SUBARU FORESTER 1999 Service Repair Manual

Manufacturer: SUBARU, Model Year: 1999, Model line: FORESTER, Model: SUBARU FORESTER 1999Pages: 345, PDF Size: 5.6 MB

Page 291 of 345

1.

Item

Starter T

V

Model

Manufacturer

V

2

Direction

Number

No-load

characteristics V

Current

Rotating

Load

characteristics V

Current

T

8.73

or 16.0

or

Rotating

Lock

characteristics V

Current

T

15.7

or 28.9

or

Generator T

Rotating-field

age response Rotating-field

age response

Model

Manufacturer

V 2V\3207

Polarity

Rotating

Armature

Output 1,500

2,500

5,000

Regulated

Ignition

&

Ignitor

assembly Model

Manufacturer

Primary

W\26110%

Secondary W\26115%

Insulation

mary More

W

Spark

plug T

facturer

Standard

Alternate

RC8YC4

BKR6E-1

K20PR-U1

Thread

Spark

2

6-1[S100]SPECIFICA

1.

Page 292 of 345

![SUBARU FORESTER 1999 Service Repair Manual 1.

H6M0492B

\(1\)

\(2\)

\(3\)

\(4\)

\(5\)

\(6\)\(7\)

\(8\)

\(9\)

\(10\)

\(1

\(12\)\(13\)

\(14\)

\(15\)

\(16\)

\(17\)

3

[C100]6-1COMPONENT

1. SUBARU FORESTER 1999 Service Repair Manual 1.

H6M0492B

\(1\)

\(2\)

\(3\)

\(4\)

\(5\)

\(6\)\(7\)

\(8\)

\(9\)

\(10\)

\(1

\(12\)\(13\)

\(14\)

\(15\)

\(16\)

\(17\)

3

[C100]6-1COMPONENT

1.](/img/17/57427/w960_57427-291.png)

1.

H6M0492B

\(1\)

\(2\)

\(3\)

\(4\)

\(5\)

\(6\)\(7\)

\(8\)

\(9\)

\(10\)

\(1

\(12\)\(13\)

\(14\)

\(15\)

\(16\)

\(17\)

3

[C100]6-1COMPONENT

1.

Page 293 of 345

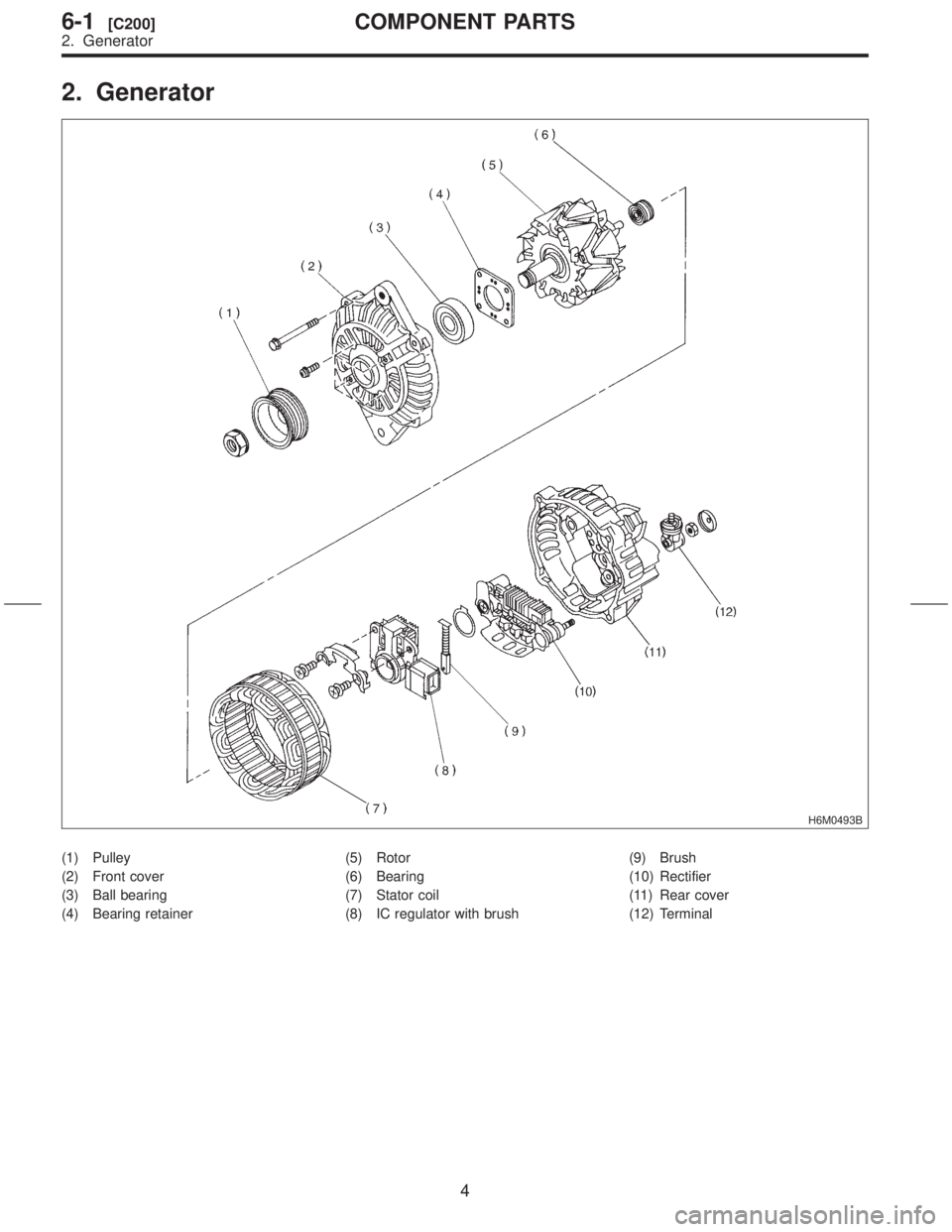

2. Generator

H6M0493B

(1) Pulley

(2) Front cover

(3) Ball bearing

(4) Bearing retainer(5) Rotor

(6) Bearing

(7) Stator coil

(8) IC regulator with brush(9) Brush

(10) Rectifier

(11) Rear cover

(12) Terminal

4

6-1[C200]COMPONENT PARTS

2. Generator

Page 294 of 345

![SUBARU FORESTER 1999 Service Repair Manual 3.

S6M0329A

\(1\)

\(2\)

\(3\)\(4\)T

T:

22\2612\2610.2,\2611.4\)

5

[C300]6-1COMPONENT

3. SUBARU FORESTER 1999 Service Repair Manual 3.

S6M0329A

\(1\)

\(2\)

\(3\)\(4\)T

T:

22\2612\2610.2,\2611.4\)

5

[C300]6-1COMPONENT

3.](/img/17/57427/w960_57427-293.png)

3.

S6M0329A

\(1\)

\(2\)

\(3\)\(4\)T

T:

22\2612\2610.2,\2611.4\)

5

[C300]6-1COMPONENT

3.

Page 295 of 345

![SUBARU FORESTER 1999 Service Repair Manual 1. Starter

A: REMOVAL AND INSTALLATION

1) Disconnect battery ground cable.

G6M0095

2) Remove air cleaner case and air intake duct.

<Ref. to 2-7 [W1A0].>

H2M2931

3) Remove air intake chamber stay.

S2M0 SUBARU FORESTER 1999 Service Repair Manual 1. Starter

A: REMOVAL AND INSTALLATION

1) Disconnect battery ground cable.

G6M0095

2) Remove air cleaner case and air intake duct.

<Ref. to 2-7 [W1A0].>

H2M2931

3) Remove air intake chamber stay.

S2M0](/img/17/57427/w960_57427-294.png)

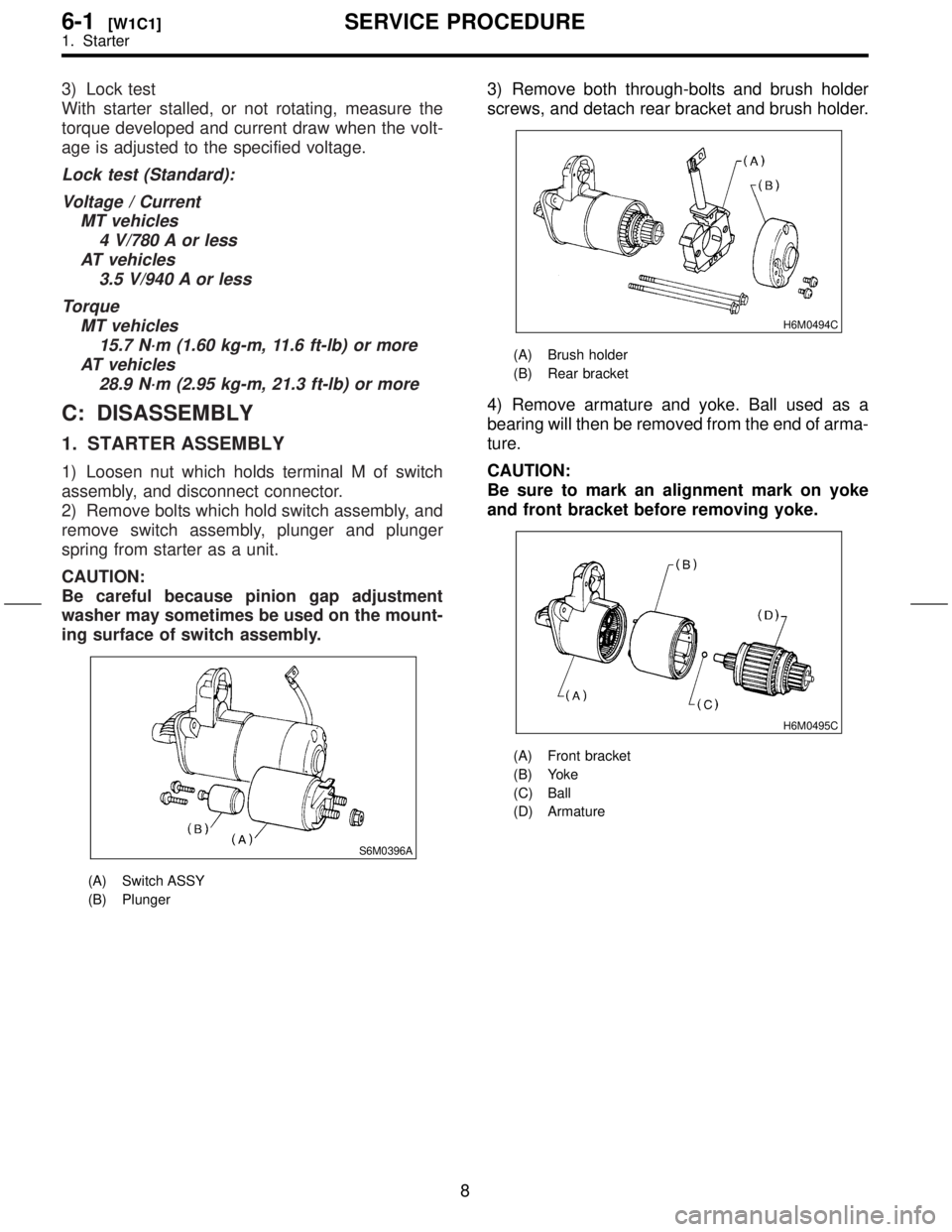

1. Starter

A: REMOVAL AND INSTALLATION

1) Disconnect battery ground cable.

G6M0095

2) Remove air cleaner case and air intake duct.

H2M2931

3) Remove air intake chamber stay.

S2M0900A

S2M0901A

4) Disconnect connector and terminal from starter.

S6M0002A

(A) Terminal

(B) Connector

5) Remove starter from transmission.

G2M0309

6) Install in the reverse order of removal.

Tightening torque:

50

±4 N´m (5.1±0.4 kg-m, 37±2.9 ft-lb)

G2M0309

B: TEST

1. SWITCH ASSEMBLY OPERATION

1) Connect terminal S of switch assembly to posi-

tive terminal of battery with a lead wire, and starter

body to ground terminal of battery. Pinion should

be forced endwise on shaft.

CAUTION:

With pinion forced endwise on shaft, starter

motor can sometimes rotate because current

flows, through pull-in coil, to motor. This is not

a problem.

6

6-1[W1A0]SERVICE PROCEDURE

1. Starter

Page 296 of 345

2) Disconnect connector from terminal M, and

connect positive terminal of battery and terminal M

using a lead wire and ground terminal to starter

body.

In this test set up, pinion should return to its origi-

nal position even when it is pulled out with a screw-

driver.

S6M0393A

(A) Terminal S

(B) Terminal M

2. PINION GAP

1) With pinion forced endwise on shaft, as outlined

in step 1) before

pinion gap.

Pinion gap:

0.5 Ð 2.0 mm (0.020 Ð 0.079 in)

S6M0394A

(A) Pinion

(B) Gap

(C) Stopper

If motor is running with the pinion forced endwise

on the shaft, disconnect connector from terminal M

of switch assembly and connect terminal M to

ground terminal (þ) of battery with a lead wire.

Next, gently push pinion back with your fingertips

and measure pinion gap.

2) If pinion gap is outside specified range, remove

or add number of adjustment washers used on the

mounting surface of switch assembly until correct

pinion gap is obtained.

3. PERFORMANCE TEST

The starter should be submitted to performance

tests whenever it has been overhauled, to assure

its satisfactory performance when installed on the

engine.

Three performance tests, no-load test, load test,

and lock test, are presented here; however, if the

load test and lock test cannot be performed, carry

out at least the no-load test.

For these performance tests, use the circuit shown

in figure.

S6M0395A

(A) Variable resistance

(B) Magnetic switch

(C) Starter body

1) No-load test

With switch on, adjust the variable resistance to

obtain 11 V, take the ammeter reading and mea-

sure the starter speed. Compare these values with

the specifications.

No-load test (Standard):

Voltage / Current

11V/90Amax.

Rotating speed

MT vehicles

2,800 rpm or more

AT vehicles

2,400 rpm or more

2) Load test

Apply the specified braking torque to starter. The

condition is satisfactory if the current draw and

starter speed are within specifications.

Load test (Standard):

Voltage / Load

MT vehicles

7.5 V/8.7 N´m (0.89 kg-m, 6.4 ft-lb)

AT vehicles

7.7 V/16.0 N´m (1.63 kg-m, 11.8 ft-lb)

Current / Speed

MT vehicles

300 A/890 rpm or more

AT vehicles

400 A/740 rpm or more

7

[W1B3]6-1SERVICE PROCEDURE

1. Starter

Page 297 of 345

3) Lock test

With starter stalled, or not rotating, measure the

torque developed and current draw when the volt-

age is adjusted to the specified voltage.

Lock test (Standard):

Voltage / Current

MT vehicles

4 V/780 A or less

AT vehicles

3.5 V/940 A or less

Torque

MT vehicles

15.7 N´m (1.60 kg-m, 11.6 ft-lb) or more

AT vehicles

28.9 N´m (2.95 kg-m, 21.3 ft-lb) or more

C: DISASSEMBLY

1. STARTER ASSEMBLY

1) Loosen nut which holds terminal M of switch

assembly, and disconnect connector.

2) Remove bolts which hold switch assembly, and

remove switch assembly, plunger and plunger

spring from starter as a unit.

CAUTION:

Be careful because pinion gap adjustment

washer may sometimes be used on the mount-

ing surface of switch assembly.

S6M0396A

(A) Switch ASSY

(B) Plunger

3) Remove both through-bolts and brush holder

screws, and detach rear bracket and brush holder.

H6M0494C

(A) Brush holder

(B) Rear bracket

4) Remove armature and yoke. Ball used as a

bearing will then be removed from the end of arma-

ture.

CAUTION:

Be sure to mark an alignment mark on yoke

and front bracket before removing yoke.

H6M0495C

(A) Front bracket

(B) Yoke

(C) Ball

(D) Armature

8

6-1[W1C1]SERVICE PROCEDURE

1. Starter

Page 298 of 345

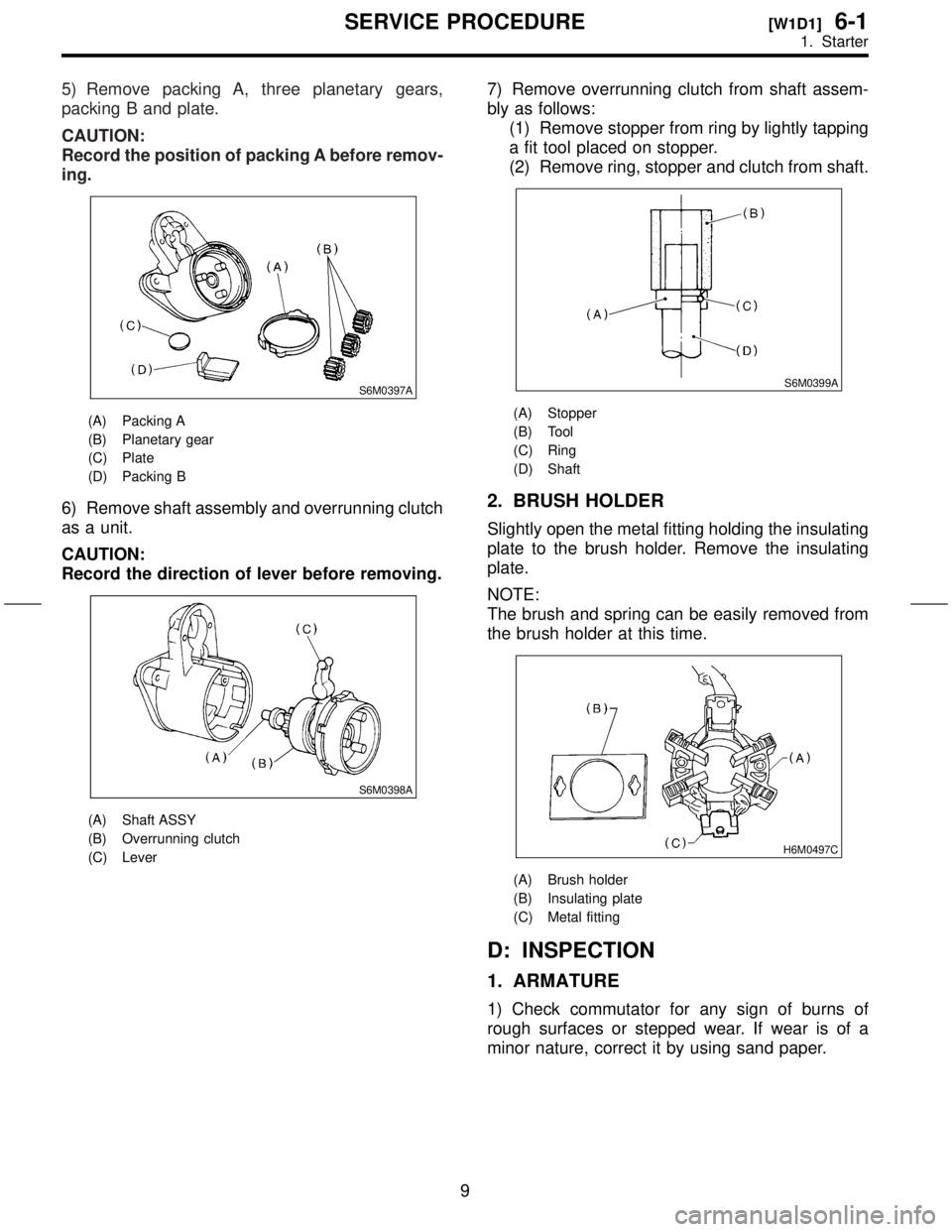

5) Remove packing A, three planetary gears,

packing B and plate.

CAUTION:

Record the position of packing A before remov-

ing.

S6M0397A

(A) Packing A

(B) Planetary gear

(C) Plate

(D) Packing B

6) Remove shaft assembly and overrunning clutch

as a unit.

CAUTION:

Record the direction of lever before removing.

S6M0398A

(A) Shaft ASSY

(B) Overrunning clutch

(C) Lever

7) Remove overrunning clutch from shaft assem-

bly as follows:

(1) Remove stopper from ring by lightly tapping

a fit tool placed on stopper.

(2) Remove ring, stopper and clutch from shaft.

S6M0399A

(A) Stopper

(B) Tool

(C) Ring

(D) Shaft

2. BRUSH HOLDER

Slightly open the metal fitting holding the insulating

plate to the brush holder. Remove the insulating

plate.

NOTE:

The brush and spring can be easily removed from

the brush holder at this time.

H6M0497C

(A) Brush holder

(B) Insulating plate

(C) Metal fitting

D: INSPECTION

1. ARMATURE

1) Check commutator for any sign of burns of

rough surfaces or stepped wear. If wear is of a

minor nature, correct it by using sand paper.

9

[W1D1]6-1SERVICE PROCEDURE

1. Starter

Page 299 of 345

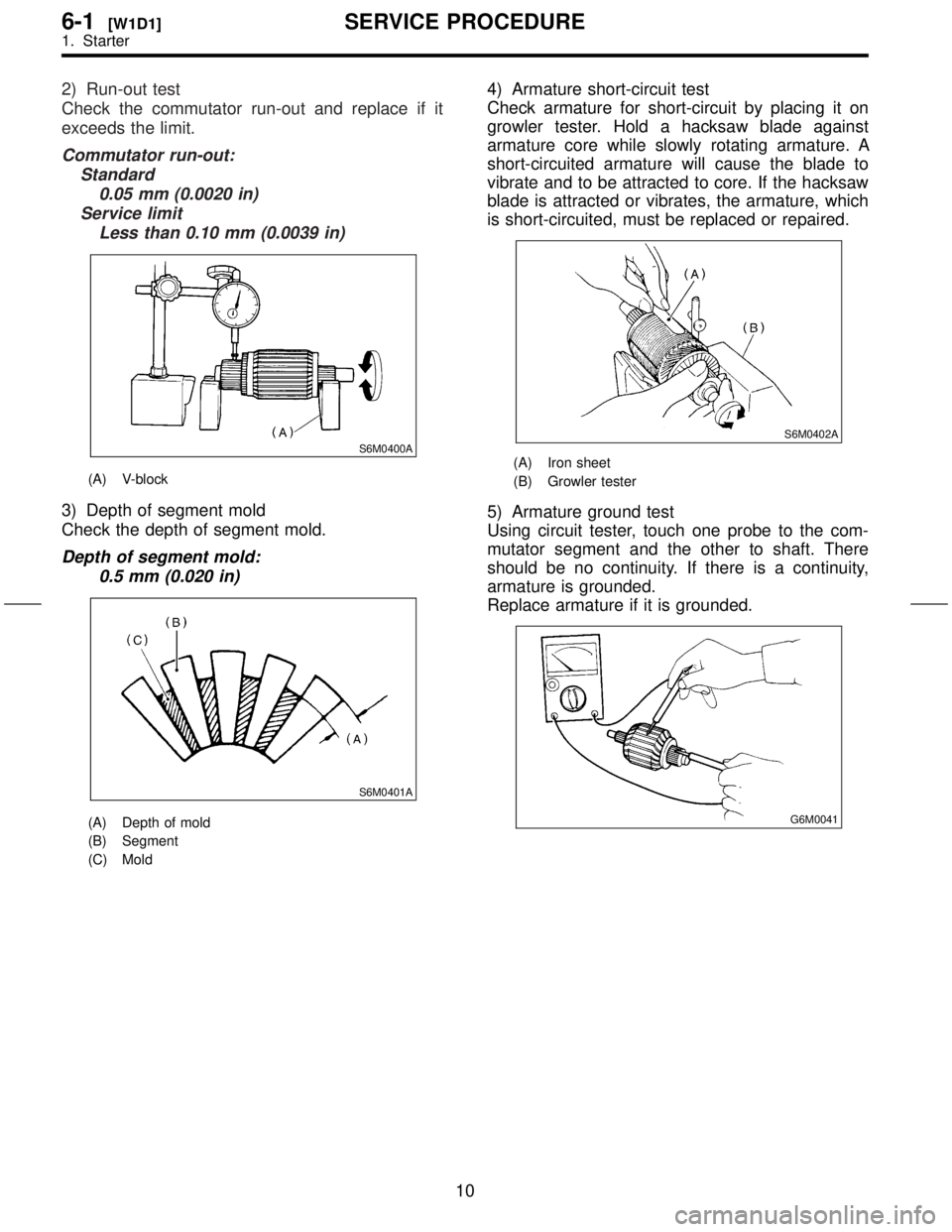

2) Run-out test

Check the commutator run-out and replace if it

exceeds the limit.

Commutator run-out:

Standard

0.05 mm (0.0020 in)

Service limit

Less than 0.10 mm (0.0039 in)

S6M0400A

(A) V-block

3) Depth of segment mold

Check the depth of segment mold.

Depth of segment mold:

0.5 mm (0.020 in)

S6M0401A

(A) Depth of mold

(B) Segment

(C) Mold

4) Armature short-circuit test

Check armature for short-circuit by placing it on

growler tester. Hold a hacksaw blade against

armature core while slowly rotating armature. A

short-circuited armature will cause the blade to

vibrate and to be attracted to core. If the hacksaw

blade is attracted or vibrates, the armature, which

is short-circuited, must be replaced or repaired.

S6M0402A

(A) Iron sheet

(B) Growler tester

5) Armature ground test

Using circuit tester, touch one probe to the com-

mutator segment and the other to shaft. There

should be no continuity. If there is a continuity,

armature is grounded.

Replace armature if it is grounded.

G6M0041

10

6-1[W1D1]SERVICE PROCEDURE

1. Starter

Page 300 of 345

2. YOKE

Make sure pole is set in position.

3. OVERRUNNING CLUTCH

Inspect teeth of pinion for wear and damage.

Replace if it is damaged. Rotate pinion in direction

of rotation (counterclockwise). It should rotate

smoothly. But in opposite direction, it should be

locked.

CAUTION:

Do not clean overrunning clutch with oil to pre-

vent grease from flowing out.

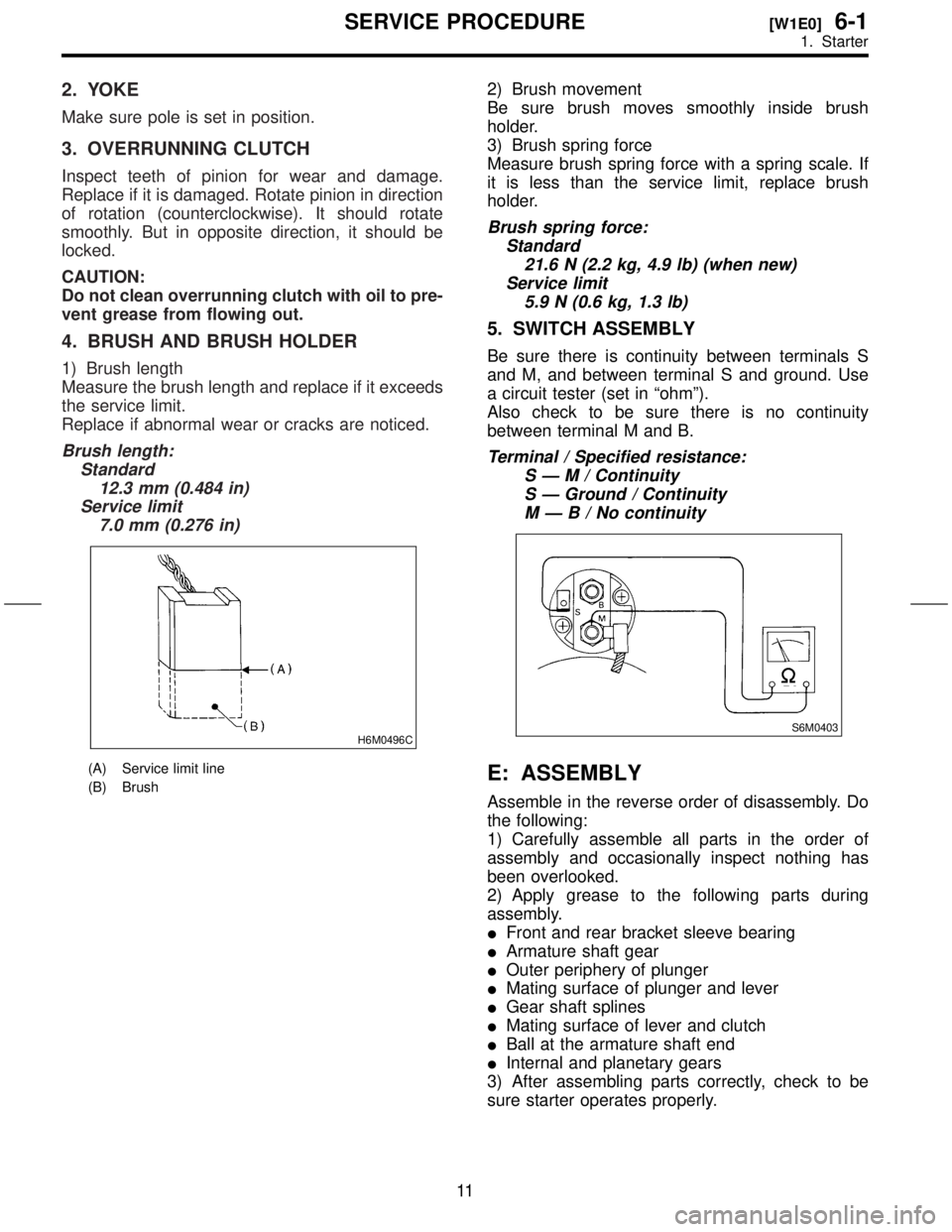

4. BRUSH AND BRUSH HOLDER

1) Brush length

Measure the brush length and replace if it exceeds

the service limit.

Replace if abnormal wear or cracks are noticed.

Brush length:

Standard

12.3 mm (0.484 in)

Service limit

7.0 mm (0.276 in)

H6M0496C

(A) Service limit line

(B) Brush

2) Brush movement

Be sure brush moves smoothly inside brush

holder.

3) Brush spring force

Measure brush spring force with a spring scale. If

it is less than the service limit, replace brush

holder.

Brush spring force:

Standard

21.6 N (2.2 kg, 4.9 lb) (when new)

Service limit

5.9 N (0.6 kg, 1.3 lb)

5. SWITCH ASSEMBLY

Be sure there is continuity between terminals S

and M, and between terminal S and ground. Use

a circuit tester (set in ªohmº).

Also check to be sure there is no continuity

between terminal M and B.

Terminal / Specified resistance:

SÐM/Continuity

S Ð Ground / Continuity

MÐB/Nocontinuity

S6M0403

E: ASSEMBLY

Assemble in the reverse order of disassembly. Do

the following:

1) Carefully assemble all parts in the order of

assembly and occasionally inspect nothing has

been overlooked.

2) Apply grease to the following parts during

assembly.

IFront and rear bracket sleeve bearing

IArmature shaft gear

IOuter periphery of plunger

IMating surface of plunger and lever

IGear shaft splines

IMating surface of lever and clutch

IBall at the armature shaft end

IInternal and planetary gears

3) After assembling parts correctly, check to be

sure starter operates properly.

11

[W1E0]6-1SERVICE PROCEDURE

1. Starter