SSANGYONG NEW ACTYON SPORTS 2012 Service Manual

NEW ACTYON SPORTS 2012

SSANGYONG

SSANGYONG

https://www.carmanualsonline.info/img/67/57513/w960_57513-0.png

SSANGYONG NEW ACTYON SPORTS 2012 Service Manual

Trending: weight, spare wheel, fuel cap release, fuel additives, automatic transmission, tow, seats

Page 231 of 828

06-111914-01

3. TROUBLESHOOTING

The followings are cautions to take in handling defects of turbocharger, which must be fully aware

of.

1) Cautions

After stopping the engine, check whether the bolts on pipe connecting section are loose as

well as the connecting condition of vacuum port and modulator, which is connected to the

actuator.

During idling of the engine, check for leakage in the connecting section of pipe (hoses and

pipes, duct connections, after the turbocharger) by applying soap water. The leakage

condition in the engine block and turbine housing opening can be determined by the

occurrence of abnormal noise of exhaust.

By running the engine at idle speed, abnormal vibration and noise can be checked.

Immediately stop the engine when abnormal vibration and noise is detected and make

thorough inspection whether the turbocharger shaft wheel has any damages as well as

checking the condition of connections between pipes.

In case where the noise of engine is louder than usual, there is possibility of dampness in the

areas related with air cleaner and engine or engine block and turbocharger. And it could affect

the smooth supply of engine oil and discharge.

Check for damp condition in exhaust gas when there is sign of thermal discoloration or

discharge of carbon in connecting area of the duct.

When the engine rotates or in case where there is change in noise level, check for clogging of

air cleaner or air cleaner duct or if there is any significant amount of dust in the compressor

housing.

During the inspection of center housing, inspect inside of the housing by removing the oil

drain pipe to check for sludge generation and its attachment condition at shaft area or turbine

side.

Inspect or replace the air cleaner when the compressor wheel is damaged by inflow of foreign

materials.

Inspect both side of the turbocharger wheel after removing inlet and outlet pipe of the

turbocharger. 1.

2.

3.

4.

5.

6.

7.

8.

9.

Page 232 of 828

06-12

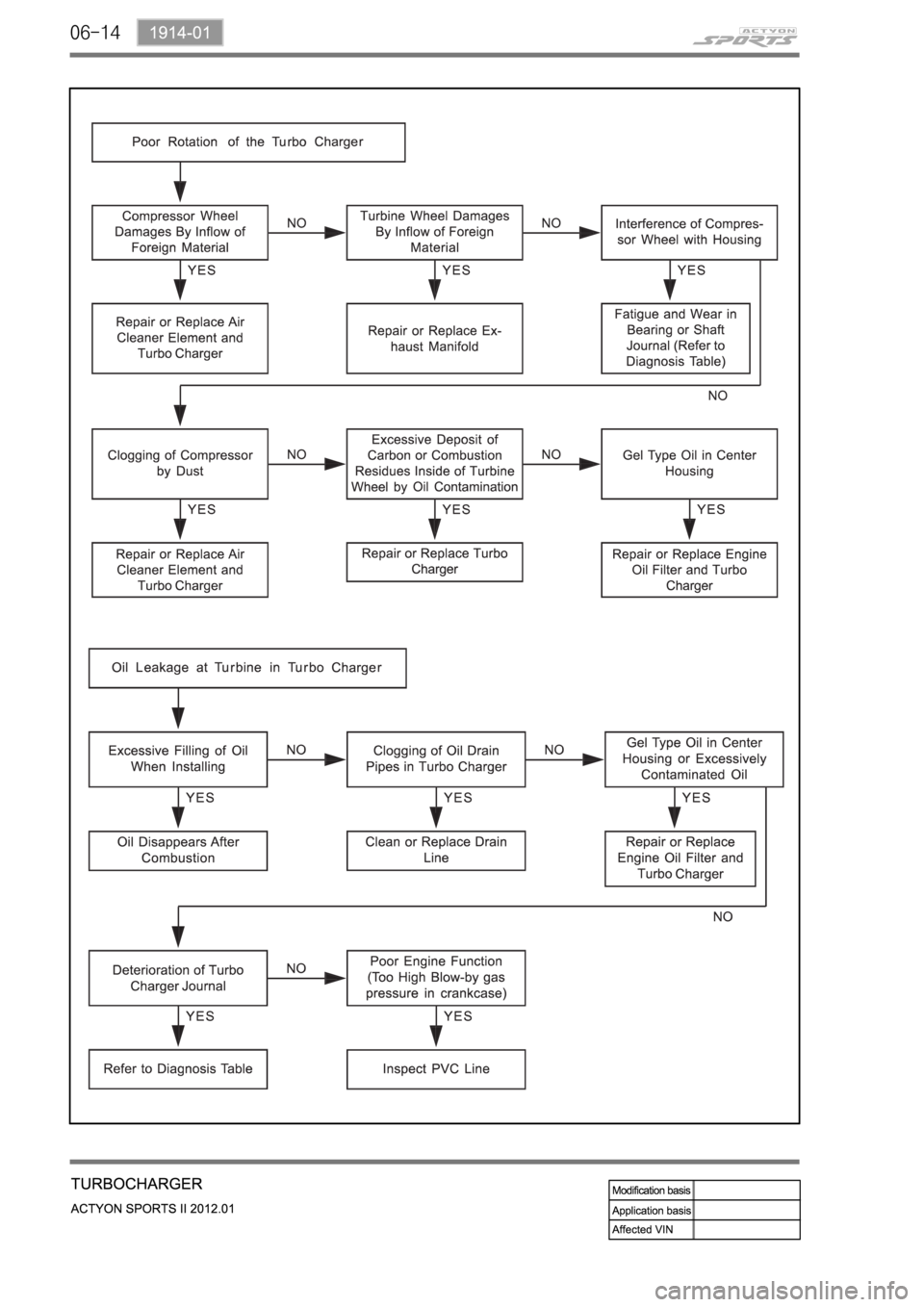

2) Work Flow for Troubleshooting

Page 233 of 828

Page 234 of 828

Page 235 of 828

Page 236 of 828

Page 237 of 828

06-171914-01

1. SYSTEM DESCRIPTION OF E-VGT

(Electric-Variable Geometry Turbine)

The E-VGT turbocharger has one shaft where at each ends are installed with two turbines having

different angles to connect one end of housing to the intake manifold and the other end to the

exhaust manifold. As the turbine, at exhaust end, is rotated by exhaust gas pressure the impeller,

at intake end, gets rotated to send air around center of the impeller, being circumferentially

accelerated by the centrifugal force, into the diffuser. The air, which has been introduced to the

diffuser having a passage with big surface, transforms its speed energy into the pressure energy

while being supplied to the cylinder improving the volume efficiency. Also, the exhaust efficiency

improves as the exhaust turbine rotates. The turbocharger is often referred to as the exhaust

turbine turbocharger.

1) Overview

Diffuser: With the meaning of spreading out it is a device that transforms fluid's speed energy into

the pressure energy by enlarging the fluid's passage to slow down the flow.

The E-VGT system installed to the D20DTR engine variably controls the passages of the turbine

housing to regulate the flow rate of the exhaust gas. The actuator of E-VGT is a DC motor

actuator (E-Actuator) which controls more quickly and precisely than the previous vacuum type

actuator.

The engine ECU controls the E-Actuator electronically as follows:

At low speed: Narrows the flow passage for the exhaust gas, resulting in increasing the

flow speed of the exhaust gas and running the turbine quickly and powerfully.

At high speed: Expands the flow passage for the exhaust gas, resulting in increasing the

mass flow of the exhaust gas and running the turbine more powerfully. -

-

Page 238 of 828

06-18

Maximizes the intake air charging efficiency (Approx. 15%) -Optimizes the exhaust gas flow rate by controlling the vanes inside the turbine housing with

the E-Actuator. 1.

(2) E-VGT Actuator (Electric-Actuator)

Target temperature and airflow control -Enhanced emmission control: By temperature control with CDPF system 1.

(1) Performance (for EURO V)

Has a faster response time than the conventional vacuum actuator. 2.

Improved low speed torque, high speed power and fuel economy.

Improved acceleration performance with rapid response time of vane. -

-

2) Features

Features

BenefitsFolding and unfolding of the

vane is controlled electrically

Easy to get low speed air

volume

Rapid response time

Electric control -

-

-

-

Improved low speed torque

and power

Reduced exhaust gas

Improved fuel consumption

Improved acceleration

performance -

-

-

-

Page 239 of 828

06-191914-01

T-MAP sensor

Booster pressure and

temperature

E-VGT turbocharger

Improves engine power

2. COMPONENTS

Engine ECU (D20DTR)

E-VGT duty controlAccelerator pedal position

sensor

Transfers driver's will to

accelerate to ECU

Atmospheric pressure, RPM

signal

HFM sensor

Improves the engine powerCoolant temperature sensor

Operates the VGT according

to engine warm-up

* 세부제어로직은 엔진제어편 참조

Page 240 of 828

06-20

3. INPUT/OUTPUT DEVICES

Trending: turn signal bulb, tow, lock, alternator, buttons, remove seats, oil capacity