SSANGYONG MUSSO 2003 Workshop Manual

MUSSO 2003

SSANGYONG

SSANGYONG

https://www.carmanualsonline.info/img/67/57511/w960_57511-0.png

SSANGYONG MUSSO 2003 Workshop Manual

Page 358 of 1574

OM600 ENGINE MECHANICAL 1B3-93

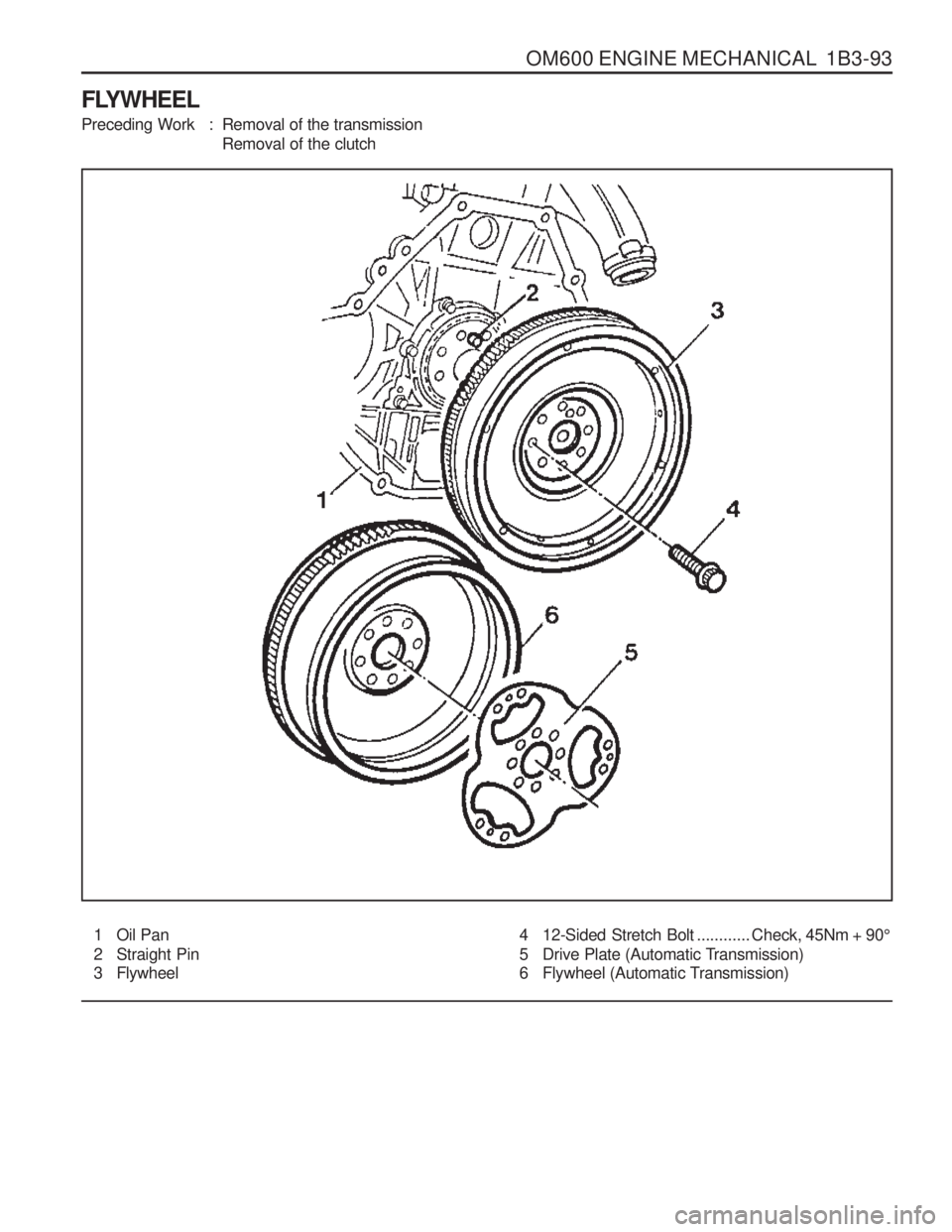

FLYWHEEL

Preceding Work : Removal of the transmissionRemoval of the clutch

1 Oil Pan

2 Straight Pin

3 Flywheel 4 12-Sided Stretch Bolt

............ Check, 45Nm + 90 °

5 Drive Plate (Automatic Transmission)

6 Flywheel (Automatic Transmission)

Page 367 of 1574

1B3-102 OM600 ENGINE MECHANICAL

CheckingNotice The noise which continues short time during short travel (frequent starting of the engine) or engine starting after a long time storage is normal operating conditions. So, it doesnot need to be repaired. Determine the malfunctions in valveclearance compensation device with noise through following

tests. If defective, replace as respectively.

1. Run the engine at more than 3000rpm for approx. 4 minutes.

2. Stop the engine. After 5minutes, check the engine oil level and adjust if necessary.

3. Remove the cylinder head cover.

4. Check the valve tappets at TDC position of each cylinders.

5. Using a drift, lightly press the valve tappet and measure clearance between the cam and valve tappet. Notice If the clearance exceeds 0.4mm, replace the valve tappet.

6. If a valve tappet moves down too far in comparison to the others, replace the valve tappet.

7. Rotate the engine and check the remaining valve tappets.

Notice

� Unnecessary rotation of the engine will damage the valve tappets.

� Do not rotate the engine by using the camshaft sprocket bolt or to the opposite direction of the engine rotation.

Page 369 of 1574

1B3-104 OM600 ENGINE MECHANICAL

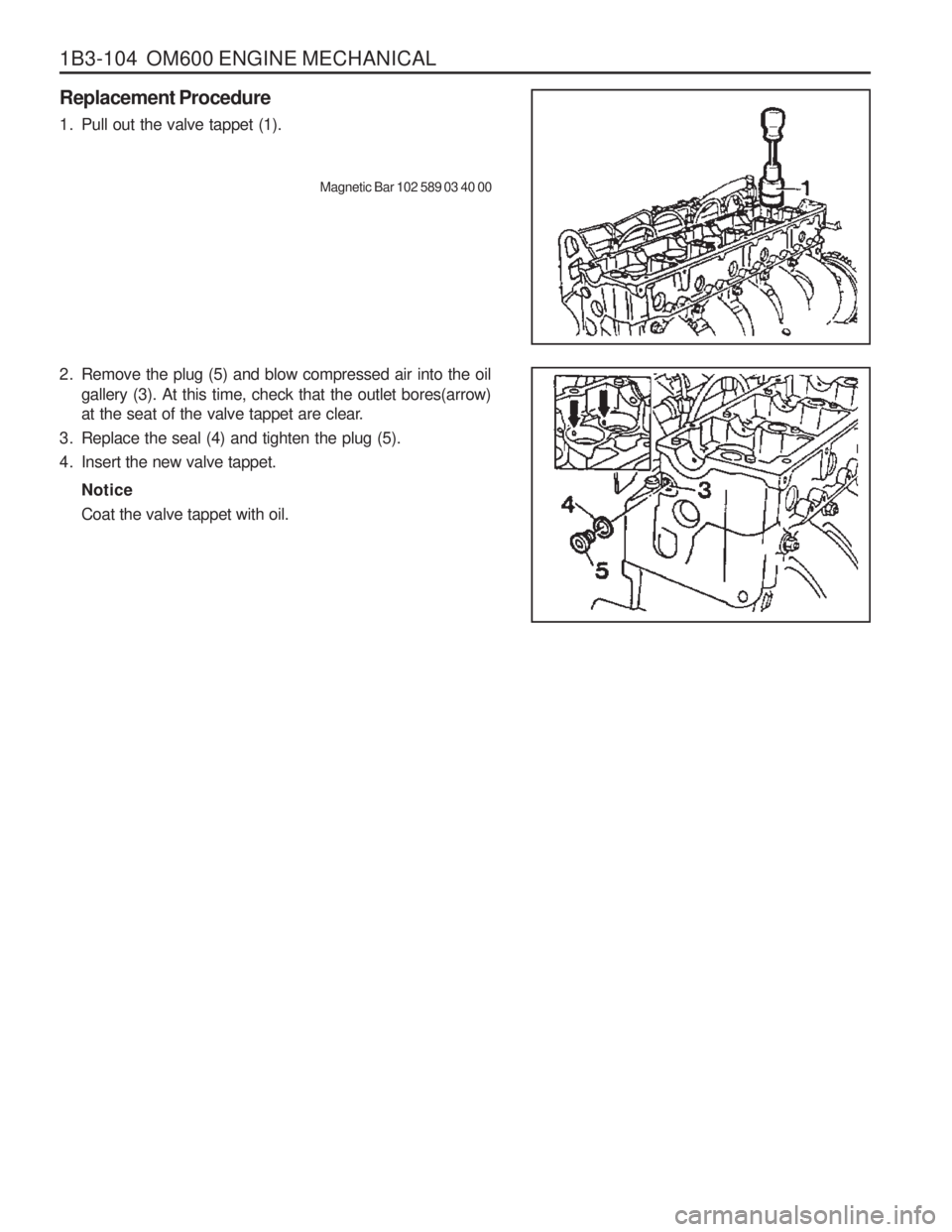

Replacement Procedure

1. Pull out the valve tappet (1).Magnetic Bar 102 589 03 40 00

2. Remove the plug (5) and blow compressed air into the oil gallery (3). At this time, check that the outlet bores(arrow)

at the seat of the valve tappet are clear.

3. Replace the seal (4) and tighten the plug (5).

4. Insert the new valve tappet.

NoticeCoat the valve tappet with oil.

Page 376 of 1574

OM600 ENGINE MECHANICAL 1B3-111

6. Remove the spring retainer(3) and spring (4).

7. Check the valve spring and replace if necessary.

8. Insert valve spring (4) with the color coding (arrow) facingdown and insert valve spring Retainer(3).

9. By press the spring retainer(3) with press lever (90), install the valve cotters with magnetic finger (10).

Press Lever 667 589 00 31 00

Magnetic Finger 116 589 06 63 00

10. Remove the supporting bar.

11. Remove the holding wheel (7) from the timing chain (5). Holding Wheel 603 589 01 40 00

13. Coat the valve tappet with oil and install it. Magnetic Bar 102 589 03 40 00

Page 404 of 1574

OM600 ENGINE MECHANICAL 1B3-139

CAMSHAFT Preceding Work : Removal of cylinder head cover

1 Bolt............................................................ 25Nm

2 Washer

3 Camshaft Bearing Cap

4 Camshaft

5 Dowel Pin

6 Locking Washer

7 Timing Chain 8 Cylinder Head

9 Oil Pan

10 Camshaft Sprocket

11 Washer

12 12-Sided Bolt (M11) ... ..........Check, 25Nm + 90 °

13 Gasket ................................................... Replace

14 Chain Tensioner ........................................ 80Nm

Page 407 of 1574

1B3-142 OM600 ENGINE MECHANICAL

4. Install the camshaft bearing caps according to markings(1,2, 3 etc.).

7. Remove the camshaft bearing cap.

8. Pull off the camshaft.

Notice

Be careful not to miss front locking washer.

9. Pull out the locking washer.Notice Check the condition of locking washer and replace if

necessary.

Installation Procedure

1. Insert the locking washer.

2. Check the valve tappet and ensure that tappet moves smoothly.

3. Coat the camshaft with oil and install the camshaft onto the cylinder head so that the TDC marking (arrow) is positioned

upward vertically.

Page 409 of 1574

1B3-144 OM600 ENGINE MECHANICAL

10. Check the TDC marking of OT on the crankshaft.8. Install the chain tensioner.

Tightening Torque 80 Nm

Notice Replace the seal.Before installation, by pumping in the oil approx. 10 times, fill the oil.

9. Remove the engine lock.

Notice If max. length ‘L’ of the 12-sided bolt exceeds 53.6mm,

replace it.

Page 422 of 1574

1B3-158 OM600 ENGINE MECHANICAL

CRANKSHAFT SPROCKET

Preceding Work : Removal of oil panRemoval of timing case cover

1 12-Sided Stretch Bolt (M11) .. Check, 25Nm + 90 °

2 Washer

3 Camshaft Sprocket

4 Timing Chain

5 Bearing Pin

6 Bearing Pin

7 Oil Pump

8 Oil Pump Sprocket

9 Oil Pump Chain

10 Washer 11 Bolt

............................................................ 25Nm

12 Crankshaft Sprocket

13 Crankshaft

15 Key

16 Guide Rail

17 Spring

18 Bushing

19 Tensioning Lever

Page 425 of 1574

OM600 ENGINE MECHANICAL 1B3-161

Installation Procedure

1. Put the same alignment mark on the new crankshaftsprocket as in the old sprocket. Notice Check the timing chain, camshaft sprocket, injection pump timing sprocket, oil pump chain and oil pump sprocket for

wear and replace if necessary.

2. Install the new crankshaft sprocket (12) by using a drift (21). Notice Align the groove of sprocket and woodruff key (arrow)

exactly. Drift 116 589 07 15 00

3. Fit the timing chain (4) on the crankshaft sprocket (12). Notice Align the alignment marks (arrow) on the chain and sprocket.

4. Install the camshaft sprocket (3).

Tightening Torque 25 Nm + 90 °

Notice Pay attention on the alignment marks and dowel pin (arrow).

Page 427 of 1574

OM600 ENGINE MECHANICAL 1B3-163

PISTON

Preceding Work : Removal of the cylinder headRemoval of the oil pump

1 Oil Ring

2 2nd Ring

3 Top Ring

4 Snap Ring.............................................. Replace

5 Piston Pin

6 Piston

7 Connecting Rod Bushing .......................... Check 8 Connecting Rod

9 Connecting Rod Upper Bearing Shell

10 Connecting Rod Lower Bearing Shell 11 Connecting Rod Bearing Cap

12 Connecting Rod Bolt ......................... 35Nm + 90 °

13 Crankcase

14 Cylinder Bore

Notice There are two kinds of connecting rods (for machining) and they are different in weight approx. 15g. When replacing the connecting rod, measure its weight and ensure that a engine has the same weight of connecting rods. If not, there would be a unbalancing of engine.