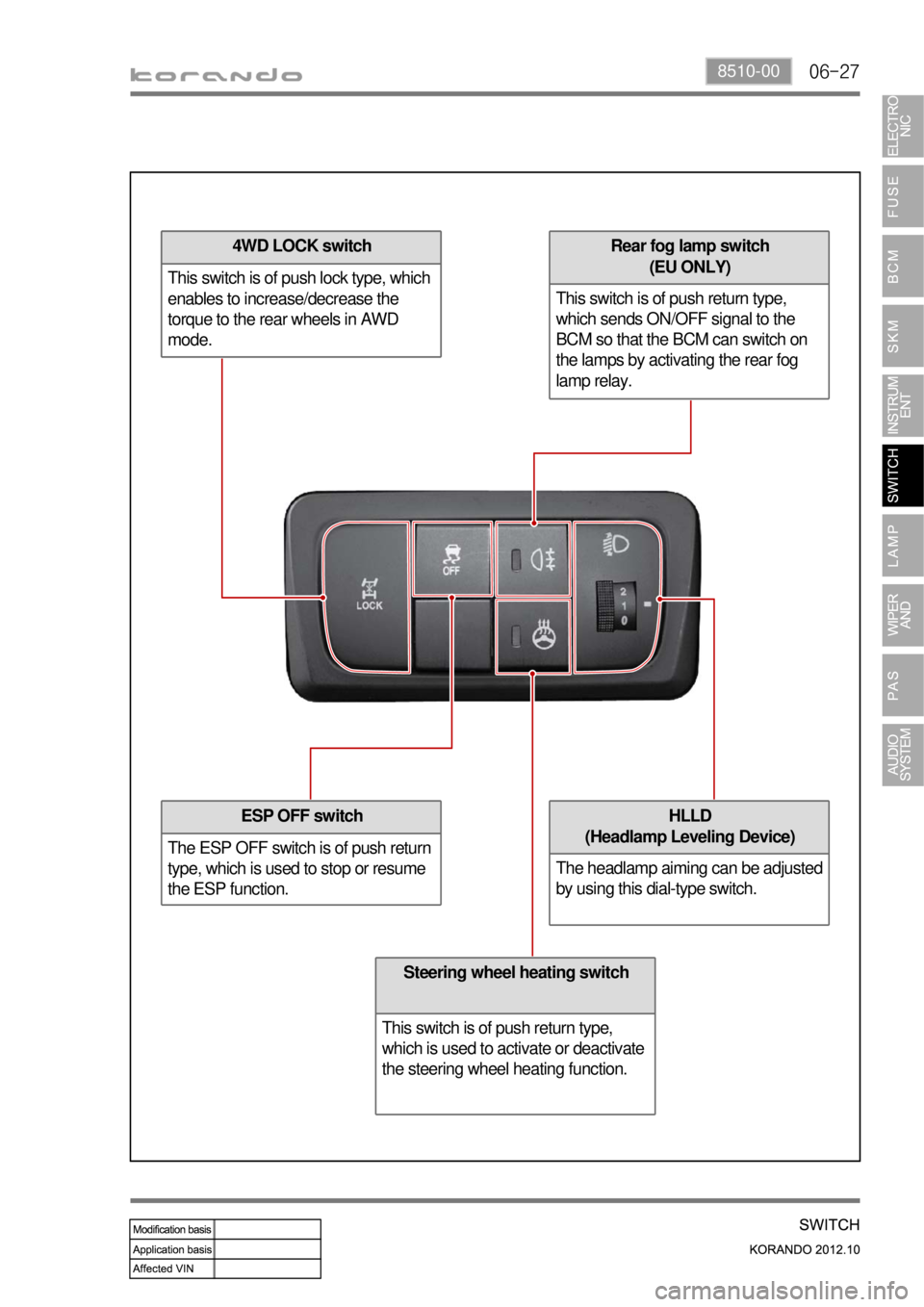

06-26

Lower main panel switch

3) Lower Main Panel Switch

Rear fog lamp switch(EU ONLY)

Steering wheel heating switchHLLD(Headlamp Leveling Device)4WD LOCK switch

ESP OFF switch

Page 738 of 1082

06-278510-00

4WD LOCK switch

This switch is of push lock type, which

enables to increase/decrease the

torque to the rear wheels in AWD

mode.

Steering wheel heating switch

This switch is of push return type,

which is used to activate or deactivate

the steering wheel heating function.

ESP OFF switch

The ESP OFF switch is of push return

type, which is used to stop or resume

the ESP function.

4WD LOCK switch

This switch is of push lock type, which

enables to increase/decrease the

torque to the rear wheels in AWD

mode.

HLLD

(Headlamp Leveling Device)

The headlamp aiming can be adjusted

by using this dial-type switch.

Rear fog lamp switch

(EU ONLY)

This switch is of push return type,

which sends ON/OFF signal to the

BCM so that the BCM can switch on

the lamps by activating the rear fog

lamp relay.