SSANGYONG MUSSO 1998 Workshop Repair Manual

MUSSO 1998

SSANGYONG

SSANGYONG

https://www.carmanualsonline.info/img/67/57510/w960_57510-0.png

SSANGYONG MUSSO 1998 Workshop Repair Manual

Trending: stop start, mileage, reset, air bleeding, fuse box diagram, coolant level, drain bolt

Page 711 of 1463

1F2-62 M161 ENGINE CONTROLS

PURGE SWITCHOVER VALVE

1 Purge Control valve

2 Line to engine

3 Line to canister

4 Canister

Functions

The fuel vaporization control system is installed to inhibit the

fuel vaporized gas from discharging into the atmosphere. The

fuel vaporized gas that is accumulated in the canister abstracts

through the purge switchover valve purification during the

engine combustion (except the decreasing mode) and coolant

temperature of over 80°C. For this reason, the ECU transacts

the engine speed, air inflow quantity, coolant temperature, and

intake temperature.

The purge switchover valve is activated by the ECU frequency

according with the engine rotating speed to adjust the

purification rate. The purification rate is determined by the

continuous valve opening interval.

The purge switchover valve is activated by the ECU for the

following conditions :

lCoolant temperature of over 80°C

lEngine speed of over 1000rpm

l2 Minutes after starting

lWhen the fuel cut-off mode is not activated

Page 712 of 1463

M161 ENGINE CONTROLS 1F2-63

4. Remove the line to canister and measure the pressure with

the vacuum pressure gauge.

Test

1. Maintain the normal temperature and idling state by

operating the engine.

2. Connect the ECU terminal No.11 and No.34 and check for

normal operation through the output waves using the

scanner.

Notice

Test during purge control switchover valve operation after

the minimum of 1 minute after the engine turned on.

3. Connect the ECU terminal No.34 and No.10 and check for

current consumption during the ignition switch ON.

Purge switchover valve output wave Specified Value

0.3 - 0.5

Specified Value

> 50mbar

(after approx. 1min.)

purge switchover valve

operates at this time

Notice

Test while at normal temperature and at idling state by

operating the engine.

Page 713 of 1463

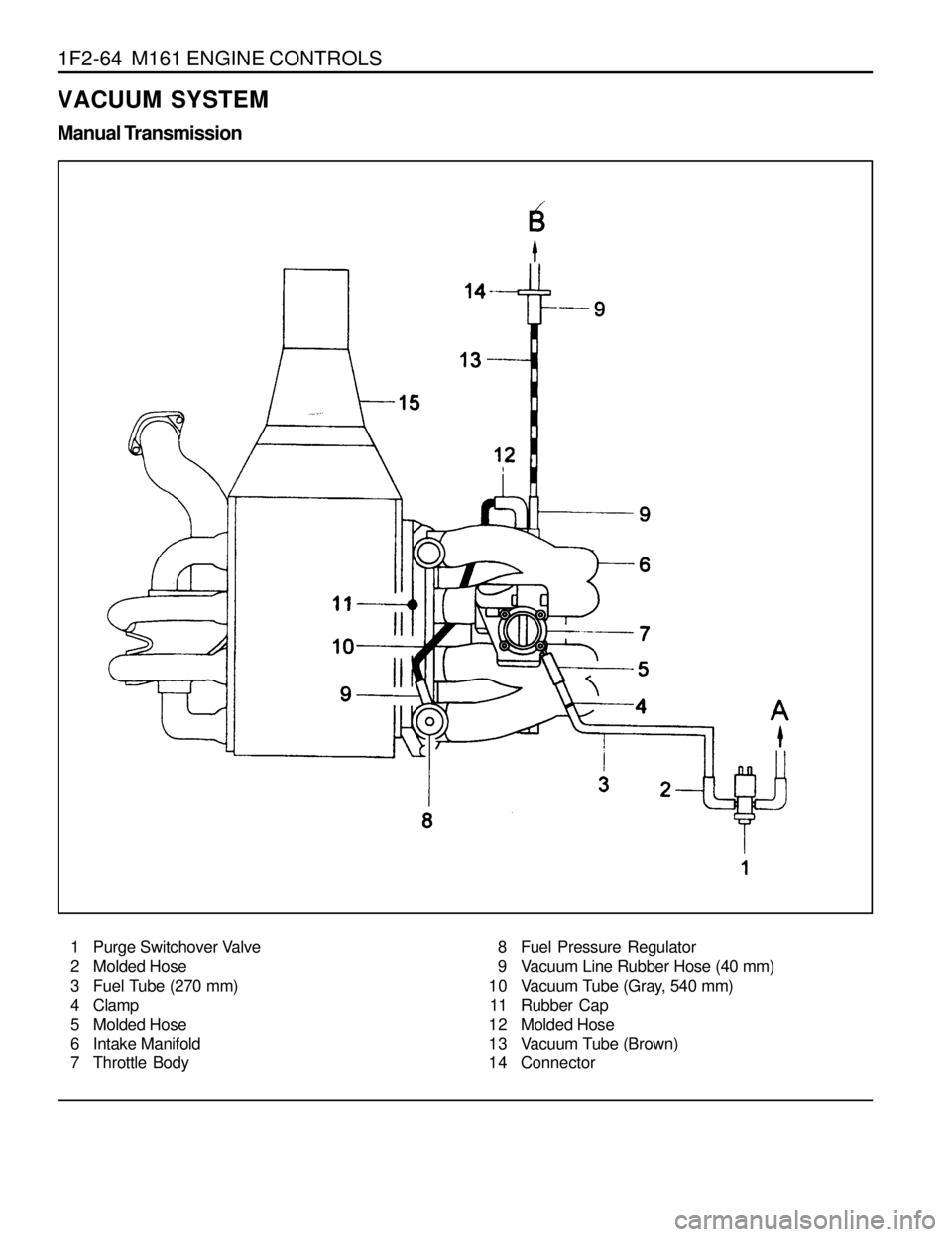

1F2-64 M161 ENGINE CONTROLS

1 Purge Switchover Valve

2 Molded Hose

3 Fuel Tube (270 mm)

4 Clamp

5 Molded Hose

6 Intake Manifold

7 Throttle Body

VACUUM SYSTEM

Manual Transmission

8 Fuel Pressure Regulator

9 Vacuum Line Rubber Hose (40 mm)

10 Vacuum Tube (Gray, 540 mm)

11 Rubber Cap

12 Molded Hose

13 Vacuum Tube (Brown)

14 Connector

Page 714 of 1463

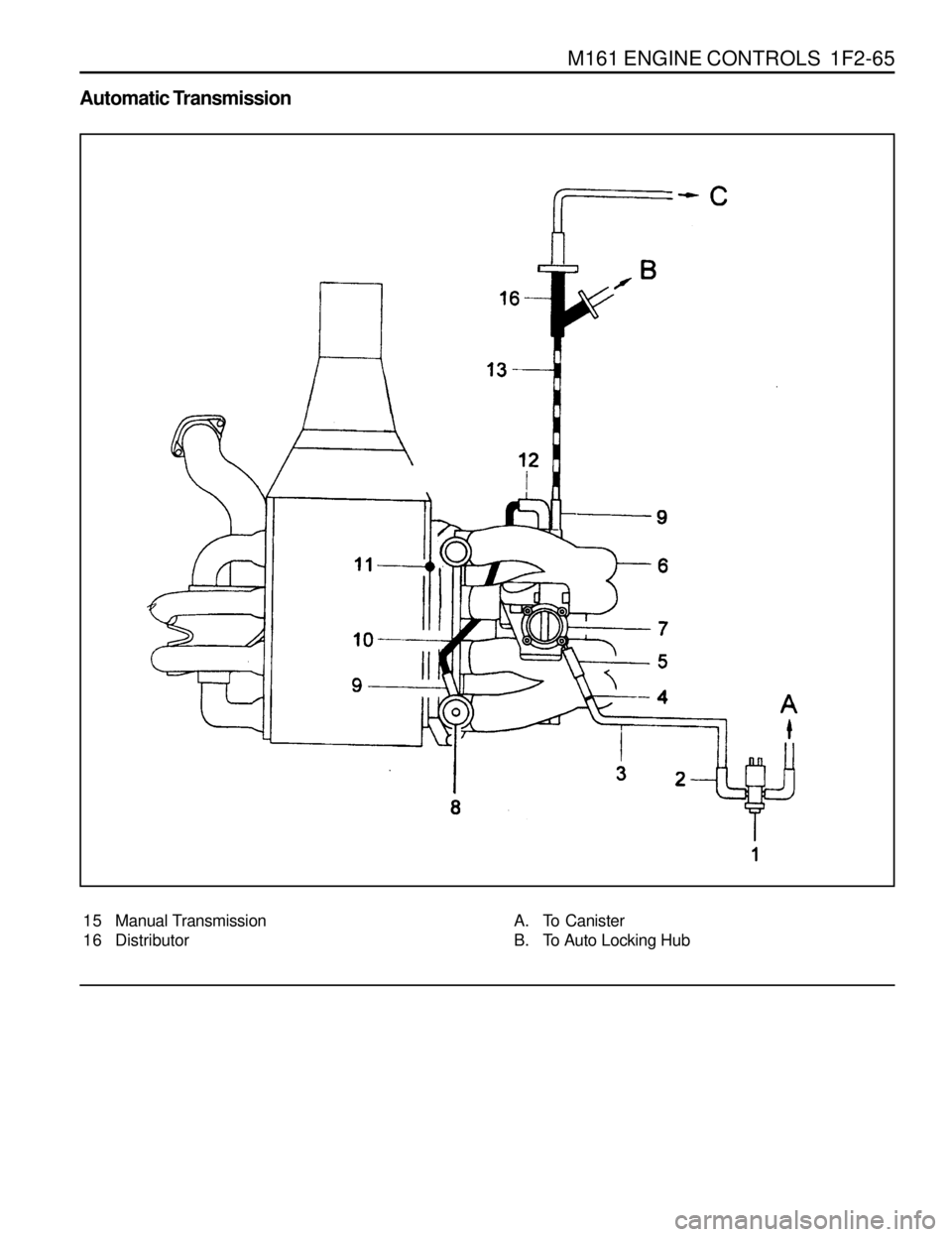

M161 ENGINE CONTROLS 1F2-65

15 Manual Transmission

16 Distributor

Automatic Transmission

A. To Canister

B. To Auto Locking Hub

Page 715 of 1463

1F2-66 M161 ENGINE CONTROLS

1 Crankshaft Position Sensor (connector)

2 Bolt (M6 X 14)........................................ 9-11 Nm

CRANKSHAFT POSITION SENSOR

Removal & Installation Procedure

1. Disconnect the wiring connector at the crankshaft position

sensor.

2. Unscrew the bolt (2) and remove the crankshaft position

sensor unit (3).

Installation Notice

3. Installation should follow the removal procedure in the

reverse order.3 Sensor Unit

Tightening Torque 9 - 11 Nm

Page 716 of 1463

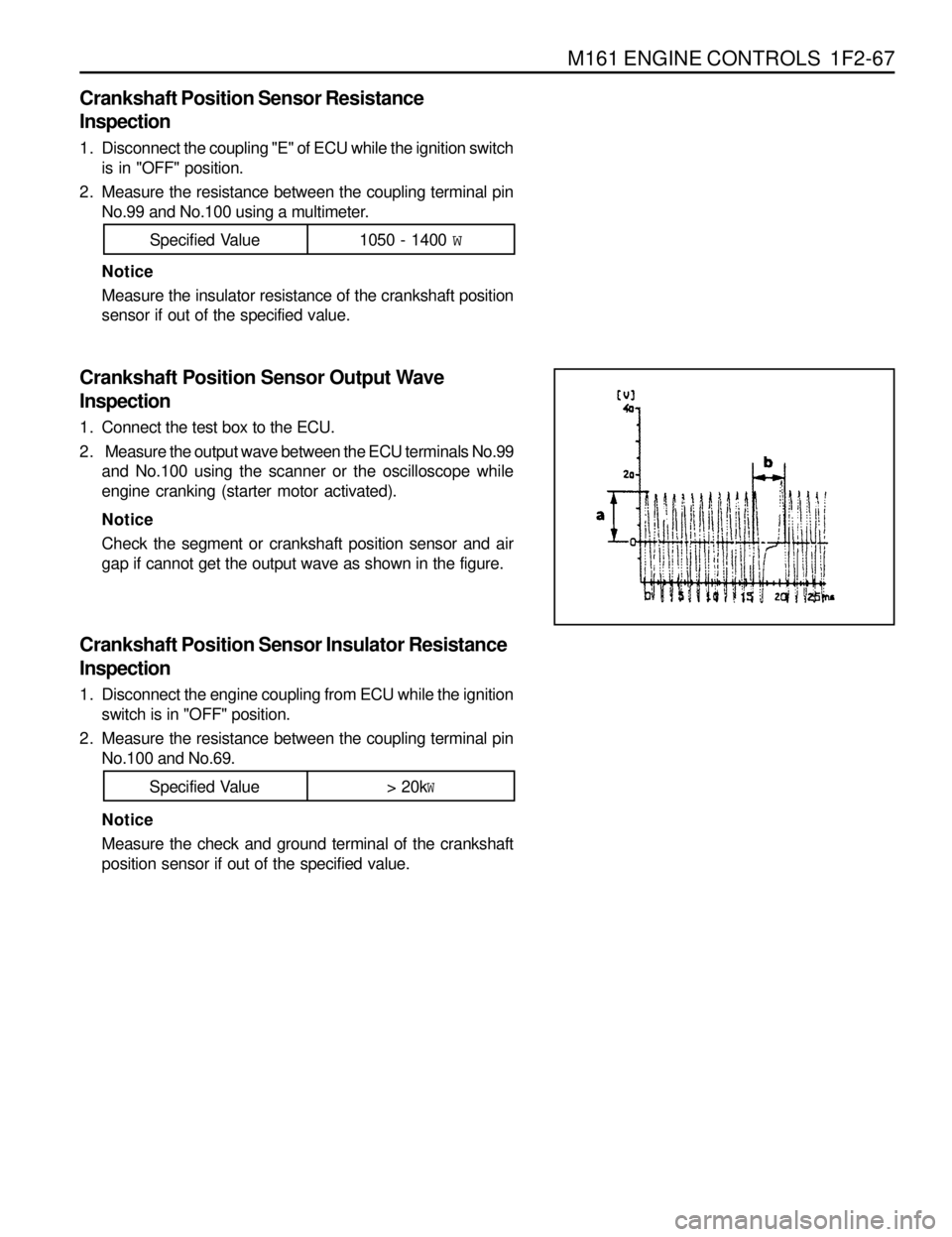

M161 ENGINE CONTROLS 1F2-67

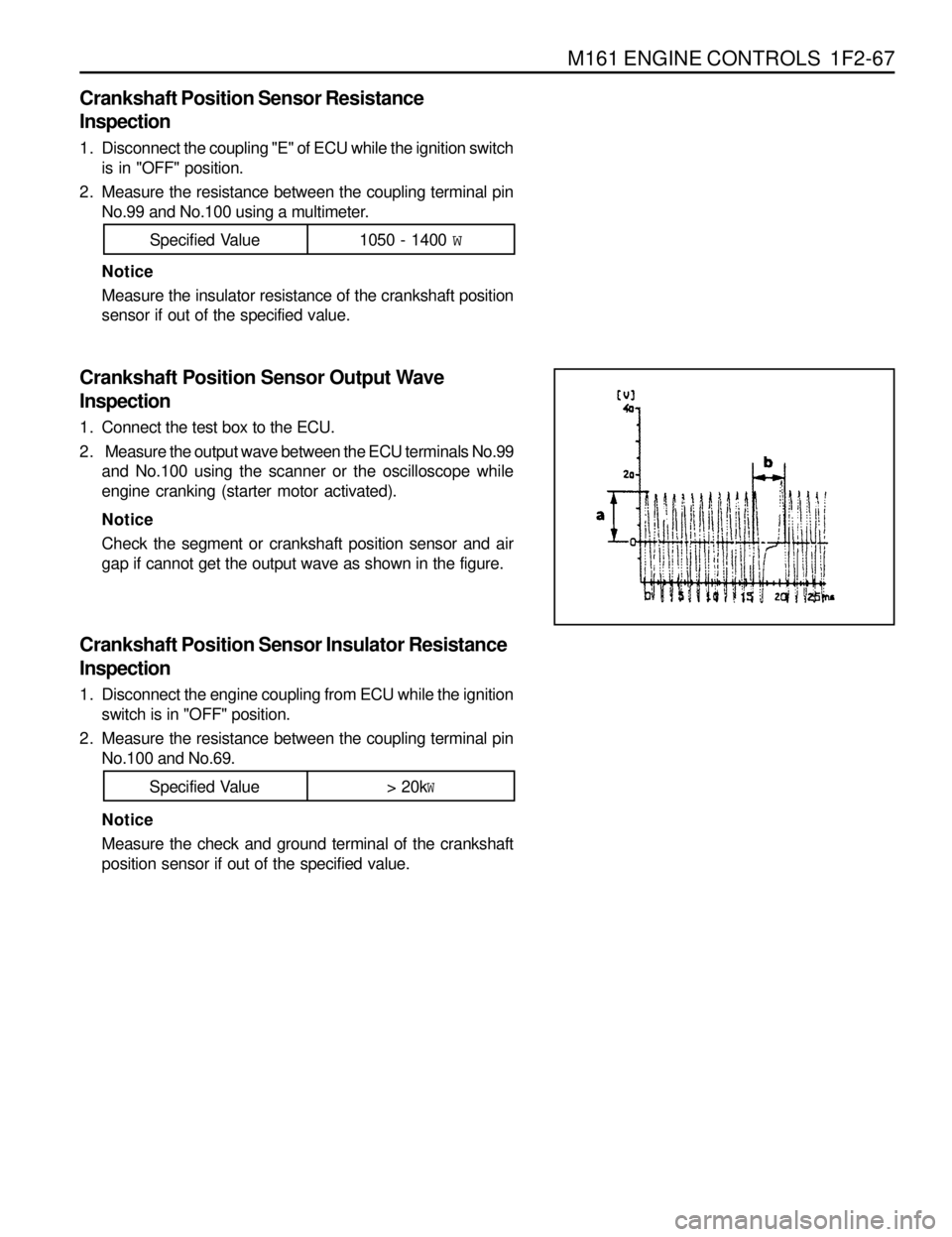

Crankshaft Position Sensor Resistance

Inspection

1. Disconnect the coupling "E" of ECU while the ignition switch

is in "OFF" position.

2. Measure the resistance between the coupling terminal pin

No.99 and No.100 using a multimeter.

Notice

Measure the insulator resistance of the crankshaft position

sensor if out of the specified value.

Crankshaft Position Sensor Output Wave

Inspection

1. Connect the test box to the ECU.

2. Measure the output wave between the ECU terminals No.99

and No.100 using the scanner or the oscilloscope while

engine cranking (starter motor activated).

Notice

Check the segment or crankshaft position sensor and air

gap if cannot get the output wave as shown in the figure.

Specified Value 1050 - 1400 W

Specified Value > 20kW

Crankshaft Position Sensor Insulator Resistance

Inspection

1. Disconnect the engine coupling from ECU while the ignition

switch is in "OFF" position.

2. Measure the resistance between the coupling terminal pin

No.100 and No.69.

Notice

Measure the check and ground terminal of the crankshaft

position sensor if out of the specified value.

Page 717 of 1463

1F2-68 M161 ENGINE CONTROLS

CAMSHAFT POSITION SENSOR

1 Bolt (M6 X 14)......................................... 9-11Nm

2 Camshaft Position Sensor

Removal & Installation Procedure

1. Disconnect the wiring connector from the camshaft position

sensor.

2. Unscrew the bolt (2) and remove the camshaft position

sensor.

Installation Notice3 Shim

5 O-ring

Tightening Torque 9 - 11 Nm

3. Check the clearance and replace the shim if necessary.

4. Check the O-ring for damage and replace it if necessary.

5. Installation should follow the removal procedure in the

reverse order.

Page 718 of 1463

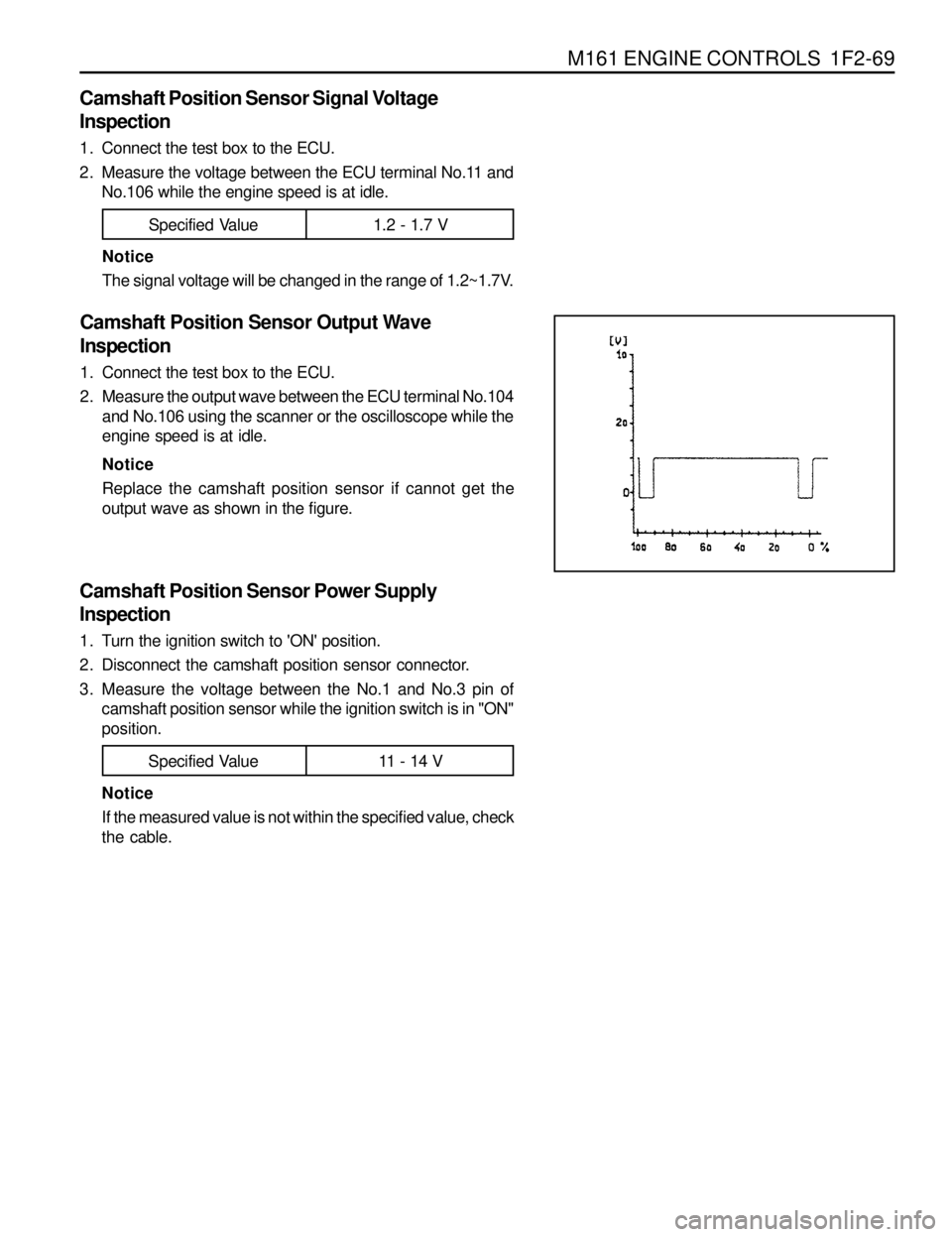

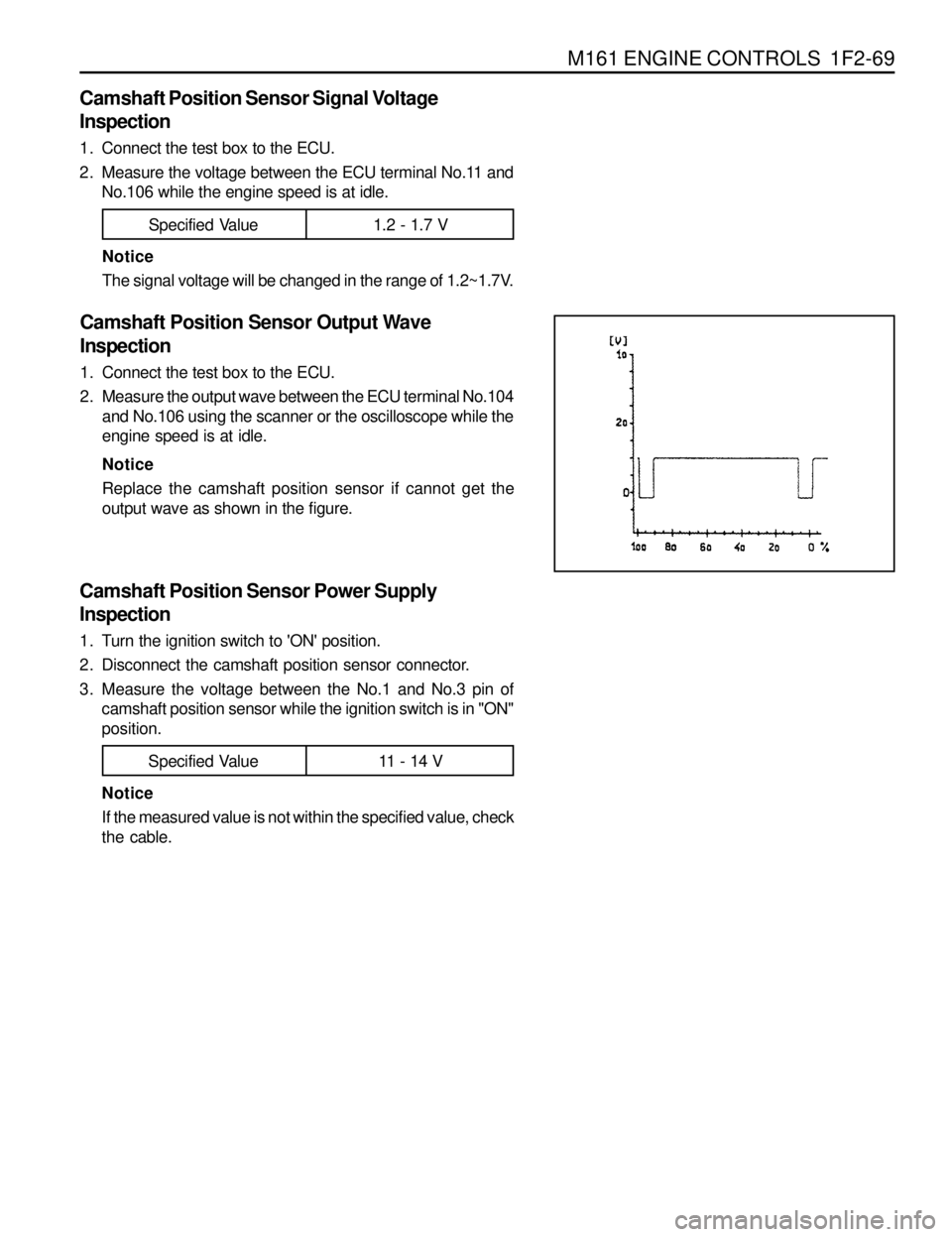

M161 ENGINE CONTROLS 1F2-69

Camshaft Position Sensor Power Supply

Inspection

1. Turn the ignition switch to 'ON' position.

2. Disconnect the camshaft position sensor connector.

3. Measure the voltage between the No.1 and No.3 pin of

camshaft position sensor while the ignition switch is in "ON"

position.

Notice

If the measured value is not within the specified value, check

the cable.Notice

The signal voltage will be changed in the range of 1.2~1.7V.

Camshaft Position Sensor Output Wave

Inspection

1. Connect the test box to the ECU.

2. Measure the output wave between the ECU terminal No.104

and No.106 using the scanner or the oscilloscope while the

engine speed is at idle.

Notice

Replace the camshaft position sensor if cannot get the

output wave as shown in the figure.

Specified Value 11 - 14 V

Specified Value 1.2 - 1.7 V

Camshaft Position Sensor Signal Voltage

Inspection

1. Connect the test box to the ECU.

2. Measure the voltage between the ECU terminal No.11 and

No.106 while the engine speed is at idle.

Page 719 of 1463

1F2-70 M161 ENGINE CONTROLS

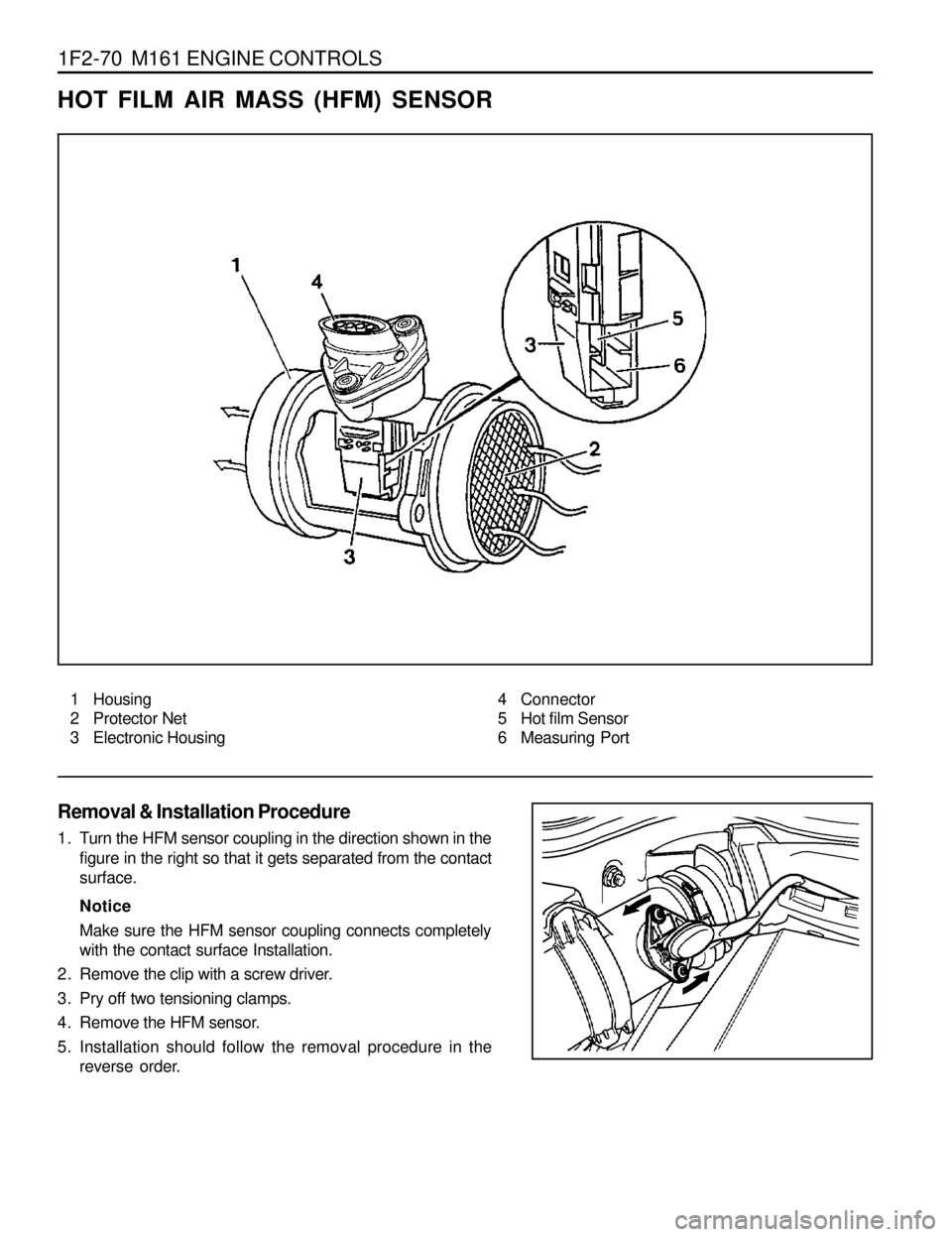

HOT FILM AIR MASS (HFM) SENSOR

1 Housing

2 Protector Net

3 Electronic Housing

Removal & Installation Procedure

1. Turn the HFM sensor coupling in the direction shown in the

figure in the right so that it gets separated from the contact

surface.

Notice

Make sure the HFM sensor coupling connects completely

with the contact surface Installation.

2. Remove the clip with a screw driver.

3. Pry off two tensioning clamps.

4. Remove the HFM sensor.

5. Installation should follow the removal procedure in the

reverse order.4 Connector

5 Hot film Sensor

6 Measuring Port

Page 720 of 1463

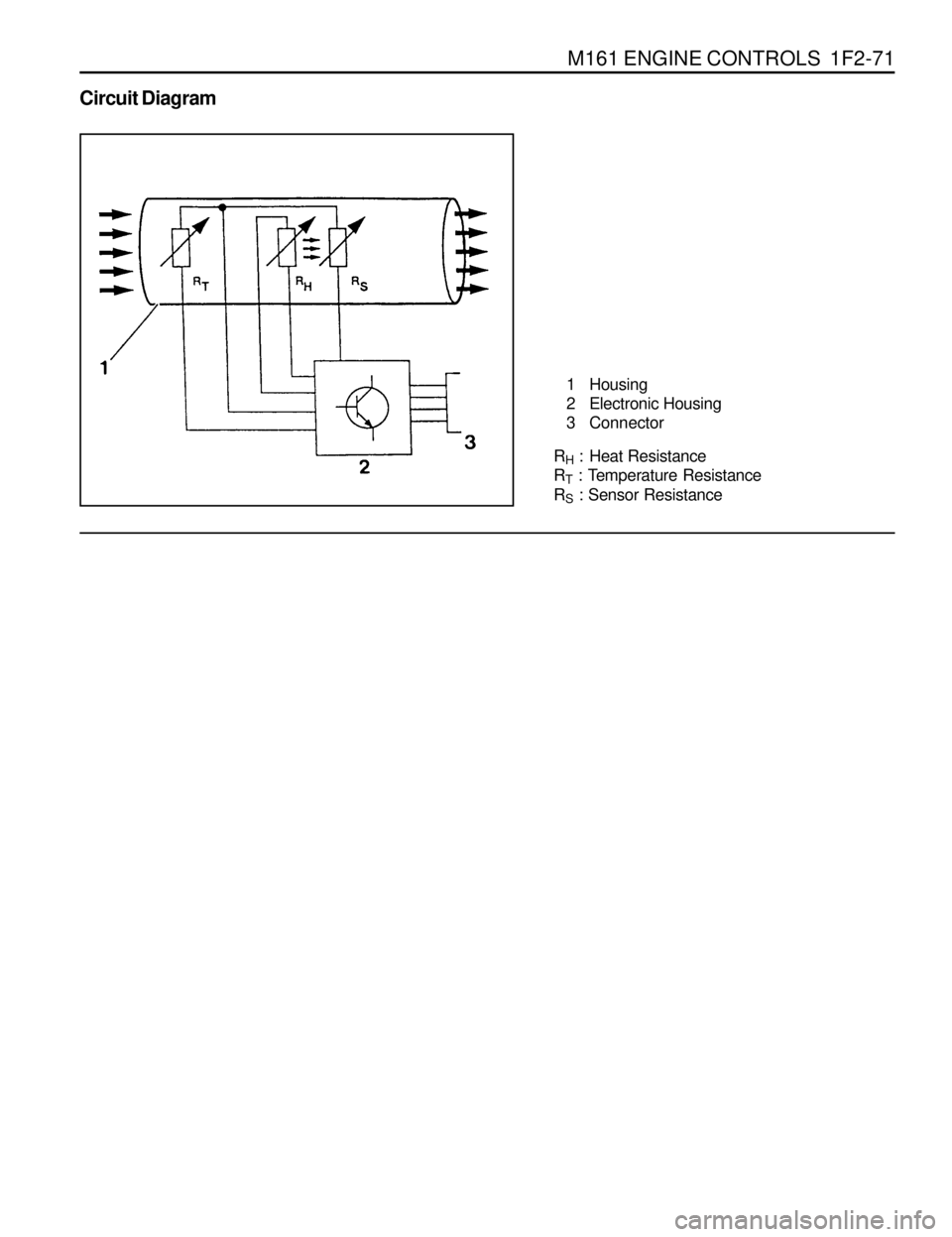

M161 ENGINE CONTROLS 1F2-71

Circuit Diagram

1 Housing

2 Electronic Housing

3 Connector

R

H : Heat Resistance

R

T : Temperature Resistance

R

S : Sensor Resistance

Trending: rear view mirror, four wheel drive, oil dipstick, clock, run flat, glow, lights