SSANGYONG MUSSO 2003 User Guide

MUSSO 2003

SSANGYONG

SSANGYONG

https://www.carmanualsonline.info/img/67/57511/w960_57511-0.png

SSANGYONG MUSSO 2003 User Guide

Page 43 of 1574

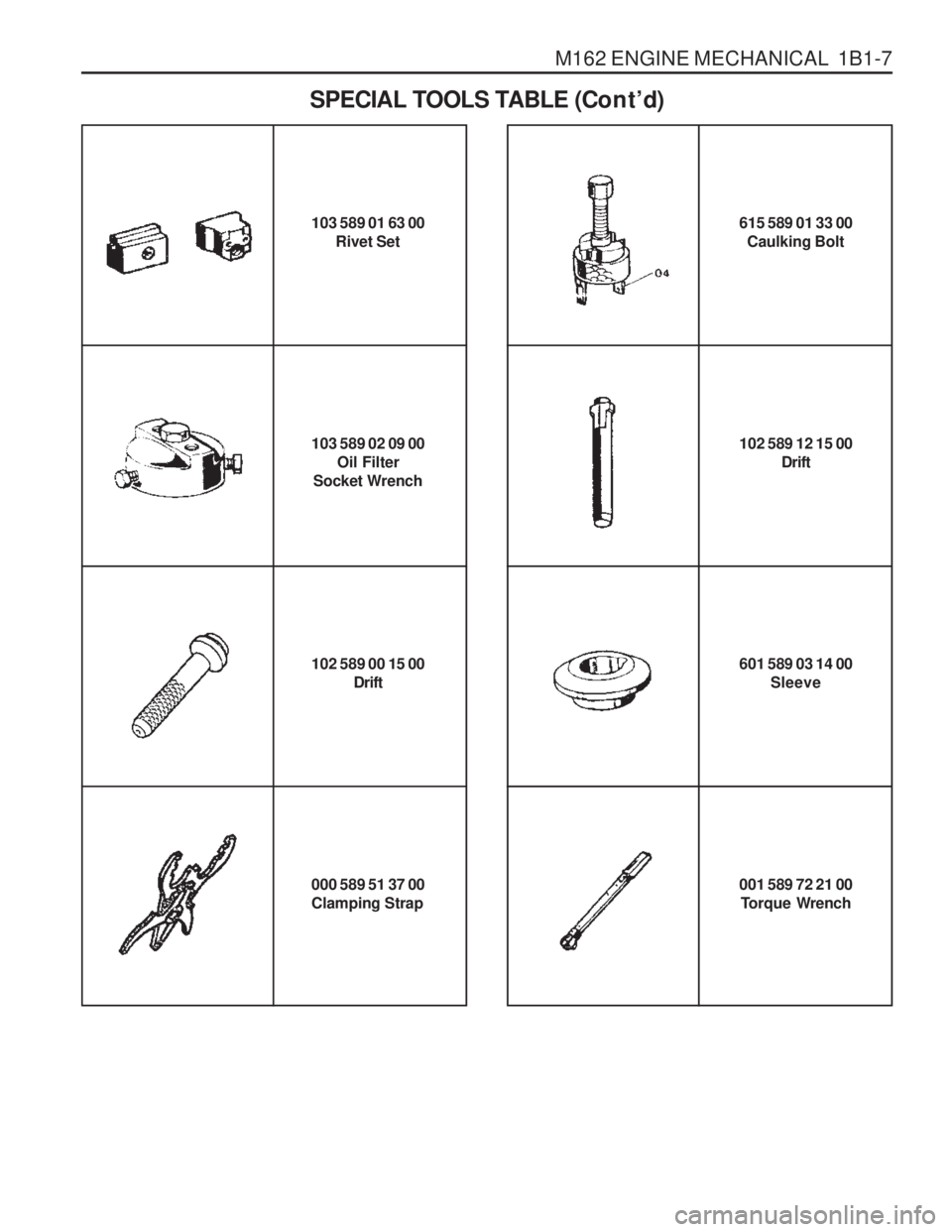

M162 ENGINE MECHANICAL 1B1-7

103 589 01 63 00Rivet Set

103 589 02 09 00 Oil Filter

Socket Wrench 102 589 12 15 00

Drift

SPECIAL TOOLS TABLE (Co n t

’d)

615 589 01 33 00

Caulking Bolt

102 589 00 15 00 Drift

000 589 51 37 00 Clamping Strap 001 589 72 21 00

Torque Wrench

601 589 03 14 00

Sleeve

Page 44 of 1574

1B1-8 M162 ENGINE MECHANICALMAINTENANCE AND REPAIR

ON-VEHICLE SERVICE

ENGINE ASSEMBLY

Tools Required

000 589 10 99 01 Torque Wrench

000 589 40 37 00 Hose Clamp

112 589 00 72 00 Oil Extractor

Page 45 of 1574

M162 ENGINE MECHANICAL 1B1-9

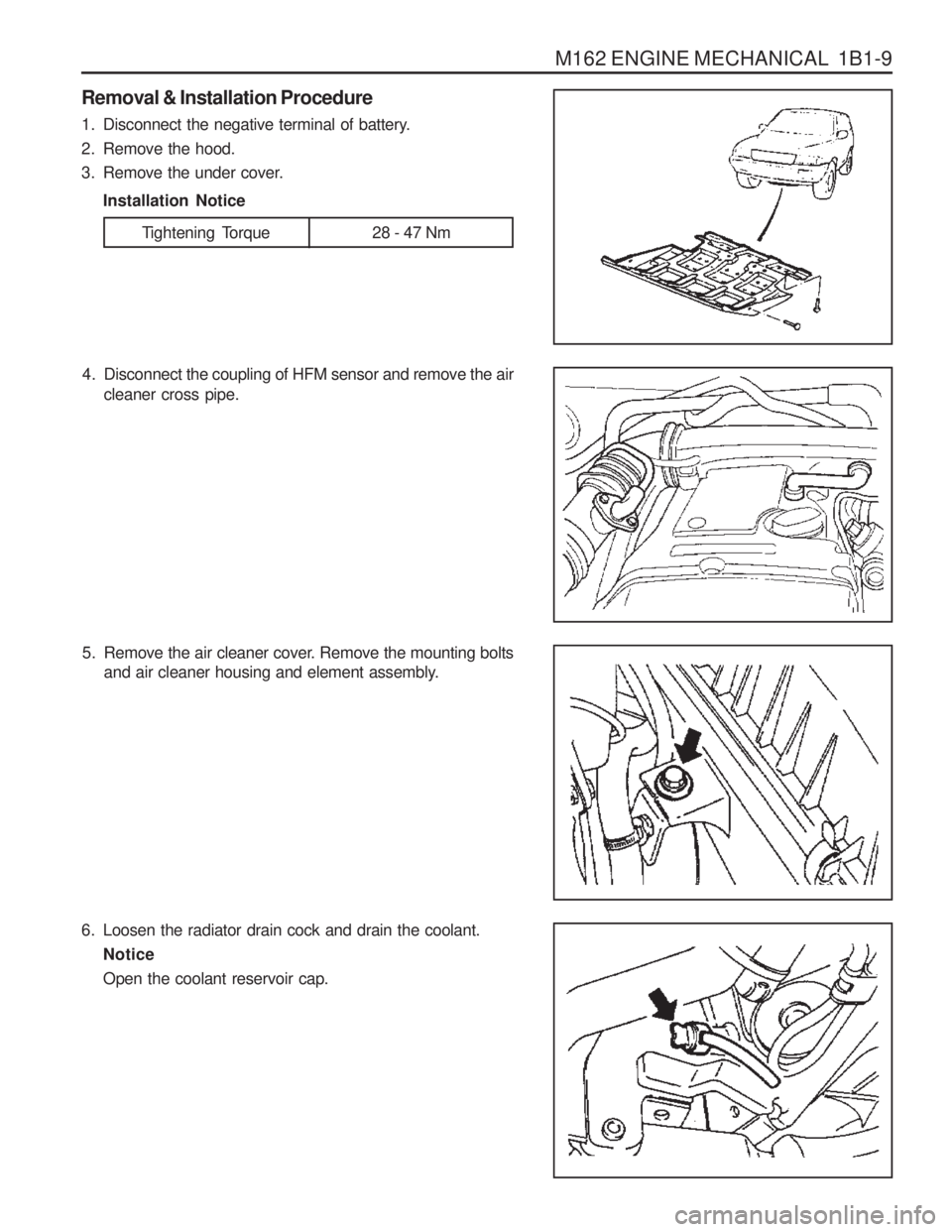

4. Disconnect the coupling of HFM sensor and remove the aircleaner cross pipe.

6. Loosen the radiator drain cock and drain the coolant. Notice Open the coolant reservoir cap.

5. Remove the air cleaner cover. Remove the mounting bolts

and air cleaner housing and element assembly.

Removal & Installation Procedure

1. Disconnect the negative terminal of battery.

2. Remove the hood.

3. Remove the under cover.

Installation Notice

Tightening Torque 28 - 47 Nm

Page 46 of 1574

1B1-10 M162 ENGINE MECHANICAL

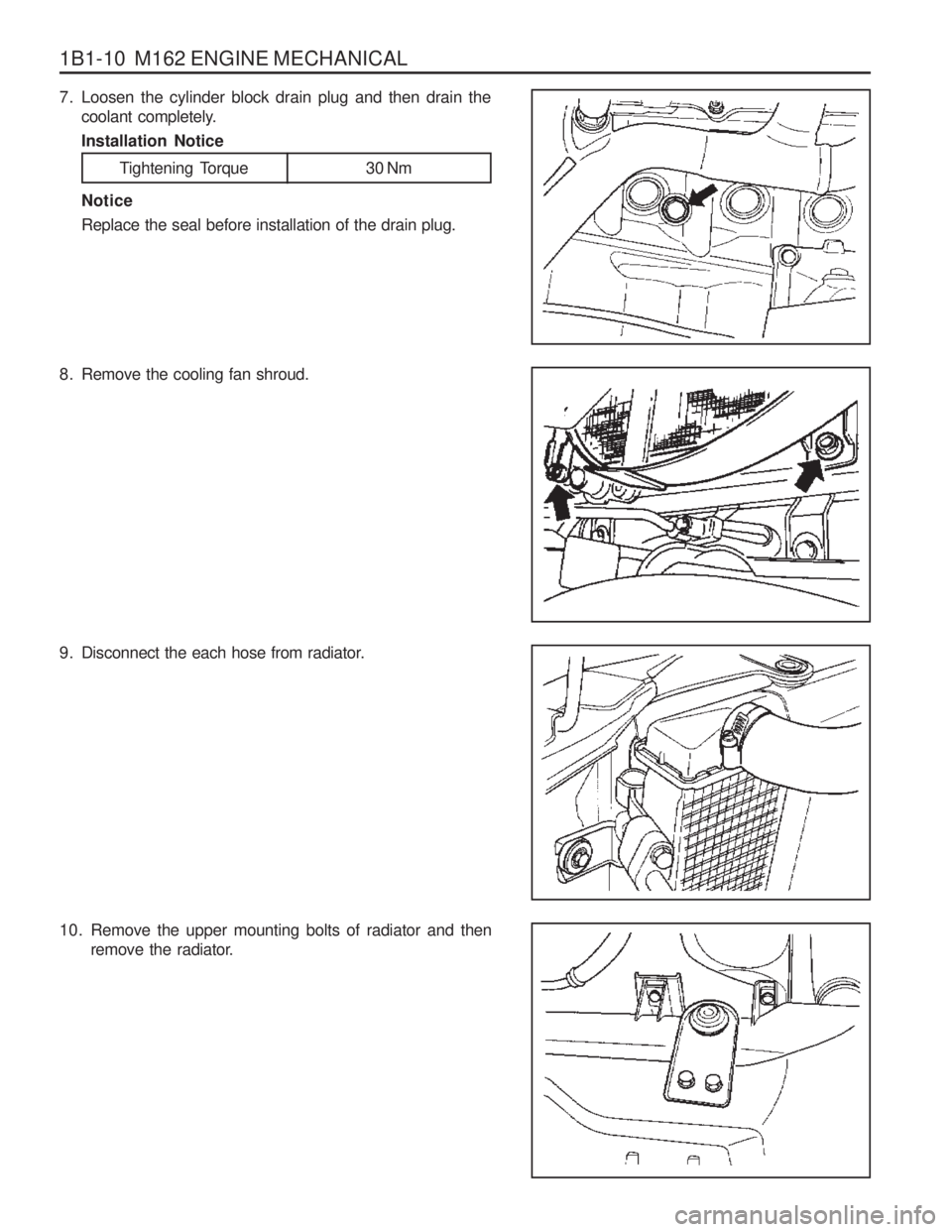

10. Remove the upper mounting bolts of radiator and thenremove the radiator.

7. Loosen the cylinder block drain plug and then drain thecoolant completely. Installation Notice

Tightening Torque 30 Nm

Notice Replace the seal before installation of the drain plug.

8. Remove the cooling fan shroud.

9. Disconnect the each hose from radiator.

Page 47 of 1574

M162 ENGINE MECHANICAL 1B1-11

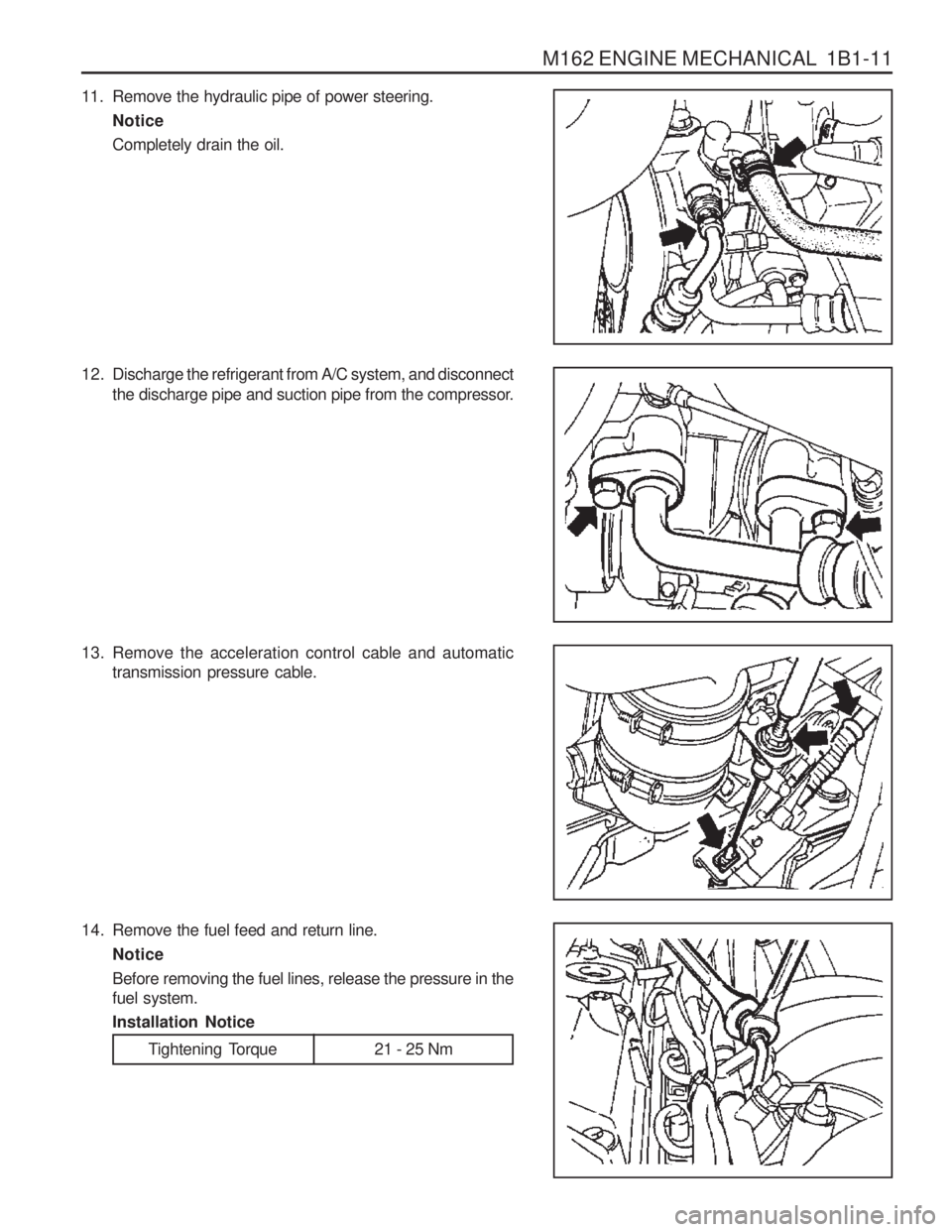

12. Discharge the refrigerant from A/C system, and disconnectthe discharge pipe and suction pipe from the compressor.

14. Remove the fuel feed and return line. Notice Before removing the fuel lines, release the pressure in the fuel system. Installation Notice

13. Remove the acceleration control cable and automatic

transmission pressure cable.

11. Remove the hydraulic pipe of power steering.

NoticeCompletely drain the oil.

Tightening Torque 21 - 25 Nm

Page 50 of 1574

1B1-14 M162 ENGINE MECHANICAL

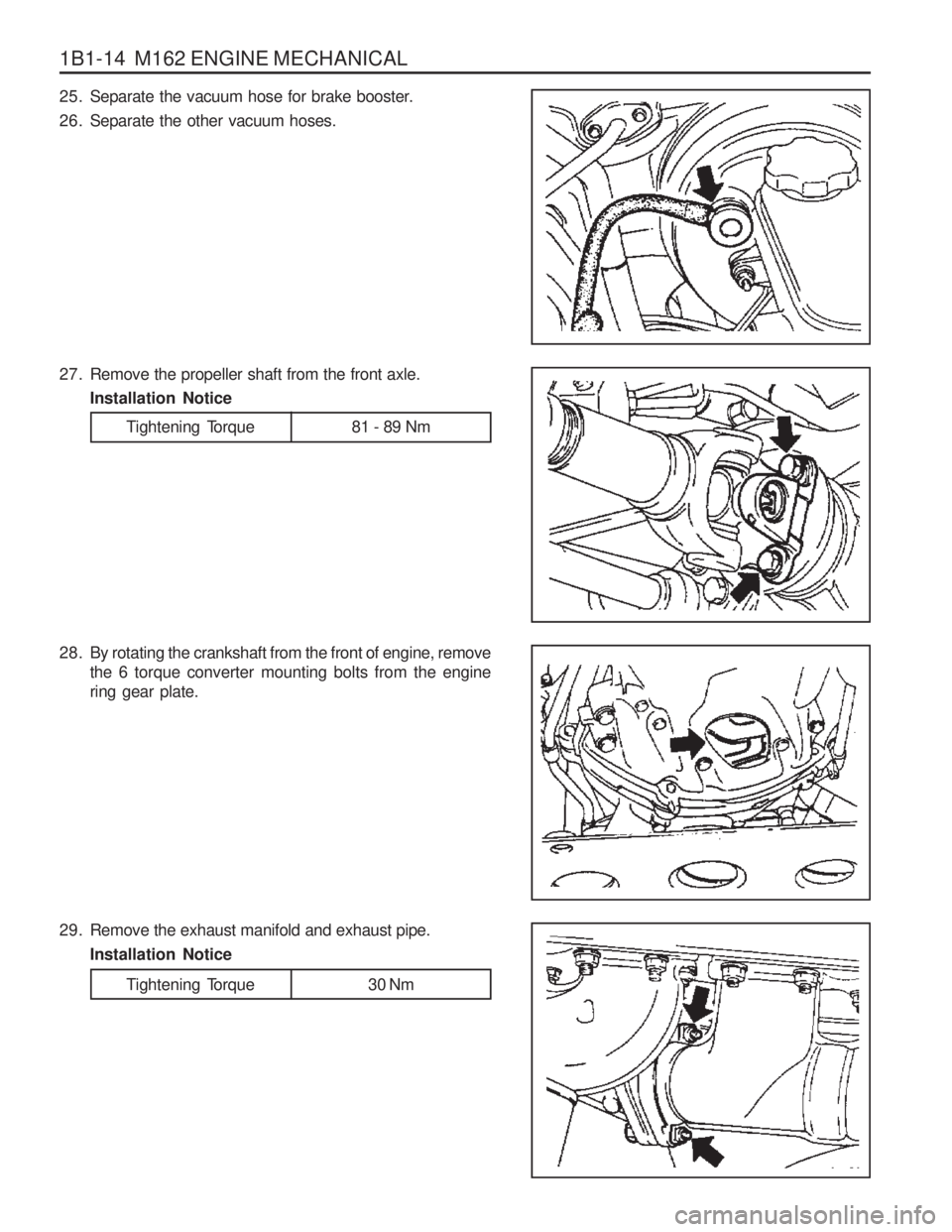

Tightening Torque 30 Nm

29. Remove the exhaust manifold and exhaust pipe.

Installation Notice

25. Separate the vacuum hose for brake booster.

26. Separate the other vacuum hoses.

27. Remove the propeller shaft from the front axle.Installation Notice

28. By rotating the crankshaft from the front of engine, remove the 6 torque converter mounting bolts from the engine ring gear plate.

Tightening Torque 81 - 89 Nm

Page 51 of 1574

M162 ENGINE MECHANICAL 1B1-15

30. Remove the transmission mounting bolts and separatethe transmission from the engine. Installation Notice

Tightening Torque 65 Nm

31. Remove the bolts for engine mounting bracket. Installation Notice

Tightening Torque 50 - 75 Nm

32. Hook the chain to the bracket of engine and by using a hoist or crane, carefully separate the engine assembly from the vehicle.

33. Installation should follow the removal procedure in the reverse order.

Page 54 of 1574

1B1-18 M162 ENGINE MECHANICAL

ALTERNATOR

1 Nut (M8)......................................... 22.5-27.5 Nm

2 Bolt (M8 x 30, 3 pieces) .................22.5-27.5 Nm

3 Bolt (M8 x 40, 1 piece) ...................22.5-27.5 Nm

Removal & Installation Procedure

1. Remove the drive belt.

2. Remove the alternator.

3. Unscrew the alternator carrier bolts and remove the carrier. Installation Notice 4 Bolt (M8 x 70, 1 piece)

...................22.5-27.5 Nm

5 Bolt (M8 x 75, 1 piece) ...................22.5-27.5 Nm

Tightening Torque 10 - 15 Nm

4. Installation should follow the removal procedure in the reverse order.

Page 56 of 1574

1B1-20 M162 ENGINE MECHANICAL Removal & Installation Procedure

1. Remove the belt pulley.Installation Notice

2. Disconnect the hydraulic pipe of the power steering pump and drain the oil.

3. Unscrew the bolts (arrows) and remove the steering pump. Installation Notice

Notice Pull the tensioning pulley clockwise as shown in the figure.

4. Remove the compressor after disconnecting the wiring connector and refrigerant pipe of A/C compressor. Notice Discharge all the refrigerant before removing the pipes.

Tightening Torque 40.5 - 49.5 Nm

Tightening Torque 22.5 - 27.5 Nm

Page 57 of 1574

M162 ENGINE MECHANICAL 1B1-21

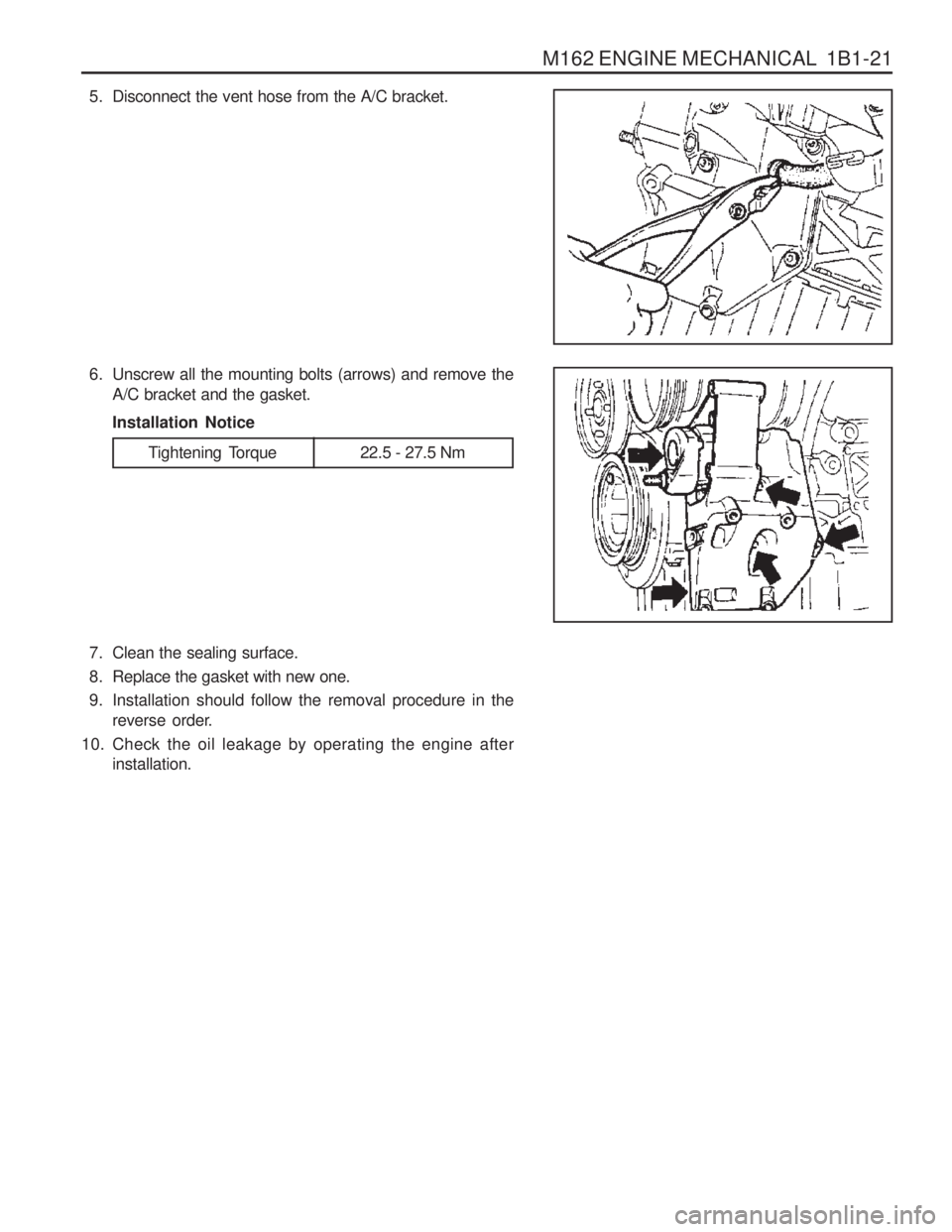

5. Disconnect the vent hose from the A/C bracket.

6. Unscrew all the mounting bolts (arrows) and remove theA/C bracket and the gasket. Installation Notice

7. Clean the sealing surface.

8. Replace the gasket with new one.

9. Installation should follow the removal procedure in the reverse order.

10. Check the oil leakage by operating the engine after installation.

Tightening Torque 22.5 - 27.5 Nm