Intake SSANGYONG KORANDO 2013 Service Manual

[x] Cancel search | Manufacturer: SSANGYONG, Model Year: 2013, Model line: KORANDO, Model: SSANGYONG KORANDO 2013Pages: 1336, PDF Size: 92.18 MB

Page 197 of 1336

0000-00

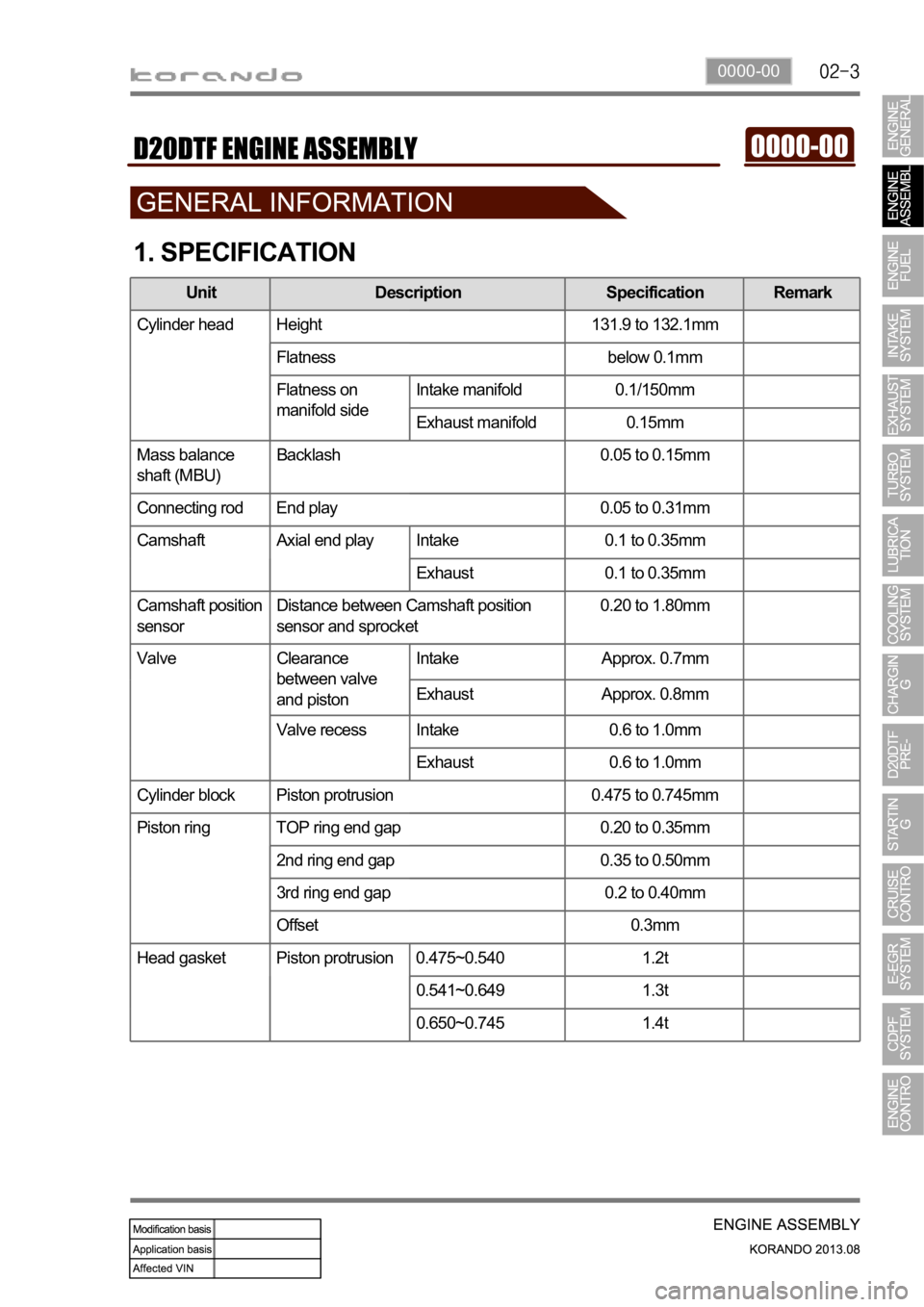

1. SPECIFICATION

Unit Description Specification Remark

Cylinder head Height 131.9 to 132.1mm

Flatness below 0.1mm

Flatness on

manifold sideIntake manifold 0.1/150mm

Exhaust manifold 0.15mm

Mass balance

shaft (MBU)Backlash 0.05 to 0.15mm

Connecting rod End play 0.05 to 0.31mm

Camshaft Axial end play Intake 0.1 to 0.35mm

Exhaust 0.1 to 0.35mm

Camshaft position

sensorDistance between Camshaft position

sensor and sprocket0.20 to 1.80mm

Valve Clearance

between valve

and pistonIntake Approx. 0.7mm

Exhaust Approx. 0.8mm

Valve recess Intake 0.6 to 1.0mm

Exhaust 0.6 to 1.0mm

Cylinder block Piston protrusion 0.475 to 0.745mm

Piston ring TOP ring end gap 0.20 to 0.35mm

2nd ring end gap 0.35 to 0.50mm

3rd ring end gap 0.2 to 0.40mm

Offset 0.3mm

Head gasket Piston protrusion 0.475~0.540 1.2t

0.541~0.649 1.3t

0.650~0.745 1.4t

Page 201 of 1336

0000-00

Knock sensor2-

Cam position sensor

1 10~14Nm -

T-MAP pressure sensor

1-

Exhaust manifold M8 10

-

Turbocharger M8 3

-

T/C support bracket bolt

1

-

T/C support bracket bolt

M8 1

-

T/C oil supply pipeM6(block side) 1

-

M6(turbo side) 1

-

T/C oil return pipe

(turbo side)2-

(block side)2-

EGR valve

3-

EGR pipe bolt

(Intake side)

2-

EGR pipe bolt

(EGR cooler side)

2-

Oil pressure sensor M24 1 Max. 50Nm -

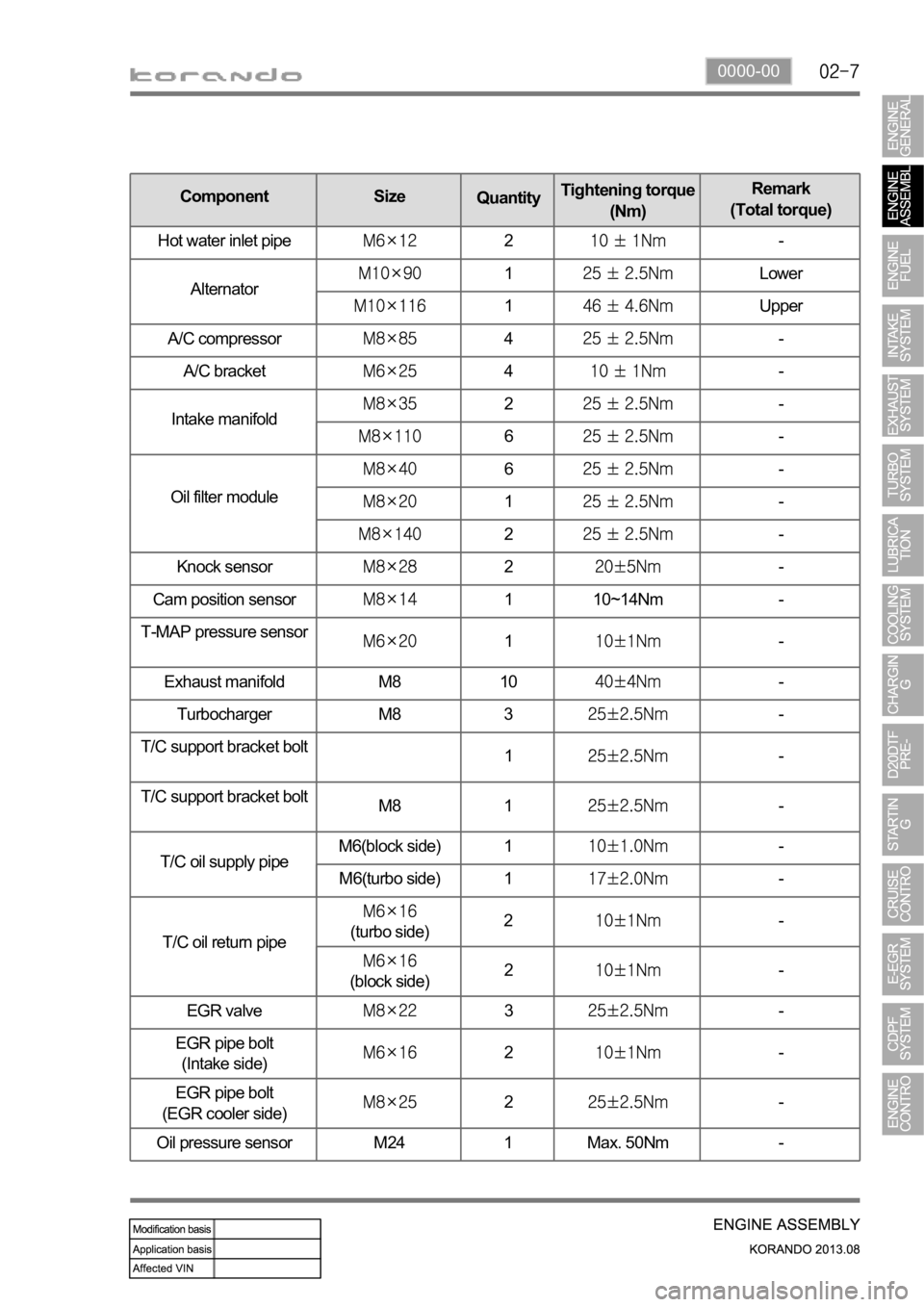

Component Size

QuantityTightening torque

(Nm)Remark

(Total torque)

Hot water inlet pipe

2-

Alternator

1Lower

1Upper

A/C compressor

4-

A/C bracket

4-

Intake manifold

2-

6-

Oil filter module

6-

1-

2-

Page 202 of 1336

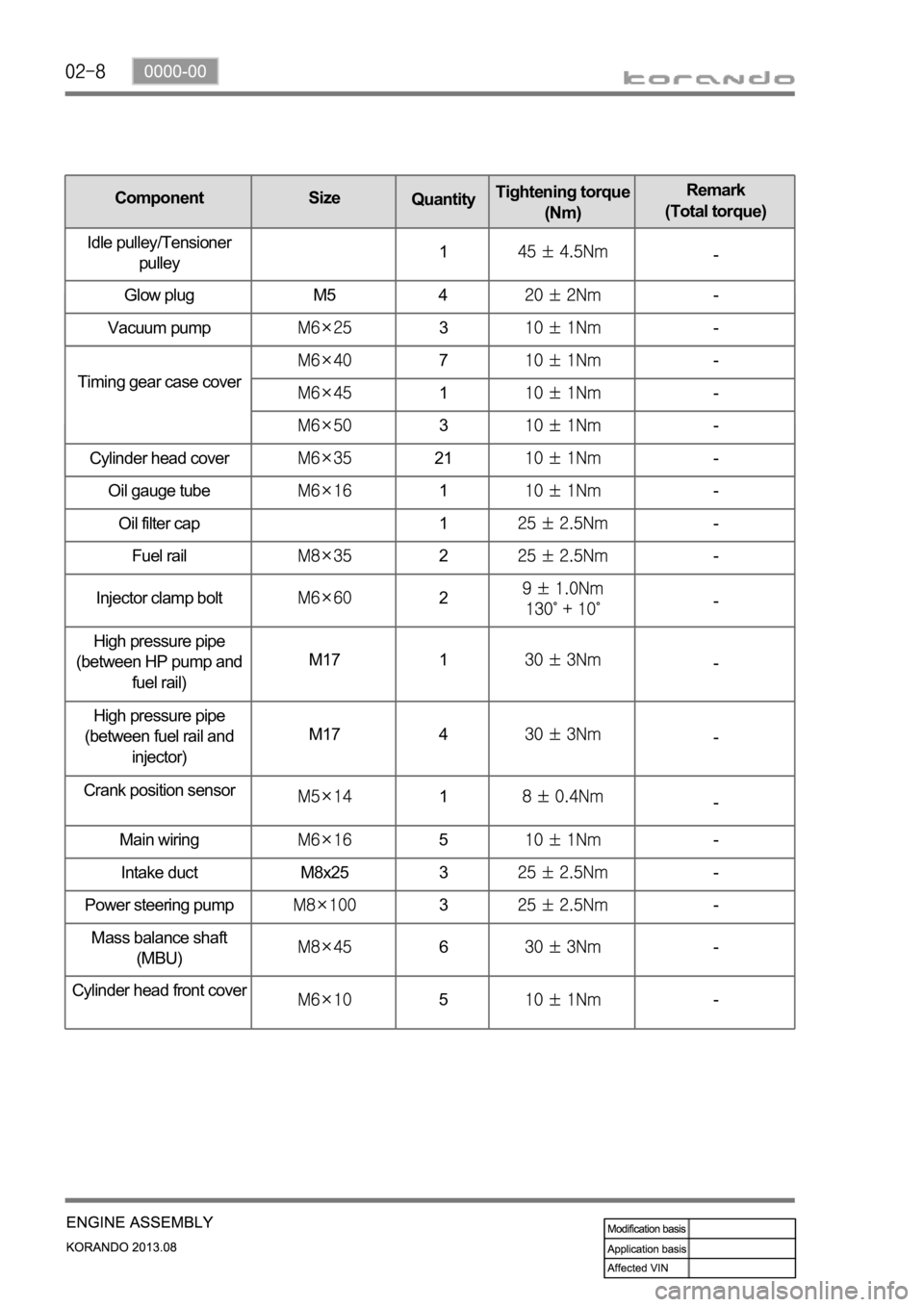

Oil gauge tube1-

Oil filter cap 1

-

Fuel rail

2-

Injector clamp bolt

2-

High pressure pipe

(between HP pump and

fuel rail)M17 1

-

High pressure pipe

(between fuel rail and

injector)M17 4

-

Crank position sensor

1-

Main wiring

5-

Intake duct M8x25 3

-

Power steering pump

3-

Mass balance shaft

(MBU)

6-

Cylinder head front cove

r5-

Timing gear case cover

7-

1-

3-

Cylinder head cover

21-

Component Size

QuantityTightening torque

(Nm)Remark

(Total torque)

Idle pulley/Tensioner

pulley1

-

Glow plug M5 4

-

Vacuum pump

3-

Page 207 of 1336

0000-00

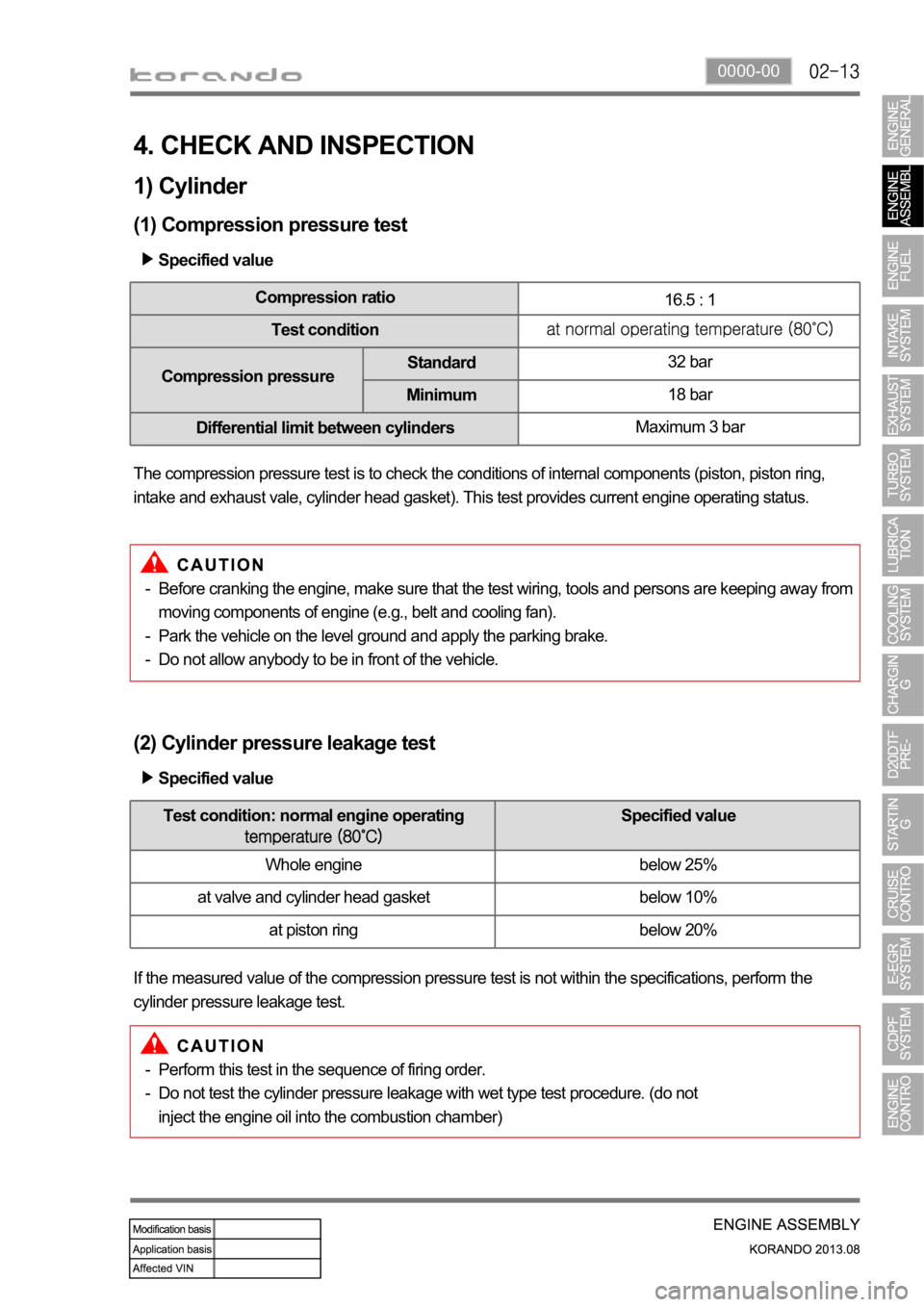

4. CHECK AND INSPECTION

1) Cylinder

(1) Compression pressure test

Specified value

Compression ratio

16.5 : 1

Test condition

Compression pressureStandard32 bar

Minimum18 bar

Differential limit between cylindersMaximum 3 bar

The compression pressure test is to check the conditions of internal components (piston, piston ring,

intake and exhaust vale, cylinder head gasket). This test provides current engine operating status.

Before cranking the engine, make sure that the test wiring, tools and persons are keeping away from

moving components of engine (e.g., belt and cooling fan).

Park the vehicle on the level ground and apply the parking brake.

Do not allow anybody to be in front of the vehicle. -

-

-

(2) Cylinder pressure leakage test

If the measured value of the compression pressure test is not within the specifications, perform the

cylinder pressure leakage test.Specified value

Perform this test in the sequence of firing order.

Do not test the cylinder pressure leakage with wet type test procedure. (do not

inject the engine oil into the combustion chamber) -

-

Test condition: normal engine operating Specified value

Whole engine below 25%

at valve and cylinder head gasket below 10%

at piston ring below 20%

Page 209 of 1336

0000-00

2) Cylinder Head

(1) Cylinder head mating surface check

Specified value

Total height "A"131.9 to 132.1 mm

Minimum height after machining131.9mm

FlatnessLongitudinal direction0.1 / 150

Transverse direction0.15

Parallel deviation of cylinder headbelow 0.1 mm

Peak-to valley of surfaceRmax7

Rz6.3

valve recess "a"Intake valve

0.6 to 1.0 mm

Exhaust valve

Measure the cylinder head height "A". 1.

If the height is less than the limit, the cylinder

head must be replaced. -

Insert the valves into the valve guides and

measure the recesses. 2.

If the measured value is out of the specified

range, machine the valve seat as much as

necessary until the specified value is

achieved. -

0.6 to 1.0 mm

(2) Cylinder head pressure Leak test

with compressed air to 2 bar.

Page 215 of 1336

0000-00

Intake manifold

4. INTAKE/EXHAUST SYSTEM

1) Intake Manifold

Intake manifold is installed on the cylinder head with 8 bolts. The variable swirl valve is introduced to

improve the EGR gas mixture and turbulence in combustion chamber and to decrease the exhaust gas.

2) Exhaust Manifold

Exhaust manifold is installed on the cylinder head with 10 stud bolts and nuts. EGR port is integrated in

cylinder head.Components

Exhaust manifold

Components

Page 217 of 1336

0000-00

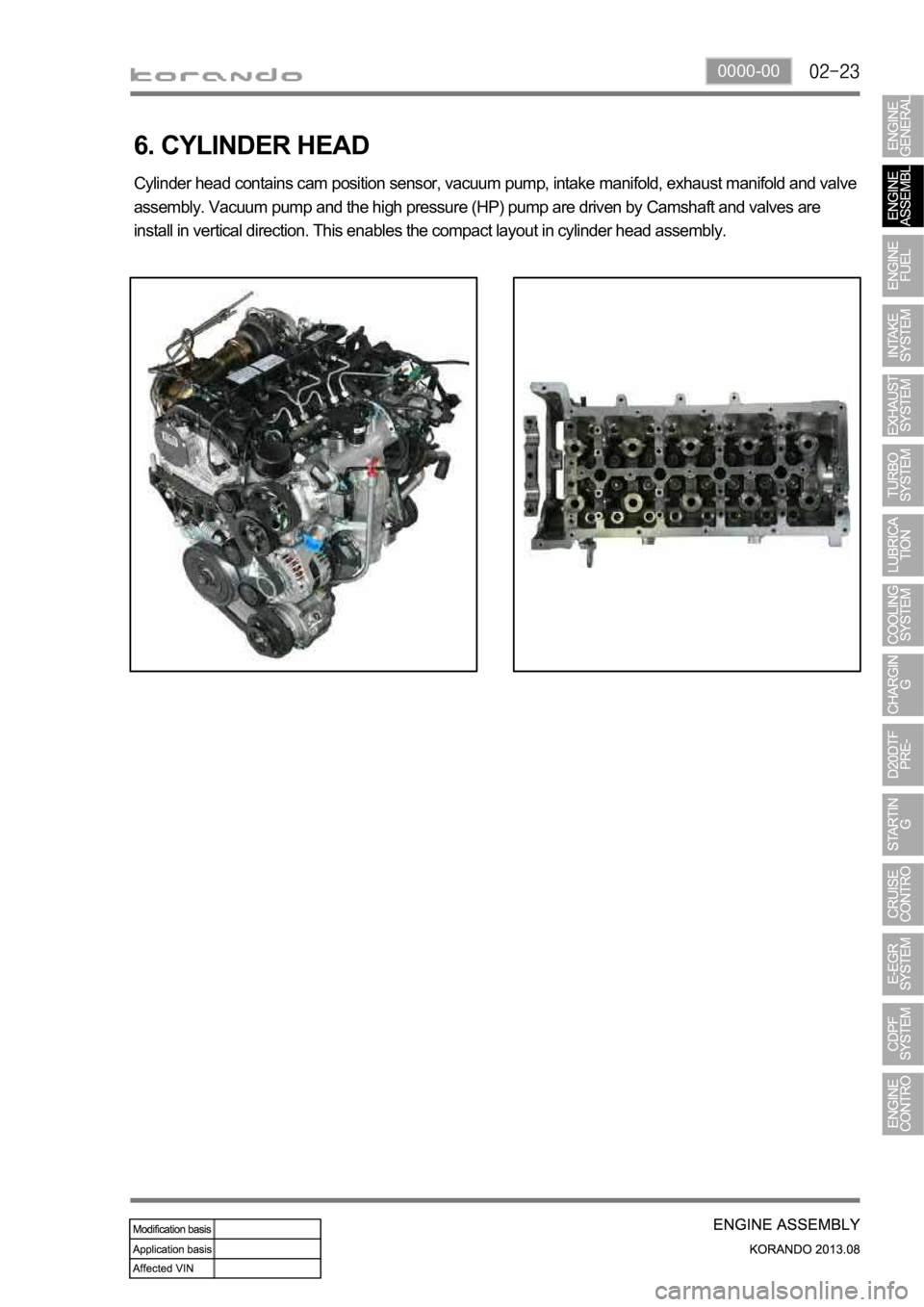

6. CYLINDER HEAD

Cylinder head contains cam position sensor, vacuum pump, intake manifold, exhaust manifold and valve

assembly. Vacuum pump and the high pressure (HP) pump are driven by Camshaft and valves are

install in vertical direction. This enables the compact layout in cylinder head assembly.

Page 218 of 1336

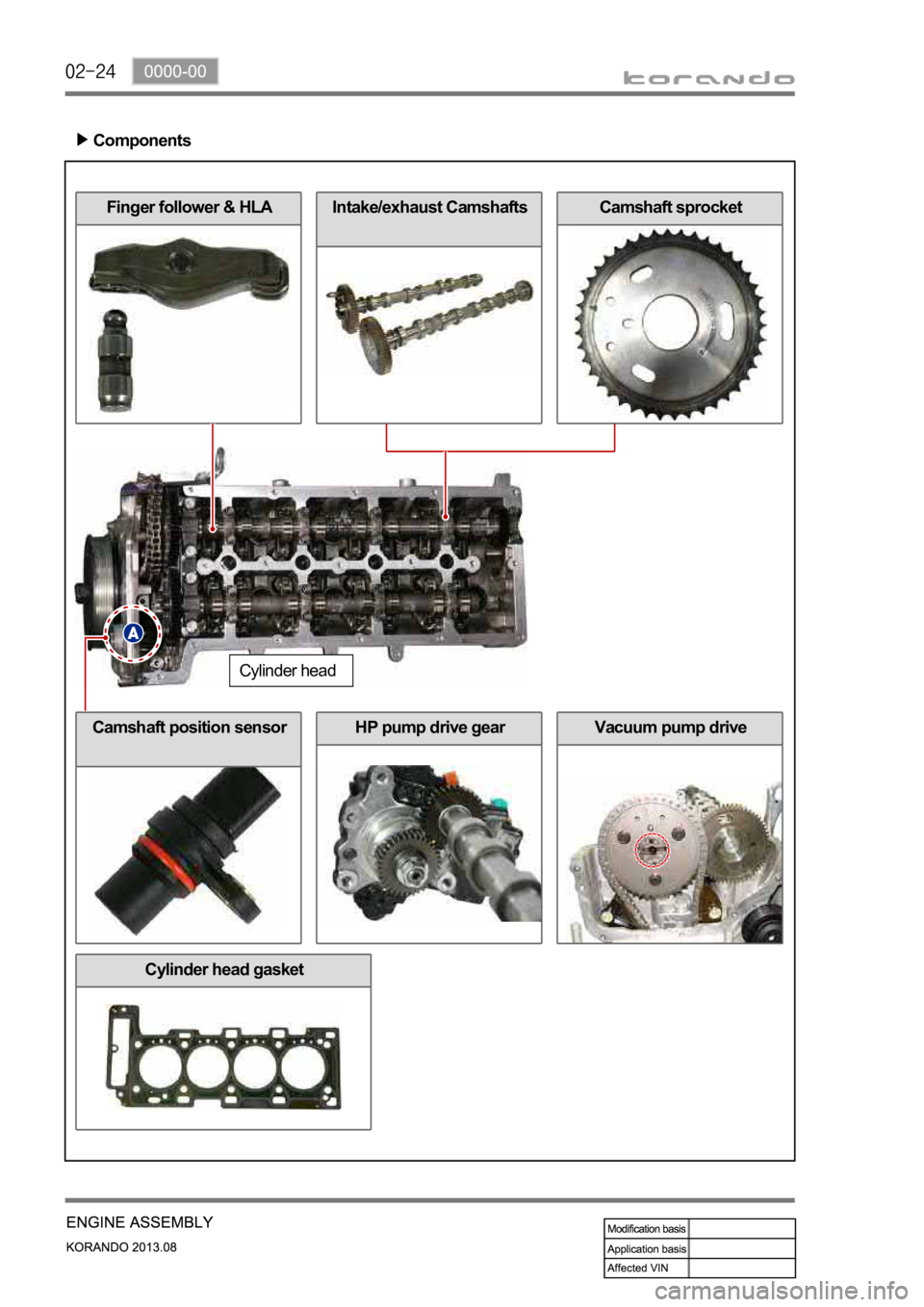

Vacuum pump drive

Intake/exhaust CamshaftsCamshaft sprocketFinger follower & HLA

Components

Cylinder head

Camshaft position sensorHP pump drive gear

Cylinder head gasket

Page 219 of 1336

0000-00

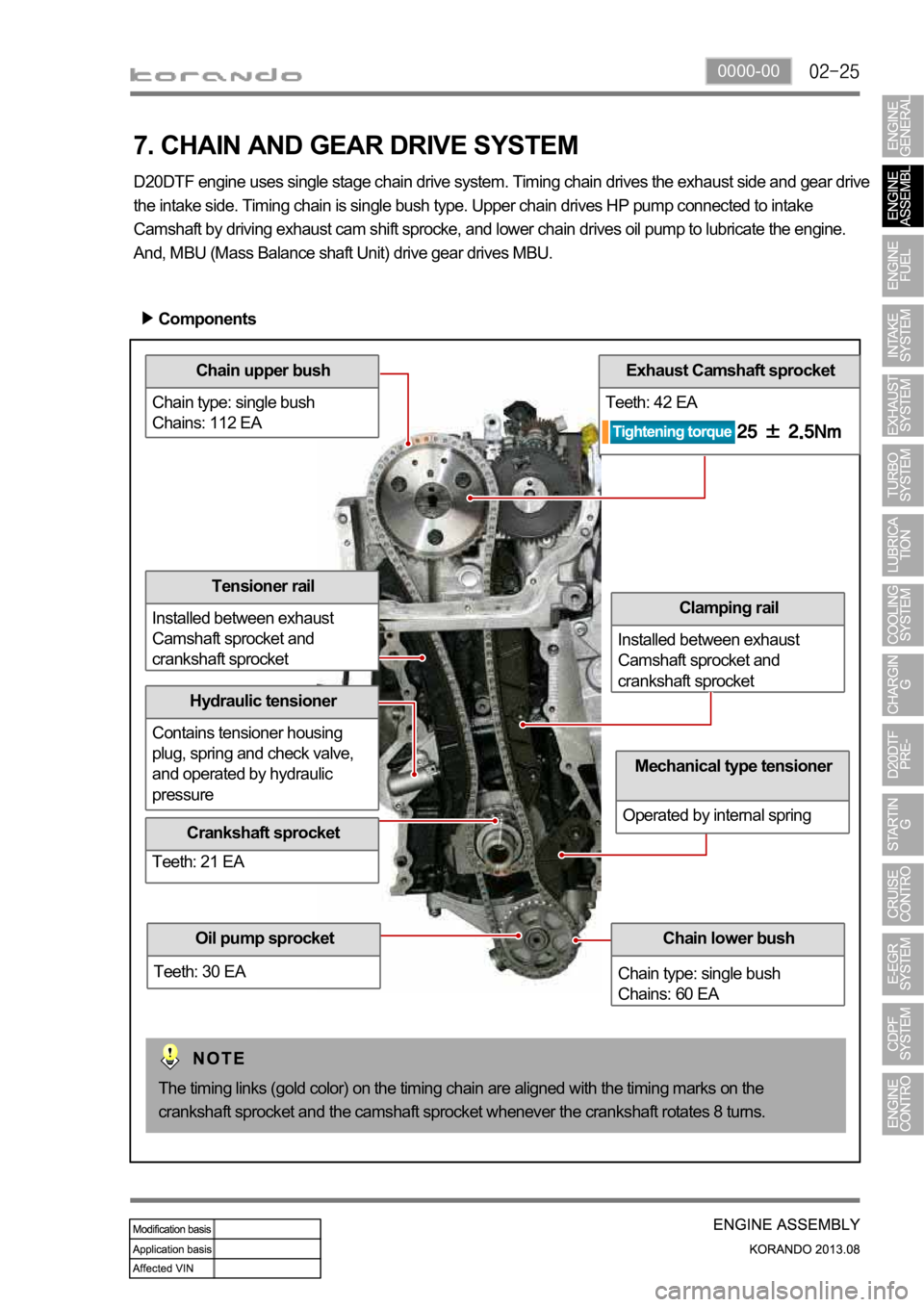

Chain upper bush

Chain type: single bush

Chains: 112 EA

Hydraulic tensioner

Contains tensioner housing

plug, spring and check valve,

and operated by hydraulic

pressure

Exhaust Camshaft sprocket

Teeth: 42 EA

Clamping rail

Installed between exhaust

Camshaft sprocket and

crankshaft sprocket

7. CHAIN AND GEAR DRIVE SYSTEM

D20DTF engine uses single stage chain drive system. Timing chain drives the exhaust side and gear drive

the intake side. Timing chain is single bush type. Upper chain drives HP pump connected to intake

Camshaft by driving exhaust cam shift sprocke, and lower chain drives oil pump to lubricate the engine.

And, MBU (Mass Balance shaft Unit) drive gear drives MBU.

Components

Chain lower bush

Chain type: single bush

Chains: 60 EA

Mechanical type tensioner

Operated by internal spring

The timing links (gold color) on the timing chain are aligned with the timing marks on the

crankshaft sprocket and the camshaft sprocket whenever the crankshaft rotates 8 turns.

Oil pump sprocket

Teeth: 30 EA

Tensioner rail

Installed between exhaust

Camshaft sprocket and

crankshaft sprocket

Crankshaft sprocket

Teeth: 21 EA

Page 220 of 1336

Intake/exhaust Camshaft assembly

Components

Intake Camshaft

HP pump drive gearExhaust

Camshaft

Connected to

vacuum pump