ECU SSANGYONG KORANDO 2013 Service Manual

[x] Cancel search | Manufacturer: SSANGYONG, Model Year: 2013, Model line: KORANDO, Model: SSANGYONG KORANDO 2013Pages: 1336, PDF Size: 92.18 MB

Page 1177 of 1336

3. TPMS ECU I/O DIAGRAM

Page 1178 of 1336

4190-00

4. TPMS PRESSURE VALUE DISPLAYING PROCESS

The TPMS ECU receives the tire pressure value from the wheel module through the wireless

transmission once every about 30 seconds and displays the pressure value on the instrument cluster

through CAN line.

Under normal circumstances, it transmits the tire pressure value and temperature value together

with its ID (Identification) once every about 30 seconds to reduce the load on the wheel module's

battery. But, in the event of emergency or situation which should give a warning to the driver, it

transmits the data once every about 1 second. Since the battery consumption will be increased

rapidly until the data transmission interval will be returned to normal after certain length of time,

adjust the tire pressure to the specified one after rectifying the cause.

The tire pressure is displayed through the following sequences, which occur at the same

time.

Wheel module detection

(Auto learning)This is a step which receives an ID signal from the wheel module fitted

to the vehicle. When the wheel module sends the signal about twice

every 1 minute, each wheel module will be identified.

Wheel module mounting

location detection

(Auto location)The TPMS ECU check which wheel module is installed to which tire.

Page 1179 of 1336

5. LOW TIRE PRESSURE WARNING

If the tire pressure is less than 13% of the proper value calculated by the TPMS ECU depending on the

ambient temperature for more than 8 minutes, the 1st low tire pressure warning is given. And, if the tire

pressure is less than 20% for more than 4 minutes, the 2nd warning is given. At this time, the "Check

tire" message is displayed on the DOT LCD display and the global warning lamp comes on.

ECU receives the ambient temperature signal from the instrument cluster through CAN

communication and calculates the proper tire pressure to correct it since the tire pressure changes

depending on the ambient temperature.

Page 1185 of 1336

7. TIRE INFLATION PROCEDURE FOR VEHICLE WITH TPMS

1) Overview

For the vehicle with TPMS, the tire should be inflated in a method different from the conventional method

since the tire pressure values displayed on the tire pressure gauge and instrument cluster are different

after inflation.

The tire pressure displayed on the instrument cluster should be checked after a certain time delay

(wireless transmission time for wheel module).

The displayed value can be changed after driving even if it was set to the specified value.

2) Tire Inflation Procedure

Park the vehicle on a flat ground and let everyone get off the vehicle. A.

This symptom is occurred as the inflation pressure displayed on the instrument cluster becomes

different by tires as different load is applied to each tire due to driving condition, number of

occupants, irregular temperature change in tire and load condition.

If there is another vehicle equipped with the TPMS, keep the distance from this vehicle for at

least 5 mm to prevent interference of wheel module transmission.

Unload cargoes if they are usually not loaded during driving.

The instrument cluster does not display every pressure change while the air is injected or

discharged to/from the tire. This is because the wheel module sends the pressure value to the

TPMS ECU every minute.

In addition, if there are other vehicles with the TPMS nearby, it might take several minutes to

display the pressure values due to radio jamming and weather condition. -

-

-

Page 1194 of 1336

2. LAYOUT

1) Exterior Layout

Liquid and suction pipe

The high/low-pressure A/C refrigerant flows

through this pipe. It is fitted with the refrigerant

pressure sensor.

Electric fan

It cools down the A/C condenser to speed up the

compression for the refrigerant in the condenser.

Refrigerant pressure sensor

It is mounted to the latter part of the right

headlamp. It converts the A/C refrigerant pressure

to voltage value and sends it to the engine ECU.

A/C compressor

It is installed to the left side of the engine

assembly, compresses the low-temperature and

low-pressure coolant and converts it to the high-

temperature and high-pressure coolant. Then, it

sends the coolant to the A/C condenser.

Page 1195 of 1336

6810-00

A/C condenser & receiver drier

It is installed in front of vehicle and condenses vapor

refrigerant into low temperature and high pressure liquid

refrigerant. The receiver drier is built in it.Ambient temperature sensor

It is mounted to the front section of the

vehicle and detects the ambient

temperature to send the voltage value

according to the resistance change to

the heater and A/C control assembly.

Engine ECU

It controls the A/C compressor, electric fan

and PTC heater according to the signal from

the A/C control panel.

Expansion valve

It is mounted to the inlet of the evaporator

core and supplies the appropriate quantity

of refrigerant to the evaporator.

Integrated receiver drier

Page 1209 of 1336

6810-00

(6) A/C control

The air conditioner is controlled by the A/C compressor of the engine ECU according to the signal from

the heater and A/C control assembly. The driver can see the air conditioner operation through the LCD

display and the indicator of the A/C switch.

Manual control

Pressing the A/C switch or selecting defrost mode turns on the A/C.

Auto control

The A/C is controlled in accordance with the indoor temperature and ambient temperature.

or below) in winter, the compressor is turned off to protect the A/C compressor.

A/C switch

LCD display (A/C operation view)

Page 1220 of 1336

(6) A/C control

The air conditioner is operated at the defroster mode and MAX air conditioner mode and when the A/C

switch is turned to "ON" position. It is controlled by the A/C compressor of the engine ECU according to

the signal from the heater and A/C control assembly. The driver can see that the A/C has been activated

when an indicator lamps at the A/C switch and MAX A/C switch comes on. If the intake sensor detects

the freezing of the evaporator core, it stops the air conditioner by turning off the compressor.

MAX A/C control

This is designed for increasing driver comfort. When the switch is pressed, the air conditioner is

operated and vent and recirculation modes are selected automatically. The discharge temperature and

fan speed are regulated depending on the driver's choice.

A/C switch

MAX A/C control switch

Page 1221 of 1336

6810-00

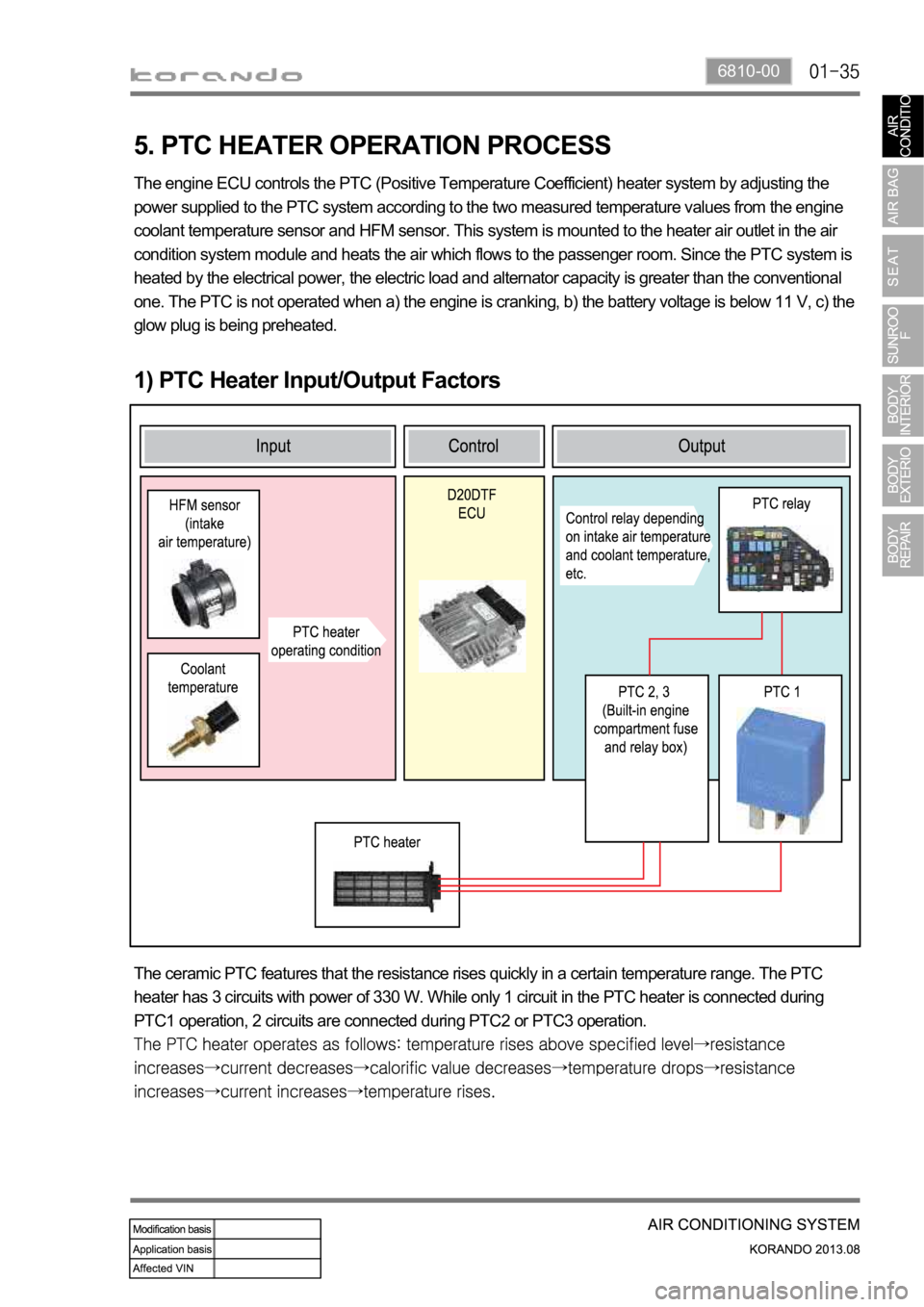

5. PTC HEATER OPERATION PROCESS

1) PTC Heater Input/Output Factors

The engine ECU controls the PTC (Positive Temperature Coefficient) heater system by adjusting the

power supplied to the PTC system according to the two measured temperature values from the engine

coolant temperature sensor and HFM sensor. This system is mounted to the heater air outlet in the air

condition system module and heats the air which flows to the passenger room. Since the PTC system is

heated by the electrical power, the electric load and alternator capacity is greater than the conventional

one. The PTC is not operated when a) the engine is cranking, b) the battery voltage is below 11 V, c) the

glow plug is being preheated.

The ceramic PTC features that the resistance rises quickly in a certain temperature range. The PTC

heater has 3 circuits with power of 330 W. While only 1 circuit in the PTC heater is connected during

PTC1 operation, 2 circuits are connected during PTC2 or PTC3 operation.

Page 1258 of 1336

7410-00

2. WARNINGS FOR POWER SEAT

Adjust the driver seat before driving.

Make sure that the seat is firmly secured after adjusting.

Never drive the vehicle with the head restraint removed or lowered excessively. Otherwise, you

r

neck, spine or other parts of the body can be severely injured in the event of an accident.

If you recline the seatback excessively, you could slide under the seat belt and be injured severely

in a collision.

Do not put any object that could damage the seat on the seat.

The front and rear seats are equipped with the heated wire (seat warmer) system. Using the seat

warmer system excessively may cause minor burns. The following occupants should exercise

special care when using the heated wire seat.

Infants, children, old or handicapped persons

Persons with sensitive skin

Exhausted persons

Persons who is drunk or took medicine which causes drowsiness such as sleeping pills, cold

tablets, etc. -

-

-

-

Do not place anything on the seat that insulates against the heat, such as a blanket or cushion.

Make sure that the head restraints are in place and secured properly. Never drive the vehicle with

the head restraint removed.

To minimize the injuries in a collision or an abrupt stop, make sure the seatback is in the upright

position before driving. If the seatback is reclined too much, the occupant could slide under the seat

belt in a collision or an abrupt stop and cannot be protected properly by the air bag system.

3. CAUTIONS FOR POWER SEAT

You can operate the power seat with the ignition switch OFF. However, frequent operation of the

seat switch with the engine stopped can result in battery becoming discharged.

Operating more than one seat adjustment switch at the same time can cause damage to the seat

motor. Therefore, operate the seat switch only one at a time.

Do not use organic solvents such as benzene, thinner, alcohol or gasoline to prevent the seat cove

r

from being damaged while cleaning.

Do not operate the seat position adjustment switch forcefully when the seat does not move or it

contacts an object.

If the power seat is not operated, check and correct the problem before driving off.