SSANGYONG MUSSO 2003 Service Manual

MUSSO 2003

SSANGYONG

SSANGYONG

https://www.carmanualsonline.info/img/67/57511/w960_57511-0.png

SSANGYONG MUSSO 2003 Service Manual

Page 478 of 1574

M161 ENGINE COOLING 1D2-11

THERMOSTAT

Removal & Installation Procedure

1. Drain the coolant from the radiator.

2. Loosen the hose mounting clip and remove the coolant hose (3, 4).

3. Unscrew the three bolts (1) and remove the thermostat cover assembly from thermostat housing.Installation Notice Do not separate the thermostat cover and thermostat.

4. Replace the O-ring if necessary.

5. Check the leakage in the cooling system.

Tightening Torque 9 - 11 Nm

1 Bolt (M6 X 25, 3 pieces)

........................ 9 -11 Nm

2 Thermostat Cover

3 De-aeration Hose 4 Coolant Outlet Hose

5 Thermostat

6 O-ring

Page 479 of 1574

1D2-12 M161 ENGINE COOLING

THERMOSTAT HOUSING ASSEMBLY Preceding Work : Removal of viscous clutch

1a Bolt (M6 X 95, 2 pieces)......................... 9-11 Nm

1b Bolt (M8 X 75, 2 pieces) .................22.5-27.5 Nm

1 c Bolt (M8 X 35, 1 piece) ...................22.5-27.5 Nm

2 Thermostat Housing Assembly

3 O-ring 4 De-aeration Hose

5 Coolant Outlet Hose

6 Coolant Bypass Hose

7 Tensioning Device Shock Absorber

8 Engine Hanger Brocket

Page 480 of 1574

M161 ENGINE COOLING 1D2-13

Removal & Installation Procedure

1. Drain the coolant.

2. Remove the de-aeration hose (4), coolant outlet hose (5) and coolant bypass hose (6).

3. Disconnect the coolant temperature sensor connector.

4. Unscrew the bolt (1c) and pry off the tensioning device shock absorber (7).Installation Notice

6. Replace the O-ring with new one.

7. Installation should follow the removal procedure in the reverse order.

8. Check for leaks in cooling system.

5. Unscrow the bolts (1a, 1b) and remove the engine

hanger bracket and thermostat housing.Installation Notice

Tightening Torque 9 - 11 Nm

22.5 - 27.5 Nm

(1a) (1b)

Tightening Torque 22.5 - 27.5 Nm

Page 481 of 1574

1D2-14 M161 ENGINE COOLING

REMOVAL AND INSTALLATION OF COOLING FAN SHROUD

Removal & Installation Procedure1. Unscrew two bolts from cooling fan shroud and remove the shrud. Installation Notice

1 Fan Suroud Assembly

Tightening Torque 3 - 7 Nm

2 Bolt (M6 X 16, 2 pieces)

...........................3-7 Nm

2. Installation should follow the removal procedure in the reverse order.

Page 482 of 1574

M161 ENGINE COOLING 1D2-15

REMOVAL AND INSTALLATION OF RADIATOR Preceding Work : Removal of cooling fan shroud

1 Inlet Hose

2 Hose (to Engine)

3 Hose (to 3-way Connector)

4 Make-up Hose (to Coolant Reservoir)

5 3-way Connector

6 Automatic Transmission Oil Cooling Hose (A/T Equippend Vehicle) 7 Bolt (M6 X 20, 4 pieces)

...........................3-7 Nm

8 Insulator

9 Radiator Bracket

10 Radiator

Page 483 of 1574

1D2-16 M161 ENGINE COOLING Removal & Installation Procedure1. Drain coolant from the radiator.

2. Remove the coolant thermo connector from the radiator.

3. Remove the each coolant hoses.

Tightening Torque 14 Nm

4. Remove the automatic transmission oil cooling hose.

Installation Notice

5. Unscrew the bolts from radiator bracket and remove the bracket and insulator. Installation Notice

Tightening Torque 3 - 7 Nm

6. Remove the radiator upper mounting bolts and then remove the bracket and insulator.

7. Remove the radiator.

8. Check the radiator pin for crack, damage, leakage and bending and replace if necessary.

9. Installation should follow the removal procedure in the reverse order.

10. Berform the cooling system leakage test.

Page 484 of 1574

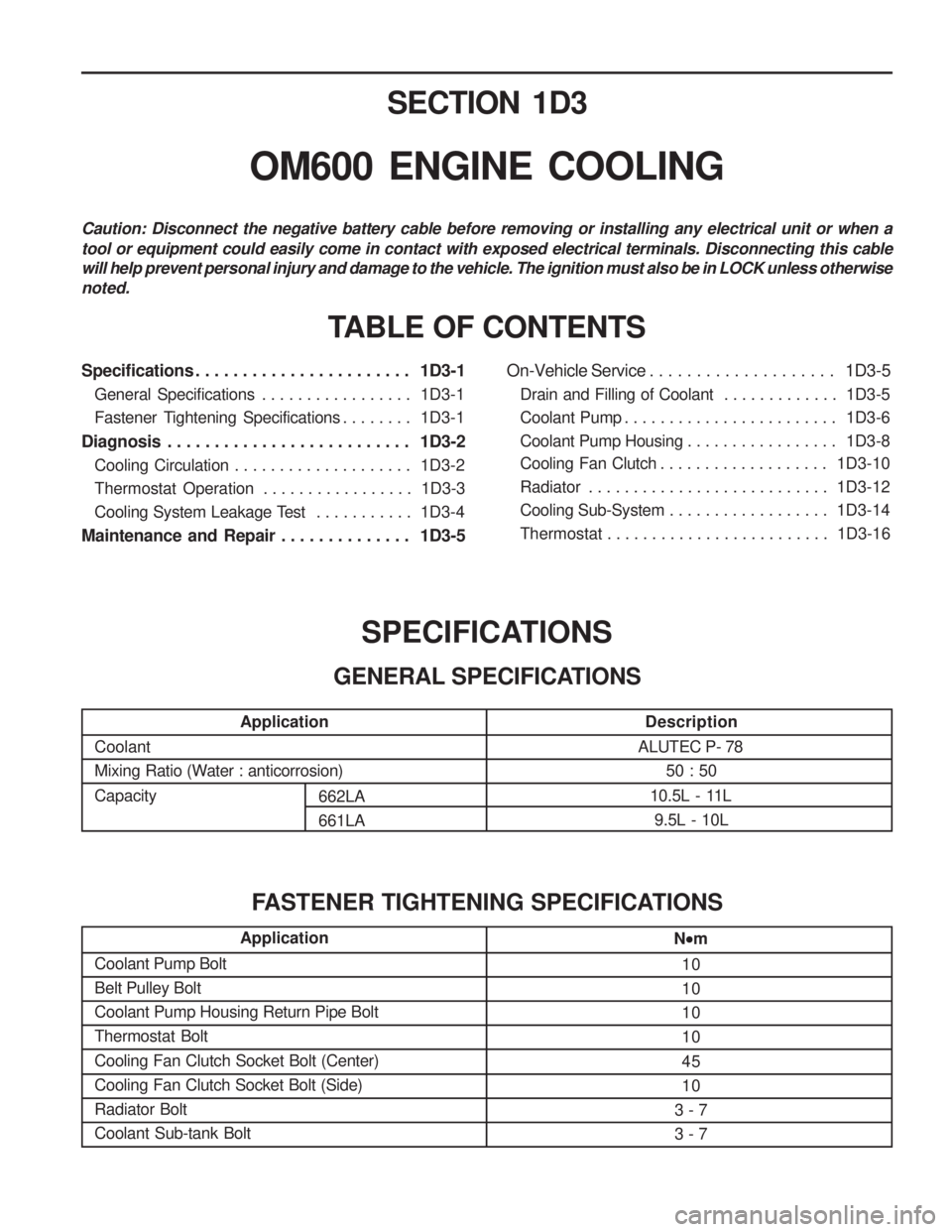

SECTION 1D3

OM600 ENGINE COOLING

Specifications . . . . . . . . . . . . . . . . . . . . . . . 1D3-1General Specifications . . . . . . . . . . . . . . . . . 1D3-1

Fastener Tightening Specifications . . . . . . . . 1D3-1

Diagnosis . . . . . . . . . . . . . . . . . . . . . . . . . . 1D3-2 Cooling Circulation . . . . . . . . . . . . . . . . . . . . 1D3-2

Thermostat Operation . . . . . . . . . . . . . . . . . 1D3-3

Cooling System Leakage Test . . . . . . . . . . . 1D3-4

Maintenance and Repair . . . . . . . . . . . . . . 1D3-5 On-Vehicle Service . . . . . . . . . . . . . . . . . . . .

1D3-5

Drain and Filling of Coolant . . . . . . . . . . . . . 1D3-5

Coolant Pump . . . . . . . . . . . . . . . . . . . . . . . . 1D3-6

Coolant Pump Housing . . . . . . . . . . . . . . . . . 1D3-8

Cooling Fan Clutch . . . . . . . . . . . . . . . . . . . 1D3-10

Radiator . . . . . . . . . . . . . . . . . . . . . . . . . . . 1D3-12

Cooling Sub-System . . . . . . . . . . . . . . . . . . 1D3-14

Thermostat . . . . . . . . . . . . . . . . . . . . . . . . . 1D3-16

TABLE OF CONTENTS

Caution: Disconnect the negative battery cable before removing or installing any electrical unit or when a tool or equipment could easily come in contact with exposed electrical terminals. Disconnecting this cable will help prevent personal injury and damage to the vehicle. The ignition must also be in LOCK unless otherwisenoted.

Application

Coolant

Mixing Ratio (Water : anticorrosion) Capacity

Description

ALUTEC P- 78 50 : 50

10.5L - 11L 9.5L - 10L

SPECIFICATIONS

GENERAL SPECIFICATIONS

Application

Coolant Pump Bolt Belt Pulley BoltCoolant Pump Housing Return Pipe BoltThermostat Bolt Cooling Fan Clutch Socket Bolt (Center) Cooling Fan Clutch Socket Bolt (Side)Radiator BoltCoolant Sub-tank BoltN

m

10 101010 45 10

3 - 73 - 7

FASTENER TIGHTENING SPECIFICATIONS

662LA 661LA

Page 485 of 1574

1D3-2 OM600 ENGINE COOLING

COOLING CIRCULATIONA Thermostat

B Radiator

D From Heater

E Hose

G Deaeration Line

H Reservoir

DIAGNOSIS

Page 486 of 1574

OM600 ENGINE COOLING 1D3-3

THERMOSTAT OPERATION Operation

1. At warming upValve closes until temperature of coolant reaches to 85 °C.

B. From Radiator

C. From Crankcase

D. To Crankcase

2. At partial opening. Valve opens partially as temperature of coolant is maintained between 85-100 °C.

3. At full opening. Valve opens full as temperature of coolant is more then 100 °C.

Page 487 of 1574

1D3-4 OM600 ENGINE COOLING

COOLING SYSTEM LEAKAGE TEST

Tools Required

124 589 15 21 00 Tester

Test

1. Loosen the pressure cap by 1 notch and remove the capafter. Notice Do not remove radiator cap when coolant is above 90 °C.

2. Add the coolant to the arrow mark of coolant reservoir.

3. Connect the special tool to the injector of reservoir and apply 1.4bar pressure. Tester 124 589 15 21 00

4. If the pressure on the tester drops, check the hose, pipe and leakage and, replace or retighten.