torque SSANGYONG MUSSO 2003 Service Manual

[x] Cancel search | Manufacturer: SSANGYONG, Model Year: 2003, Model line: MUSSO, Model: SSANGYONG MUSSO 2003Pages: 1574, PDF Size: 26.41 MB

Page 231 of 1574

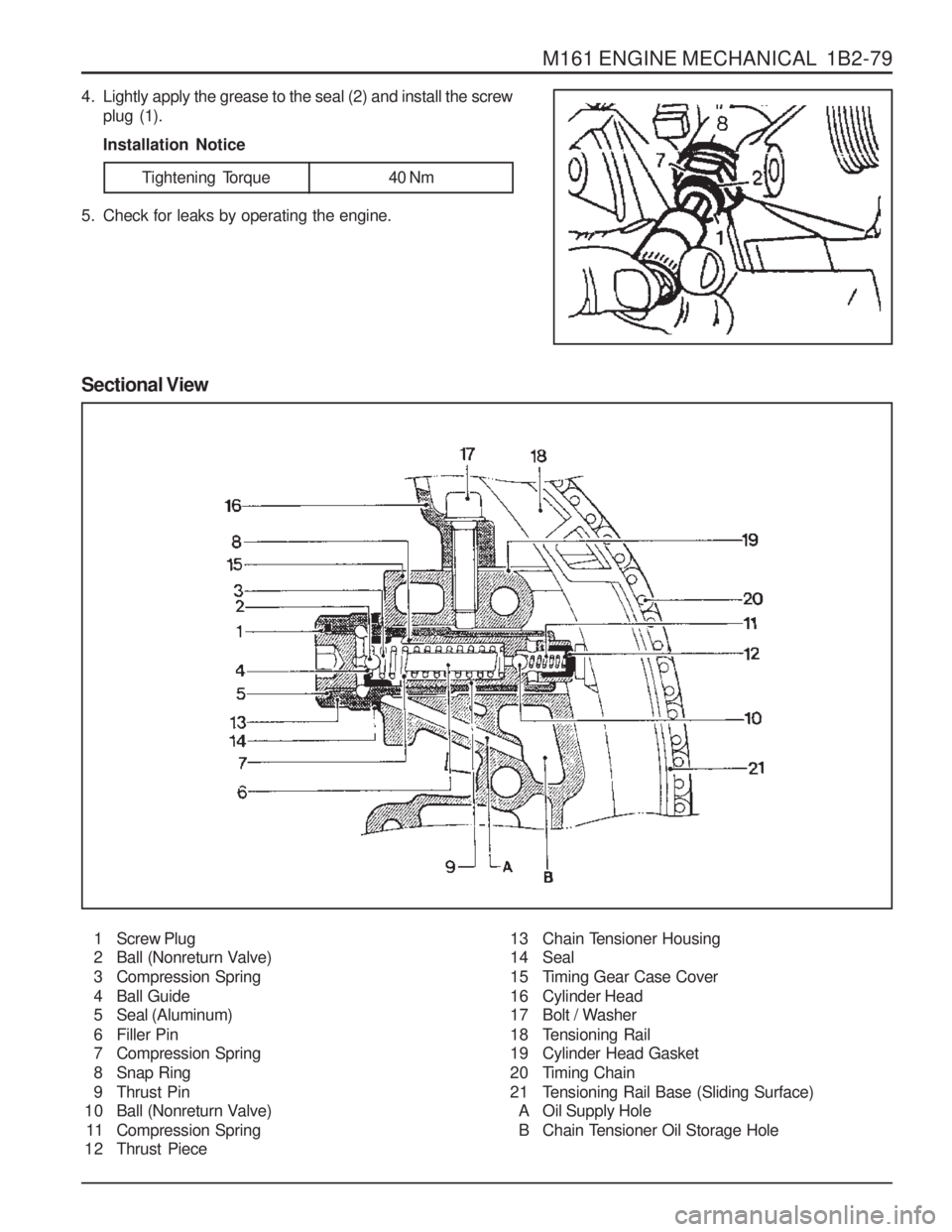

M161 ENGINE MECHANICAL 1B2-79

4. Lightly apply the grease to the seal (2) and install the screwplug (1). Installation Notice

Sectional View

1 Screw Plug

2 Ball (Nonreturn Valve)

3 Compression Spring

4 Ball Guide

5 Seal (Aluminum)

6 Filler Pin

7 Compression Spring

8 Snap Ring

9 Thrust Pin

10 Ball (Nonreturn Valve)

11 Compression Spring

12 Thrust Piece 13 Chain Tensioner Housing

14 Seal

15 Timing Gear Case Cover

16 Cylinder Head

17 Bolt / Washer

18 Tensioning Rail

19 Cylinder Head Gasket

20 Timing Chain

21 Tensioning Rail Base (Sliding Surface)

A Oil Supply Hole

B Chain Tensioner Oil Storage Hole

5. Check for leaks by operating the engine.

Tightening Torque 40 Nm

Page 233 of 1574

M161 ENGINE MECHANICAL 1B2-81

Tools Required

000 589 58 43 00 Chain Assembly

103 589 01 63 00 Rivet Set

001 589 72 21 00 Torque Wrench Replacement Procedure

1. Position the NO.1 cylinder to ATDC 20°.

4. Mount the wedges to both sides of the camshaft sprocket as shown in the figure.

2. Insert the pin to the intake and exhaust camshaft flange.

3. Remove the chain tensioner.

5. Cover the chain housing with a clean cloth, and grind off

the timing chain pin from the intake camshaft sprocket with

the grinder.

Page 235 of 1574

M161 ENGINE MECHANICAL 1B2-83

15. Replace the thrust piece (b) as shown in the figure.

13. Install the assembly tool above the link and tighten the

spindle (c) until a block is felt.

14. Place the assembly tool.

12. Place the outer plate (7, thickness 1.2mm) inside the thrust

piece (b).

16. Install the assembly tool to the link pin and tighten the spindle (c).

Tightening Torque 30 Nm

Page 236 of 1574

1B2-84 M161 ENGINE MECHANICAL

17. Rivet the link pin.Check the condition and it again if necessary.

18. Install the chain tensioner. Installation Notice

19. Check the camshaft timing position. Tightening Torque

Screw Plug

40 Nm

Tensioner Assembly 72 - 88 Nm

Page 238 of 1574

1B2-86 M161 ENGINE MECHANICAL

CYLINDER HEAD GUIDE RAIL Preceding Work : Removal of cylinder head cover

1 Bolt (M6 X 45, 2 pieces).................. 9-11 Nm

2 Guide Rail

Removal & Installation Procedure

1. Position the number 1 cylinder to ATDC20 ° guide rail.

2. Install the pin (special tool : 111 589 03 15 00) into the no.1 and no.6 bearing cap hole.

3. Remove the chain tensioner. Installation Notice

Tightening Torque Screw Plug40 Nm

Tensioner Assembly

72 - 88 Nm

4. Unscrew the bolt (1) and remove the guide rail. Installation Notice

Tightening Torque 9 - 11 Nm

5. Installation should follow the removal procedure in the reverse order.

Page 241 of 1574

M161 ENGINE MECHANICAL 1B2-89

Tools Required

615 589 01 33 00 Caulking Bolt Removal & Installation Procedure

1. Put the assembly mark at the crankshaft sprocket (4) andthe timing chain (10) with the paint (arrow). Installation Notice Align the assembly marks on cranshaft sprocket and timing chain. Also, align the assembly marks on camshaft sprocketand timing chain when installing.

2. Unscrew the bolt (6) and remove the oil pump sprocket (7) from the oil pump. Installation Notice

Caulking (04) 615 589 01 33 00

3. Remove the oil pump roller chain (9).

4. Remove the oil pump chain tensioner (1), oil pump chain

bushing (3), and the oil pump chain spring (2).

5. Remove the crankshaft sprocket (4) using the puller (04, special tool). Notice

�Make sure not to lose the crankshaft pulley key (5) when

removing.

� Install the crankshaft sprocket (4) after warming it up.

6. Installation should follow the removal procedure in the reverse order.

Tightening Torque 29 - 35 Nm

Page 243 of 1574

M161 ENGINE MECHANICAL 1B2-91

Tools Required

001 589 72 21 00 Torqued Wrench

000 589 04 14 00 Clamping Strap Removal Procedure

1. Unscrew the connecting rod bolt (3) and remove the cap.

2. Remove the connecting rod and the piston upward.Notice Make sure that the bearing cap and shell are not changed

each other.

3. Remove the snap ring (5) and pull out the piston pin (6).

Notice Remove the snap ring using a clean cloth as shown in the right picture so that the piston, piston ring, and the snapring don ’t get damaged.

Installation Procedure

Page 244 of 1574

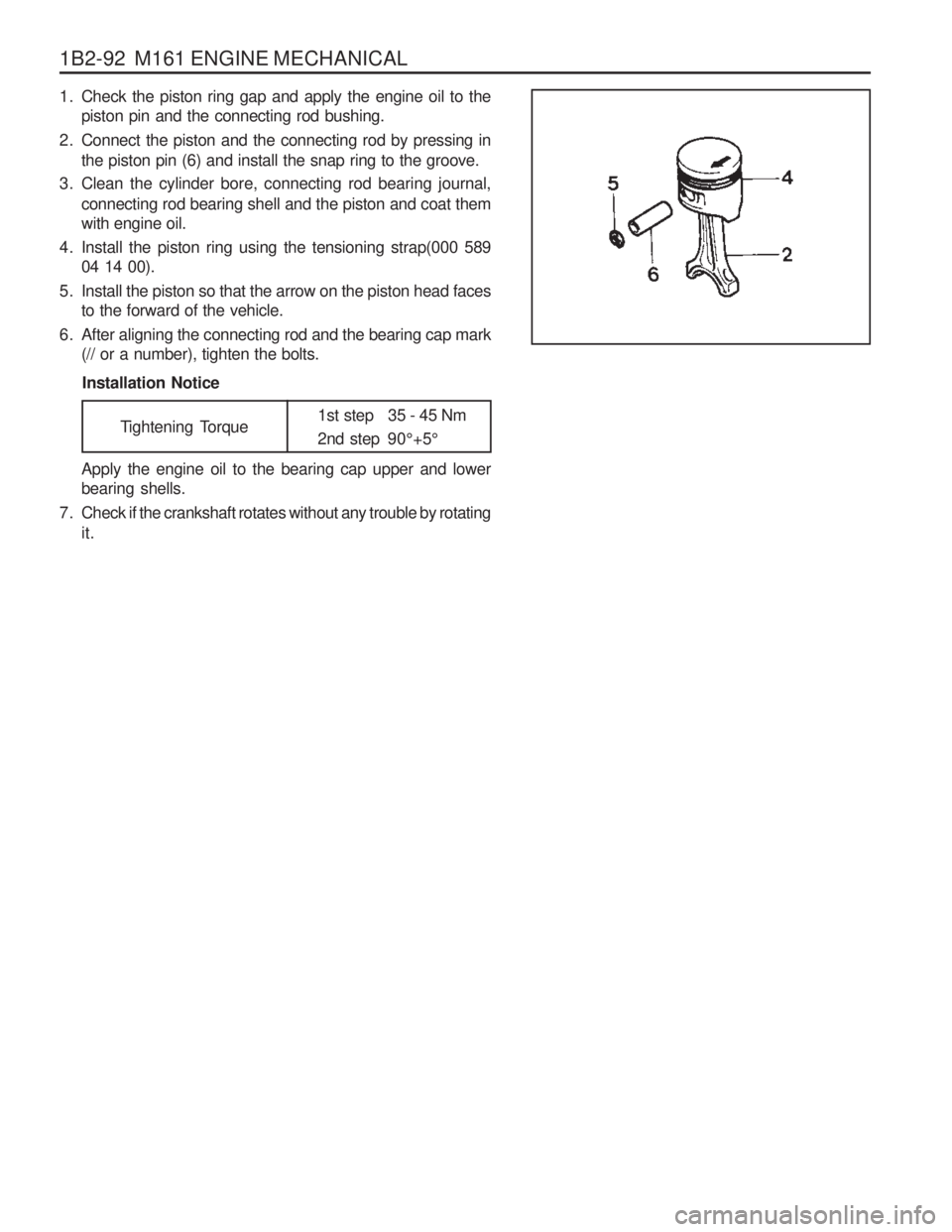

1B2-92 M161 ENGINE MECHANICAL

1. Check the piston ring gap and apply the engine oil to thepiston pin and the connecting rod bushing.

2. Connect the piston and the connecting rod by pressing in the piston pin (6) and install the snap ring to the groove.

3. Clean the cylinder bore, connecting rod bearing journal, connecting rod bearing shell and the piston and coat them with engine oil.

4. Install the piston ring using the tensioning strap(000 589 04 14 00).

5. Install the piston so that the arrow on the piston head faces to the forward of the vehicle.

6. After aligning the connecting rod and the bearing cap mark (// or a number), tighten the bolts.

Installation Notice

Tightening Torque 1st step 35 - 45 Nm

2nd step 90

°+5 °

Apply the engine oil to the bearing cap upper and lower bearing shells.

7. Check if the crankshaft rotates without any trouble by rotating it.

Page 246 of 1574

1B2-94 M161 ENGINE MECHANICAL Inspection

1. Measure the basic bore of the connecting rod bearing.Notice If the basic bore exceeds the value of 51.614mm, replace the bearing or check the connecting rod.

2. Check connecting rod bolts.

3. Check the assembly mark(indication//or number:arrow) of the connecting rods and the bearing cap when installing. Notice

�Make sure it doesn ’t exceed over 4g with other

connecting rods when replacing the connecting rods.

� Check if the connecting rod and the bearing cap are accurately seated on the groove when replacing the bearing.

Notice If the length exceeds max. length, replace it.

Length When New (L)

Max. Length (L)

Tightening Torque 51.7 - 52 mm

52.9 mm

1st step 40 + 5 Nm 2nd step 90 °+10 °

Page 249 of 1574

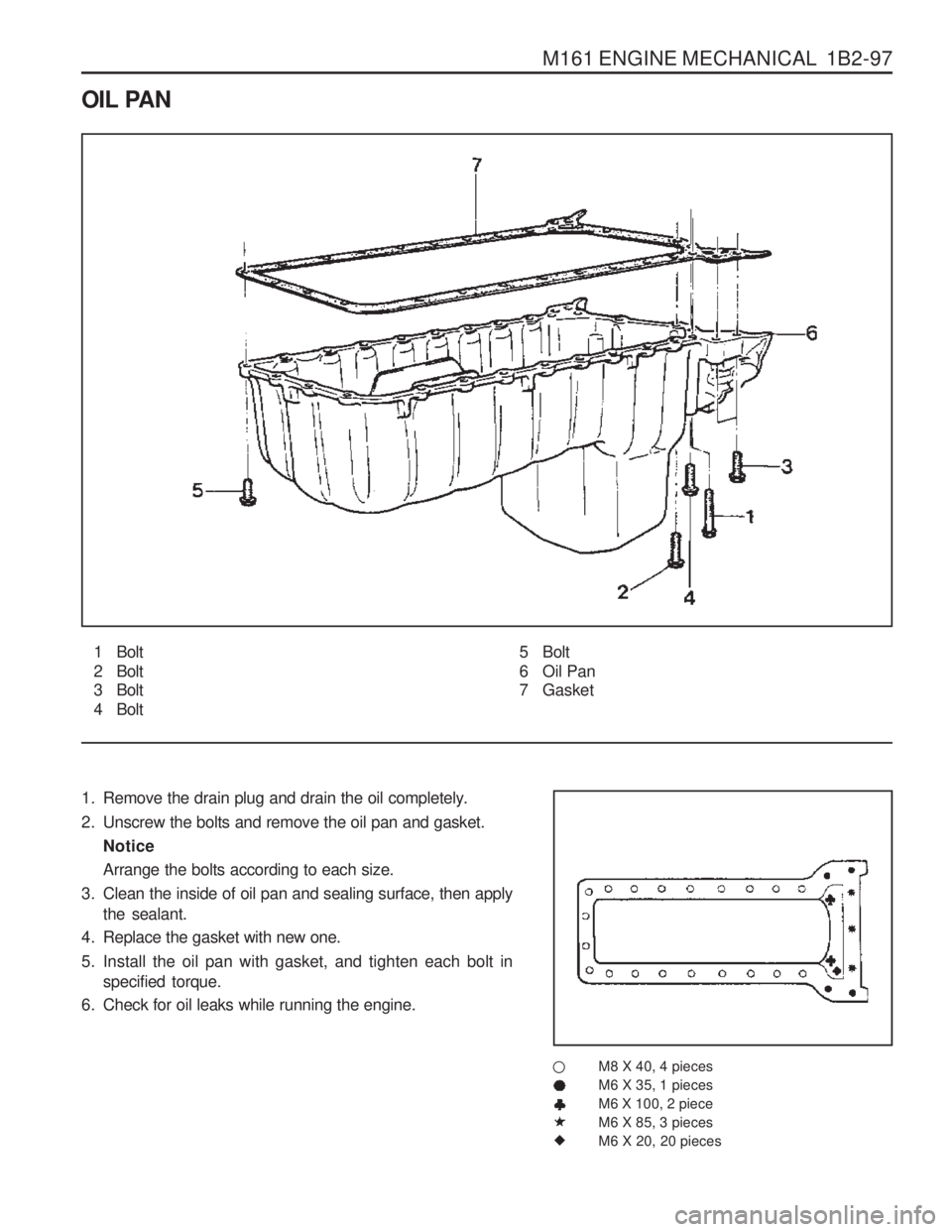

M161 ENGINE MECHANICAL 1B2-97

OIL PAN

1 Bolt

2 Bolt

3 Bolt

4 Bolt

1. Remove the drain plug and drain the oil completely.

2. Unscrew the bolts and remove the oil pan and gasket. Notice Arrange the bolts according to each size.

3. Clean the inside of oil pan and sealing surface, then apply the sealant.

4. Replace the gasket with new one.

5. Install the oil pan with gasket, and tighten each bolt in specified torque.

6. Check for oil leaks while running the engine.

M8 X 40, 4 pieces M6 X 35, 1 piecesM6 X 100, 2 pieceM6 X 85, 3 piecesM6 X 20, 20 pieces5 Bolt

6 Oil Pan

7 Gasket

�