SSANGYONG RODIUS 2005 Service Manual

RODIUS 2005

SSANGYONG

SSANGYONG

https://www.carmanualsonline.info/img/67/57522/w960_57522-0.png

SSANGYONG RODIUS 2005 Service Manual

Trending: trunk, transmission oil, brake pads, torque, battery replacement, fuses, heater

Page 201 of 502

0-4

RODIUS 2005.07

3170-01

MANUAL TRANSMISSION

1. MANUAL TRANSMISSION OVERVIEW

4WD

2WD

TSM54/52 transmission is designed to link the gear ratio, installation dimensions and shapes

with current T5 transmission and BTRA automatic transmission. It provides maximum

drivability by the optimized engine torque and gear ratio.

TSM54/52 transmission uses linkage type shift elements directly connected to the

transmission. It prevent the transmission from shifting to the reverse gear from 5th gea

r

when shifting to reverse gear. It also prevents the break and wear. 1.

2.

Page 202 of 502

0-5

MANUAL TRANSMISSION

RODIUS 2005.07

3170-01

1) Features

All gears use the helical type and high

strength materials. 3.

The helical type gear provides less noise.

The synchronizing devices are installed in

1/2, 3/4, 5/R gears. To prevent the double

engagement, the independent interlock

devices are installed. 4.

TSM54/52 transmission uses the inertia

lock type key to make smooth gea

r

engagement and to provide silent gea

r

engagement.

The clutch release system is available to

use CSC (Concentric Slave Cylinder) o

r

Fork type according to the vehicle model.

New Rexton uses the fork type

clutch release system.

The semi-remote control type gear shift

mechanism is used to prevent incorrect

shifting. 5.

6.

Page 203 of 502

0-6

RODIUS 2005.07

3170-01

MANUAL TRANSMISSION

2. CIRCUIT DIAGRAM (BACKUP LAMP)

Page 204 of 502

0-3

CLUTCH

RODIUS 2005.07

3010-01

3010-01CLUTCH

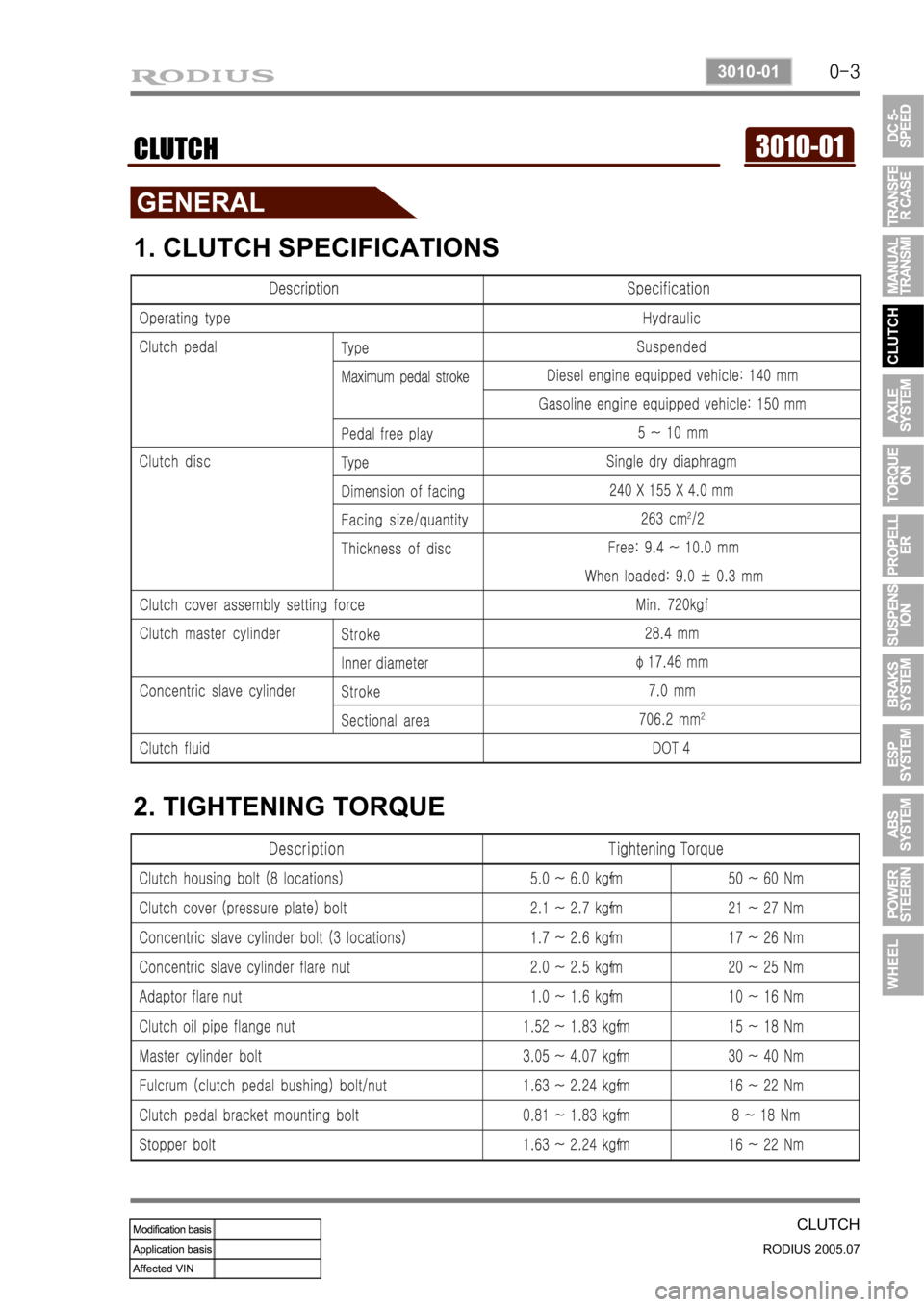

1. CLUTCH SPECIFICATIONS

2. TIGHTENING TORQUE

Page 205 of 502

0-4

RODIUS 2005.07

3010-01

CLUTCH

1. OVERVIEW

1) Driving Elements

The driving elements consist of two flat surfaces machined to a smooth finish.

One of these is the rear face of the engine flywheel and the other is the clutch cover pressure

plate. The clutch pressure plate is fitted into a clutch steel cover, which is bolted to the flywheel.

2) Driven Elements

The driven element is the clutch disc with a splined hub which is free to slide lengthwise along

the splines of the input shaft. The driving and driven elements are held in contact by spring

pressure. This pressure is exerted by a diaphragm spring in the clutch cover pressure plate

assembly.

3) Operating Elements

The clutch control system consists of the clutch pedal, clutch master cylinder, concentric slave

cylinder. This system directly releases the clutch by using hydraulic pressure while the

conventional clutch system releases the clutch by using release lever and release fork. This

system provides higher efficiency than conventional clutch system, and its durability is superior.

Adaptor (mounted on transmission case) Concentric slave cylinder pipe (mounted inside o

f

transmission) Concentric slave cylinder (mounted inside of transmission)

Page 206 of 502

0-5

CLUTCH

RODIUS 2005.07

3010-01

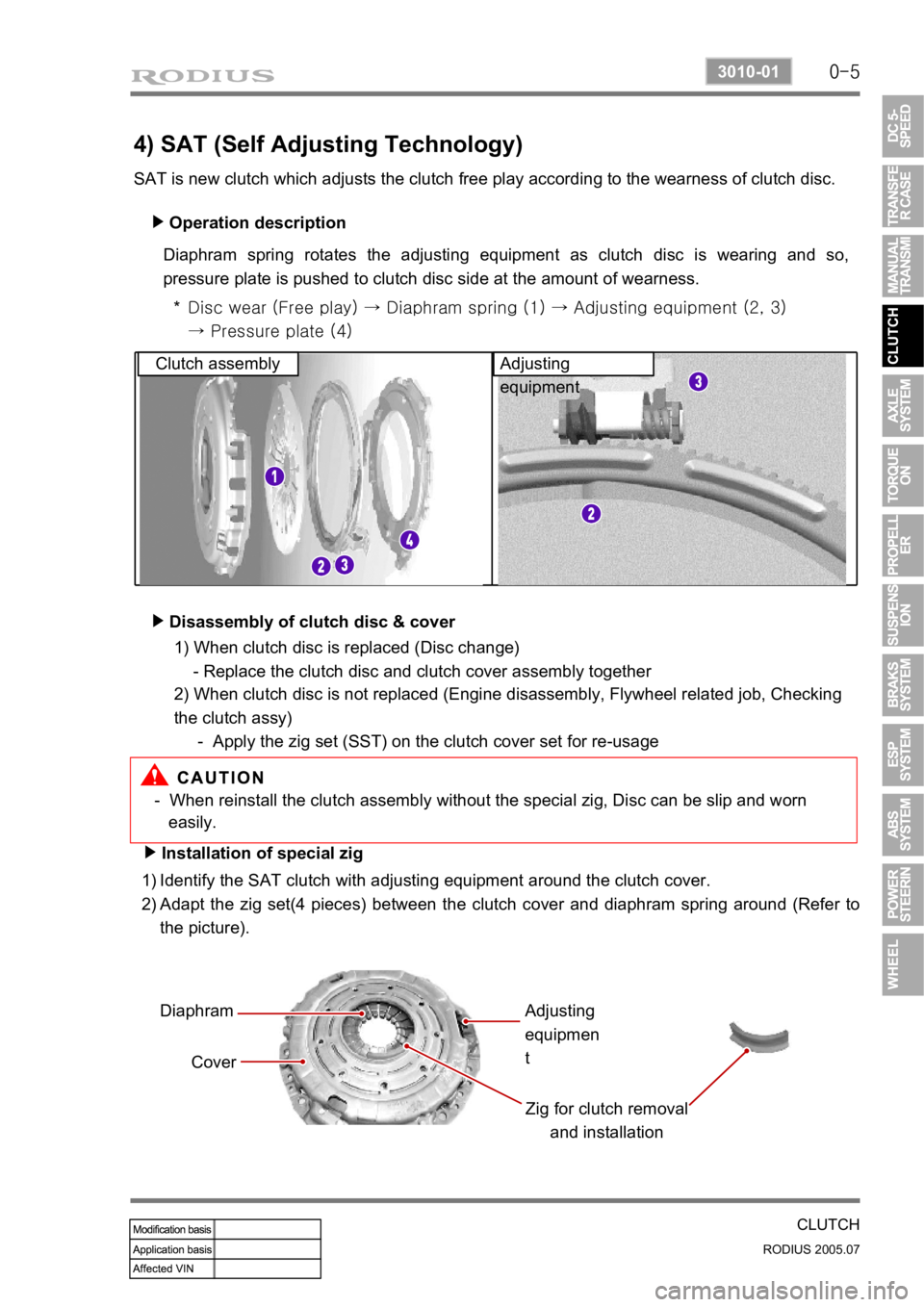

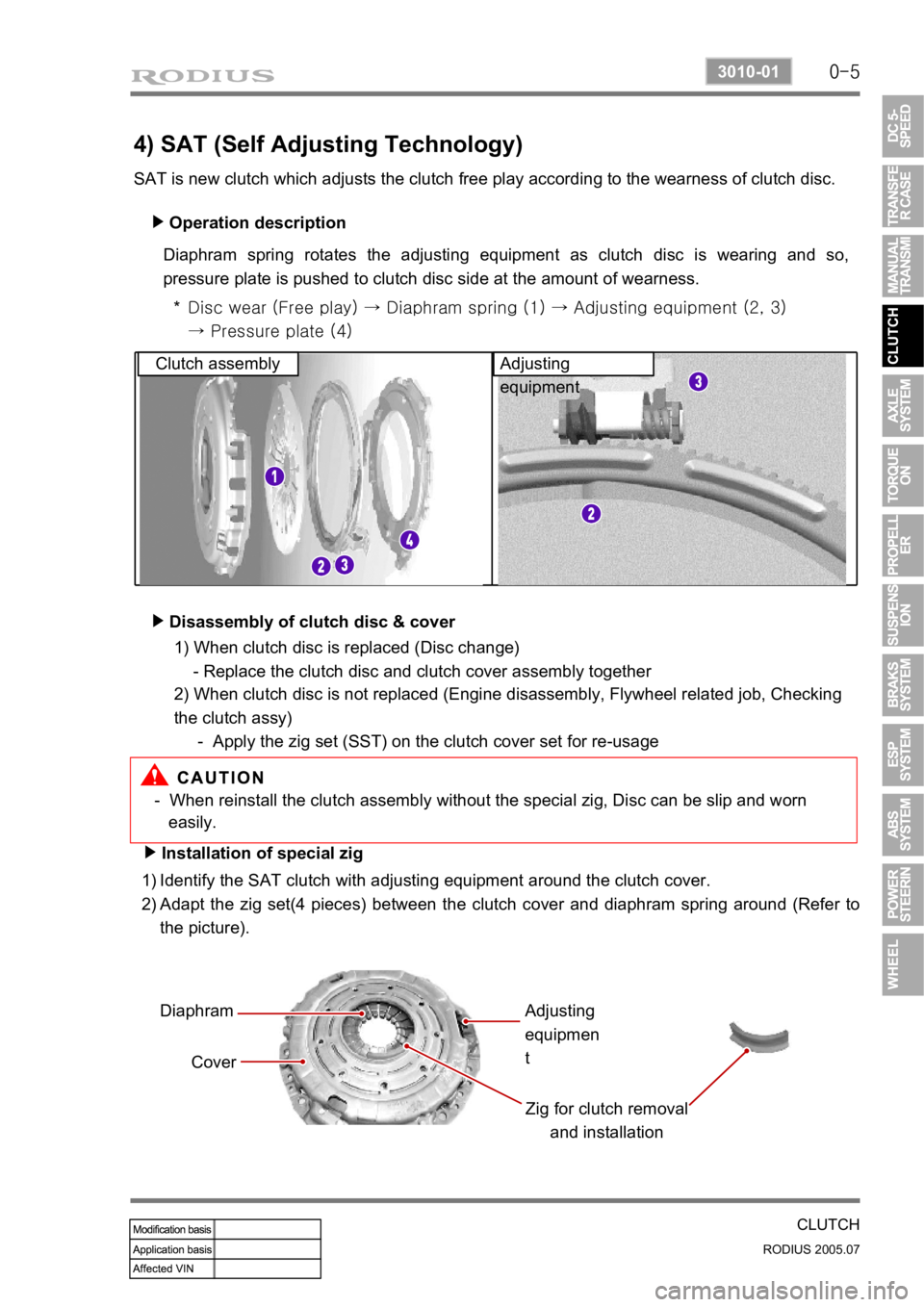

4) SAT (Self Adjusting Technology)

SAT is new clutch which adjusts the clutch free play according to the wearness of clutch disc. Operation description

▶

Diaphram spring rotates the adjusting equipment as clutch disc is wearing and so,

pressure plate is pushed to clutch disc side at the amount of wearness.

Disc wear (Free play) → Diaphram spring (1) → Adjusting equipme nt (2, 3)

→ Pressure plate (4)

*

Clutch assembly Adjusting

equipment

Disassembly of clutch disc & cover

▶

- When reinstall the clutch assembly without the special zig, Disc can be slip and worn

easily.

Installation of special zig

▶

Identify the SAT clutch with adjusting equipment around the clutch cover.

Adapt the zig set(4 pieces) between the clutch cover and diaphram spring around (Refer to

the picture).

1)

2)

Diaphram

Cover Zig for clutch removal and installationAdjusting

equipmen

t

1) When clutch disc is replaced (Disc change)

- Replace the clutch disc and clutch cover assembly together

2) When clutch disc is not replaced (Engine disassembly, Flywheel related job, Checking

the clutch assy)

- Apply the zig set (SST) on the clutch cover set for re-usage

Page 207 of 502

0-6

RODIUS 2005.07

3010-01

CLUTCH

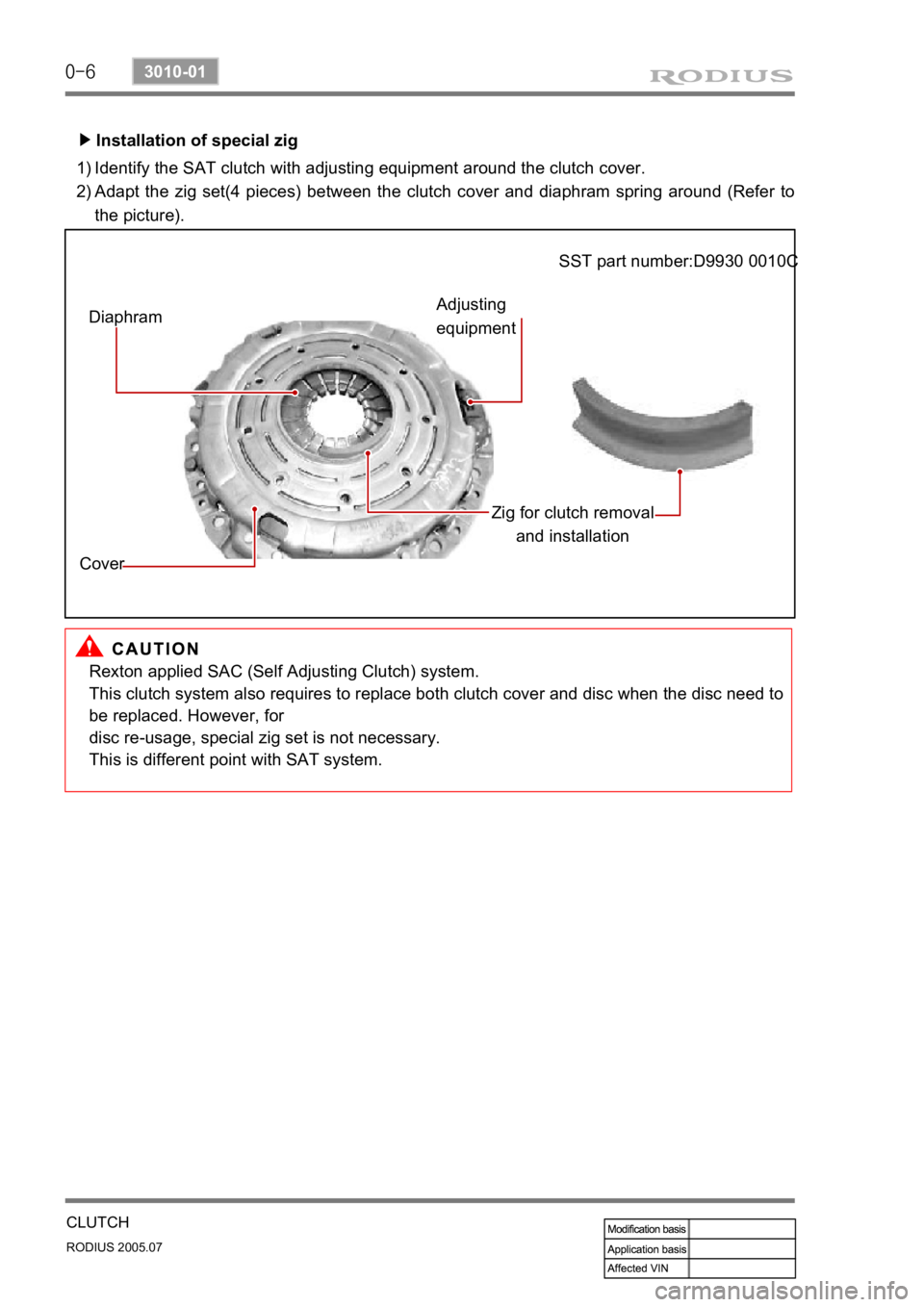

Installation of special zig

▶

Identify the SAT clutch with adjusting equipment around the clutch cover.

Adapt the zig set(4 pieces) between the clutch cover and diaphram spring around (Refer to

the picture).

1)

2)

Diaphram

Cover Zig for clutch removal

and installation

Adjusting

equipment SST part number:D9930 0010C

Rexton applied SAC (Self Adjusting Clutch) system.

This clutch system also requires to replace both clutch cover and disc when the disc need to

be replaced. However, for

disc re-usage, special zig set is not necessary.

This is different point with SAT system.

Page 208 of 502

0-7

CLUTCH

RODIUS 2005.07

3010-01

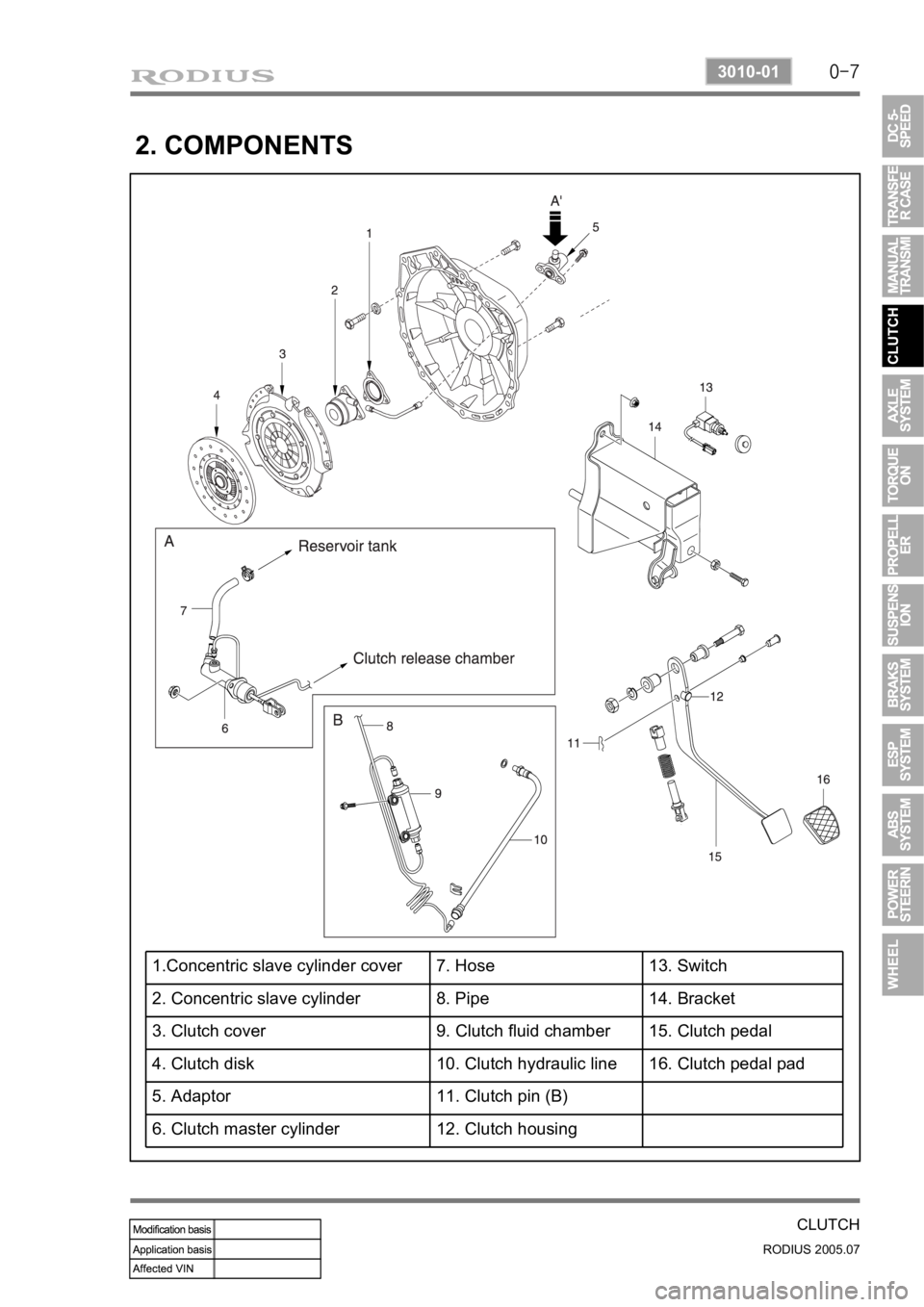

2. COMPONENTS

1.Concentric slave cylinder cover 7. Hose 13. Switch

2. Concentric slave cylinder 8. Pipe 14. Bracket

3. Clutch cover 9. Clutch fluid chamber 15. Clutch pedal

4. Clutch disk 10. Clutch hydraulic line 16. Clutch pedal pad

5. Adaptor 11. Clutch pin (B)

6. Clutch master cylinder 12. Clutch housing

Page 209 of 502

0-3

AXLE SYSTEM

RODIUS 2005.07

0000-00

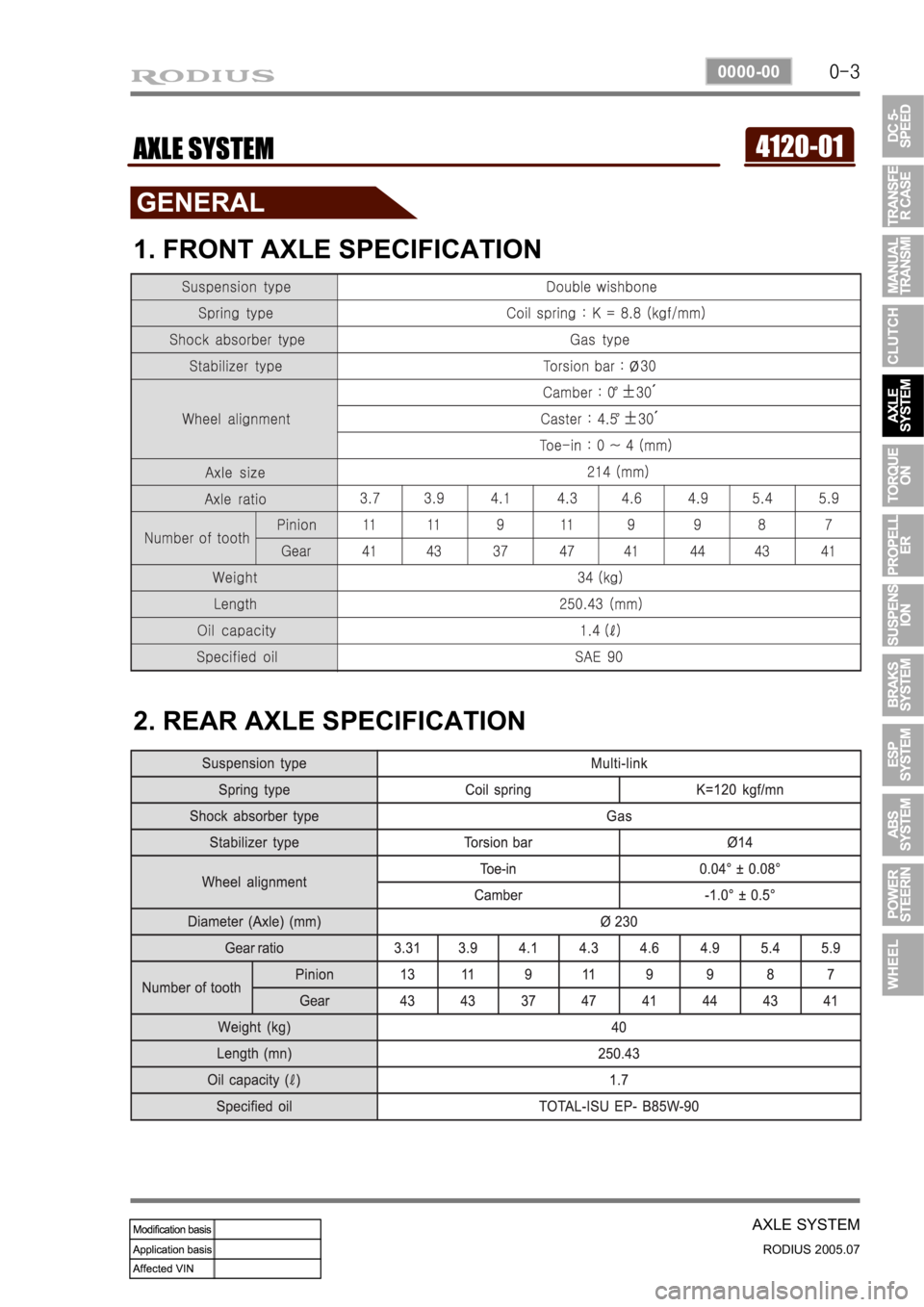

4120-01AXLE SYSTEM

1. FRONT AXLE SPECIFICATION

2. REAR AXLE SPECIFICATION

Page 210 of 502

0-3

TORQUE ON DEMAND

RODIUS 2005.07

3240-01

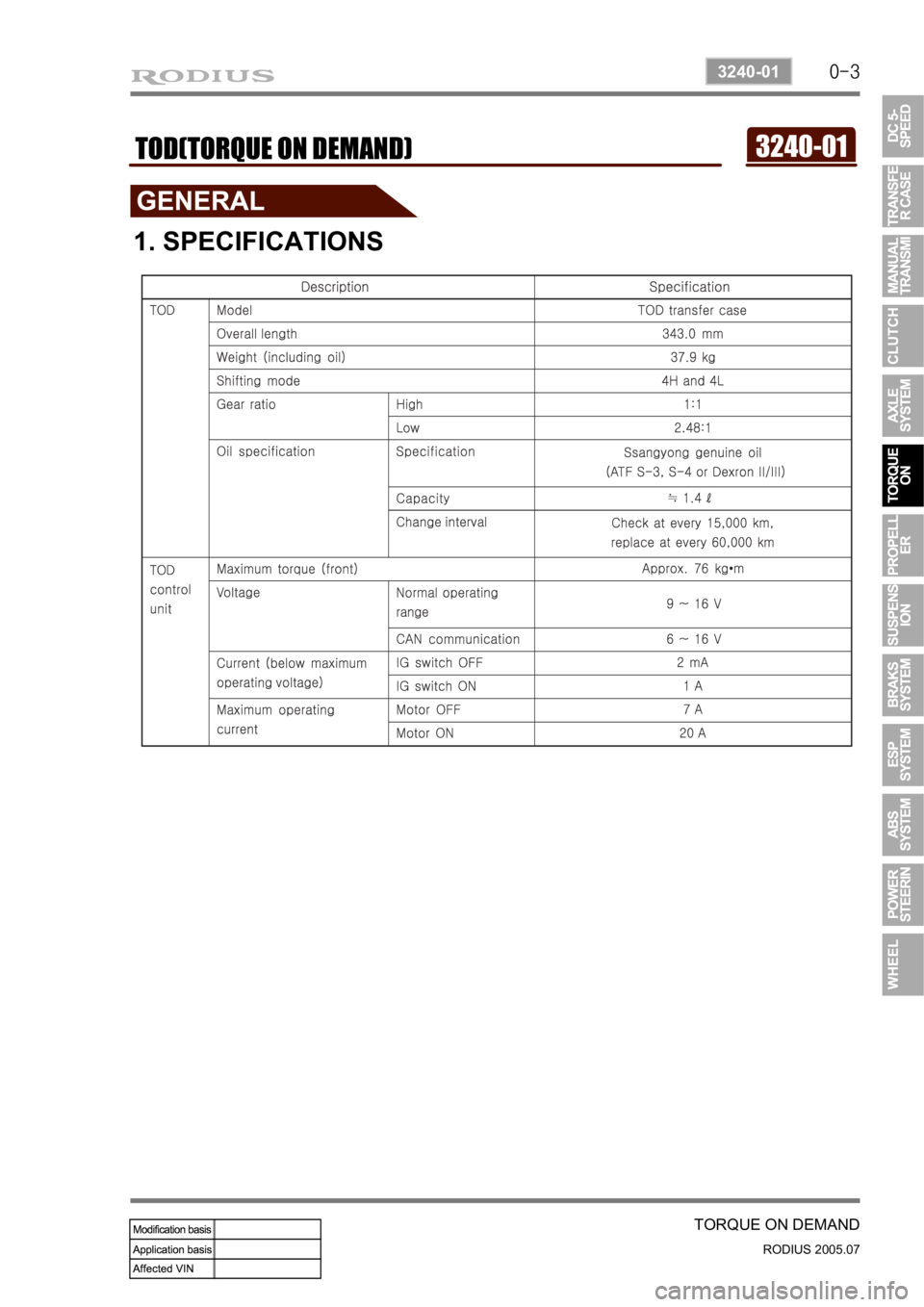

3240-01TOD(TORQUE ON DEMAND)

1. SPECIFICATIONS

Trending: parking sensors, change time, wiring, windshield wipers, wheel alignment, traction control, length