engine SSANGYONG MUSSO 2003 Service Manual

[x] Cancel search | Manufacturer: SSANGYONG, Model Year: 2003, Model line: MUSSO, Model: SSANGYONG MUSSO 2003Pages: 1574, PDF Size: 26.41 MB

Page 468 of 1574

Circulation Type RadiationCapabilitySECTION 1D2

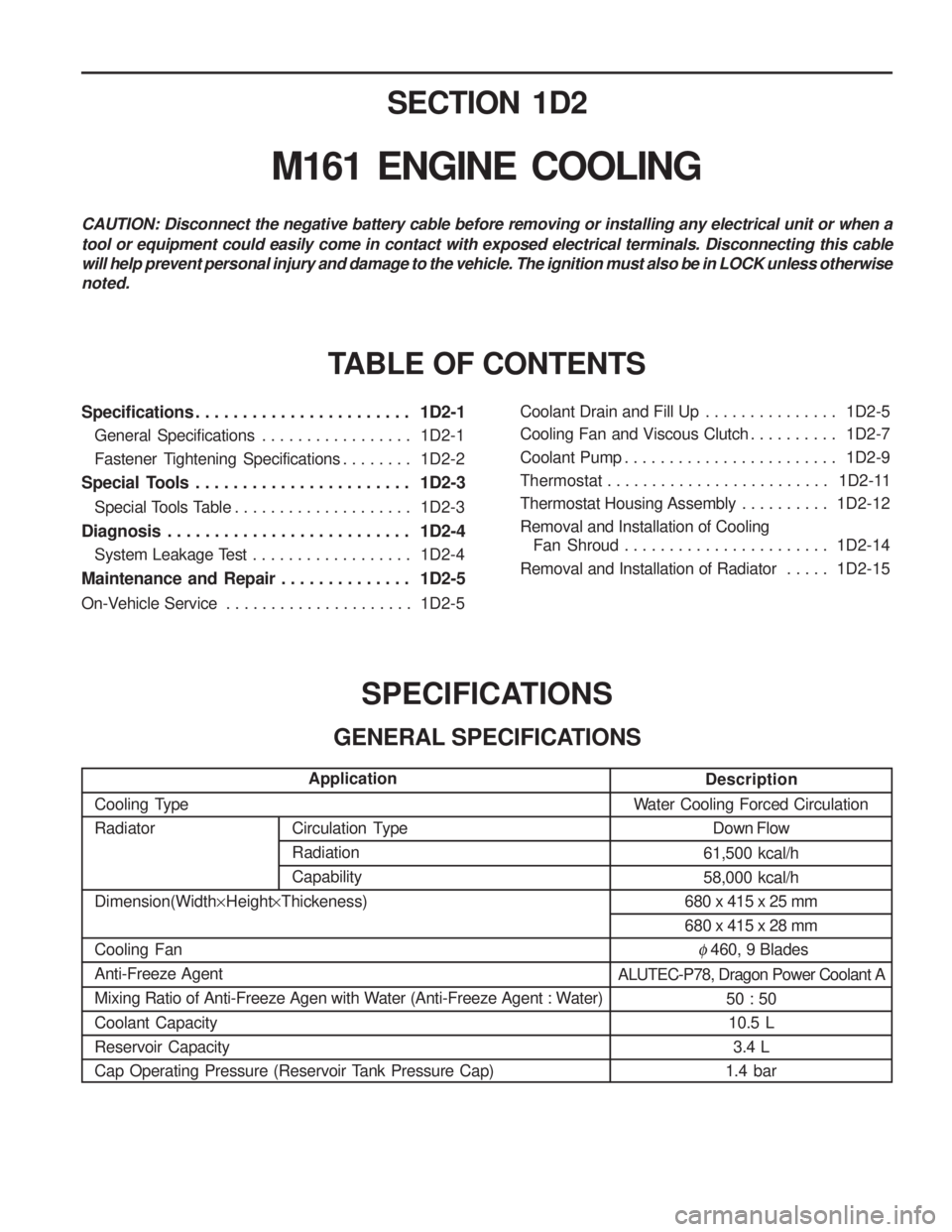

M161 ENGINE COOLING

Specifications . . . . . . . . . . . . . . . . . . . . . . . 1D2-1

General Specifications . . . . . . . . . . . . . . . . . 1D2-1

Fastener Tightening Specifications . . . . . . . . 1D2-2

Special Tools . . . . . . . . . . . . . . . . . . . . . . . 1D2-3

Special Tools Table . . . . . . . . . . . . . . . . . . . . 1D2-3

Diagnosis . . . . . . . . . . . . . . . . . . . . . . . . . . 1D2-4 System Leakage Test . . . . . . . . . . . . . . . . . . 1D2-4

Maintenance and Repair . . . . . . . . . . . . . . 1D2-5

On-Vehicle Service . . . . . . . . . . . . . . . . . . . . . 1D2-5Coolant Drain and Fill Up . . . . . . . . . . . . . . .

1D2-5

Cooling Fan and Viscous Clutch . . . . . . . . . . 1D2-7

Coolant Pump . . . . . . . . . . . . . . . . . . . . . . . . 1D2-9

Thermostat . . . . . . . . . . . . . . . . . . . . . . . . . 1D2-11

Thermostat Housing Assembly . . . . . . . . . . 1D2-12

Removal and Installation of Cooling Fan Shroud . . . . . . . . . . . . . . . . . . . . . . . 1D2-14

Removal and Installation of Radiator . . . . . 1D2-15

SPECIFICATIONS

GENERAL SPECIFICATIONS

CAUTION: Disconnect the negative battery cable before removing or installing any electrical unit or when a tool or equipment could easily come in contact with exposed electrical terminals. Disconnecting this cable will help prevent personal injury and damage to the vehicle. The ignition must also be in LOCK unless otherwisenoted.

TABLE OF CONTENTS

Description

Water Cooling Forced Circulation Down Flow

61,500 kcal/h 58,000 kcal/h

680 x 415 x 25 mm680 x 415 x 28 mm

� 460, 9 Blades

ALUTEC-P78, Dragon Power Coolant A 50 : 5010.5 L 3.4 L

1.4 bar

Application

Cooling TypeRadiator Dimension(Width ×Height ×Thickeness)

Cooling Fan Anti-Freeze Agent

Mixing Ratio of Anti-Freeze Agen with Water (Anti-Freeze Agent : Water) Coolant Capacity Reservoir Capacity

Cap Operating Pressure (Reservoir Tank Pressure Cap)

Page 469 of 1574

1D2-2 M161 ENGINE COOLINGFASTENER TIGHTENING SPECIFICATIONS

N

m

30

22.5 - 27.5

9 - 11

9 - 11

9 - 11

40.5 - 49.5

3 - 73 - 7

Application

Coolant Drain PlugEngine Hanger Bracket and Coolant OutletPort Bolt Thermostat Cover Bracket Bolt Oil Cooler Pipe Line BoltCooling Fan BoltViscous Clutch Bolt

Automatic Transmission Oil Cooling Hose Bolt Cooling Fan Shroud Bolt

Page 470 of 1574

M161 ENGINE COOLING 1D2-3

SPECIAL TOOLS

SPECIAL TOOLS TABLE

124 589 15 21 00 Tester

603 589 00 40

Counter Holder

111 589 02 01 00

Open End Wrench111 589 00 40 00

Open End Wrench

Page 471 of 1574

1D2-4 M161 ENGINE COOLINGDIAGNOSIS

3. Connect the special tool to the reservoir filler cap and apply 1.4 bar of pressure.

SYSTEM LEAKAGE TEST

Tools Required

124 589 15 21 00 Tester

Test Procedure

1. Loosen the cap a little and release pressure and remove

the cap. Notice For the risk of scalding, cap must not be opened unless the coolant temperature is below 90 °C.

2. Fill coolant up to upper edge (arrow) of reservoir.

Tester 124 589 15 21 00

4. If the pressure on the tester drops, check leakage at the all coolant hoses and pipes and each connections. Replace

or retighten if necessary.

Page 472 of 1574

M161 ENGINE COOLING 1D2-5

MAINTENANCE AND REPAIR

ON-VEHICLE SERVICE

COOLANT DRAIN AND FILL UP Draning & Filling up Procedure 1. Loosen the cap a little and release pressure and remove the cap. NoticeFor the risk of scalding, the cap must not be opened unless the coolant temperature is below 90oC.

2. Loosen the radiator lower drain cock and drain the coolant.

Notice

Collect coolant by using a proper container.

3. Drain the coolant from the crankcase by inserting a hose(dia. 14mm) onto the drain bolt on the side of crankcase (exhaust manifold) and by loosening the plug. Notice

� Just loosen the drain plug to drain the coolant and do

not remove the plug completely.

� Collect coolant by using proper container.

Page 473 of 1574

1D2-6 M161 ENGINE COOLING

4. After complete draining of the coolant, remove the hoseconnector to drain plug and reinstall the drain plug. Installation Notice

5. Tighten the radiator lower drain cock.

6. Remove the de-aeration hose clamp in the coolant pumpand remove the de-aeration hose.

7. Fill up the coolant through the coolant reservoir tank. Notice

� Match the anti-freeze and the water ratio to 50 : 50.

� Supplement the coolant until the coolant overflows to the deaeration hose.

Tightening Torque 30 Nm

8. Insert the de-aeration hose and completely tighten the clamp.

9. Check the coolant level in the coolant reservoir tank.

10. Warm up(until thermostat is opened) the engine and recheck the coolant level in the reservoir tank and fill up

the coolant if necessary.

Page 474 of 1574

M161 ENGINE COOLING 1D2-7

COOLING FAN AND VISCOUS CLUTCH

1 Bolt (M6 X 14, 3 piece) ........................... 9-11 Nm

2 Cooling Fan 3 Viscous Clutch

4 Union Nut (Left Threaded Screw) ... 40.5-49.5 Nm

Page 475 of 1574

1D2-8 M161 ENGINE COOLING

Tools Required

111 589 02 01 00 Open End Wrench

111 589 00 40 00 Open End Wrench Removal & Installation Procedure

1. Install the holder (special tool : 111 589 00 40 00) to the boltat the pulley as shown in the right figure to hold the pulley.

2. Remove the viscous clutch using an open end wrench (special tool : 111 589 02 01 00). Installation Notice

Notice

The union nut is left threaded screw.

3. Remove the 3 bolts (1) from the viscous clutch and remove the cooling fan and the viscous clutch.Installation Notice

Tightening Torque 40.5 - 49.5 Nm

Tightening Torque 9 - 11 Nm

Notice

You may change the procedure (2) and (3) if necessary.

4. Installation should follow the removal procedure in the reverse order.

Page 476 of 1574

M161 ENGINE COOLING 1D2-9

COOLANT PUMP Preceding Work : Removal of viscous clutch

1 Bolt (M6 X 45, 1 piece) ........................... 9-11 Nm

2 Bolt (M6 X 95, 1 piece) ........................... 9-11 Nm

3 Bolt (M6 X 25, 4 piece) ........................... 9-11 Nm

4 Bolt (M8 X 85, 2 piece) ...................20.5-20.5 Nm

5 Coolant Pump Housing

6 Bolt (M6 X 16, 4 piece) ........................... 9-11 Nm 7 Coolant Pump Pulley

8 Coolant Inlet Hose

9 Heater Hose

10 Coolant Bypass Hose 11 Gasket

Page 477 of 1574

1D2-10 M161 ENGINE COOLING

Tools Required

124 589 15 21 00 Tester Removal & Installation Procedure

1. Drain the coolant.

2. Disconnect the coolant hoses (8, 9, 10).

3. Tak off the drive belt.

4. Unscrew the four bolts (6) from coolant pump pulley andremove the pulley (7).Installation Notice

Tightening Torque 9 - 11 Nm

22.5 - 27.5 Nm

(1, 2, 3)

(4)

Notice Hold the pulley with special tool (603 589 00 40 00) while

removing the pulley.

Tightening Torque 9 - 11 Nm

5. Unscrew the bolts (1, 2, 3, 4) from coolant pump housing (5) and remove the coolant pump. Installation Notice

6. Clean the sealing surface.

7. Replace the gasket with new one. NoticeApply the sealant when the sealing surface of coolant pump housing and coolant mounting area is clean.

8. Installation should follow the removal procedure in the reverse order.

9. Check for leaks by starting the engine.