SSANGYONG MUSSO 1998 Workshop Repair Manual

Manufacturer: SSANGYONG, Model Year: 1998, Model line: MUSSO, Model: SSANGYONG MUSSO 1998Pages: 1463, PDF Size: 19.88 MB

Page 691 of 1463

1F2-42 M161 ENGINE CONTROLS

Pin No.

61

62

63

64

65

66

67

68

69

70

71

72

73

74

75

76

77

78

79

80

81

82

83

84

85

86

87

88

89

90

Abbreviation Description

-

-

Injector-cylinder 1

Injector-cylinder 2

Injector-cylinder 3

Injector-cylinder 4

E-GAS motor plus

E-GAS motor minus

Power ground TM.31

-

Ignition coil cylinder 2+3

Ignition coil cylinder 1+4

Camshaft control

-

Second air pump relay

-

Engine coolant temperature

Temperature ground

Intake air temperature

Hot film air mass signal

-

-

E-GAS potentiometer ground

E-GAS potentiometer 2 signal

-

E-GAS potentiometer 1 signal

-

-

-

-

-

EV1

EV4

EV2

EV3

M+

M-

TM.31

-

ZSB23

ZSA14

NWS

-

-

SLP

-

MT

GND

LT

HFM

-

-

-

IP2S

-

IP1S

-

-

--

-

l

l

l

l

l

l

l

-

l

l

l

-

-

¡

-

l

l

l

l

-

-

l

l

-

l

-

-

-

-

-

l

l

l

l

l

l

l

-

l

l

l

-

-

¡

-

l

l

l

l

-

-

l

l

-

l

-

-

-

E23 ENG,

4speed A/T E23 ENG,

5speed A/T

Page 692 of 1463

M161 ENGINE CONTROLS 1F2-43

Pin No.Abbreiation Description

-

-

-

-

-

-

-

-

Crankshaft sensor ground

Crankshaft sensor signal

-

-

-

Camshaft sensor ground

Hot film air mass ground

Camshaft sensor signal

-

Hot film air mass supply

-

-

-

E-GAS potentiometer supply

-

-

-

-

Knock sensor 1 ground

Knock sensor 1 signal

-

-

91

92

93

94

95

96

97

98

99

100

101

102

103

104

105

106

107

108

109

11 0

111

11 2

11 3

11 4

11 5

11 6

11 7

11 8

11 9

120-

-

-

-

-

-

-

-

KW-

KW+

-

-

-

NOWE-

GND

NOWE+

-

V-REF.HFM

-

-

-

V-REF.DK

-

-

-

-

GND

KS1

-

-

-

-

-

-

-

-

-

-

l

l

-

-

-

l

l

l

-

l

-

-

-

l

-

-

-

-

l

l

-

--

-

-

-

-

-

-

-

l

l

-

-

-

l

l

l

-

l

-

-

-

l

-

-

-

-

l

l

-

-

E23 ENG,

4speed A/T E23 ENG,

5speed A/T

-

-

-

-

-

-

-

-

l

l

-

-

-

l

l

l

-

l

-

-

-

l

-

-

-

-

l

l

-

-

E23 ENG,

4speed A/T

Page 693 of 1463

1F2-44 M161 ENGINE CONTROLS

Removal & Installation Procedure

· ·· ·

·When removing the ECU only

1. Turn the ignition switch to "OFF" position.

2. Disconnect the negative battery cable.

3. Disconnect the couplings from ECU.

4. Unscrew the left and right bolt (3) on bolt (1) and auxiliarly

bracket and remove the auxiliarly bracket from the bracket

assembly (2).

Installation Notice

5. Unscrew the four bolts (5) and disconnect the ECU (6) from

the bracket assenbly.

Installation Notice

6. Installation should follow the removal procedure in the

reverse order.

Tightening Torque6 - 8 Nm

5 - 7 Nm(1)

(3)

Tightening Torque 5 - 7 Nm

8. Unscrew the bolts (5) and disconnect the ECU (6) from the

bracket assenbly.

Installation Notice · ·· ·

·When Removing the ECU with ABS or ABS/ASR Unit

1. Turn the ignition switch to "OFF" position.

2. Disconnect the negative battery cable.

3. Disconnect the couplings from ECU.

4. Disconnect the coupling from ABS or ABS/ASR unit.

5. Unscrew the bolt (1) and the left and right flange nuts.

6. Remove the ECU with ABS or ABS/ASR unit assembly.

7. Unscrew the left and right bolt (3) on the auxiliary bracket

and remove the auxiliary bracket from the bracket assembly.

Installation Notice

Tightening Torque 6 - 8 Nm

Tightening Torque 5 - 7 Nm

Tightening Torque 5 - 7 Nm

9. Installation should follow the removal procedure in the

reverse order.

Page 694 of 1463

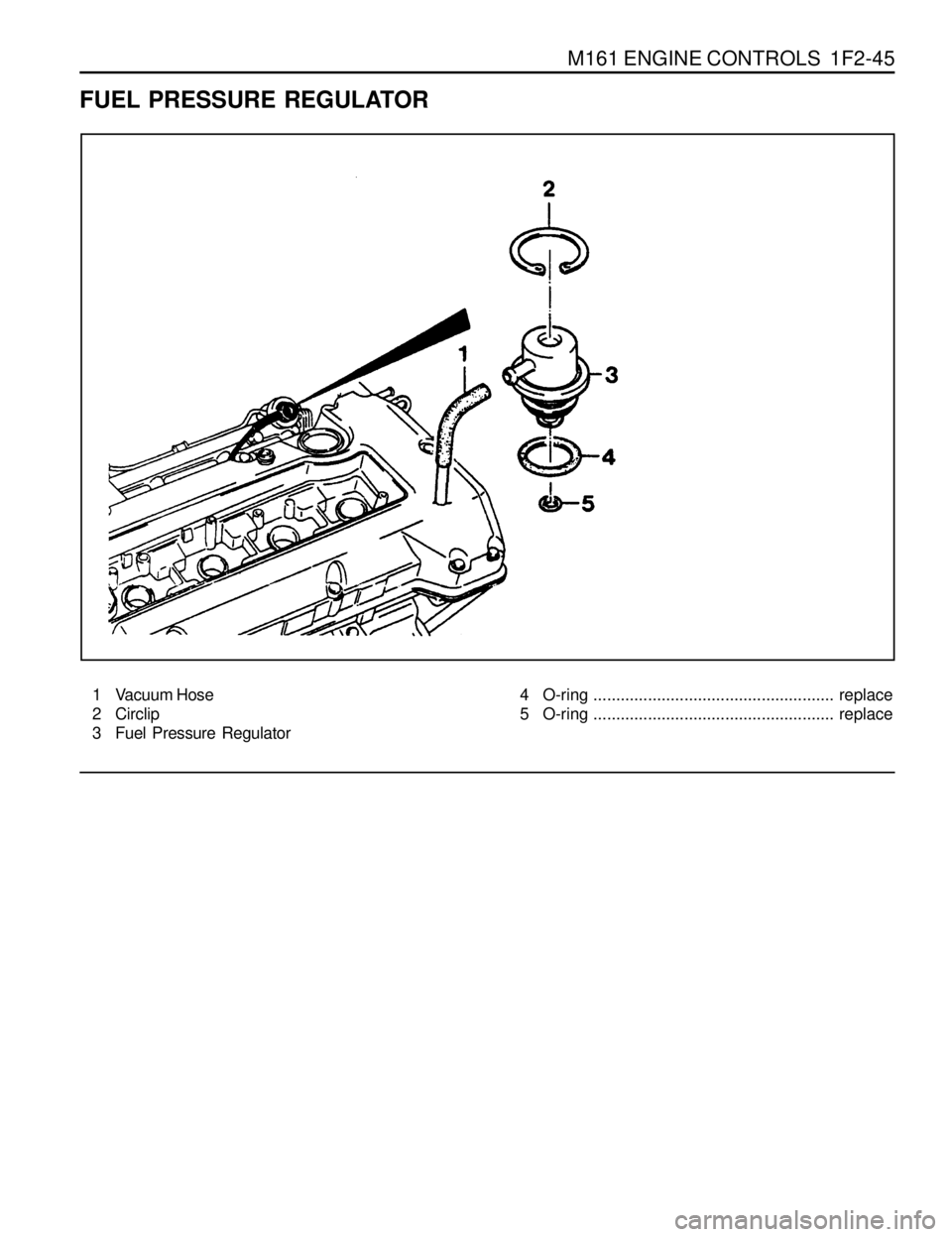

M161 ENGINE CONTROLS 1F2-45

1 Vacuum Hose

2 Circlip

3 Fuel Pressure Regulator

FUEL PRESSURE REGULATOR

4 O-ring ..................................................... replace

5 O-ring ..................................................... replace

Page 695 of 1463

1F2-46 M161 ENGINE CONTROLS

3. Disconnect the vacuum hose.

4. Disconnect the circlip and remove the fuel pressure

regulator.

5. Apply the oil to O-ring lightly and then replace it.

6. Installation should follow the removal procedure in the

reverse order.

7. Check for fuel pressure and internal leaks by operating the

engine. 2. Discharge the pressure in fuel supply system by pressing

the service valve.

Removal & Installation Procedure

1. Remove the fuel pressure test connector.

Page 696 of 1463

M161 ENGINE CONTROLS 1F2-47

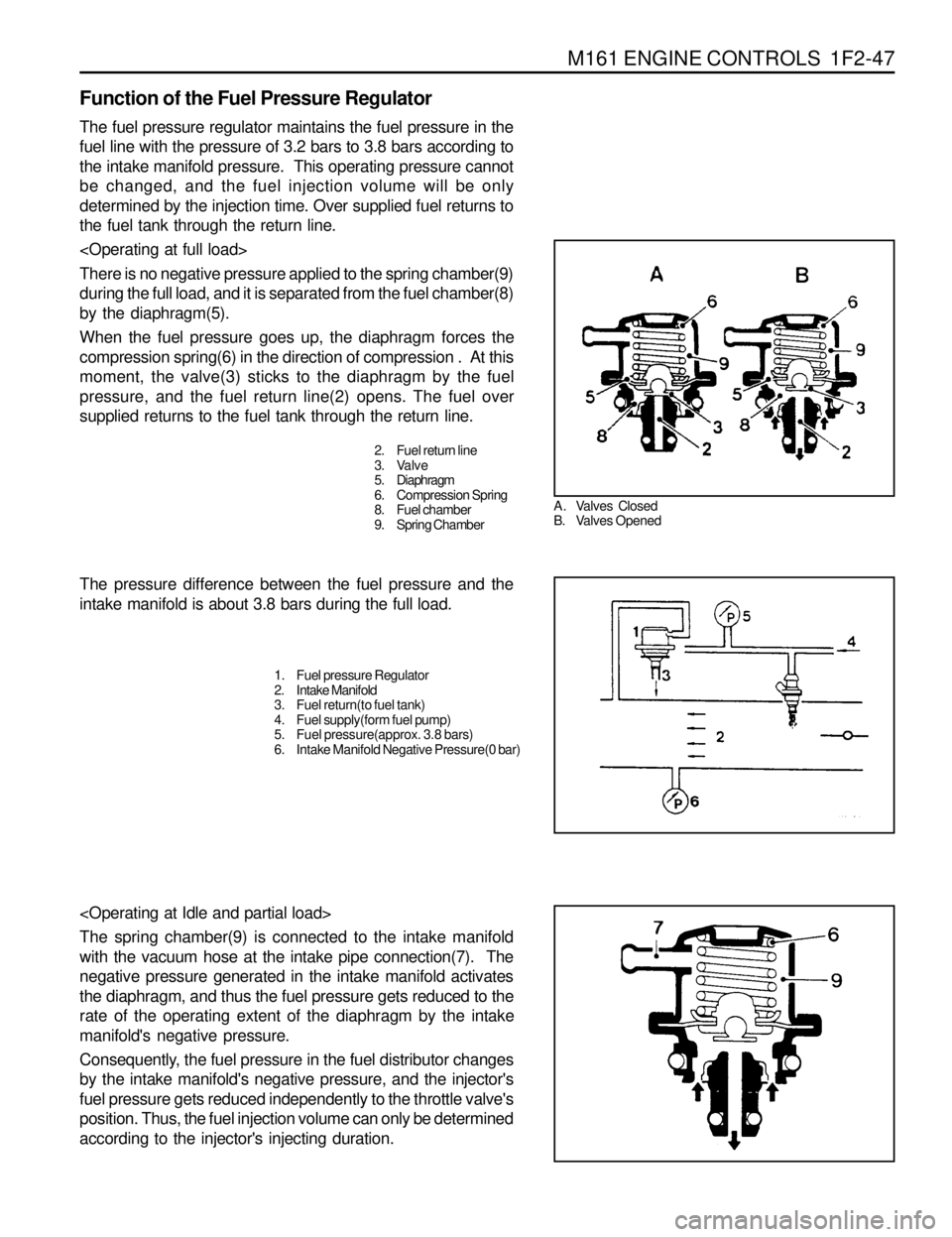

A . Valves Closed

B. Valves Opened

The pressure difference between the fuel pressure and the

intake manifold is about 3.8 bars during the full load.

The spring chamber(9) is connected to the intake manifold

with the vacuum hose at the intake pipe connection(7). The

negative pressure generated in the intake manifold activates

the diaphragm, and thus the fuel pressure gets reduced to the

rate of the operating extent of the diaphragm by the intake

manifold's negative pressure.

Consequently, the fuel pressure in the fuel distributor changes

by the intake manifold's negative pressure, and the injector's

fuel pressure gets reduced independently to the throttle valve's

position. Thus, the fuel injection volume can only be determined

according to the injector's injecting duration.

2. Fuel return line

3. Valve

5. Diaphragm

6. Compression Spring

8. Fuel chamber

9. Spring Chamber

1. Fuel pressure Regulator

2. Intake Manifold

3. Fuel return(to fuel tank)

4. Fuel supply(form fuel pump)

5. Fuel pressure(approx. 3.8 bars)

6. Intake Manifold Negative Pressure(0 bar)

Function of the Fuel Pressure Regulator

The fuel pressure regulator maintains the fuel pressure in the

fuel line with the pressure of 3.2 bars to 3.8 bars according to

the intake manifold pressure. This operating pressure cannot

be changed, and the fuel injection volume will be only

determined by the injection time. Over supplied fuel returns to

the fuel tank through the return line.

There is no negative pressure applied to the spring chamber(9)

during the full load, and it is separated from the fuel chamber(8)

by the diaphragm(5).

When the fuel pressure goes up, the diaphragm forces the

compression spring(6) in the direction of compression . At this

moment, the valve(3) sticks to the diaphragm by the fuel

pressure, and the fuel return line(2) opens. The fuel over

supplied returns to the fuel tank through the return line.

Page 697 of 1463

1F2-48 M161 ENGINE CONTROLS

The pressure difference between the fuel pressure and

the intake manifold is approx. 3.2 bars during idling.

1. Fuel pressure Regulator

2. Intake Manifold

3. Fuel Return(to fuel tank)

4. Fuel Supply(from fuel pump)

7. Fuel Pressure(approx. 3.2 bars)

8. Intake Manifold Negative Pressure(0.6 bars)

A. Fuel pressure

B. Intake Manifold Negative Pressure

LL. Idling

TL. Partial load

VL. Full load

Page 698 of 1463

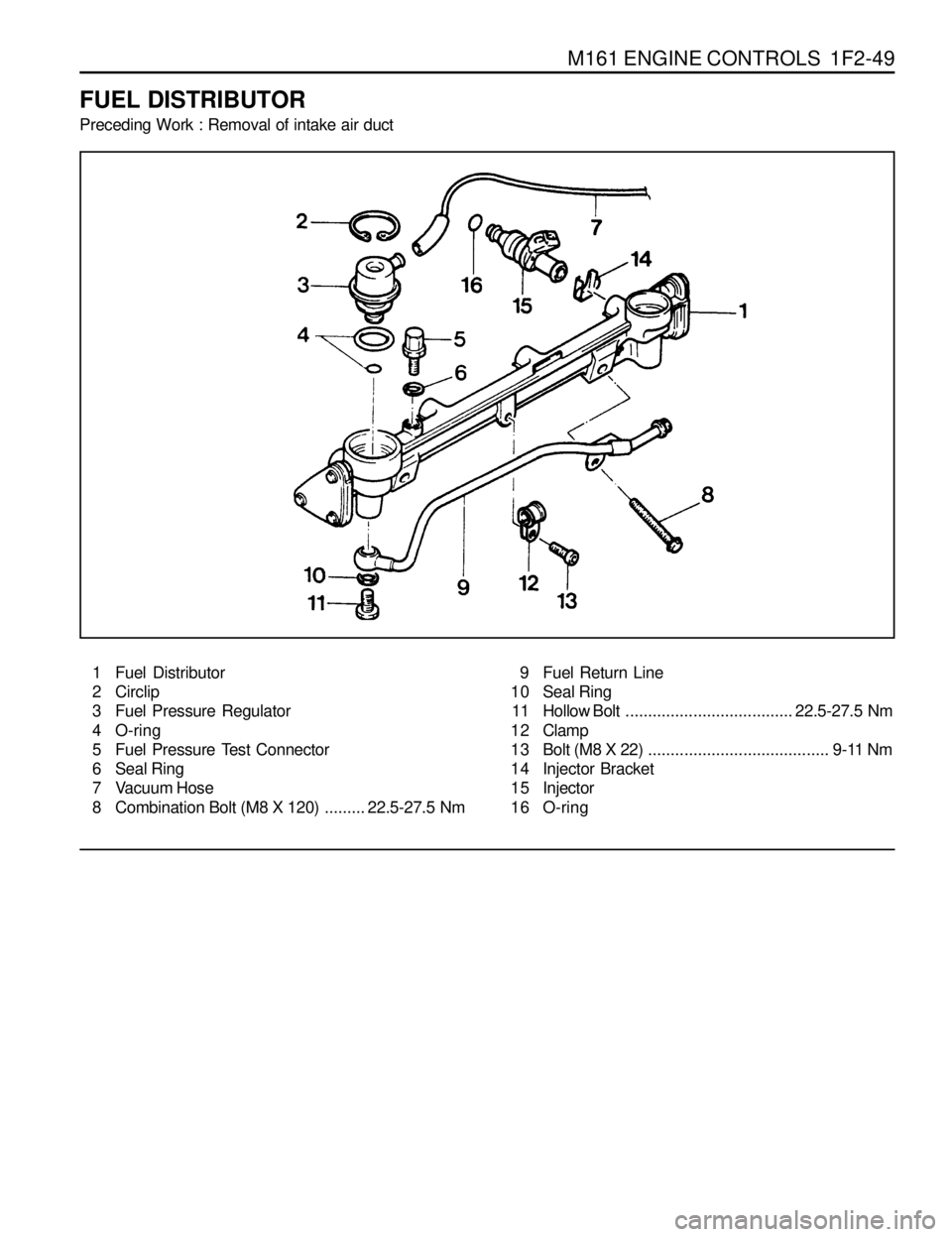

M161 ENGINE CONTROLS 1F2-49

FUEL DISTRIBUTOR

Preceding Work : Removal of intake air duct

1 Fuel Distributor

2 Circlip

3 Fuel Pressure Regulator

4 O-ring

5 Fuel Pressure Test Connector

6 Seal Ring

7 Vacuum Hose

8 Combination Bolt (M8 X 120).........22.5-27.5 Nm9 Fuel Return Line

10 Seal Ring

11 Hollow Bolt.....................................22.5-27.5 Nm

1 2 Clamp

13 Bolt (M8 X 22)........................................ 9-11 Nm

14 Injector Bracket

15 Injector

16 O-ring

Page 699 of 1463

1F2-50 M161 ENGINE CONTROLS

Tightening Torque

22.5 - 27.5 Nm

Tightening Torque22.5 - 27.5 Nm

Removal & Installation Procedure

1. Discharge the fuel pressure from the fuel pressure test

connector by pushing service valve (arrow).

2. Disconnect the battery ground cable.

3. Disconnect the vacuum hose from the fuel pressure

regulator.

4. Disconnect the cable from ignition coil.

5. Remove the fuel return and supply line.

Installation Notice

Notice

lFor removal, cover around parts with cloths not to

bestained by fuel.

lIn case of checking the injector only, do not remove the

fuel return and supply line.

6. Remove the four injector connectors (arrows).

7. Unscrew the two combination bolts (8).

Installation Notice

Page 700 of 1463

M161 ENGINE CONTROLS 1F2-51

9. Installation should follow the removal procedure in the

reverse order.

10. Check for fuel pressure and internal leakage by operating

the engine. 8. Pull out the injector from intake manifold and remove the

fuel distributor.

Notice

Replace the injector O-ring with new one.

Ignition Coil & Cable

lIgnition coil T1/1 No.1 cylinder + No.4 cylinder

lInition coil T1/2 No.1 cylinder + No.4 cylinder