brake SSANGYONG RODIUS 2005 Owner's Manual

[x] Cancel search | Manufacturer: SSANGYONG, Model Year: 2005, Model line: RODIUS, Model: SSANGYONG RODIUS 2005Pages: 502, PDF Size: 70.43 MB

Page 247 of 502

0-14

RODIUS 2005.07

4892-01

ESP SYSTEM

(1) System Overview

When equipped with ABS, the braking force at each wheel will be controlled with 3-channel 4-

sensor method. And when equipped with ESP, 4 wheels will be controlled independently with 4-

channel method. (When controlling ABS system only, it will be operated with 3-channel

method.) When compared to the vehicle equipped with ABS/EBD only, the internal hydraulic

circuit has a normally-open separation valve and a shuttle valve in primary circuit and in

secondary circuit. When the vehicle brakes are not applied during engine running or when

applying the non-ABS operating brakes, the normally-open separation valve and the inlet valve

are open, whereas the normally-closed shuttle valve and the outlet valve are closed. When the

ESP system is operating, the normally-open separation valve will be closed by the solenoid

valve operation and the hydraulic circuit will be established by the shuttle valve. Then, the inlet

and outlet valves will be

closed or open depending on the braking pressure increase, decrease or unchanged

conditions.

<0d96007b008f008c0047009e00880099009500900095008e004700930088009400970047008a00960094008c009a004700960095004700880095008b0047009e00880099009500900095008e00470089008c008c00970047009a0096009c0095008b009a00

47009e008f008c00950047009b008f008c0047006c007a0077> is operating

▶Driving feeling when the ESP is operating

<0d96007500960090009a008c004700880095008b0047009d0090008900990088009b0090009600950047009b008f0088009b0047008b00990090009d008c00990047009a008c0095009a008c009a0047009e008f008c00950047009b008f008c0047006c00

7a007700470090009a004700960097008c00990088009b0090>ng When the ESP operates during vehicle movement, the ESP warning lamp on the instrument

panel flickers and beep comes on every 0.1 seconds. The ESP operation shows that the

vehicle stability is extremely unstable and it is used to warn the driver. The ESP system is just a

supplementary system for the vehicle motion and it cannot control the vehicle when it exceeds

the physical limits. Do not solely rely on the system but be advised to drive the vehicle safely.

When the ESP system activates, the driving feeling can be different depending on vehicle

driving conditions. For example, you will feel differently when the ESP system is activated

during when ABS is operating with the brakes applied and when brakes are not applied on a

curve. Thus, the ESP system would make the driver feel more abruptly when the brakes are

applied during the ESP system activation.

The ESP system may transfer noise and vibration to the driver due to the pressure changes

caused by the motor and valve operations in a very short period of time. Extreme cornering will

trigger the ESP operation and this will make the driver feel noise and vibration due to sudden

brake application. Also, the ESP system controls the engine output. So, the driver may notice

the engine output decrease even when the accelerator pedal is being applied.

Page 248 of 502

0-15

ESP SYSTEM

RODIUS 2005.07

4892-01

<0d96006c007a00770047006f00a0008b00990088009c00930090008a0047009c00950090009b00470090009500470090008b009300900095008e004700880095008b00470095009600990094008800930047008900990088009200900095008e0047009700

96009a0090009b009000960095>

In this position, the separation valve and the inlet valve are open (normal open), the electrically

operated shuttle valve and the outlet valve are closed. When the brake is applied under these

conditions, the brake fluid will be sent to each wheel via the separation valve and inlet valve.

Page 252 of 502

0-19

ESP SYSTEM

RODIUS 2005.07

4892-01

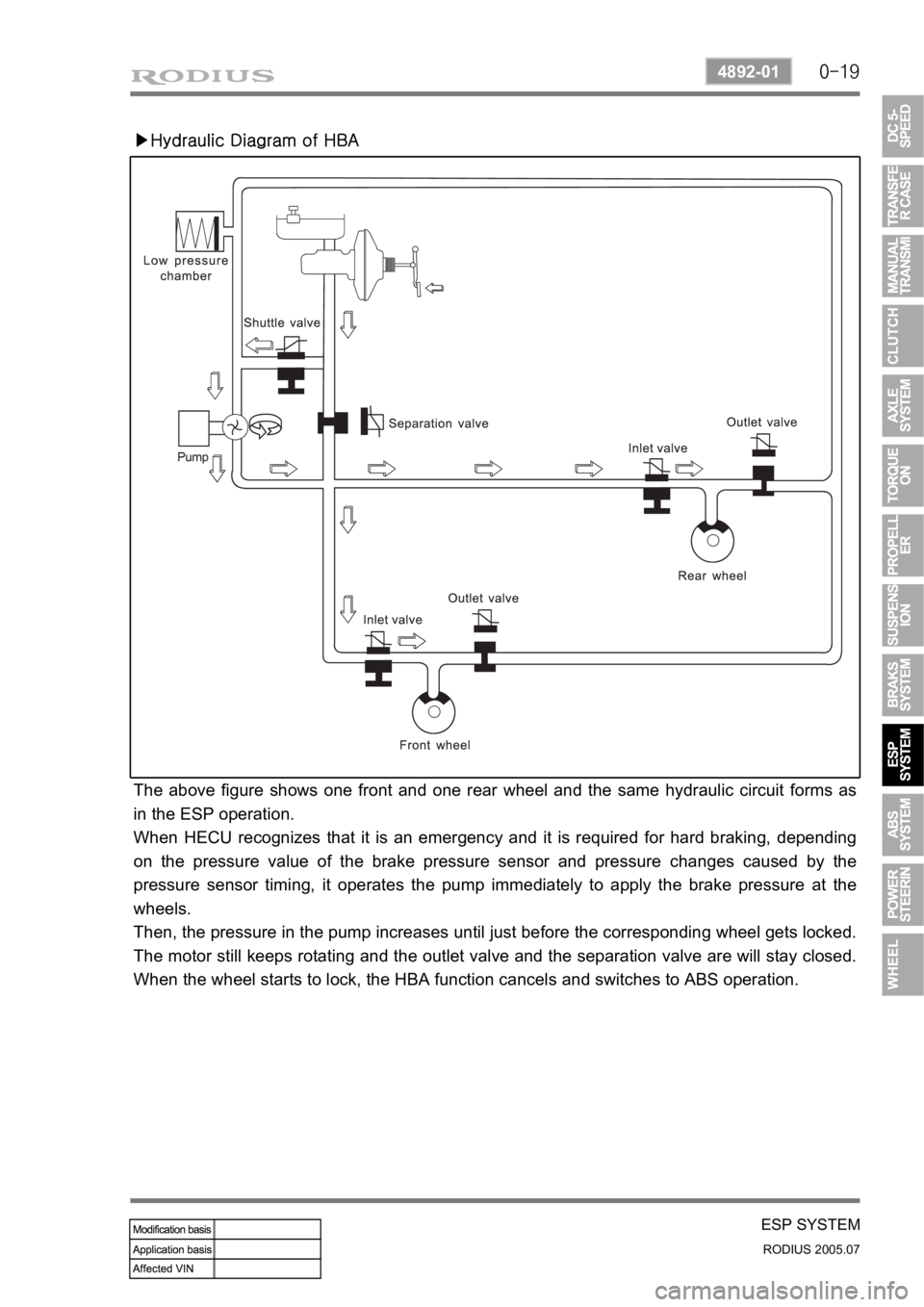

▶Hydraulic Diagram of HBA

The above figure shows one front and one rear wheel and the same hydraulic circuit forms as

in the ESP operation.

When HECU recognizes that it is an emergency and it is required for hard braking, depending

on the pressure value of the brake pressure sensor and pressure changes caused by the

pressure sensor timing, it operates the pump immediately to apply the brake pressure at the

wheels.

Then, the pressure in the pump increases until just before the corresponding wheel gets locked.

The motor still keeps rotating and the outlet valve and the separation valve are will stay closed.

When the wheel starts to lock, the HBA function cancels and switches to ABS operation.

Page 256 of 502

0-4

RODIUS 2005.07

4892-01

ABS SYSTEM

2. GENERAL INFORMATION

The aim of the ABS is to mmaintain steerability and driving stability and to take the burden off

the driver. If the stopping distance is shorter on some road surfaces (carriageway conditions),

this is a gift of physics and not a development aim.

ABS is a device which senses that one or more of the wheels are locking up during braking. It

monitors the rotational speeds of the wheels and reduces hydraulic pressure to any wheel it

senses locking up. It is controlled by both mechanical and electronic components. When you

apply the brakes, the ABS will regulate the flow of brake fluid being delivered to the brake

calipers. By the use of electronic computers, the brakes rapidly alternate (at a rate of 30 times

per second) from full pressure to full release.

1) DRIVING PHYSICS

To give you a better understanding of the tasks and functions of ABS, we will first look at the

physics principles.

(1) The Stopping Distance

The stopping distance depends on the vehicle weight and initial speed when braking starts.

This also applies for vehicle with ABS, where ABS always tries to set an optimum brake force

on each wheel. As great forces are exerted between the tires and the carriageway when

braking, even with ABS the wheels may scream and rubber is left on the road. With an

ABS

skid mark one may be able to clearly recognize the tire profile. The skid mark of an ABS vehicle

does not however leave any hint of the speed of the vehicle in the case of an accident, as it can

only be clearly drawn at the start of braking.

(2) Brake Force on a Wheel

The maximum possible brake force on a wheel depends on the wheel load and the adhesion

coefficient between tire and carriageway. With a low adhesion coefficient the brake force, which

can be obtained is very low. You are bound to know the result already from driving on winte

r

roads. With a high adhesion coefficient on a dry road, the brake force, which can be obtained,

is considerably higher. The brake force, which can be obtained, can be calculated from below

formula:

Page 257 of 502

0-5

ABS SYSTEM

RODIUS 2005.07

4892-01

Maximum brake force ▶

FBmax = Vehicle Weight x Adhesion

coefficientmh

The braking process cannot be described

sufficiently accurately with the brake forces

calculated. The values calculated only apply

if the wheel is not locked. In the case of a

locking wheel, the static friction turns into

lower sliding friction, with the result that the

stopping distance is increased. This loss of

friction is termed “slip” in specialist

literature.

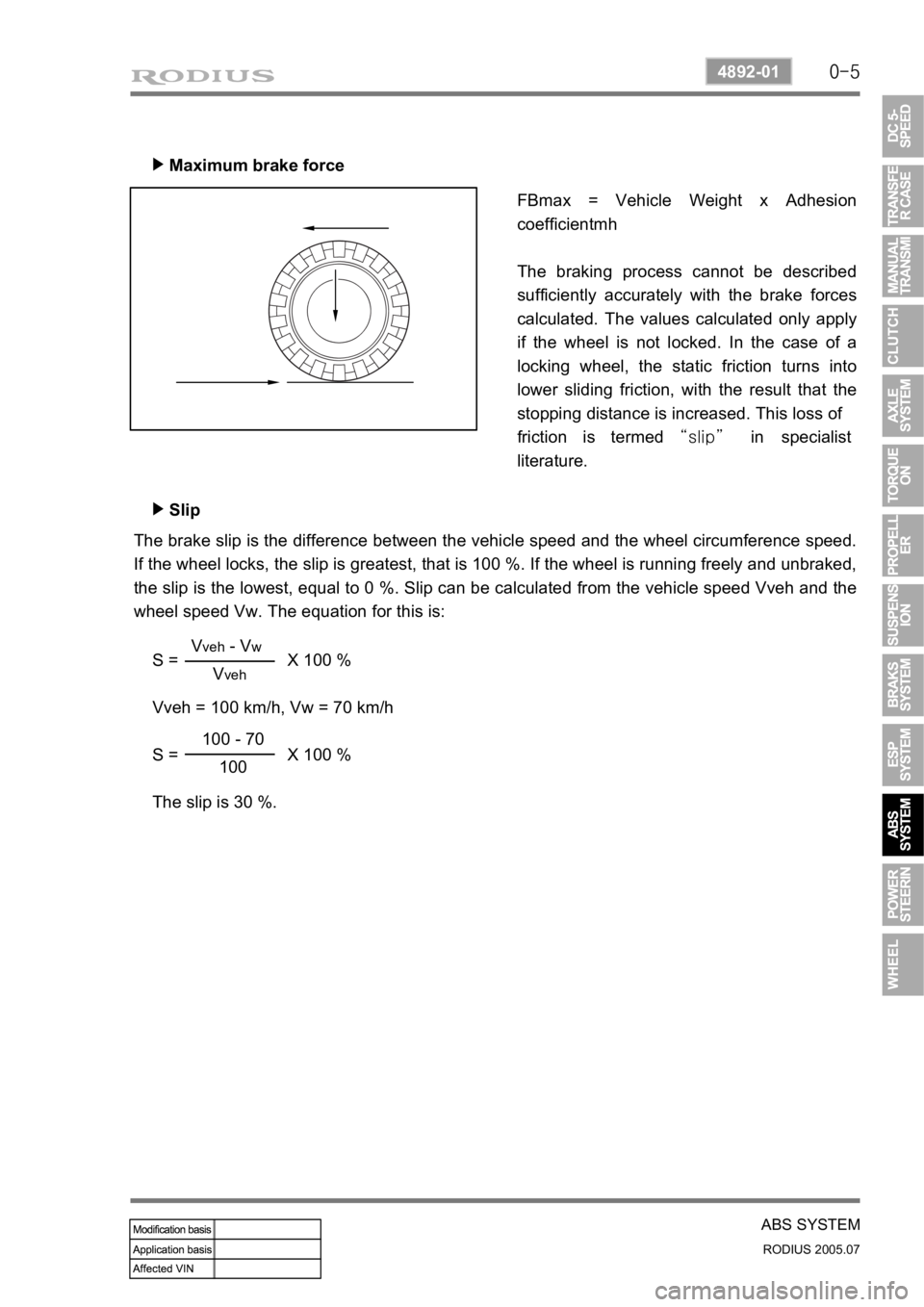

Slip ▶

The brake slip is the difference between the vehicle speed and the wheel circumference speed.

If the wheel locks, the slip is greatest, that is 100 %. If the wheel is running freely and unbraked,

the slip is the lowest, equal to 0 %. Slip can be calculated from the vehicle speed Vveh and the

wheel speed Vw. The equation for this is:

S = X 100 %

Vveh = 100 km/h, Vw = 70 km/h

S = X 100 %

The slip is 30 %.

Vveh - Vw

Vveh

100 - 70

100

Page 259 of 502

0-7

ABS SYSTEM

RODIUS 2005.07

4892-01

Kamm circle ▶

Before we go into the Kamm circle, you

should know that a tire offers a maximum o

f

100 % transmissibility. It is all the same fo

r

the tire whether we require 100 % in the

direction of braking or in the direction of the

acting lateral force, e.g. when driving round

curves. If we drive into a curve too fast and

the tire requires 100 % transmissibility as

cornering force, the tire cannot transmit any

additional brake force. In spite of the ABS

the car is carried out of the curve. The

relationship between brake force B and

cornering force S is shown very clearly in

the Kamm circle. If we put a vehicle wheel in

this circle, the relationship becomes even

clearer. In this relationship: as long as the

acting forces and the resulting force remain

within the circle, the vehicle is stable to

drive. If a force exceeds the circle, the

vehicle leaves the road.

Page 260 of 502

0-8

RODIUS 2005.07

4892-01

ABS SYSTEM

Brake force

When depressing the brake pedal the

brake force increases to the maximum,

then the brake force decreases until the

wheel locks.

Cornering force

The cornering force is a maximum when

the wheel is turning freely with zero slip.

When braking the cornering force falls to

zero if the wheel locks (slip 100 %).

ABS operating range

The operating range starts just before the

maximum brake force and ends in

maximum, for the unstable range then

begins, in which no further modulation is

possible. The ABS controls the regulation

of the brake pressure so that the brake

force only becomes great enough for a

sufficient proportion of cornering force to

remain. With ABS we remain in the

Kamm circle as long as the car is driving

sensibly. We will leave driving physics

with these statements and turn to the

braking systems with and without ABS. -

-

- Brake and cornering force ▶

Page 261 of 502

0-9

ABS SYSTEM

RODIUS 2005.07

4892-01

(3) Basic ABS Controls

Applications of the ABS control unit

The signals produced by the wheel sensors

are evaluated in the electronic control unit.

From the information received, the control

unit must first compute the following

variables:

- Wheel speed

- Reference speed

- Deceleration

- Slip

Reference speed ▶

The reference speed is the mean, I.e. average speed of all wheel speeds determined by simple

approximation.

Simplified ABS control ▶

If, during braking, one wheel speed deviates from the reference speed, the ABS control unit

attempts to correct that wheel speed by modulating the brake pressure until it again matches

the reference speed. When all four wheels tend to lock, all four wheels speeds suddenly

deviate from the previously determined reference speed. In that case, the control cycle is

initiated again in order to again correct the wheel speed by modulating the brake pressure.

Selector low control ▶

This control is used for regulating the brake pressure for rear axle during ABS operation. This

control uses lower adhesion coefficient to prevent the rear wheels from locking.

Page 262 of 502

0-10

RODIUS 2005.07

4892-01

ABS SYSTEM

3. ON-VEHICLE SERVICE

(1) Electronic system service precautions

Take care to avoid electronic brake control module (HECU) circuit overloading. In testing for

opens or shorts, do not ground or apply voltage to any circuit unless instructed to do so by the

diagnostic procedure. Test circuits only with a high-impedance multi-meter. Never remove o

r

apply power to any control module with the ignition switch in the ON position. Always turn the

ignition to the OFF position before removing or connecting battery cables, fuses or connectors.

(2) General service precautions

Disconnect the HECU connector before performing any vehicle welding work using an electric

arc welder. Do not attempt to disassemble any component designated as nonserviceable. The

hydraulic modulator and the HECU can be seperated. (There is however no access to repai

r

the each components.)

(3) Bleeding system

Replacement modulators are shipped already filled and bled. In normal procedures requiring

removal of the modulator, such as to replace the HECU, air will not enter the modulator, and

normal bleeding will be all that is needed.

If air enters the hydraulic modulator, or if an unfilled modulator is installed, use the brake

bleeding program in the scan tool to bleed the modulator. Manual bleeding of the hydraulic

modulator is not possible.

1) Service Precautions

Brake Fluid may irritate eyes and skin. In case of contact, take the following actions:

Eye contact - rinse thoroughly with water.

Skin contact - wash with soap and water.

Ingestion - consult a physician immediately. -

-

-

To help avoid personal injury due to poor braking. DO NOT Tap into the vehicle’s

brake system to operate a trailer brake system.

When fasteners are removed, always reinstall them at the same location from which they

were removed. If a fastener needs to be replaced, use the correct part number fastener

for is not available, a fastener of equal size and strength (or stronger) may be used.

Fasteners that are not reused, and those requiring thread-locking compound will be

called out. The correct torque values must be used when installing fasteners that require

them. If the above procedures are not followed, parts or system damage could result.

Page 263 of 502

0-11

ABS SYSTEM

RODIUS 2005.07

4892-01

Use only DOT-3 equivalent hydraulic brake fluid. The use of DOT-5 (silicone) brake fluid is

not recommended. Reduced brake performance or durability may result.

Avoid spilling brake fluid on any the vehicle’s painted surfaces, wiring, cables or

electrical connectors. Brake fluid will damage paint and electrical connections. If any fluid is

spilled on the vehicle, flush the area with water to lessen the damage.