torque SSANGYONG MUSSO 2003 Service Manual

[x] Cancel search | Manufacturer: SSANGYONG, Model Year: 2003, Model line: MUSSO, Model: SSANGYONG MUSSO 2003Pages: 1574, PDF Size: 26.41 MB

Page 337 of 1574

1B3-72 OM600 ENGINE MECHANICAL

Tools Required 601 589 03 43 00 Oil Seal Assmbler Removal Procedure

1. Remove the bolts (3, 6) from end cover, By pulling out thelugs (arrow), remove the cover. Notice Be careful not to damage the oil pan gasket.

2. Remove the radial seal (4) with care not to damage the sealing surface.

Installation Procedure

1. Thoroughly clean the sealing surface of end cover and applyLoctite 573.

2. Clean the groove of radial seal.

3. Apply Loctite 573 on the bolts and install the end cover.

Tightening Torque 10 Nm

Notice Be careful not to damage the oil pan gasket.

4. Install the inner oil seal assembler to the crankshaft flange.

Oil Seal Assembler 601 589 03 43 00

Page 343 of 1574

1B3-78 OM600 ENGINE MECHANICAL Installation Procedure

1. Install the hub.Notice Exactly align the woodruff key and the groove of hub (arrow).

2. Install the washer (7) and tighten the bolt (6).

Washer (new) : 1 EA 200 Nm + 90°

3. Install the vibration damper. Notice Exactly align and insert onto the straight pin.

4. Install the belt pulley.

Tightening Torque 25 Nm

Notice Align the alignment marks.

Page 344 of 1574

OM600 ENGINE MECHANICAL 1B3-79

5. Install the timing sensor bracket.Notice See the ‘TDC setting ’.

6. Install the cooling fan pulley.

Tightening Torque 10 Nm

7. Install the cooling fan.

8. Install the fan belt.

9. Remove the engine lock.

Page 354 of 1574

OM600 ENGINE MECHANICAL 1B3-89

14. Measure crankshaft bearing journal diameter (F).Notice When measured in A and B, the runout should not exceed 0.010mm.

8. Thoroughly clean the oil gallery.

9. Select a proper new bearing shells with reference to table.

10. Coat the new bearing shells with oil and insert into the crankcase and into the crankshaft bearing caps. Notice Do not mix up upper and lower crankshaft bearing shells.

11. Install the bearing caps according to marking and tighten the 12-sided stretch bolts.

Tightening Torque 35 - 40 Nm

Notice No. 1 is vibration damper side.

12. Measure crankshaft bearing diameters (E).

Extension 366 589 00 21 05

13. Measure at 3 points (A, B and C) and if the average value of B and C is less than A ’s value, the average value of B

and C is the mean value and if more than A ’s value, A ’ s

value is the mean value.

Page 356 of 1574

OM600 ENGINE MECHANICAL 1B3-91

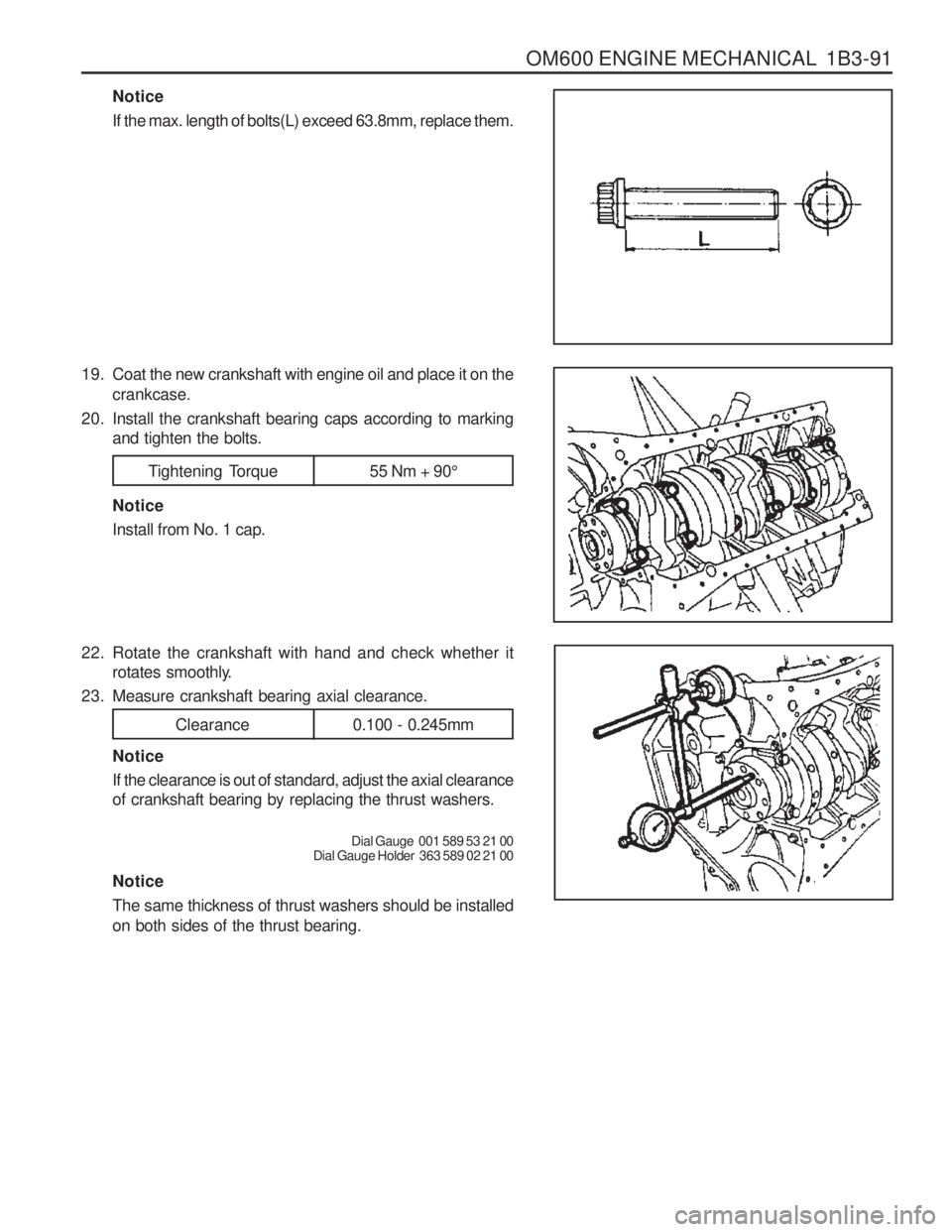

Notice If the max. length of bolts(L) exceed 63.8mm, replace them.

19. Coat the new crankshaft with engine oil and place it on the crankcase.

20. Install the crankshaft bearing caps according to marking and tighten the bolts.

Tightening Torque 55 Nm + 90 °

Notice Install from No. 1 cap.

22. Rotate the crankshaft with hand and check whether it rotates smoothly.

23. Measure crankshaft bearing axial clearance.

Clearance 0.100 - 0.245mm

Notice If the clearance is out of standard, adjust the axial clearance of crankshaft bearing by replacing the thrust washers.

Dial Gauge 001 589 53 21 00

Dial Gauge Holder 363 589 02 21 00

Notice The same thickness of thrust washers should be installed on both sides of the thrust bearing.

Page 357 of 1574

1B3-92 OM600 ENGINE MECHANICAL

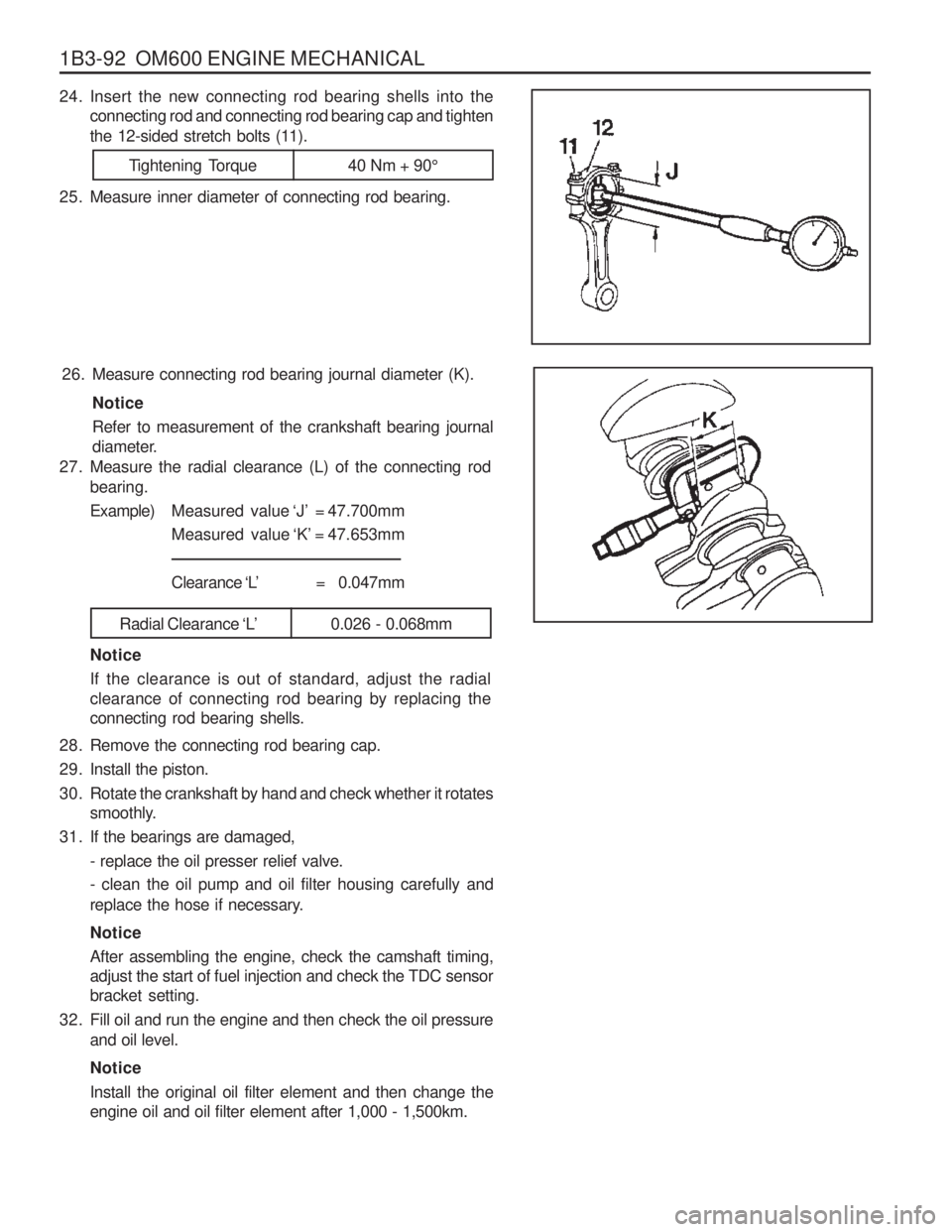

28. Remove the connecting rod bearing cap.

29. Install the piston.

30. Rotate the crankshaft by hand and check whether it rotatessmoothly.

31. If the bearings are damaged,

- replace the oil presser relief valve. - clean the oil pump and oil filter housing carefully and

replace the hose if necessary. Notice After assembling the engine, check the camshaft timing, adjust the start of fuel injection and check the TDC sensorbracket setting.

32. Fill oil and run the engine and then check the oil pressure and oil level. Notice Install the original oil filter element and then change the engine oil and oil filter element after 1,000 - 1,500km.

27. Measure the radial clearance (L) of the connecting rod

bearing. Example) Measured value ‘J’ = 47.700mm

Measured value ‘K’ = 47.653mm

Clearance ‘L’ = 0.047mm

Radial Clearance ‘L’0.026 - 0.068mm

Notice If the clearance is out of standard, adjust the radial clearance of connecting rod bearing by replacing theconnecting rod bearing shells.

26. Measure connecting rod bearing journal diameter (K).

Notice Refer to measurement of the crankshaft bearing journal

diameter.

24. Insert the new connecting rod bearing shells into theconnecting rod and connecting rod bearing cap and tighten

the 12-sided stretch bolts (11).

25. Measure inner diameter of connecting rod bearing.

Tightening Torque 40 Nm + 90 °

Page 360 of 1574

OM600 ENGINE MECHANICAL 1B3-95

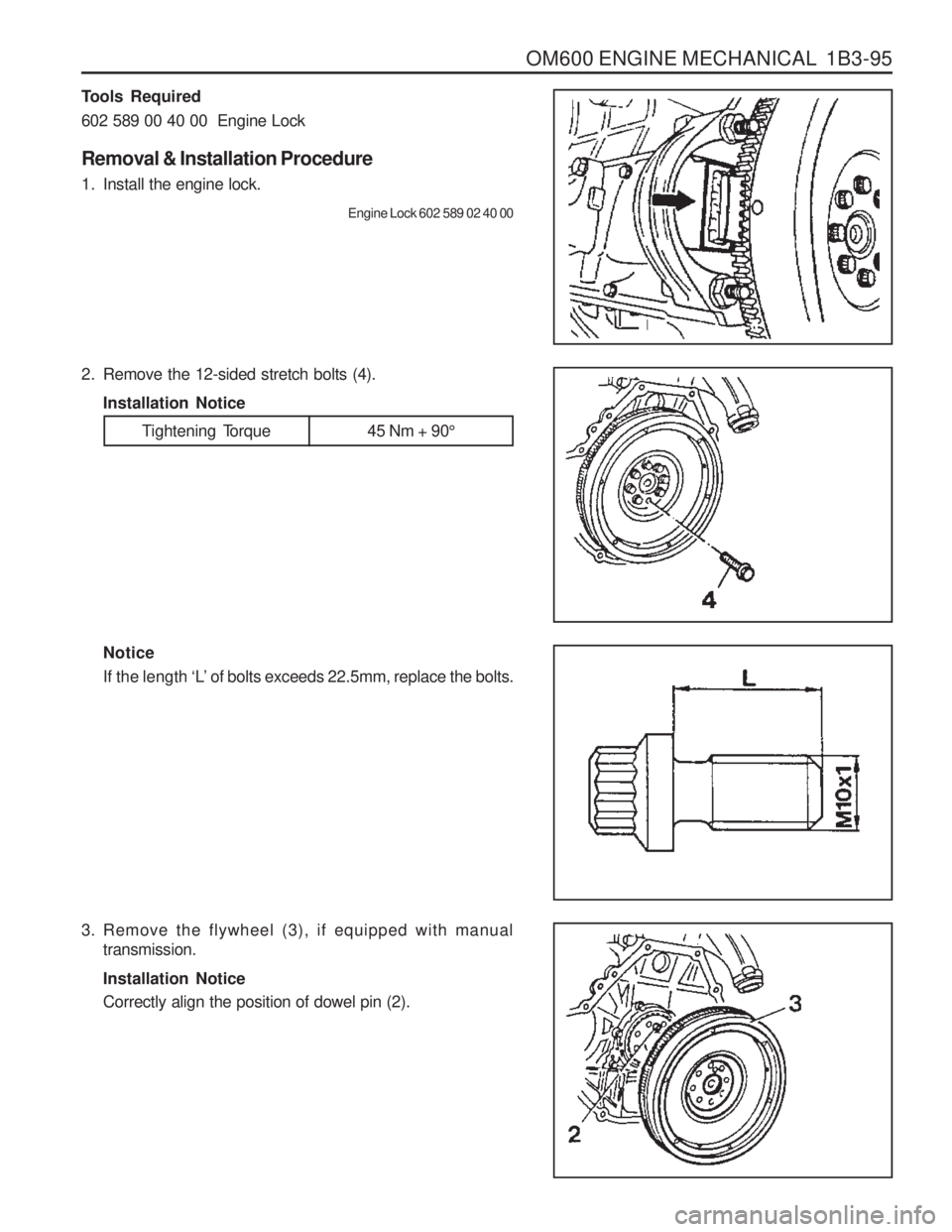

3. Remove the flywheel (3), if equipped with manualtransmission. Installation Notice Correctly align the position of dowel pin (2).

Tools Required 602 589 00 40 00 Engine Lock Removal & Installation Procedure

1. Install the engine lock.

Engine Lock 602 589 02 40 00

2. Remove the 12-sided stretch bolts (4). Installation Notice

Tightening Torque 45 Nm + 90 °

Notice If the length ‘L’ of bolts exceeds 22.5mm, replace the bolts.

Page 372 of 1574

OM600 ENGINE MECHANICAL 1B3-107

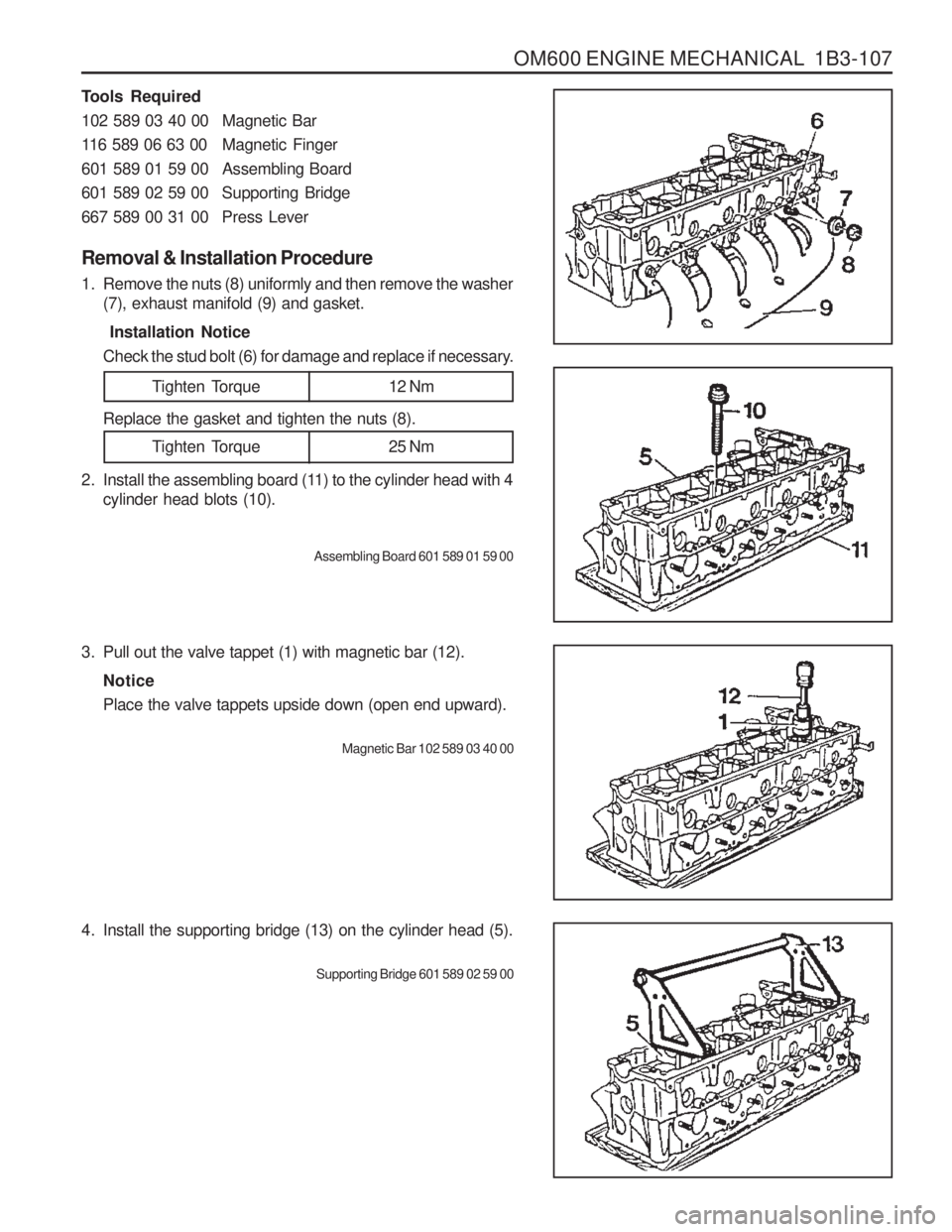

Removal & Installation Procedure

1. Remove the nuts (8) uniformly and then remove the washer(7), exhaust manifold (9) and gasket. Installation Notice

Check the stud bolt (6) for damage and replace if necessary.

Tighten Torque 12 Nm

Tighten Torque 25 Nm

Tools Required

102 589 03 40 00 Magnetic Bar

116 589 06 63 00 Magnetic Finger

601 589 01 59 00 Assembling Board

601 589 02 59 00 Supporting Bridge

667 589 00 31 00 Press Lever

Replace the gasket and tighten the nuts (8).

2. Install the assembling board (11) to the cylinder head with 4 cylinder head blots (10).

Assembling Board 601 589 01 59 00

3. Pull out the valve tappet (1) with magnetic bar (12). NoticePlace the valve tappets upside down (open end upward).

Magnetic Bar 102 589 03 40 00

4. Install the supporting bridge (13) on the cylinder head (5).Supporting Bridge 601 589 02 59 00

Page 403 of 1574

1B3-138 OM600 ENGINE MECHANICAL

6. Check the timing.New

After approx. 20,000km ATDC 11.33

°

ATDC 12 °

Notice If timing is out standard, the camshaft should be checked for wear and the timing chain for stretch. If a difference of more than 4 ° exists, the timing chain should be replaced.

7. Replace the gasket and install the cylinder head cover.

Tightening Torque 10 Nm

Measurement Procedure

1. Remove the cylinder head cover.

2. Rotate the engine in the direction of engine rotation until the intake valve of NO. 1 cylinder is completely closed. The cam lobe faces up (arrow). Notice Do not rotate the engine at the bolt of the crankshaft sprocket. Do not rotate the engine in the opposite directionof engine rotation. If do, this will cause serious measuringerrors.

3. Install the dial gauge holder and dial gauge (7) with theextension (8) to the cylinder head and position the tracer pin (9) onto the valve tappet (intake valve of cylinder NO.1)with a preload of min. 3mm. Notice The tracer pin should be positioned exactly vertical.

Dial gauge Holder 363 589 02 21 00Dial Gauge 001 589 53 21 00Extension 366 589 00 21 05

4. Set the dial gauge to ‘0’.

5. Rotate the engine further in direction of rotation until the dial gauge has moved back by 2mm (valve lift) to 1mm.

Tools Required 001 589 53 21 00 Dial Gauge363 589 02 21 00 Dial Gauge Holder366 589 00 21 05 Extension

Page 408 of 1574

OM600 ENGINE MECHANICAL 1B3-143

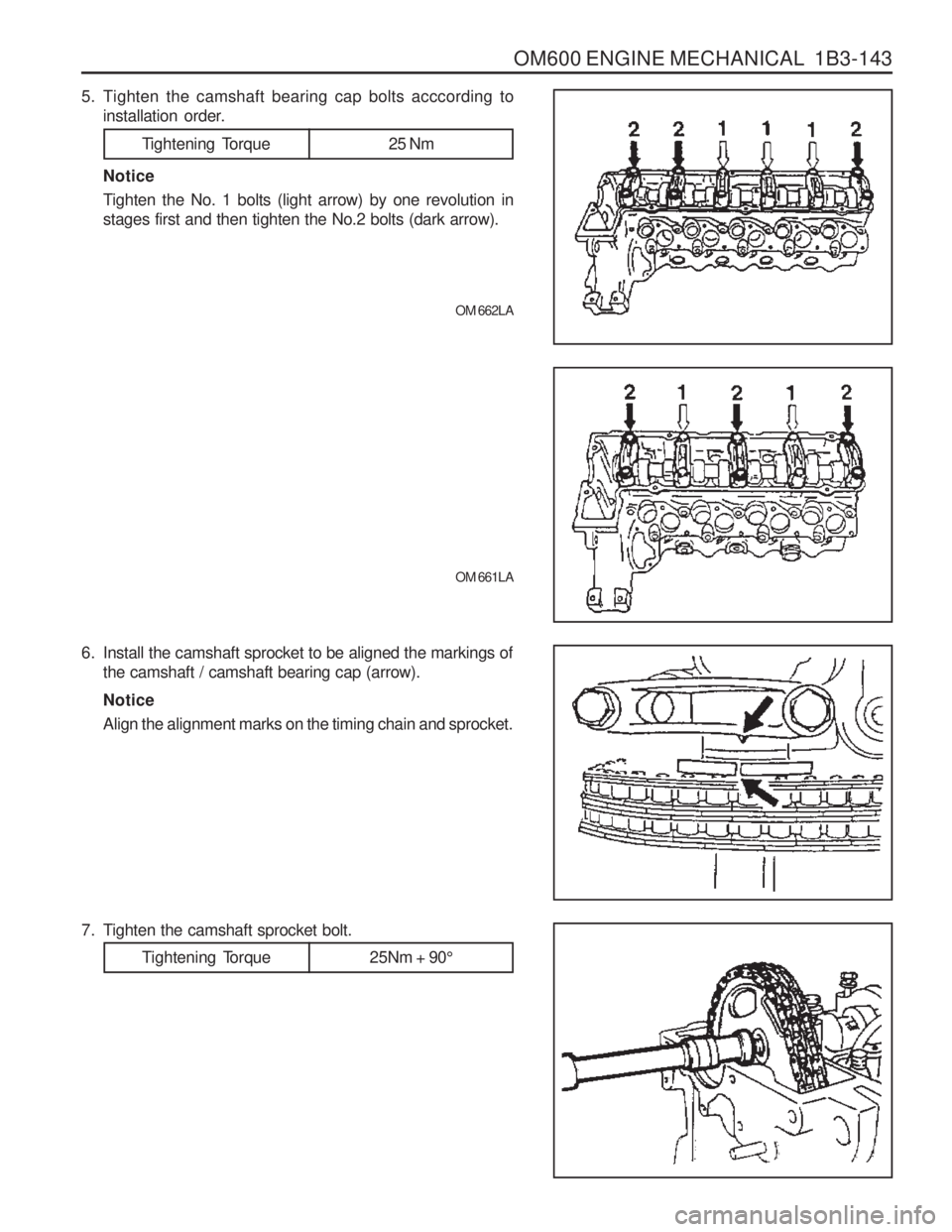

5. Tighten the camshaft bearing cap bolts acccording toinstallation order.

6. Install the camshaft sprocket to be aligned the markings of the camshaft / camshaft bearing cap (arrow). Notice Align the alignment marks on the timing chain and sprocket.

Tightening Torque 25 Nm

Notice

Tighten the No. 1 bolts (light arrow) by one revolution in stages first and then tighten the No.2 bolts (dark arrow).

OM 661LA

OM 662LA

7. Tighten the camshaft sprocket bolt.

Tightening Torque 25Nm + 90 °