SSANGYONG MUSSO 2003 Service Manual

MUSSO 2003

SSANGYONG

SSANGYONG

https://www.carmanualsonline.info/img/67/57511/w960_57511-0.png

SSANGYONG MUSSO 2003 Service Manual

Page 438 of 1574

1B3-174 OM600 ENGINE MECHANICAL

OIL SPRAY NOZZLE

1 Fitting Sleeve

2 Oil Spray Nozzle

Disassembly Procedure

1. Remove oil pan or crankshaft.

2. Loose the bolt and then remove the nozzle.3 Combination Bolt ..................................... 10 Nm

A Oil Duct

Page 439 of 1574

OM600 ENGINE MECHANICAL 1B3-175

OIL PUMP

1 Oil Pump

2 Piston

3 Pressure Spring

4 Guide Pin5 Screw Plug

................................................ 50 Nm

6 Combination Bolt ...................................... 25 Nm

7 Oil Strainer

8 Bracket

Disassembly Procedure

1. Remove the oil pan.

2. Unscrew the mounting bolt of spracket.

Page 440 of 1574

1B3-176 OM600 ENGINE MECHANICAL

Tightening Torque 10 Nm

3. Unscrew the oil strainer bracket bolt.

4. Remove the oil pump.

5. Unscrew the screw plug and remove the relief valve.

6. Installation should follow the removal procedure in thereverse order.

Page 441 of 1574

OM600 ENGINE MECHANICAL 1B3-177

CYLINDER HEAD PRESSURE LEAKAGE TEST Preceding Work : Removal of the cylinder head Removal of the exhaust manifold Removal of the valve

1 Feed Pipe

2 Bolt

3 Return Connection

4 Gasket ................................................................ Replace

5 Coolant Gallery ................................................... Sealing

6 Pressure Measuring Plate ..................................Completely tight to the cylinder head

7 Cylinder Head .....................................................

Immerse with pressure measuring plate into warm water of approx. 60 °C and pressurize with compressed

airof 2 bar.

Notice If air bubbles are seen, replace the cylinderhead.

Tools Required

115 589 34 63 00 Pressure Measuring Plate 601 589 00 25 00 Suspension Device

UNIT REPAIR

Page 442 of 1574

1B3-178 OM600 ENGINE MECHANICALHeight ‘A’

(cylinder head surface - cylinder head cover surface) Minimum height after machiningPermissible unevenness of parting surface Permissible variation of parallelism (longitud. Direction) Peak-to-valley height

Valve arrears ‘a’

Prechamber protrusion

Service Data

In longitudinal direction In transverse direction Intake valve Exhaust valve

142.9 - 143.1mm

142.5mm0.08mm0.0mm

Max. 0.1mm

0.0017mm

0.1 - 0.7mm 0.1 - 0.7mm 7.6 - 8.1mm

FACING CYLINDER HEAD MATING SURFACE

Preceding Work : Removal of prechamber Cylinder head pressure leakage test

1 Valve

2 Cylinder Head

3 Prechamber

A Height of Cylinder Head B Longitudinal Direction

C Transverse Direction

a Valve Arrears

b Prechamber Protrusion

Page 443 of 1574

OM600 ENGINE MECHANICAL 1B3-179

Measurement Procedure

1. Measure height ‘A’ .

Limit 142.5 mm

Notice If the height is less than 142.5mm, replace the cylinder head.

2. Insert the valve (1) and measure valve arrears ‘a’.

Valve Arrears ‘a’ 0.1 - 0.7 mm

Notice If out of standard, machine the valve seat.

3. Install the prechamber and measure protrusion ‘C’.

Protrusion ‘C’ 7.6 - 8.1mm

4. Assemble the engine and check the valve timing.

Page 444 of 1574

1B3-180 OM600 ENGINE MECHANICAL

REPLACEMENT OF CRANKCASE CORE PLUG Left

Right

Core plug .......................................................

� 34mm

OM661LA - 2EA OM662LA - 3EA Core plug

.......................................................� 34mm

OM661LA - 2EAOM662LA - 3EA

Core plug .......................................................

� 17mm

OM661LA - 1EA OM662LA - 1EA Core plug

.......................................................� 34mm

OM661LA - 1EAOM662LA - 1EA

Left

Right

Page 445 of 1574

OM600 ENGINE MECHANICAL 1B3-181

Tools Required 102 589 00 15 00 Drift 102 589 12 15 00 Drift Replacement Procedure

1. Completely drain the coolant.

2. Remove any parts which impede access.(Example : transmission, injection pump)

3. Place the screwdriver to the deepdrawn edge of the core plug and pull forward and then rotate 90 °.

4. Pull out the core plug with pliers.

5. Thoroughly clean the sealing surface and apply Loctite 241.

6. Install the new core plug by using a drift. Drift 102 589 00 15 00 (F34) Drift 102 589 12 15 00 (F17)

7. Install the removed parts and fill the coolant. Notice The adhesive must be allowed to harden for about 45 minutes before filling of coolant.

8. Warm up the engine and check the coolant for leaks.

Page 446 of 1574

1B3-182 OM600 ENGINE MECHANICAL Service Data

Height ‘Y’

Permissible unevenness of contacting surface Permissible roughness upper contacting surface Permissible variation of parallelism of crankcase uppersurface to lower surface in longitudinal directionPiston protrusion at TDC to crankcase upper surface

In longitudinal direction (B) In transverse direction (C) Min. 299.62 mm

0.06 mm 0.06 mm

0.0006 - 0.0016 mm 0.05 mm

0.965 mm0.735 mm

Max. Min.

FACING CRANKCASE CONTACTING SURFACE

1 Crankcase

2 Crankcase Contacting Surface

Y Height (crankcase upper surface - crankcase lower surface) B Longitudinal Direction

C Transverse Direction H Chamfer Heightb Chamfer Angle

Page 447 of 1574

OM600 ENGINE MECHANICAL 1B3-183

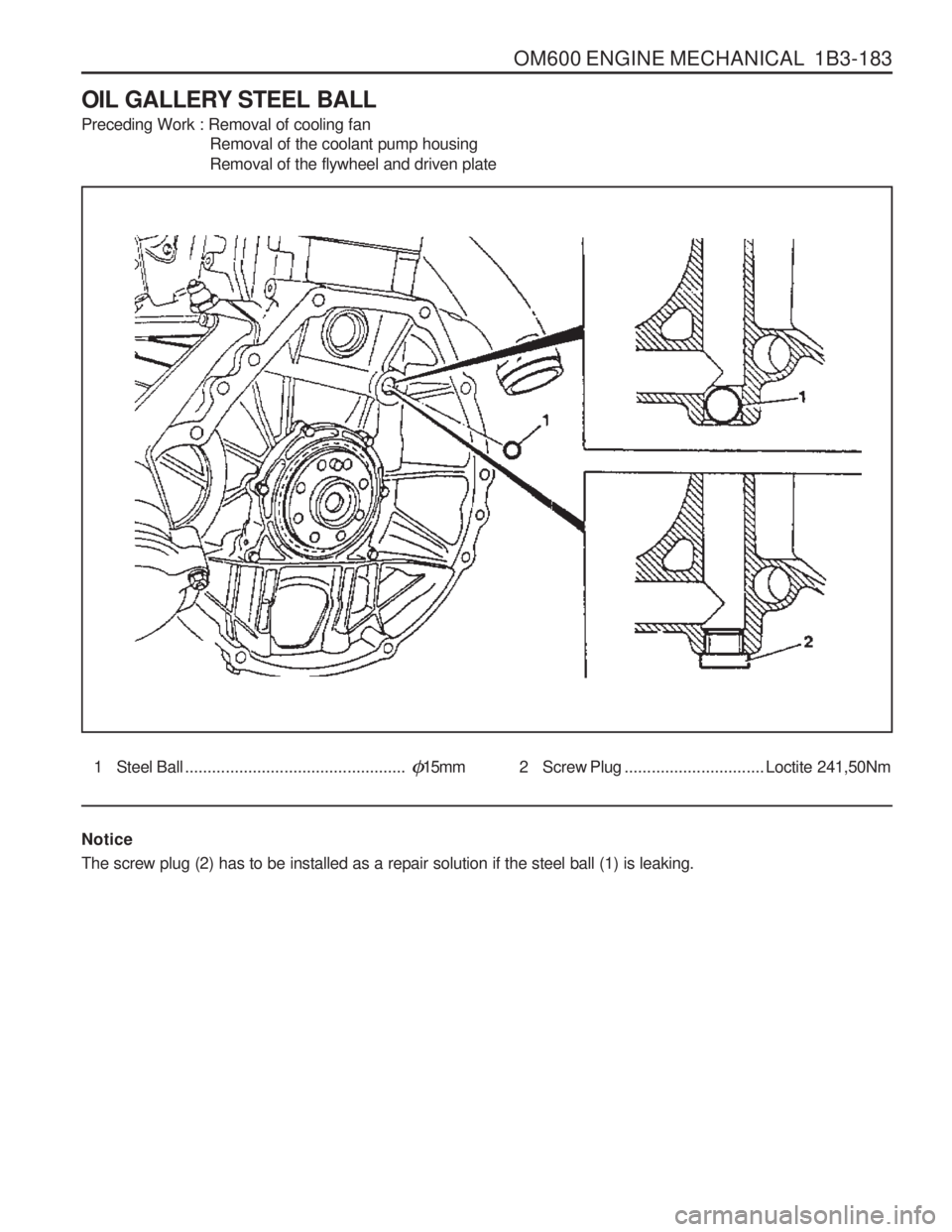

OIL GALLERY STEEL BALL Preceding Work : Removal of cooling fan Removal of the coolant pump housing Removal of the flywheel and driven plate

1 Steel Ball.................................................�15mm 2 Screw Plug ............................... Loctite 241,50Nm

Notice The screw plug (2) has to be installed as a repair solution if the steel ball (1) is leaking.