SSANGYONG RODIUS 2012 Service Manual

RODIUS 2012

SSANGYONG

SSANGYONG

https://www.carmanualsonline.info/img/67/57525/w960_57525-0.png

SSANGYONG RODIUS 2012 Service Manual

Page 143 of 715

02-70000-00

4620-02 Power Steering Gear

- Changed tie rod end

Newly Installed Equipment

Located in left quarter trim

Repair kit

Sealant

Front

Front

2WD

(A/T, M/T)4WD (A/T)2WD

(A/T, M/T)

Wheel and Tire Repair Kit

4170-07 Wheel

- For 4WD vehicle, installed new wheel

- New wheel

- Installed tire repair kit

3170-01Manual Transmission

- Installed 6-speed manual

transmission

1990-10Transmission Cross Member

- Changed cross member

Page 156 of 715

01-14

Name SizeNumbers of

fastenerTightening

torque (Nm)Note (total

tightening

torque)

Idler pulley/tensioner

pulley1 45±4.5Nm -

Glow plug M5 4 20±2Nm -

Vacuum pumpM8×25 3 10±1Nm -

Timing gear case coverM6×40 7 10±1Nm -

M6×45 1 10±1Nm -

M6×50 3 10±1Nm -

Cylinder head coverM6×35 21 10±1Nm -

Oil dipstick gauge coverM6×16 1 10±1Nm -

Oil filter cap 1 25±2.5Nm -

Fuel railM8×25 2 25±2.5Nm -

Injector clamp boltM6×44 2 9±1.0Nm

130˚±10˚ -

High pressure pipe

(between high pressure

pump and fuel rail

assembly)M17 1 30±3Nm -

High pressure pipe

(between fuel rail

assembly and injector)M17 4 30±3Nm -

Crankshaft position sensorM5×14 1 8±0.4Nm -

Main wiringM6×16 5 10±1Nm -

Intake ductM8×25 3 25±2.5Nm -

Power steering pumpM8×100 3 25±2.5Nm -

Cylinder head front coverM6×10 5 10±1Nm -

Ladder frameM8×16 5 30±3Nm -

Page 163 of 715

02-6

Cylinder head coverM6×352110±1Nm-

Oil gauge tubeM6×16110±1Nm-

Oil filter cap 125±2.5Nm-

Fuel railM8×25225±2.5Nm-

Injector clamp boltM6×4429±1.0Nm

130˚±10˚-

High pressure pipe

(between HP pump and

fuel rail)M17 130±3Nm-

High pressure pipe

(between fuel rail and

injector)M17 430±3Nm-

Crank position sensorM5×1418±0.4Nm-

Main wiringM6×16510±1Nm-

Intake ductM8×25325±2.5Nm-

Power steering pumpM8×100325±2.5Nm-

Cylinder head front

coverM6×10510±1Nm-

Ladder frame M8x16 530±3Nm-

Component SizeBolt

QuantitySpecified torque

(Nm)Remark

(Total torque)

Glow plug M5 420±2Nm-

Vacuum pumpM8×25310±1Nm-

Timing gear case coverM6×40710±1Nm-

M6×45110±1Nm-

M6×50310±1Nm-

Page 181 of 715

02-24

Vacuum pump driveHP pump drive gear

Cylinder head gasket

Camshaft position sensor

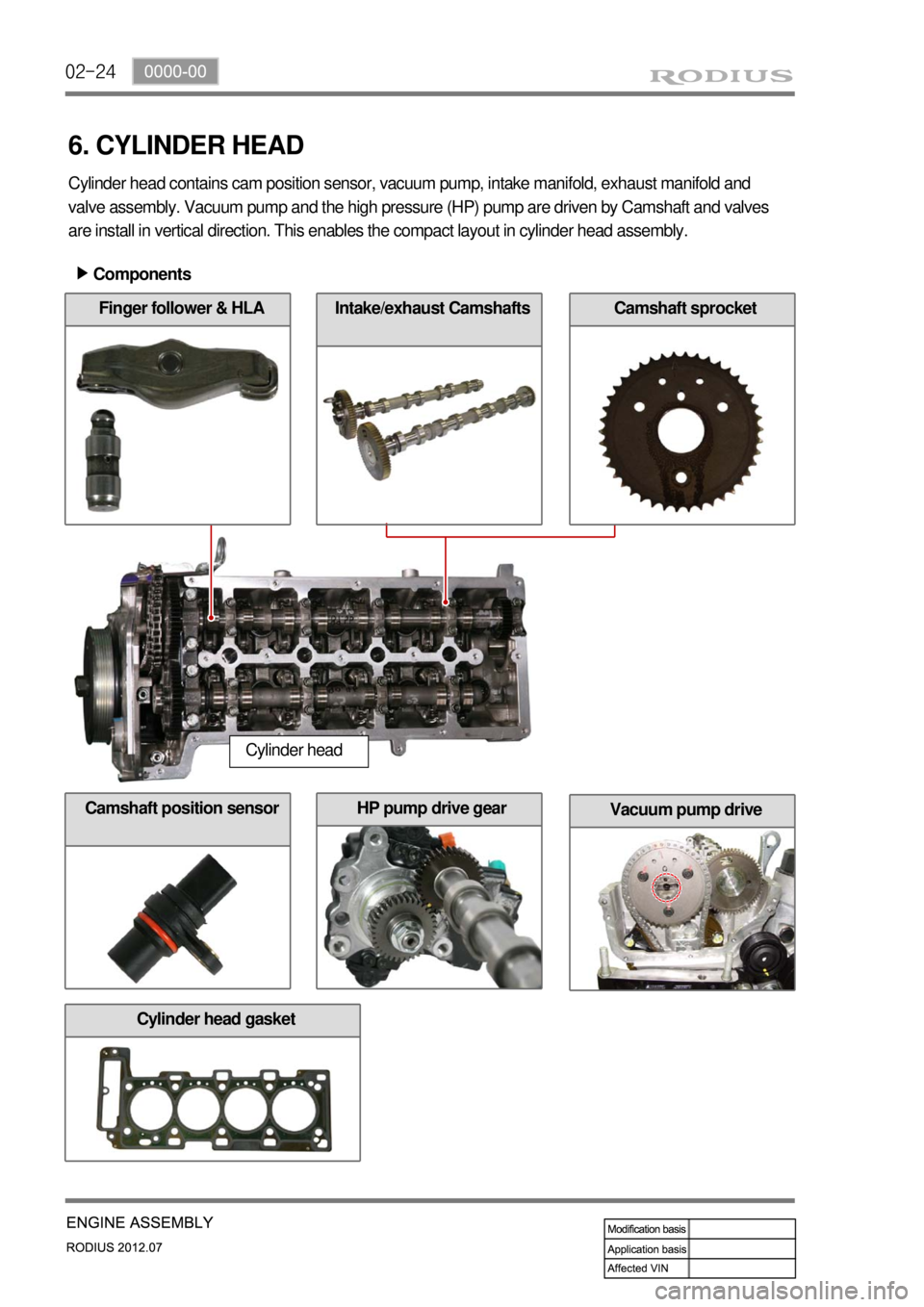

Components ▶

Cylinder head

Cylinder head contains cam position sensor, vacuum pump, intake manifold, exhaust manifold and

valve assembly. Vacuum pump and the high pressure (HP) pump are driven by Camshaft and valves

are install in vertical direction. This enables the compact layout in cylinder head assembly.

6. CYLINDER HEAD

Finger follower & HLACamshaft sprocketIntake/exhaust Camshafts

Page 183 of 715

02-26

Intake/Exhaust Camshafts

2) Camshaft

(1) Overview

Hollow type camshaft contains cam, octagon cam, HP pump gear and intake/exhaust gears.

Camshaft operates the intake/exhaust valves, vacuum pump and HP pump, and transfers the

engine oil to vacuum pump through the internal oil passage.

(2) Location

Exhaust CamshaftExhaust Camshaft

Thrust journalIntake Camshaft

Closed flow type water jacket (improving cooling performance) ▶

Octagon cam

(for tooling)

Connected to

vacuum pump

Page 186 of 715

02-290000-00

1) Chain Drive

(1) Overview

The drive chain is single chain drive system with simple design and variable performance, and it

utilizes the hydraulic tensioner to reduce the wave impact generated by the chain. This chain is light

weight and has high durability through single bush chain. Shoulder bolts are used for better NHV.

7. CHAIN AND GEAR DRIVE SYSTEM

D20DTR engine uses single stage chain drive system. Timing chain drives the exhaust side and

gear drive the intake side. Timing chain is single bush type. Upper chain drives HP pump

connected to intake Camshaft by driving exhaust cam shift sprocke, and lower chain drives oil

pump to lubricate the engine.

Page 188 of 715

02-310000-00

2) Timing Chain and Gear

(1) Timing chain

Simple layout: optimized timing, enhanced

NVH

Single stage layout: minimized chain load

The brass link on crankshaft is at

symmetric position of that on camshaft. -

-

-

Chain upper bush

- Single bush type (112 EA)

Chain lower bush

- Single bush type (60 EA)

(2) Tensioner

Tensioner adjusts the chain tension to keep it tight during engine running. This reduces the wear

in guide rail and spoke.

Operating principle

- Use the spring tension in tensioner and hydraulic pressure

Tensioner type

- Compensation and impact absorbing

Static and dynamic force

- Spring + Hydraulic pressure 1.

2.

3.

Plunger

HousingSpring

Check valve

Hydraulic tensioner assembly ▶

Page 190 of 715

02-330000-00

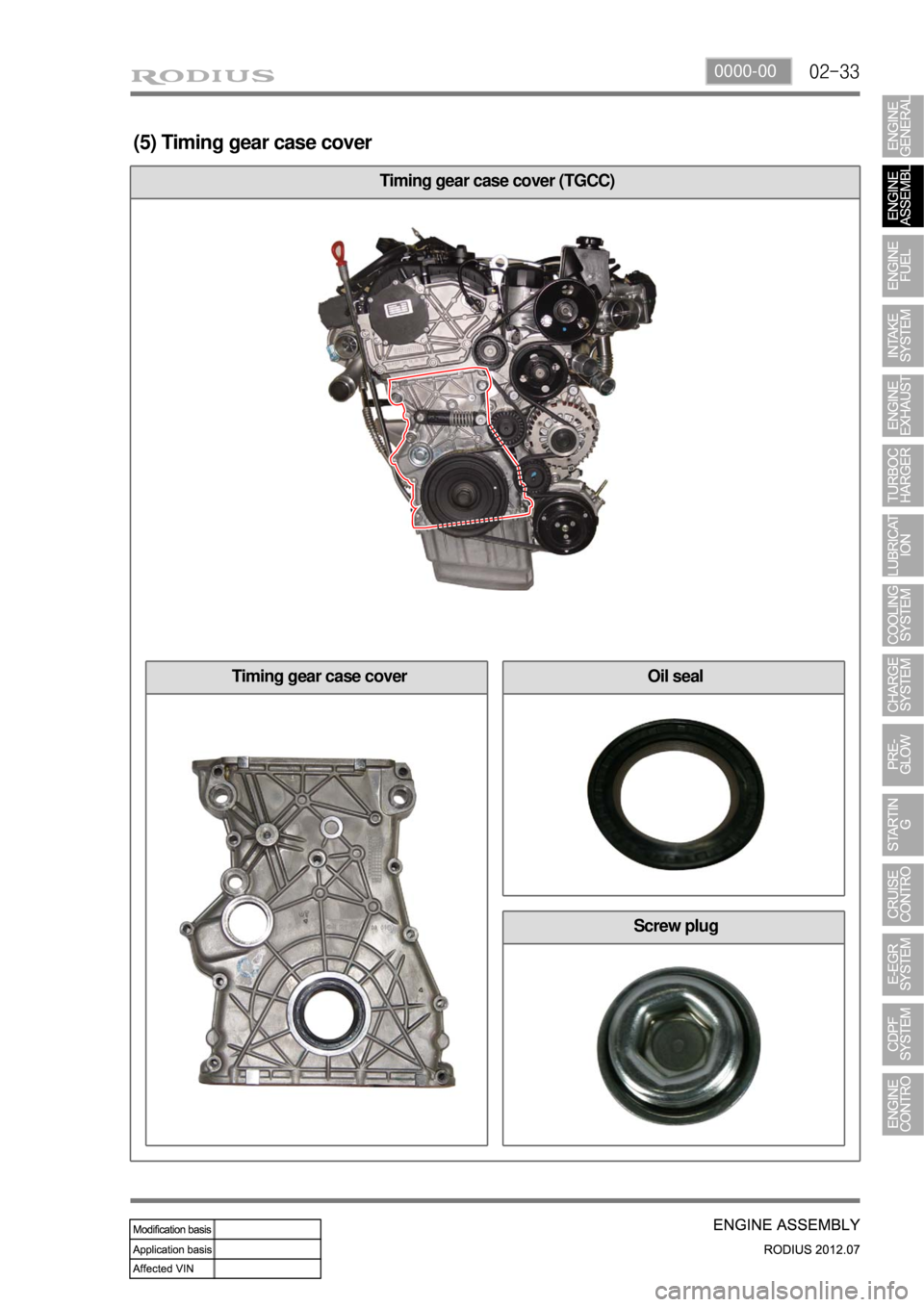

Screw plug

Oil sealTiming gear case cover

Timing gear case cover (TGCC)

(5) Timing gear case cover

Page 191 of 715

02-34

Features

Major function: Protecting the chain drive system, minor function: Shielding the chain noise.

Install crankshaft front seal and screw plug on the timing gear case cover. ▶

-

-

Do not touch the inner lip of crankshaft front seal.

Be careful not to damage the screw thread when removing the lock pin to release the chain

tensioner.

Be careful not to damage the O-ring when installing the screw plug. -

-

-

A671 997 01 46

Crankshaft front seal

Location of chain tensioner

screw plug

Page 193 of 715

02-36

9. DUAL MASS FLYWHEEL (DMF) & DRIVE PLATE

1) Overview

Flywheel is installed on crankshaft. When

starting the engine, this functions as follows:

Reducing the irregular speed of crankshaft

due to unbalanced combustion ->

Improving the power train NVH, Improving

the driving performance

Reducing the clutch noise by using ball

bearing

Improving the durability of DMF by using

strong arch spring -

-

-

2) Layout

Spring guide

Drive plate

Primary cover

Primary flywheel

Internal/external ringSecondary flywheel

Ring gear