check oil SSANGYONG MUSSO 2003 Workshop Manual

[x] Cancel search | Manufacturer: SSANGYONG, Model Year: 2003, Model line: MUSSO, Model: SSANGYONG MUSSO 2003Pages: 1574, PDF Size: 26.41 MB

Page 430 of 1574

1B3-166 OM600 ENGINE MECHANICAL Installation Procedure

1. Fit the piston onto the connecting rod so that the arrow(15) and the locking slot (16) are facing in direction of the vehicle.

2. Coat the piston pin (15) with engine oil and insert it by hand. Notice Do not heat up the piston.

3. Install the new snap ring (4) into the grooves (arrow).

4. Check the piston rings (1, 2, 3) and replace them if necessary.

5. Install and arrange the piston rings to be evenly 120 ° from

each ends gap.

Page 432 of 1574

1B3-168 OM600 ENGINE MECHANICAL

12. Coat the bolts (12) with oil and then tighten the bolts.

Tightening Torque40Nm + 90°

13. Rotate the crankshaft and check axial clearance between the connecting rod and crankshaft.

14. Measure clearance between the piston crown and cylinder

Standard Max. 0.12mm

15. Position the piston at TDC and measure the distance between the piston crown and the crankcase surface.

Notice Measure at points marked. Dial Gauge 001 589 00 53 21

Dial Gauge Holder 363 589 02 21 00

Standard Max. 0.965 mm

Page 449 of 1574

OM600 ENGINE MECHANICAL 1B3-185

Removal & Installation Procedure

1. Remove the timing case cover.

2. By inserting a round bar (6) approx. 0.7m from the back tothe front side through the oil gallery, knock out the steel balls (1,3). Notice Be careful not to damage the bores of the steel balls.

6 Shop-made tool

3. Thoroughly clean the bores of steel balls.

4. Place the steel ball (3) onto the drift (7) with a little grease and position to the bore and then tap until the drift stops.

Drift 601 589 08 15 00

5. Place the steel ball (1) onto the drift (7) with a little grease and position to the bore and then tap until the drift stops.

Drift 601 589 08 1500

6. Warm up the engine and check the oil for leaks.

Page 462 of 1574

M162 ENGINE COOLING 1D1-11

OIL COOLER PIPE LINE Preceding Work : Removal of upper intake manifold

Tightening Torque 9 - 11 Nm

1 Upper Intake Manifold

2 Bolt (M6 X 35, 1 piece)

...........................9-11 Nm

3 Bolt (M6 X 16, 2 pieces) .........................9-11 Nm4 Oil Cooler Pipe Line

5 O-ring .................................................... Replace

Removal & Installation Procedure

1. Drain the coolant.

2. Unscrew the bolts (2, 3) and remove the oil cooler pipe line (4). Replace the O-ring with new one. Installation Notice

3. Installation should follow the removal procedure in the reverse order.

4. Fill up the coolant as specified.

5. Check the leaks in the cooling system.

Page 467 of 1574

1D1-16 M162 ENGINE COOLING Removal & Installation Procedure1. Drain coolant from the radiator.

2. Remove the coolant thermo connector from the radiator.

3. Remove the each coolant hoses.

Tightening Torque 14 Nm

4. Remove the automatic transmission oil cooling hose.

Installation Notice

5. Remove the automatic transmission oil cooling line bolts and then remove the oil cooling line.

6. Remove the radiator upper mounting bolts and then remove the bracket and insulator.

7. Remove the radiator.

8. Check the radiator pin for crack, damage, leakage and bending and replace if necessary.

9. Installation should follow the removal procedure in the reverse order.

10. Do cooling system leakage test.

Page 483 of 1574

1D2-16 M161 ENGINE COOLING Removal & Installation Procedure1. Drain coolant from the radiator.

2. Remove the coolant thermo connector from the radiator.

3. Remove the each coolant hoses.

Tightening Torque 14 Nm

4. Remove the automatic transmission oil cooling hose.

Installation Notice

5. Unscrew the bolts from radiator bracket and remove the bracket and insulator. Installation Notice

Tightening Torque 3 - 7 Nm

6. Remove the radiator upper mounting bolts and then remove the bracket and insulator.

7. Remove the radiator.

8. Check the radiator pin for crack, damage, leakage and bending and replace if necessary.

9. Installation should follow the removal procedure in the reverse order.

10. Berform the cooling system leakage test.

Page 496 of 1574

OM600 ENGINE COOLING 1D3-13

Removal & Installation Procedure

1. Drain coolant from the radiator.

2. Remove the coolant thermoswich connector from radiator.

3. Remove the each coolant hose.

4. Remove the auto T/M oil cooling hose and cooling line.Installation Notice

5. Loosen the radiator upper mounting bolt and remove the mounting stopper and insulator.

6. Remove the radiator.

7. Check the radiator pin for crack, leakage and bending and replace it if necessany.

8. Installation should follow the removal procedure in the reverse order.

Tightening Torque Hose : 29 - 40Nm

Page 511 of 1574

M162 ENGINE ELECTRICAL 1E1-11

Circuit Diagram

Inspection & Maintenance Procedure (for MSE)

1. While the ignition switch is in 'OFF' position, remove thewiring connectors (1 and 15) from ignition coil and measure the primary resistance between terminal No.1 and No.15.

2. During engine cranking, measure primary voltage (T1/1) between ECU terminal No. 71 and No. 69.

Notice If out of specified value, replace the ignition coil.

Specified Value

0.9 - 1.6 � (20 °C)

Specified Value 200 - 350 V

Notice

� Measure remaining cables.

- T1/2 : No. 72 and 69.

- T1/3 : No. 70 and 69.

� If out of specified value, check ignition cable and ECU.

3. Using a multi-tester, measure the secondary coil resistance between 5a and 5b.

Specified Value 6 - 8.5 k�

Page 523 of 1574

M161 ENGINE ELECTRICAL 1E2-11

Inspection & Maintenance (for E2.3 MSE)

1. Measure the primary resistance between the cable terminals1 and 15 after removing the ignition cable wiring connector

(1 and 15) with ignition switch OFF. Notice Replace the ignition coil if out of the specified resistance.

� T1/2 : between No.71 and No.69

Notice Check the ignition cable and the ECU if out of the

specified value.

3. Measure the secondary cable resistance between the ignition coil 5a and 5b using a multimeter.

2. Measure the primary voltage(T1/1) between the ECU

terminals No.72 and No.69 during the engine cranking (starter motor activated).

Specified Value 6 - 8.5 K �

Specified Value0.9 - 1.6 �

Specified Value 200 - 350 V

Page 553 of 1574

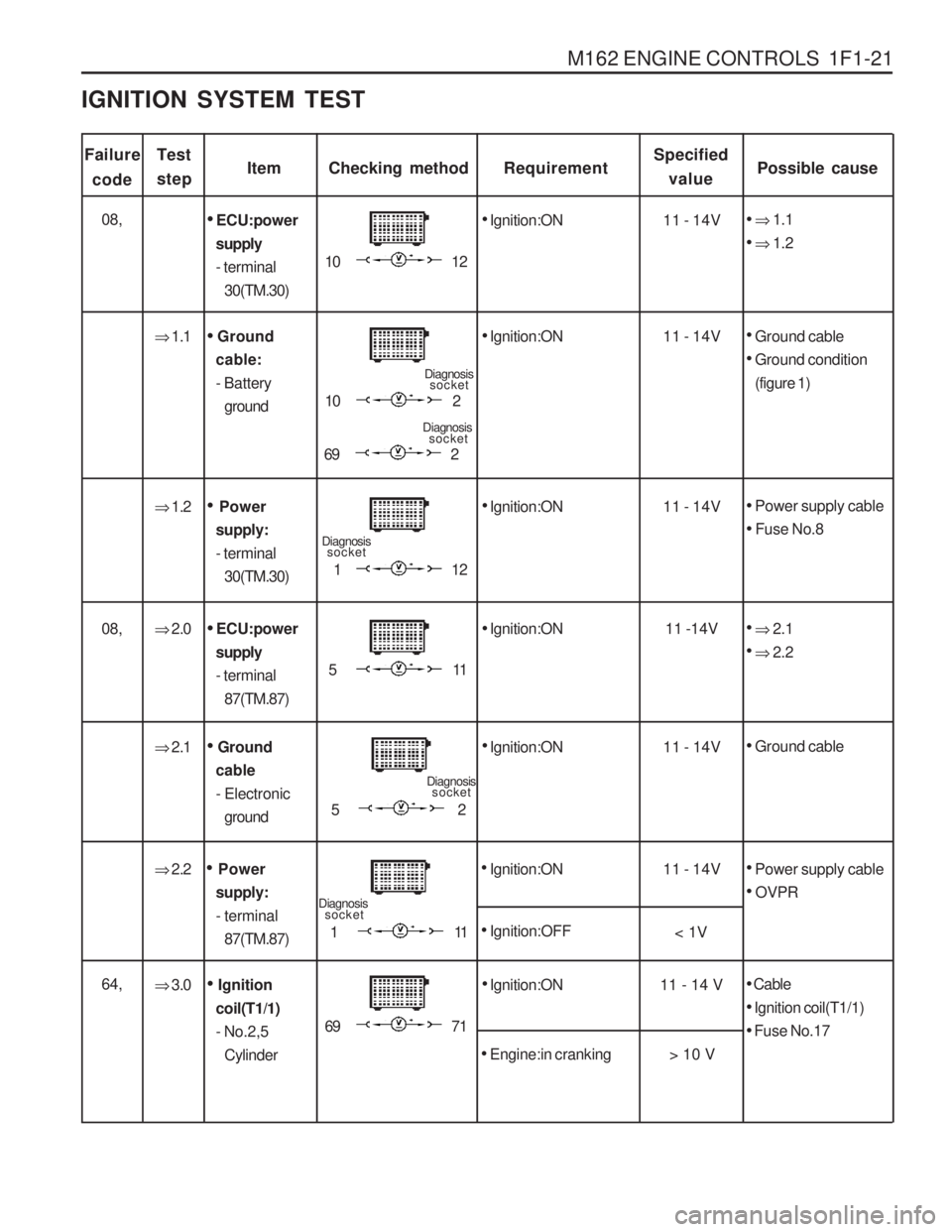

M162 ENGINE CONTROLS 1F1-21

Failurecode ItemChecking method

Ignition:ON

Test stepRequirementSpecified

value Possible cause

10 12 11 - 14V

ECU:power

supply - terminal 30(TM.30)

� 2.2

Power

supply:

- terminal 87(TM.87)

Ignition:ON

Power supply cable

OVPR

IGNITION SYSTEM TEST

08,

� 1.1

� 1.2

� 1.1

Ignition:ON

10 2 11 - 14V

Ground

cable:- Battery ground

Ground cable

Ground condition

(figure 1)

Diagnosis

socket

69 2

Diagnosis socket

� 1.2

Ignition:ON

11 2 11 - 14V

Power

supply: - terminal 30(TM.30)

Power supply cable

Fuse No.8

Diagnosis socket

� 2.0

Ignition:ON

51 1 11 -14V

ECU:power

supply - terminal 87(TM.87)

08,

� 2.1

� 2.2

� 2.1

Ignition:ON 11 - 14V

Ground

cable - Electronic ground

Ground cable

52

Diagnosis socket

11 1

Diagnosis

socket

Ignition:OFF

11 - 14V

< 1V

� 3.0

Ignition:ON

69 71 11 - 14 V

Ignition

coil(T1/1) - No.2,5 Cylinder64,

Cable

Ignition coil(T1/1)

Fuse No.17

Engine:in cranking > 10 V