SSANGYONG RODIUS 2006 Manual Online

RODIUS 2006

SSANGYONG

SSANGYONG

https://www.carmanualsonline.info/img/67/57523/w960_57523-0.png

SSANGYONG RODIUS 2006 Manual Online

Trending: oil type, ECO mode, coolant reservoir, bulb, fuel, audio, coolant capacity

Page 81 of 444

06-4

RODIUS 2007.07

0000-00

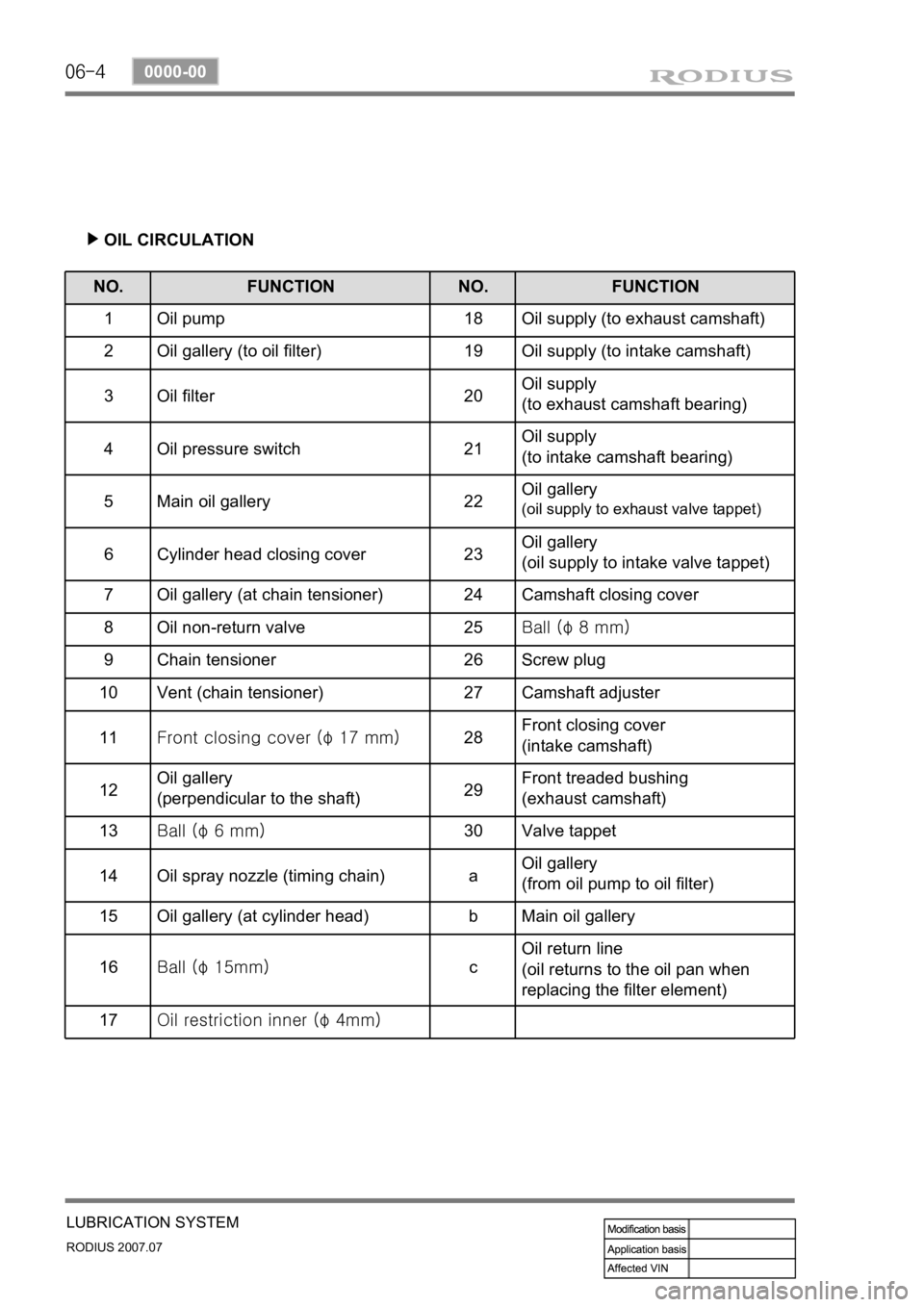

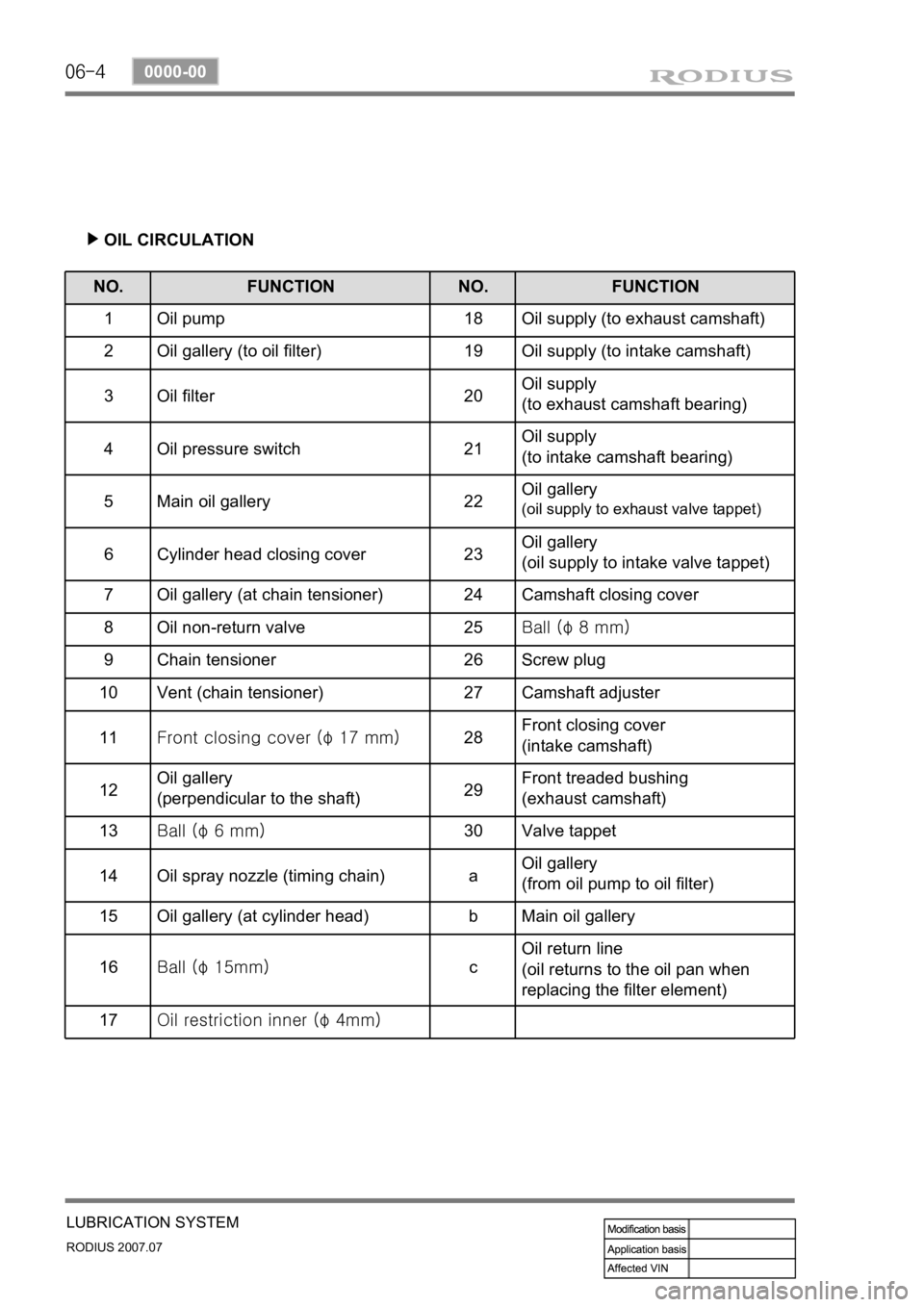

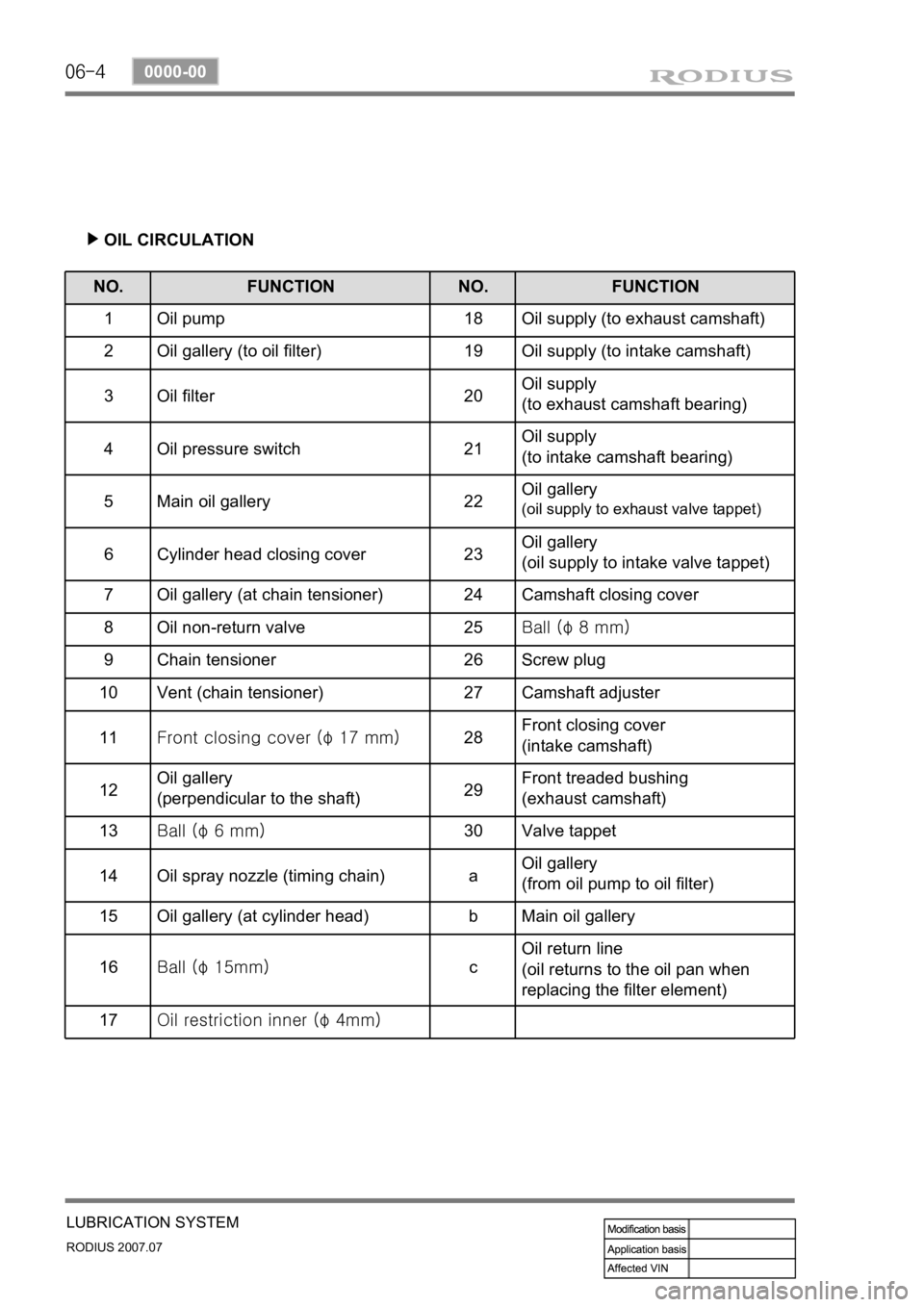

LUBRICATION SYSTEM

NO. FUNCTION NO. FUNCTION

1 Oil pump 18 Oil supply (to exhaust camshaft)

2 Oil gallery (to oil filter) 19 Oil supply (to intake camshaft)

3 Oil filter 20Oil supply

(to exhaust camshaft bearing)

4 Oil pressure switch 21Oil supply

(to intake camshaft bearing)

5 Main oil gallery 22Oil gallery

(oil supply to exhaust valve tappet)

6 Cylinder head closing cover 23Oil gallery

(oil supply to intake valve tappet)

7 Oil gallery (at chain tensioner) 24 Camshaft closing cover

8 Oil non-return valve 25Ball (φ 8 mm)

9 Chain tensioner 26 Screw plug

10 Vent (chain tensioner) 27 Camshaft adjuster

11Front closing cover (φ 17 mm)28Front closing cover

(intake camshaft)

12Oil gallery

(perpendicular to the shaft)29Front treaded bushing

(exhaust camshaft)

13Ball (φ 6 mm)30 Valve tappet

14 Oil spray nozzle (timing chain) aOil gallery

(from oil pump to oil filter)

15 Oil gallery (at cylinder head) b Main oil gallery

16Ball (φ 15mm)cOil return line

(oil returns to the oil pan when

replacing the filter element)

17Oil restriction inner (φ 4mm)

OIL CIRCULATION ▶

Page 82 of 444

07-3

COOLING SYSTEM

RODIUS 2007.07

0000-00

2110-01ENGINE COOLING SYSTEM

1. GENERAL SPECIFICATIONS

Page 83 of 444

07-4

RODIUS 2007.07

0000-00

COOLING SYSTEM

2. SPECIAL TOOLS AND EQUIPMENT

Page 84 of 444

07-5

COOLING SYSTEM

RODIUS 2007.07

0000-00

3. FASTENER TIGHTENING SPECIFICATIONS

Page 85 of 444

07-6

RODIUS 2007.07

0000-00

COOLING SYSTEM

1. GENERAL DESCRIPTION

The cooling system maintains the engine temperature at an efficient level during all engine

operating conditions. When the engine is cold, the cooling system cools the engine slowly o

r

not at all. This slow cooling of the engine allows the engine to warm up quickly. The cooling

system includes a radiator and recovery subsystem, cooling fans, a thermostat and housing, a

water pump, and a water pump drive belt. The timing belt drives the water pump.

All

components must function properly for the cooling system to operation. The water pump draws

the coolant from the radiator.

The coolant then circulates through water jackets in the engine block, the intake manifold, and

the cylinder head. When the coolant reaches the operating temperature of the thermostat, the

thermostat opens. The coolant then goes back to the radiator where it cools. This system

directs some coolant through the hoses to the heat core. This provides for heating and

defrosting. The coolant reservoir is connected to the radiator to recover the coolant displaced

by expansion from the high temperatures. The coolant reservoir maintains the correct coolant

level. The cooling system for this vehicle has no radiator cap or filler neck. The coolant is

added to the cooling system through the coolant reservoir.

Page 86 of 444

07-7

COOLING SYSTEM

RODIUS 2007.07

0000-00

2. COMPONENT LOCATOR

Page 87 of 444

07-8

RODIUS 2007.07

0000-00

COOLING SYSTEM

Radiator

Electric fan

Shroud

Deaeration tube

Clamp

Deaeration hose (radiator)

Electric fan mounting bracket

Bolt (M6, 8 pieces)

Bolt (M6, 4 pieces)

Bolt (M6, 4 pieces)

Upper radiator insulator

Lower radiator insulator

Plate

Clip 1.

2.

3.

4.

5.

6.

7.

8.

9.

10.

11.

12.

13.

14.Inlet hose

Outlet hose

3 way hose

Deaeration hose (reserver tank)

Clamp

Clamp

Make up hose holder

Reserver tank

Bolt (M6, 2 piece)

Cooling fan

Viscous clutch

Bolt (M6, 1 piece)

Bolt (M6, 3 piece) 15.

16.

17.

18.

19.

20.

21.

22.

23.

24.

25.

26.

27.

Page 88 of 444

08-3

ENGINE ELECTRIC DEVICES

RODIUS 2007.07

0000-00

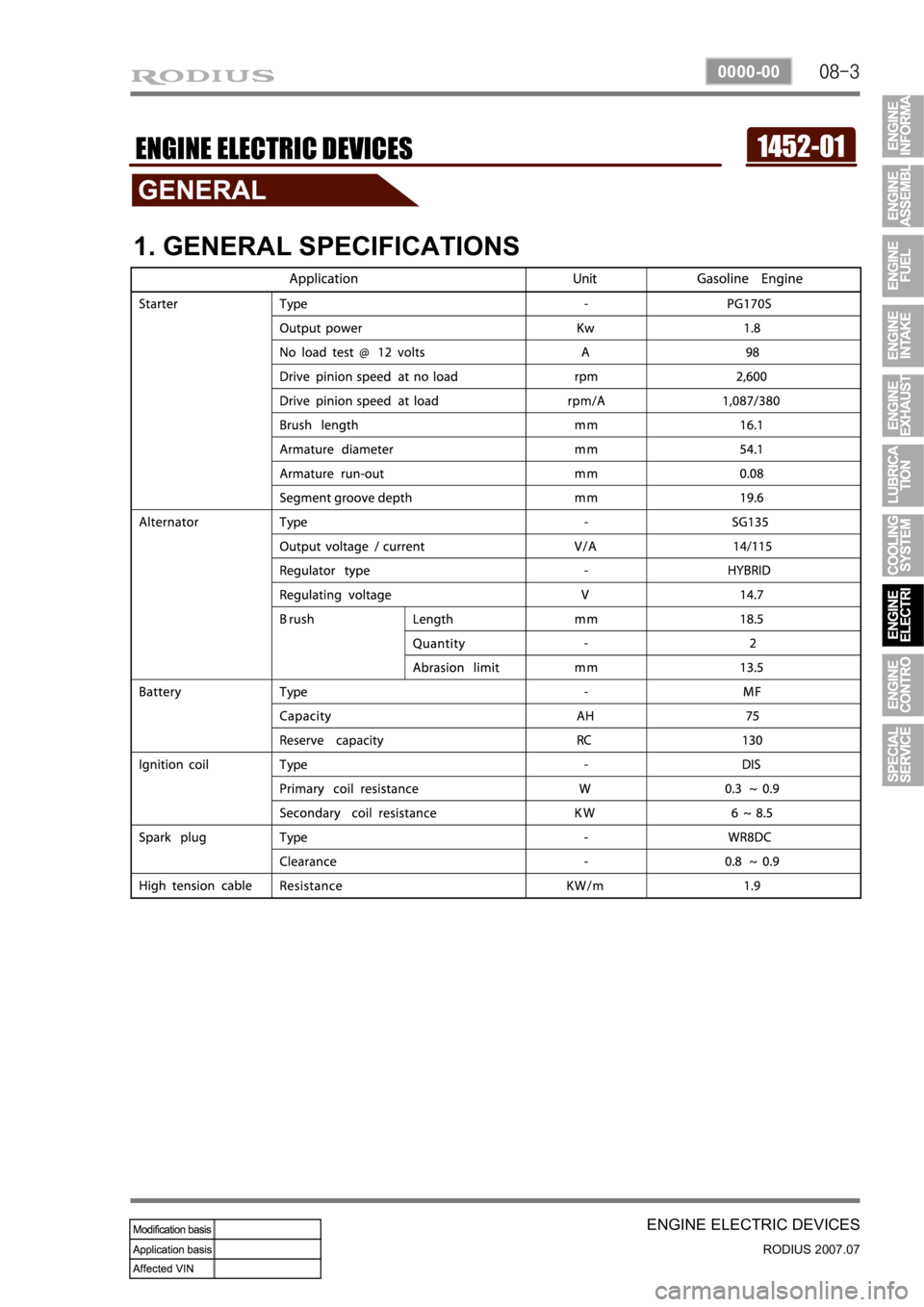

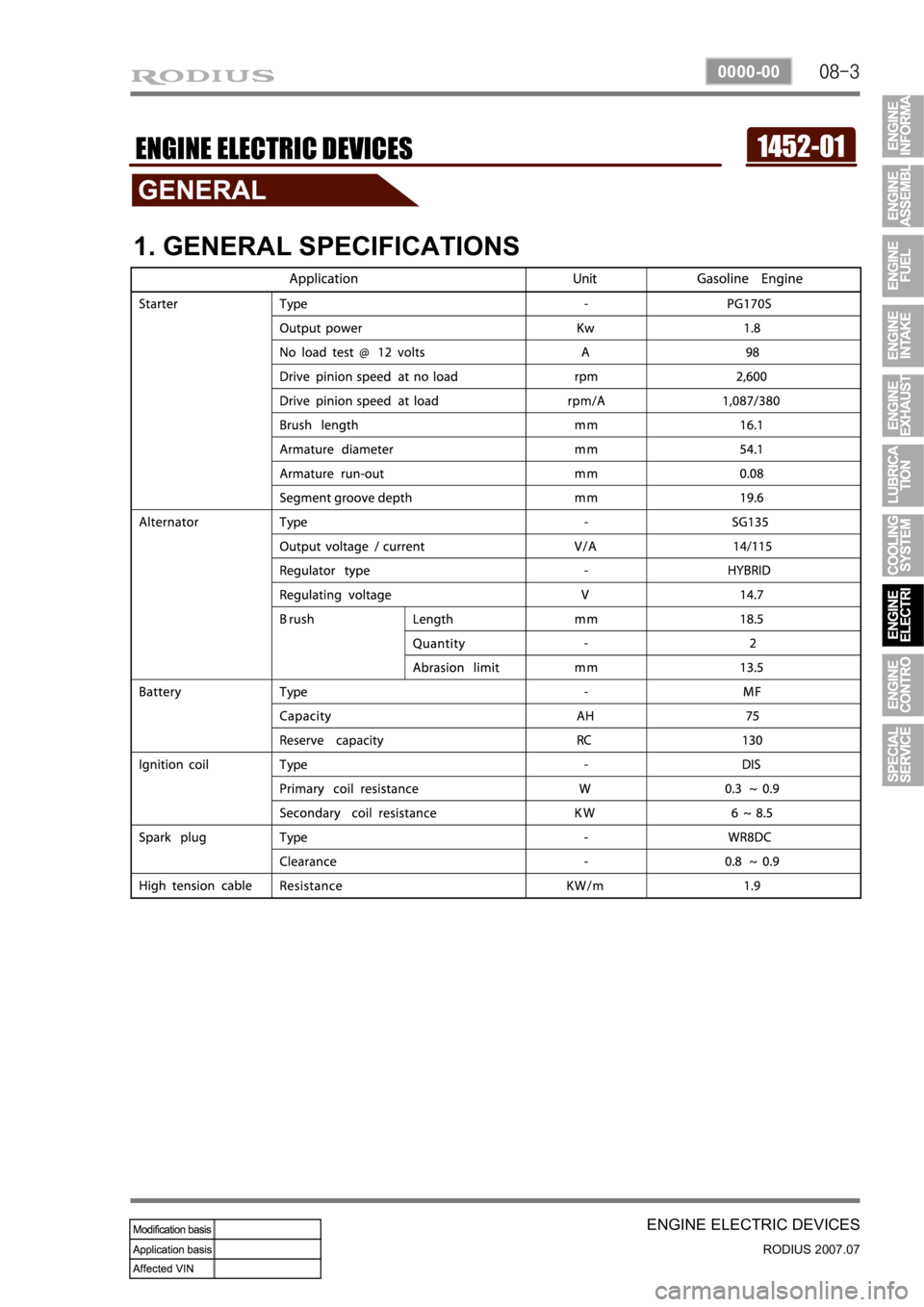

1452-01ENGINE ELECTRIC DEVICES

1. GENERAL SPECIFICATIONS

Page 89 of 444

08-4

RODIUS 2007.07

0000-00

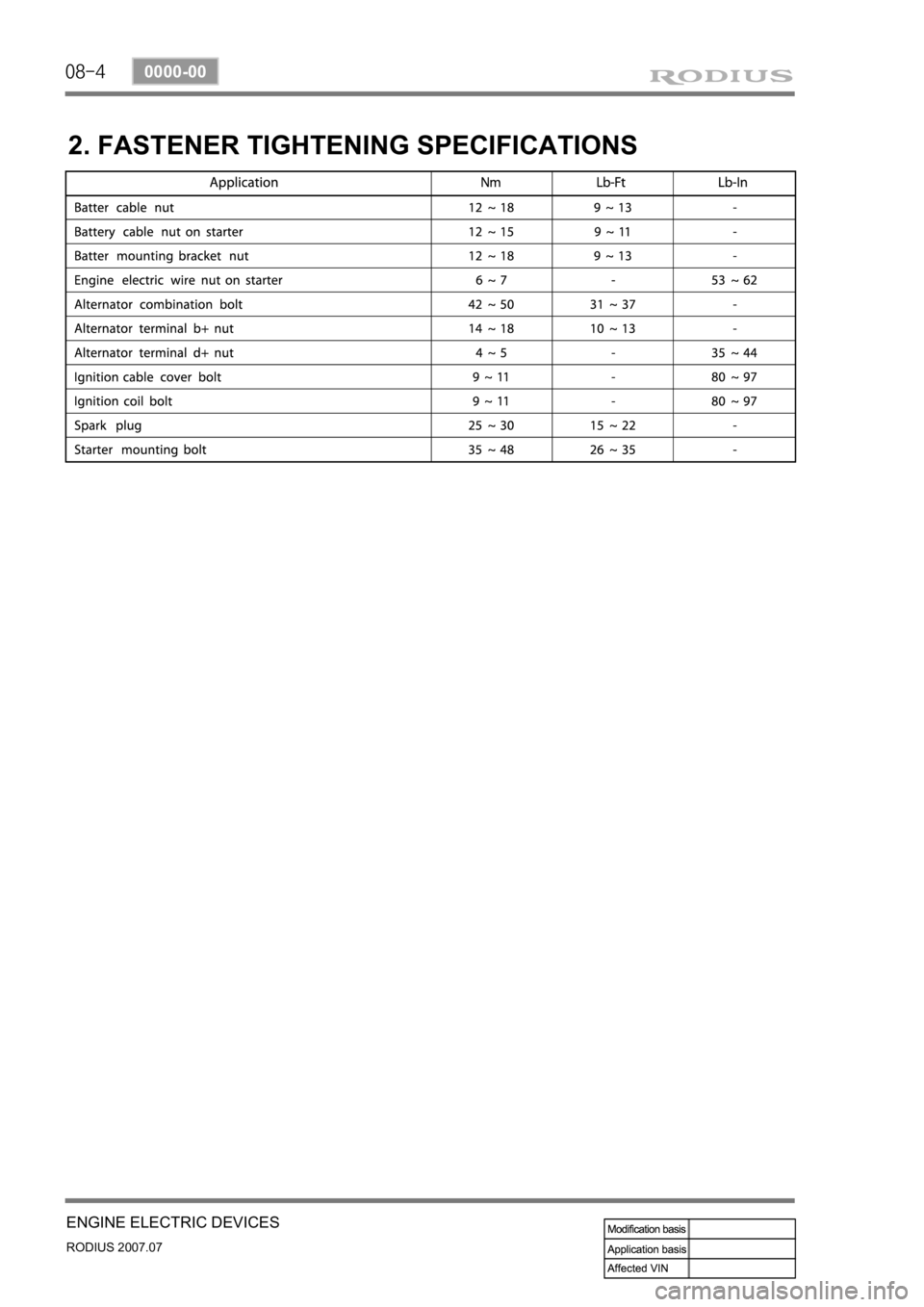

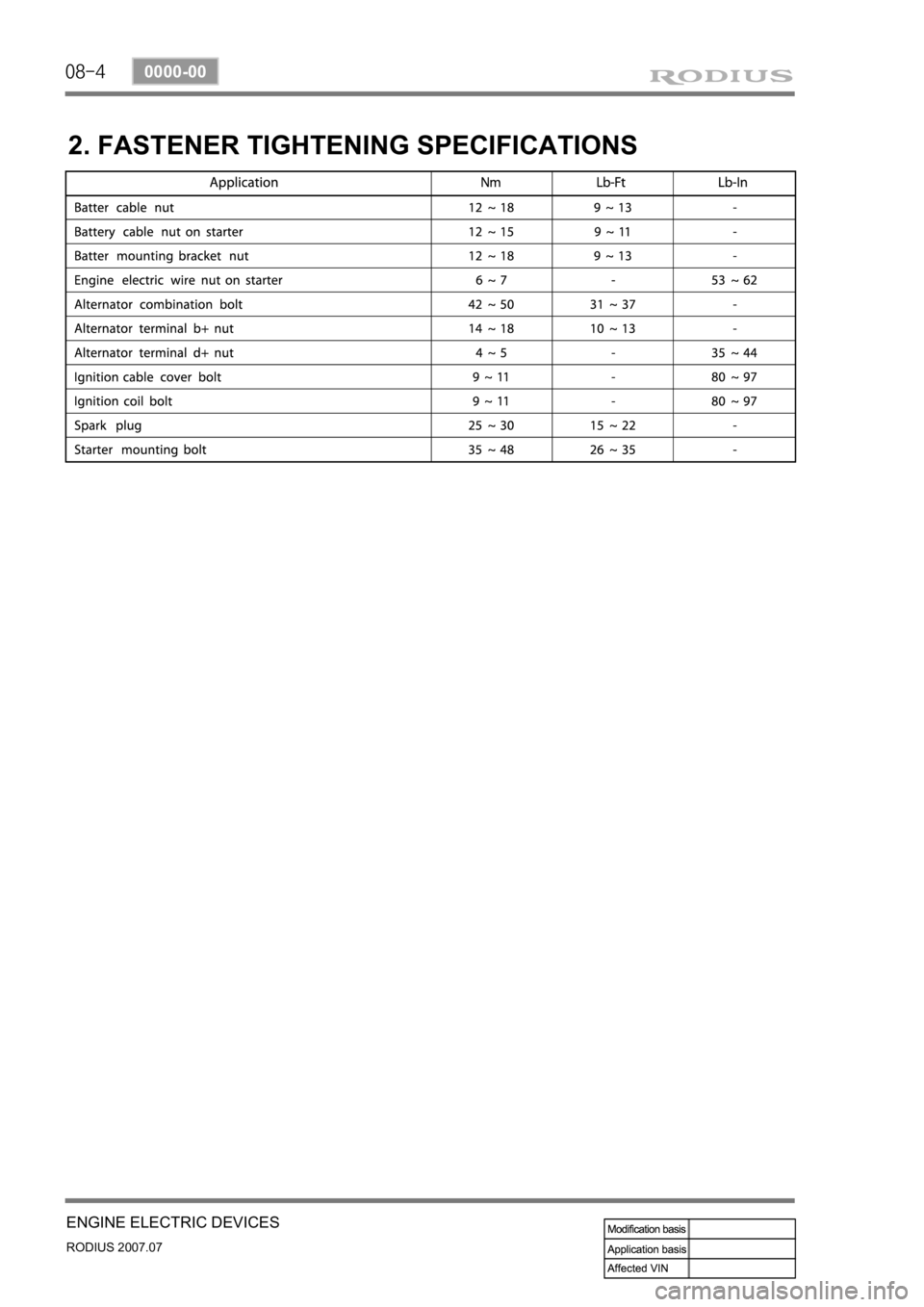

ENGINE ELECTRIC DEVICES

2. FASTENER TIGHTENING SPECIFICATIONS

Page 90 of 444

08-5

ENGINE ELECTRIC DEVICES

RODIUS 2007.07

0000-00

1. CHARGING SYSTEM OPERATION

Alternators use a new type of regulator that incorpo-rates a diode trio. A Delta stator, a rectifier

bridge, and a rotor with slip rings and brushes are electrically similar to earlier alternators.

A conventional pulley and fan are used. There is no test hole.

1) CHARGING TIME REQUIRED

The time required to charge a battery will vary depending upon the following factors:

▶ Size of Battery

A Completely discharged large heavy-duty battery required more than twice the

recharging time as a completely discharged small passenger car battery. -

▶ Temperature

A longer time will be needed to charge any battery at -18°C (0°F) than at 27°C

(80°F). When a fast charger is connected to a cold battery, the current accepted

by the battery will be very low at first. The battery will accept a higher current rate as the

battery warms. -

▶ Charger Capacity

A charger which can supply only 5 amperes will require a much longer charging period

than a charger that can supply 30 amperes or more. -

▶ State-of-Charge

A completely discharged battery requires more than twice as much charge as a onehal

f

charged battery. Because the electrolyte is nearly pure water and a poor conductor in a

completely discharged battery, the current accepted by the battery is very low at first.

Later, as the charging current causes the electrolyte acid content to increase, the

charging current will likewise increase. -

2. STARTING SYSTEM OPERATION

The engine electrical system includes the battery, the ignition, the starter, the alternator, and all

the related wiring. Diagnostic tables will aid in troubleshooting system faults. When a fault is

traced to a particular component, refer to that component section of the service manual. The

starting system circuit consists of the battery, the starter motor, the ignition switch, and all the

related electrical wiring. All of these components are connected electrically.

Trending: coolant level, spare tire, radio antenna, service indicator, tow, differential, relay