engine coolant SSANGYONG MUSSO 1998 Workshop Manual PDF

[x] Cancel search | Manufacturer: SSANGYONG, Model Year: 1998, Model line: MUSSO, Model: SSANGYONG MUSSO 1998Pages: 1463, PDF Size: 19.88 MB

Page 537 of 1463

1D3-16 OM600 ENGINE COOLING

THERMOSTAT

1 Thermostat

2 Seal....................................................... Replace

3 Thermostat Housing Cover4 Coolant Hose

5 Bolt............................................................10Nm

Page 538 of 1463

OM600 ENGINE COOLING 1D3-17

Removal & Installation Procedure

1. Drain the coolant completely.

2. Disconnect the coolant hose(4) from the thermostat housing

cover(3).

3. Remove the bolts(5) and then remove the thermostat(1)

and housing cover(3)

Installation Notice

Align the groove on thermostat and the housing cover

rib(arrow).

Tightening Torque 10 Nm

Notice

Replace the seal(2).

4. Installation should follow the removal procedure in the

reverse order.

Page 564 of 1463

1E3-2 OM600 ENGINE ELECTRICAL

Preheating System

General information

The preheating system consists of control, coolant temperature

sensor and glow plugs.

lControl relay - preheating time.

lCoolant temperature sensor.

lGlow plug.

GLOW PLUG

1 Wiring Harness

2 Nut .............................................................. 4 Nm3 Wire Terminal

4 Glow Plug

MAINTENANCE AND REPAIR

ON-VEHICLE SERVICE

Page 565 of 1463

OM600 ENGINE ELECTRICAL 1E3-3

1. Preheating time - control relay.

Control relay functions as followings :

lSwitching of preheating current.

lIndication of preheating finish.

lControl of preheating sequence.

lIndication of fault.

2. Coolant temperature sensor.

Coolant temperature sensor senses coolant’s temperature

and signals it to the preheating relay continuously.

3. Glow plug

The glow plug parts are housing with M12 ´ 1.25 thread

and heating pin in housing. It is connected in a parallel circuit

with the specified voltage of 11.5V.

The heating element has a heating coil and a control coil

and they are connected in series.

1. Control Coil

2. Heater Coil

4. Current and temperature of glow plug

lCurrent of glow plug

While the preheating system operates, current of about

30A flows in each glow plug and temperature of heating

coil rises very fast.

Due to the rise of temperature, the resistance of control

coil increases therefore the current is controlled to

about 8~15A and that protects the glow plug from over-

heating.

lTemperature of glow plug

The temperature of the glow plug reaches up to 900°C

after about 9 seconds and up to 1,050°C after 30

seconds.

Page 566 of 1463

1E3-4 OM600 ENGINE ELECTRICAL

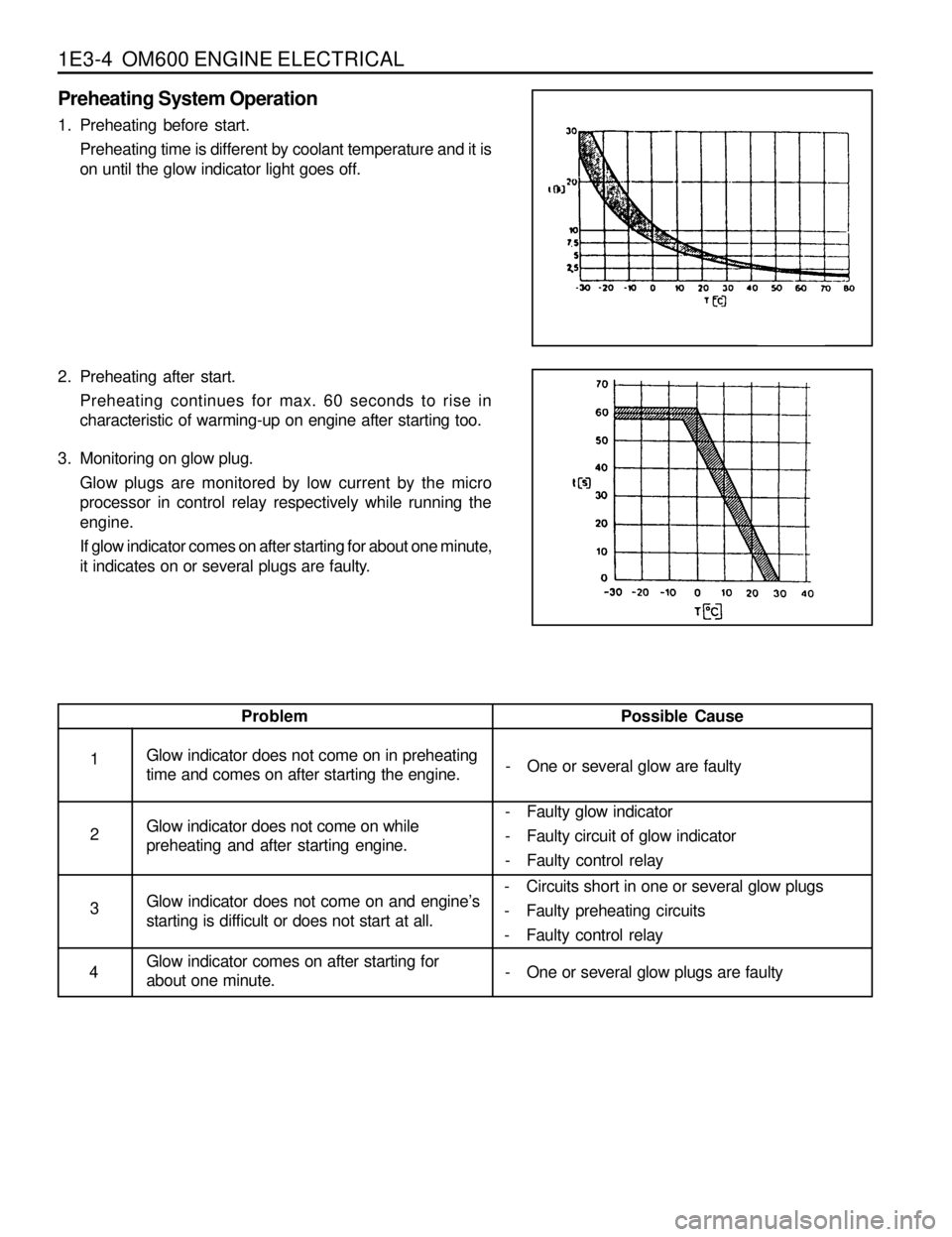

Preheating System Operation

1. Preheating before start.

Preheating time is different by coolant temperature and it is

on until the glow indicator light goes off.

2. Preheating after start.

Preheating continues for max. 60 seconds to rise in

characteristic of warming-up on engine after starting too.

3. Monitoring on glow plug.

Glow plugs are monitored by low current by the micro

processor in control relay respectively while running the

engine.

If glow indicator comes on after starting for about one minute,

it indicates on or several plugs are faulty.

Possible Cause

- One or several glow are faulty Problem

Glow indicator does not come on in preheating

time and comes on after starting the engine.

Glow indicator does not come on while

preheating and after starting engine.

Glow indicator does not come on and engine’s

starting is difficult or does not start at all.

Glow indicator comes on after starting for

about one minute.1

2

3

4- Faulty glow indicator

- Faulty circuit of glow indicator

- Faulty control relay

- Circuits short in one or several glow plugs

- Faulty preheating circuits

- Faulty control relay

- One or several glow plugs are faulty

Page 571 of 1463

SECTION 1F1

M162 ENGINE CONTROLS

TABLE OF CONTENTS

CAUTION: Disconnect the negative battery cable before removing or installing any electrical unit or when a

tool or equipment could easily come in contact with exposed electrical terminals. Disconnecting this cable

will help prevent personal injury and damage to the vehicle. The ignition must also be in LOCK unless otherwise

noted.

Specifications . . . . . . . . . . . . . . . . . . . . . . . 1F1-2

Fastener Tightening Specifications . . . . . . . . 1F1-2

Special Tools . . . . . . . . . . . . . . . . . . . . . . . 1F1-3

Special Tools Table . . . . . . . . . . . . . . . . . . . . 1F1-3

Schematic and Routing Diagrams . . . . . . . 1F1-4

E32 ECU (HFM) . . . . . . . . . . . . . . . . . . . . . . 1F1-4

E32 ECU (MSE) . . . . . . . . . . . . . . . . . . . . . . 1F1-5

Diagnosis . . . . . . . . . . . . . . . . . . . . . . . . . . 1F1-6

Self Diagnosis Socket Pin Numbers and

Descriptions . . . . . . . . . . . . . . . . . . . . . . . . 1F1-6

Self Diagnosis Failure Code . . . . . . . . . . . . . 1F1-7

Test Box Connection . . . . . . . . . . . . . . . . . . 1F1-10

Fuel Injection System Test (MSE3.62) . . . . . 1F1-11

Ignition System Test . . . . . . . . . . . . . . . . . . 1F1-21

Idling Control and Electronic Pedal

System Test . . . . . . . . . . . . . . . . . . . . . . . 1F1-26

Air Conditioner Control System Test . . . . . . 1F1-28

Fuel Pressure and Internal Leakage Test . . 1F1-29

Fuel Pump Test . . . . . . . . . . . . . . . . . . . . . . 1F1-31Injector Test . . . . . . . . . . . . . . . . . . . . . . . . 1F1-33

Maintenance and Repair . . . . . . . . . . . . . 1F1-35

On-Vehicle Service . . . . . . . . . . . . . . . . . . . . 1F1-35

ECU . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1F1-35

Fuel Pressure Regulator . . . . . . . . . . . . . . 1F1-46

Fuel Distributor . . . . . . . . . . . . . . . . . . . . . . 1F1-50

Injector . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1F1-54

Fuel Filter . . . . . . . . . . . . . . . . . . . . . . . . . . 1F1-57

Fuel Pump . . . . . . . . . . . . . . . . . . . . . . . . . 1F1-58

Purge Switchover Valve . . . . . . . . . . . . . . . 1F1-62

Vacuum System . . . . . . . . . . . . . . . . . . . . . 1F1-64

Crankshaft Position Sensor . . . . . . . . . . . . 1F1-65

Camshaft Position Sensor . . . . . . . . . . . . . 1F1-67

Hot Film Air Mass (HFM) Sensor . . . . . . . . . 1F1-69

Oxygen Sensor . . . . . . . . . . . . . . . . . . . . . . 1F1-72

Knock Sensor . . . . . . . . . . . . . . . . . . . . . . . 1F1-74

Coolant Temperature Sensor . . . . . . . . . . . 1F1-75

Accelerator Pedal Module . . . . . . . . . . . . . . 1F1-78

Page 572 of 1463

1F1-2 M162 ENGINE CONTROLS

SPECIFICATIONS

FASTENER TIGHTENING SPECIFICATIONS

Application

Fuel Return and Supply Line

Fuel Distributor Assembly Bolt

Pressure Test Connector

Fuel Inlet and Outlet Line

Fuel Filter Mounting Bracket Bolt

Crankshaft Position Sensor Bolt

Camkshaft Position Sensor Bolt

Knock Sensor Mounting Bolt

Coolant Temperature BoltN·m

25 - 30

22.5 - 27.5

21.6 - 26.4

25 - 30

4 - 8

9 - 11

9 - 11

22.5 - 27.5

18 - 22

Page 577 of 1463

M162 ENGINE CONTROLS 1F1-7

41

44

45

56

57

58

59

60

62

64

65

66

67

71

72

73

74

75

76

77

78

79

80

81

82

83

86

87

89 00

01

02

03

04

05

08

09

10

11

17

18

19

20

21

23

24

25

26

27

29

30

31

34

35

40

Failure

codeDescription

Coolant temperature sensor open

Coolant temperature sensor short

Coolant temperature sensor signal failure

Intake temperature sensor open

Intake temperature sensor short

Intake temperature sensor signal failure

Low battery voltage

HFM sensor signal failure

HFM sensor signal failure(Low)

HFM sensor signal failure(High)

Crankshaft position sensor signal failure

(no engine revolution signal)

Crankshaft position sensor signal failure

(rpm > max. value)

No.1 cylinder recognition failure

Crankshaft position sensor signal failure

(gab recognition failure)

Transmission coding failure

CAN communication failure : ASR

-

Transponder signal failure

CAN communication failure : TCU(A/T only)

CAN communication failure : TOD(E32 only)

-

-

CAN communication failure :

communication initialization failure

Fuel pump relay short(PWR)

Fuel pump relay open/short(GND)

Purge valve short

Failure

codeDescription

Purge valve open/short

Condenser fan(HI) relay short(PWR)

Condenser fan(HI) relay short(GND)

No.1 knock sensor signal failure

No.2 knock sensor signal failure

No.1 cylinder synchronization failure

-

-

Cluster S/W defectave

No ignition voltage output(No.1 ignition coil)

No ignition voltage output(No.2 ignition coil)

No ignition voltage output(No.3 ignition coil)

Crankshaft position sensor adaptation failure

Start signal recognition failure

No.1 injector short(PWR)

No.1 injector open/short(GND)

No.2 injector short(PWR)

No.2 injector open/short(GND)

No.3 injector short(PWR)

No.3 injector open/short(GND)

No.4 injector short(PWR)

No.4 injector open/short(GND)

High oxygen sensor voltage

Low oxygen sensor amplifying voltage

Oxygen sensor operating failure

Not excessive lean indication in oxygen

sensor(during coasting)

Oxygen sensor heater short(PWR)

Oxygen sensor heater open/short(GND)

Low oxygen sensor voltage

SELF DIAGNOSIS FAILURE CODE

Page 582 of 1463

1F1-12 M162 ENGINE CONTROLS

Failure

codeItem

09,

10,

11,

Checking method Te s t

stepRequirementSpecified

valuePossible cause

Þ 4.0· ·· ·

· HFM sensor

signal

105 81· Ignition:ON0.9 - 1.1V· Þ 4.1 - 4.3

· Cable

· External air inflow

· HFM sensor

· Engine:in Idle

(Coolant temperature

: > 70°C )

: voltage value is

increased when

engine rpm is

increased1.3 - 1.7V

Þ 4.1

105 4

· Ignition:ON

· HFM sensor

connector removed4.7 - 5.2V

· Cable

· ECU coupling

· ·· ·

· HFM sensor:

- 5V power

supplyHFM

sensor

Þ 4.2

3 108· Ignition:ON

· HFM sensor

connector removed4.7 - 5.2V

· Þ 4.3

· Cable

· ·· ·

· HFM sensor:

- 5V power

supplyHFM

sensor

Þ 4.3

104 2· Ignition:ON

· HFM sensor

connector removed11 - 14V

· Cable

· OVPR

· ·· ·

· HFM sensor:

- 12V power

supplyHFM

sensor

03,

04,

05,Þ 5.0· ·· ·

· Intake air

temperature

sensor:

- Voltage105 80· Ignition:ON· Þ 5.1

· ECU

± 5%

Þ 5.1· Ignition:OFF

· No.2 ECU coupling

removed 105 80

· Cable

· HFM sensor

· ·· ·

· Intake air

temperature

sensor:

- Resistance°C

10

20

30

40

50

60

± 5%W

3600

2420

1662

1166

853

600 °C

10

20

30

40

50

60V

3.1

2.65

2.18

1.76

1.4

1.1

Page 583 of 1463

M162 ENGINE CONTROLS 1F1-13

Failure

codeItemChecking method Te s t

stepRequirement

Specified

valuePossible cause

Þ 6.1· Ignition:ON0.1 - 0.3A· Cable

· Fuel pump relay

· ECU

· ·· ·

· Fuel pump

relay:

- Current

consumption

00,

01,

02,

06,Þ 7.0· ·· ·

· Coolant

temperature

sensor:

- Voltage79 78· Ignition:ON°CV

20 3.57

80 1.22

100 0.78· Þ 7.1

· ECU

±5% Þ 6.0

· Ignition:ON

(Fuel pump relay will

operate for 1 - 2

seconds when the

ignition switch is

turned to "ON" after

stopping the engine)

· Engine:cranking 33 11

· Cable

· Fuel pump relay

· ·· ·

· Fuel pump

relay:

- Operation34,11 - 14V

(approx.1-

2sec.)

11 - 14V

(Cranking or

driving)

533

Þ 7.1· Ignition:OFF

(Remove the No.2

coupling from ECU) 79 78· Þ 7.2

· Cable

· ·· ·

· Coolant

temperature

sensor:

- Resistance

& cable°CW

20 2500

80 322

100 185

±5%

Þ 7.2· ·· ·

· Coolant

temperature

sensor:

- ResistanceCoolant temperature

sensor:

14

· Remove the

connector from

coolant temperature

sensor and measure

the resistance

between No.1 and

No.2 pin with

multimeter.· Þ refer to

specified

resistance

value of 7.1· Coolant

temperature

sensor 34,

35,