engine SSANGYONG MUSSO 2003 Service Manual

[x] Cancel search | Manufacturer: SSANGYONG, Model Year: 2003, Model line: MUSSO, Model: SSANGYONG MUSSO 2003Pages: 1574, PDF Size: 26.41 MB

Page 518 of 1574

1E2-6 M161 ENGINE ELECTRICAL

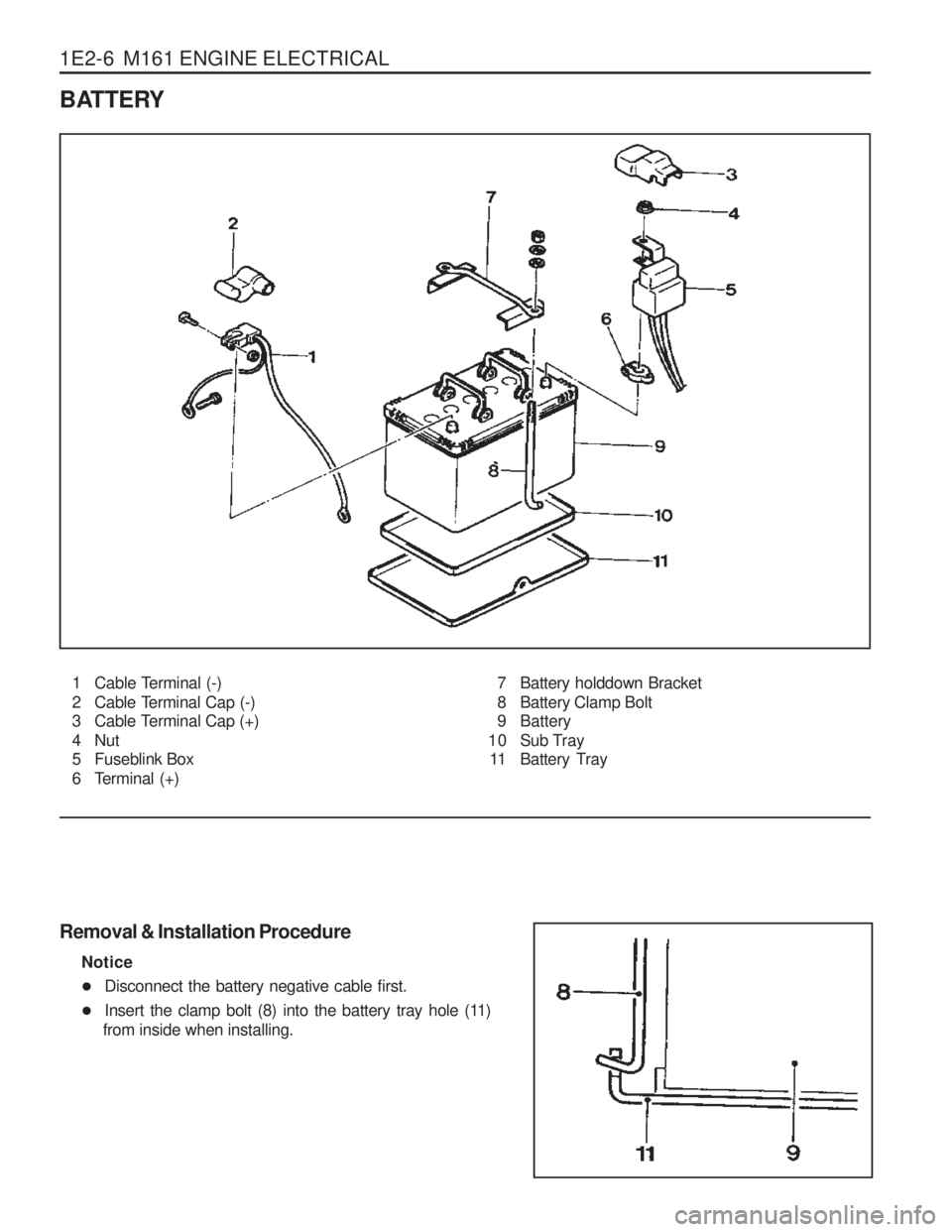

BATTERY

1 Cable Terminal (-)

2 Cable Terminal Cap (-)

3 Cable Terminal Cap (+)

4 Nut

5 Fuseblink Box

6 Terminal (+)7 Battery holddown Bracket

8 Battery Clamp Bolt

9 Battery

10 Sub Tray 11 Battery Tray

Removal & Installation Procedure Notice

� Disconnect the battery negative cable first.

� Insert the clamp bolt (8) into the battery tray hole (11)

from inside when installing.

Page 519 of 1574

M161 ENGINE ELECTRICAL 1E2-7

SPARK PLUG Preceding Work : Removal of intake air duct

Tools Required

119 589 01 09 00 Spark Plug Wrence1 Screw (3 pieces)

.................................. 9 - 11 Nm

2 Adaptor (3 pieces)

3 Ignition Coil Cable Cover

4 Spark Plug Connector

5 Ignition Coil Connector 6 Bolts (M6 X 25, 4 pieces)

..................... 9 - 11 Nm

7 Ignition Coil (T1/1)

8 Coupling Plug

9 Spark Plug ......................................... 25 - 30 Nm

10 Ignition Coil (T1/2)

Page 520 of 1574

1E2-8 M161 ENGINE ELECTRICAL

Tightening Torque 9 - 11Nm

Replacement Procedure

1. Unscrew the three screws(1) and remove the ignition coil

cable cover Installation Notice

Tightening Torque

Clearance 25 - 30 Nm

0.8 + 0.1 mm

2. Disconnect the cable from ignition coil and spark plug.

4. Using the special tool, remove the spark plug . Installation Notice

Spark Plug Wrench 119 589 01 09 00

Notice

� Tighten the spark plug with specified torque.

� Install the ignition coil to number 2 and 4 cylinder, and

connect the cable to number 1, 4 and 2, 3 cylinder

- T1/1 : cylinder 1 and 4

- T1/2 : cylinder 2 and 3

3. Unscrew two bolts(M6 X 25) from each ignition coil and remove the ignition coil(arrow) . Installation Notice

Tightening Torque 9 - 11Nm

Page 521 of 1574

M161 ENGINE ELECTRICAL 1E2-9

IGNITION CABLE Preceding Work : Removal of intake air duct

1 Control Cable Connection

2 Ignition Cable

3 Spark Plug Connector

4 Coupling Plug5a, 5b Secondary Voltage Connection

E Iron Core

L1 Secondary Ignition Coil

L2 Primary Ignition Coil

Page 522 of 1574

1E2-10 M161 ENGINE ELECTRICAL Ignition Cable and Cable Lay-out

1. Firing Order : 1-3-4-2

2. T1/1 : Connect the cylinder 1 + 4

3. T1/2 : Connect the cylinder 2 + 3

Removal & Installation Procedure

1. Disconnect the battery negative cable.

2. Unscrew the 3 screws and remove the ignition cable ductcover. Installation Notice

3. Seperate the cable from the ignition cable and the spark plug.

4. Remove the 2 bolts from each ignition cable and remove the ignition cables. Installation Notice Install the ignition cable to the cylinder 2 and 4 and connect the cable from 1 to 4, and from 2 to 3. - T1/1 : Cylinder 1 and 4- T1/2 : Cylinder 2 and 3

5. Installation should follow the removal procedure in the reverse order.

Tightening Torque 9 - 11 Nm

Tightening Torque 9 - 11 Nm

Page 523 of 1574

M161 ENGINE ELECTRICAL 1E2-11

Inspection & Maintenance (for E2.3 MSE)

1. Measure the primary resistance between the cable terminals1 and 15 after removing the ignition cable wiring connector

(1 and 15) with ignition switch OFF. Notice Replace the ignition coil if out of the specified resistance.

� T1/2 : between No.71 and No.69

Notice Check the ignition cable and the ECU if out of the

specified value.

3. Measure the secondary cable resistance between the ignition coil 5a and 5b using a multimeter.

2. Measure the primary voltage(T1/1) between the ECU

terminals No.72 and No.69 during the engine cranking (starter motor activated).

Specified Value 6 - 8.5 K �

Specified Value0.9 - 1.6 �

Specified Value 200 - 350 V

Page 524 of 1574

1E2-12 M161 ENGINE ELECTRICALUNIT REPAIR

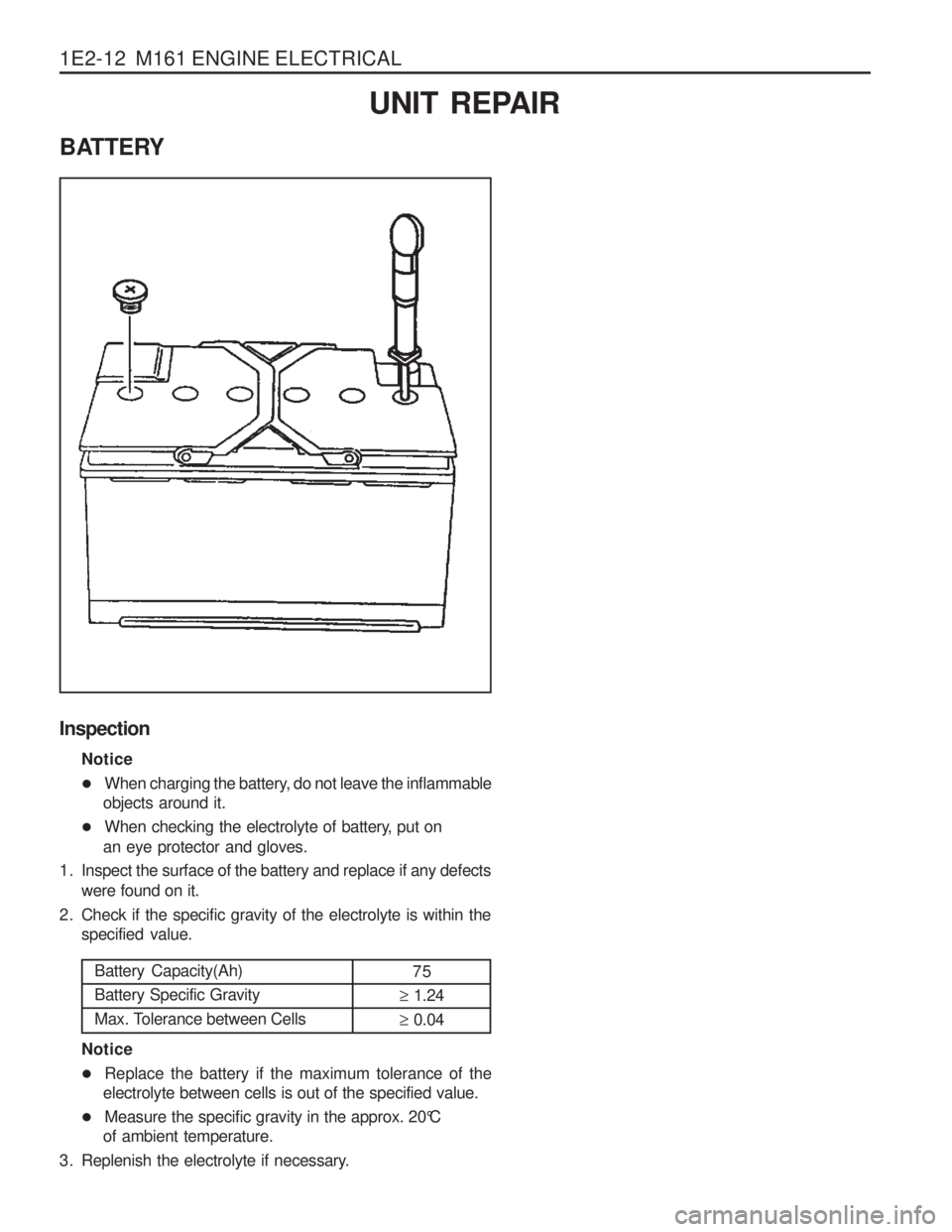

BATTERY

Inspection Notice

� When charging the battery, do not leave the inflammable

objects around it.

� When checking the electrolyte of battery, put on

an eye protector and gloves.

1. Inspect the surface of the battery and replace if any defects were found on it.

2. Check if the specific gravity of the electrolyte is within the specified value. Notice

� Replace the battery if the maximum tolerance of the

electrolyte between cells is out of the specified value.

� Measure the specific gravity in the approx. 20 °C

of ambient temperature.

3. Replenish the electrolyte if necessary. Battery Capacity(Ah)Battery Specific Gravity

Max. Tolerance between Cells

75

� 1.24

� 0.04

Page 525 of 1574

SECTION 1E3

OM600 ENGINE ELECTRICAL

Specifications . . . . . . . . . . . . . . . . . . . . . . . 1E3-1General Specifications . . . . . . . . . . . . . . . . . 1E3-1

Maintenance and Repair . . . . . . . . . . . . . . 1E3-2

On-Vehicle Service . . . . . . . . . . . . . . . . . . . . . 1E3-2

TABLE OF CONTENTS

Caution: Disconnect the negative battery cable before removing or installing any electrical unit or when a tool or equipment could easily come in contact with exposed electrical terminals. Disconnecting this cable will help prevent personal injury and damage to the vehicle. The ignition must also be in LOCK unless otherwisenoted.

Application

Alternator Starter Glow Plug

Description 12V - 75A

12V - 2.2kW

11.5V

SPECIFICATIONS

GENERAL SPECIFICATIONS

Glow Plug . . . . . . . . . . . . . . . . . . . . . . . . . . . 1E3-2

Alternator . . . . . . . . . . . . . . . . . . . . . . . . . . . 1E3-6

Starter Motor . . . . . . . . . . . . . . . . . . . . . . . . . 1E3-8

Page 526 of 1574

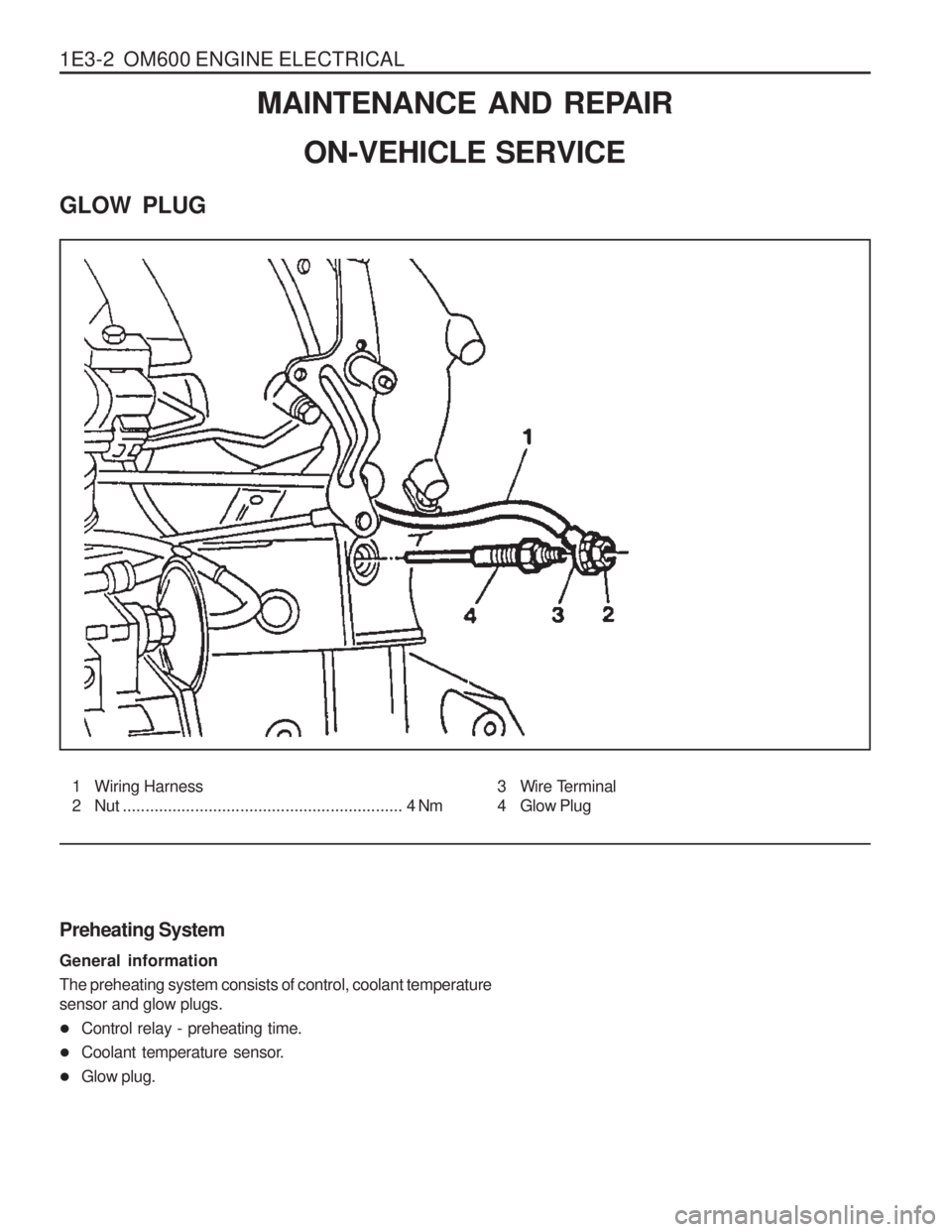

1E3-2 OM600 ENGINE ELECTRICAL

Preheating System General information The preheating system consists of control, coolant temperature sensor and glow plugs.

�Control relay - preheating time.

� Coolant temperature sensor.

� Glow plug.

GLOW PLUG

1 Wiring Harness

2 Nut .............................................................. 4 Nm 3 Wire Terminal

4 Glow Plug

MAINTENANCE AND REPAIR

ON-VEHICLE SERVICE

Page 527 of 1574

OM600 ENGINE ELECTRICAL 1E3-3

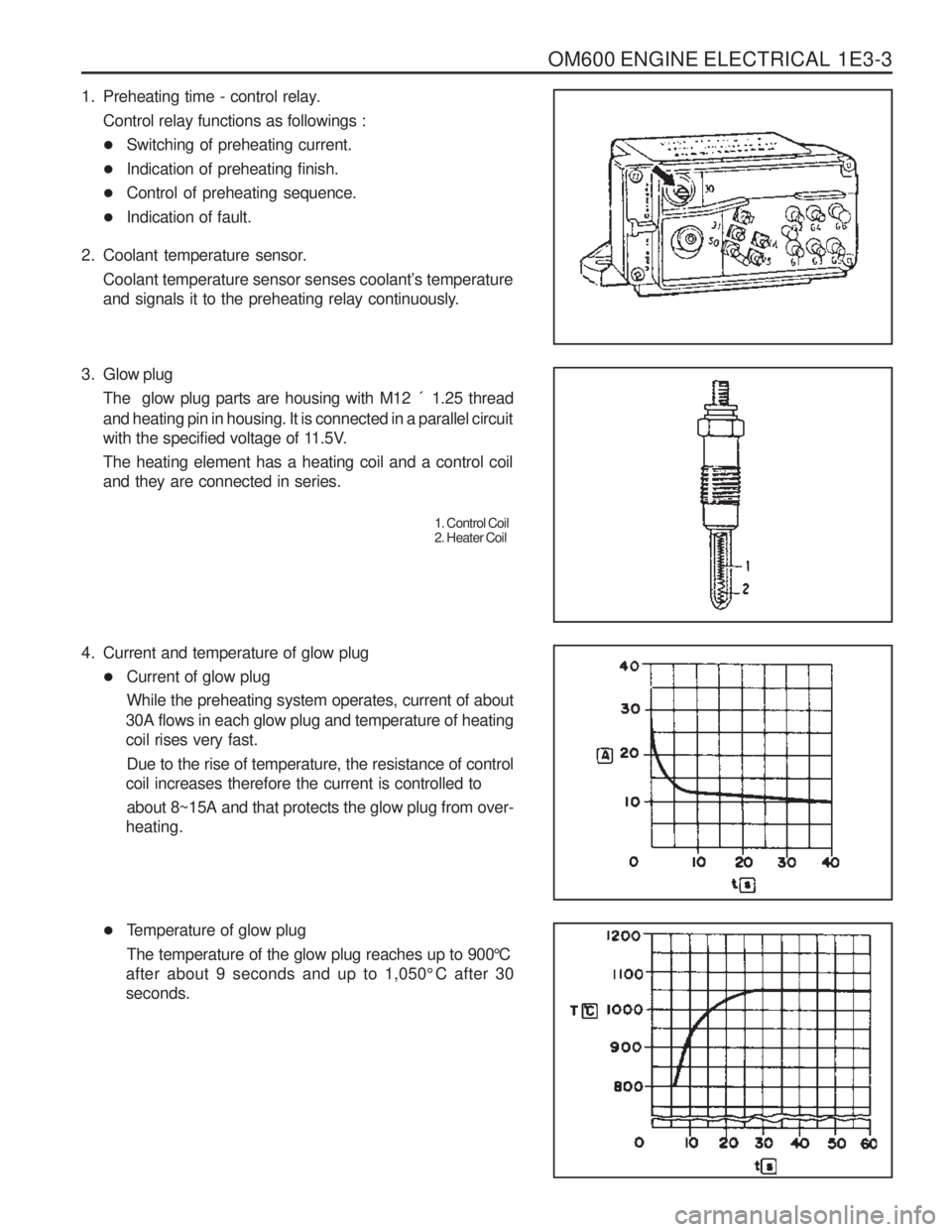

1. Preheating time - control relay.Control relay functions as followings :

� Switching of preheating current.

� Indication of preheating finish.

� Control of preheating sequence.

� Indication of fault.

2. Coolant temperature sensor. Coolant temperature sensor senses coolant ’s temperature

and signals it to the preheating relay continuously.

3. Glow plug The glow plug parts are housing with M12 ´ 1.25 thread

and heating pin in housing. It is connected in a parallel circuit

with the specified voltage of 11.5V. The heating element has a heating coil and a control coil and they are connected in series.

1. Control Coil 2. Heater Coil

4. Current and temperature of glow plug � Current of glow plug While the preheating system operates, current of about

30A flows in each glow plug and temperature of heating coil rises very fast.

Due to the rise of temperature, the resistance of control

coil increases therefore the current is controlled to

about 8~15A and that protects the glow plug from over-

heating.

� Temperature of glow plug The temperature of the glow plug reaches up to 900 °C

after about 9 seconds and up to 1,050 °C after 30

seconds.