air condition SUBARU FORESTER 1999 Service Repair Manual

[x] Cancel search | Manufacturer: SUBARU, Model Year: 1999, Model line: FORESTER, Model: SUBARU FORESTER 1999Pages: 345, PDF Size: 5.6 MB

Page 10 of 345

4. Diagnostics Chart for On-

board Diagnostic System

A: BASIC DIAGNOSTICS

PROCEDURE

4A1 : CHECK AIRBAG WARNING LIGHT

ILLUMINATES.

1) Turn ignition switch to ON (engine OFF).

2) Check airbag warning light illuminates.

:Does airbag warning light stay ON

after about 7 seconds or remain OFF,

or come back ON after 30 seconds?

: Repair and replace.

: Go to step4A2.

4A2 : CHECK TROUBLE CODE INDICATES.

Perform ON-BOARD DIAGNOSTICS.

:Does trouble code indicate?

: Repair and replace.

: Repair and replace.

4A3 : CHECK AIRBAG WARNING LIGHT

ILLUMINATES.

1) Turn ignition switch to ON (engine OFF).

2) Check airbag warning light illuminates.

:Does airbag warning light stay ON

after about 7 seconds or come back

ON after 30 seconds?

: Repair and replace.

: Go to step4A4.4A4 : CHECK AIRBAG WARNING LIGHT

ILLUMINATES.

Check airbag warning light illuminates.

:Does airbag warning light come ON

for about 7 seconds, then go out and

stay out?

: Perform clear memory.

: Go to step4A1.

B: ON-BOARD DIAGNOSTIC

When the airbag system is in functioning condition,

the airbag warning light will remain on for about 7

seconds and go out when the ignition switch is set

to ON.

If there is any malfunction, the airbag warning light

will either stay on or off continuously. In such

cases, perform on-board diagnostic in accordance

with the specified procedure to determine trouble

codes.

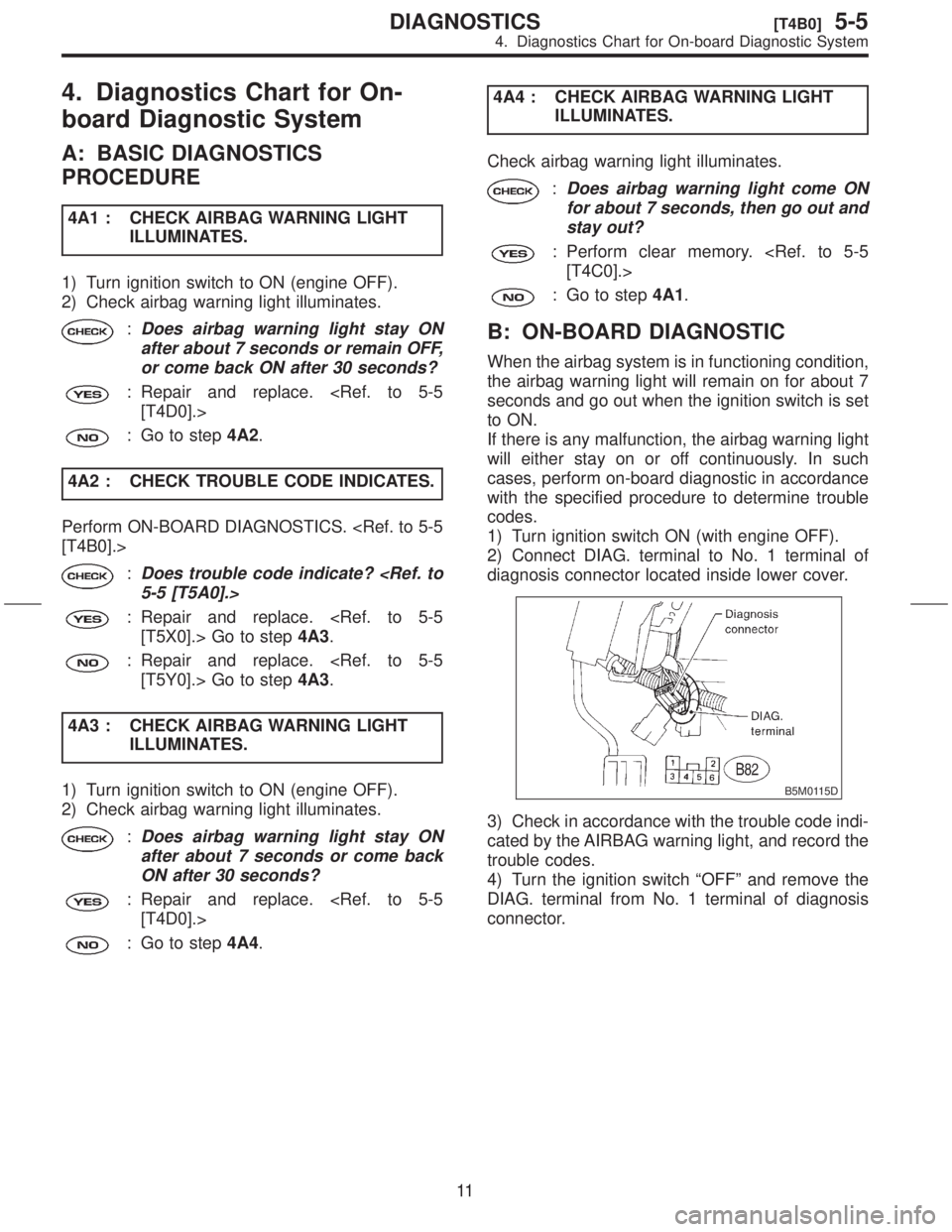

1) Turn ignition switch ON (with engine OFF).

2) Connect DIAG. terminal to No. 1 terminal of

diagnosis connector located inside lower cover.

B5M0115D

3) Check in accordance with the trouble code indi-

cated by the AIRBAG warning light, and record the

trouble codes.

4) Turn the ignition switch ªOFFº and remove the

DIAG. terminal from No. 1 terminal of diagnosis

connector.

11

[T4B0]5-5DIAGNOSTICS

4. Diagnostics Chart for On-board Diagnostic System

Page 79 of 345

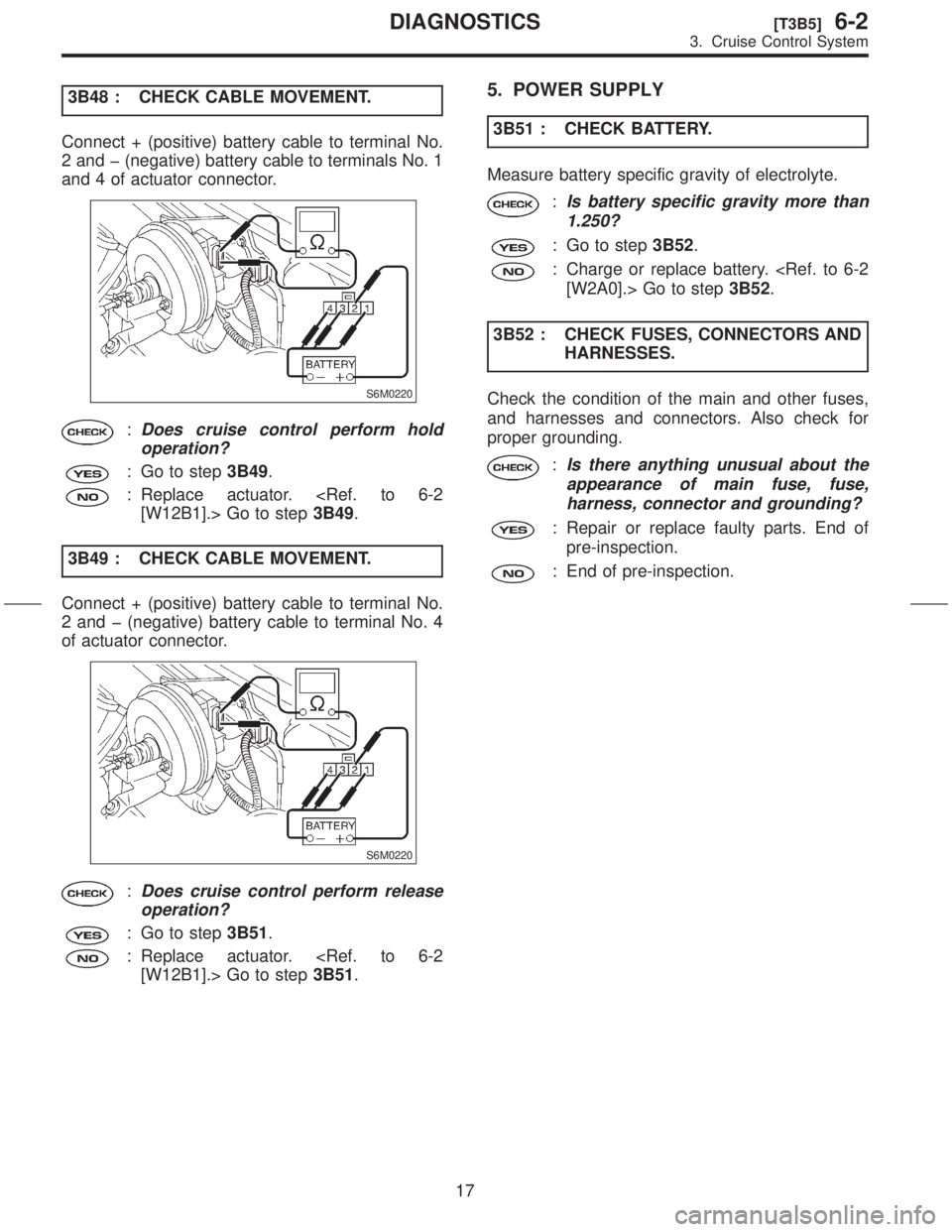

3B48 : CHECK CABLE MOVEMENT.

Connect + (positive) battery cable to terminal No.

2 and þ (negative) battery cable to terminals No. 1

and 4 of actuator connector.

S6M0220

:Does cruise control perform hold

operation?

: Go to step3B49.

: Replace actuator.

3B49 : CHECK CABLE MOVEMENT.

Connect + (positive) battery cable to terminal No.

2 and þ (negative) battery cable to terminal No. 4

of actuator connector.

S6M0220

:Does cruise control perform release

operation?

: Go to step3B51.

: Replace actuator.

5. POWER SUPPLY

3B51 : CHECK BATTERY.

Measure battery specific gravity of electrolyte.

:Is battery specific gravity more than

1.250?

: Go to step3B52.

: Charge or replace battery.

3B52 : CHECK FUSES, CONNECTORS AND

HARNESSES.

Check the condition of the main and other fuses,

and harnesses and connectors. Also check for

proper grounding.

:Is there anything unusual about the

appearance of main fuse, fuse,

harness, connector and grounding?

: Repair or replace faulty parts. End of

pre-inspection.

: End of pre-inspection.

17

[T3B5]6-2DIAGNOSTICS

3. Cruise Control System

Page 192 of 345

6. Repair Instructions for Colored PP Bumper

All PP bumpers are provided with a grained surface, and if the surface is damaged, it cannot normally be

restored to its former condition. Damage limited to shallow scratches that cause only a change in the lus-

tre of the base material or coating, can be almost fully restored. Before repairing a damaged area, explain

this point to the customer and obtain his or her understanding. Repair methods are outlined below, based

on a classification of the extent of damage.

A: MINOR DAMAGE CAUSING ONLY A CHANGE IN THE LUSTRE OF THE

BUMPER DUE TO A LIGHT TOUCH

Almost restorable.

Process

No.Process name Job contents

1 Cleaning Clean the area to be repaired using water.

2 Sanding Grind the repairing area with #500 sand paper in a ªfeatheringº motion.

3 FinishResin section Coated section

Repeatedly apply wax to the affected area

using a soft cloth (such as flannel). Recom-

mended wax: NITTO KASEI Soft 99 TIRE

WAX BLACK, or equivalent.Perform either the same operation as for the

resin section or process No. 18 and subse-

quent operations in the ª(3)º section, depend-

ing on the degree and nature of damage.

Polish the waxed area with a clean cloth after

5 to 10 minutes.

B: DEEP DAMAGE CAUSED BY SCRATCHING FENCES, ETC.

A dent cannot be repaired but a whitened or swelled part can be removed.

Process

No.Process name Job contents

1 Cleaning Clean damaged area with water.

2Removal of dam-

aged areaCut off protruding area, if any, due to collision, using a putty knife.

3 Sanding Grind the affected area with #100 to #500 sand paper.

4 FinishResin section Coated section

Same as Process No. 3 in the ª(1)º section.Perform Process No. 12 and subsequent

operations in the ª(3)º section.

34

5-1[W600]SERVICE PROCEDURE

6. Repair Instructions for Colored PP Bumper

Page 195 of 345

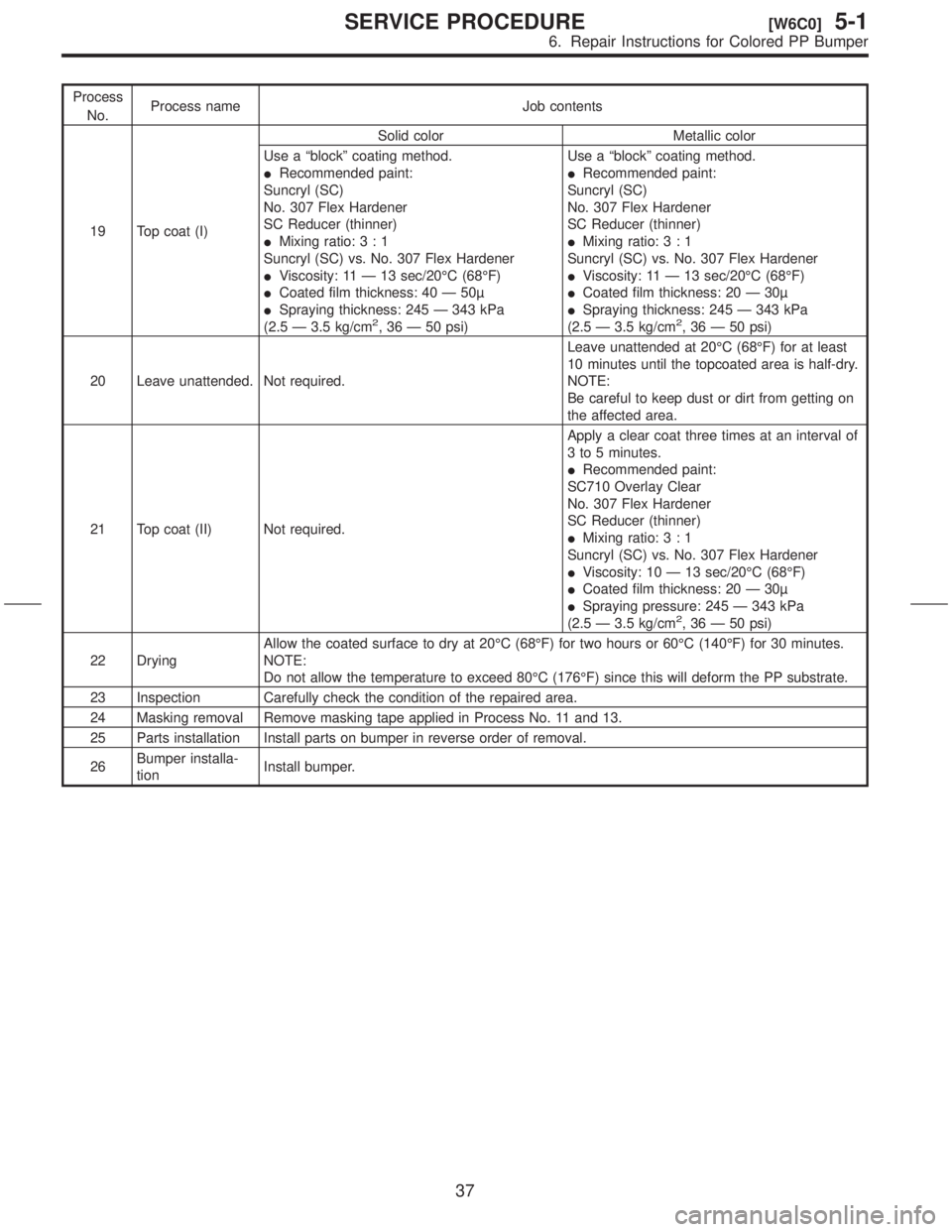

Process

No.Process name Job contents

19 Top coat (I)Solid color Metallic color

Use a ªblockº coating method.

IRecommended paint:

Suncryl (SC)

No. 307 Flex Hardener

SC Reducer (thinner)

IMixing ratio:3:1

Suncryl (SC) vs. No. 307 Flex Hardener

IViscosity: 11 Ð 13 sec/20ÉC (68ÉF)

ICoated film thickness: 40 Ð 50

ISpraying thickness: 245 Ð 343 kPa

(2.5 Ð 3.5 kg/cm

2, 36 Ð 50 psi)Use a ªblockº coating method.

IRecommended paint:

Suncryl (SC)

No. 307 Flex Hardener

SC Reducer (thinner)

IMixing ratio:3:1

Suncryl (SC) vs. No. 307 Flex Hardener

IViscosity: 11 Ð 13 sec/20ÉC (68ÉF)

ICoated film thickness: 20 Ð 30

ISpraying thickness: 245 Ð 343 kPa

(2.5 Ð 3.5 kg/cm2, 36 Ð 50 psi)

20 Leave unattended. Not required.Leave unattended at 20ÉC (68ÉF) for at least

10 minutes until the topcoated area is half-dry.

NOTE:

Be careful to keep dust or dirt from getting on

the affected area.

21 Top coat (II) Not required.Apply a clear coat three times at an interval of

3 to 5 minutes.

IRecommended paint:

SC710 Overlay Clear

No. 307 Flex Hardener

SC Reducer (thinner)

IMixing ratio:3:1

Suncryl (SC) vs. No. 307 Flex Hardener

IViscosity: 10 Ð 13 sec/20ÉC (68ÉF)

ICoated film thickness: 20 Ð 30

ISpraying pressure: 245 Ð 343 kPa

(2.5 Ð 3.5 kg/cm

2, 36 Ð 50 psi)

22 DryingAllow the coated surface to dry at 20ÉC (68ÉF) for two hours or 60ÉC (140ÉF) for 30 minutes.

NOTE:

Do not allow the temperature to exceed 80ÉC (176ÉF) since this will deform the PP substrate.

23 Inspection Carefully check the condition of the repaired area.

24 Masking removal Remove masking tape applied in Process No. 11 and 13.

25 Parts installation Install parts on bumper in reverse order of removal.

26Bumper installa-

tionInstall bumper.

37

[W6C0]5-1SERVICE PROCEDURE

6. Repair Instructions for Colored PP Bumper

Page 278 of 345

3. Airbag Module

A: REMOVAL AND INSTALLATION

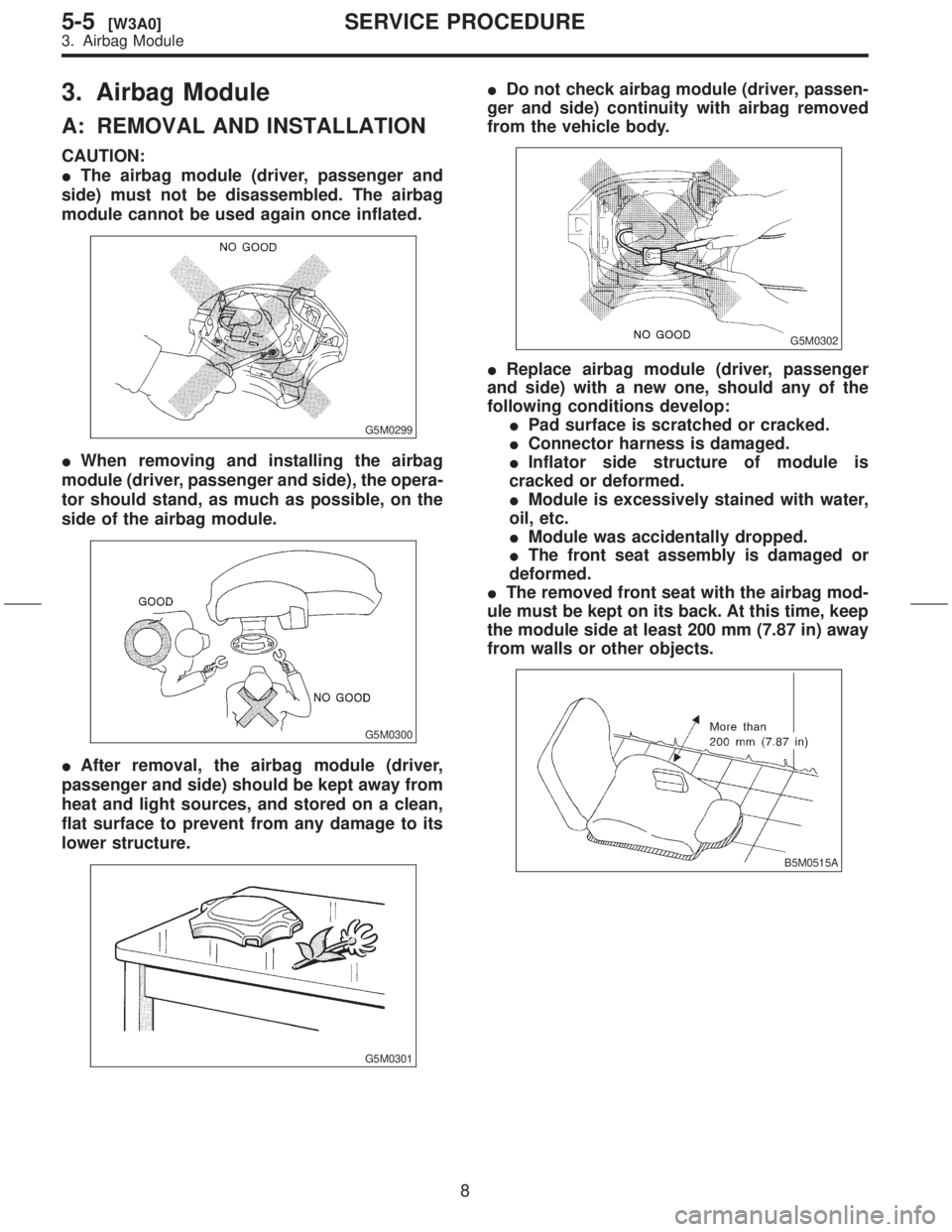

CAUTION:

IThe airbag module (driver, passenger and

side) must not be disassembled. The airbag

module cannot be used again once inflated.

G5M0299

IWhen removing and installing the airbag

module (driver, passenger and side), the opera-

tor should stand, as much as possible, on the

side of the airbag module.

G5M0300

IAfter removal, the airbag module (driver,

passenger and side) should be kept away from

heat and light sources, and stored on a clean,

flat surface to prevent from any damage to its

lower structure.

G5M0301

IDo not check airbag module (driver, passen-

ger and side) continuity with airbag removed

from the vehicle body.

G5M0302

IReplace airbag module (driver, passenger

and side) with a new one, should any of the

following conditions develop:

IPad surface is scratched or cracked.

IConnector harness is damaged.

IInflator side structure of module is

cracked or deformed.

IModule is excessively stained with water,

oil, etc.

IModule was accidentally dropped.

IThe front seat assembly is damaged or

deformed.

IThe removed front seat with the airbag mod-

ule must be kept on its back. At this time, keep

the module side at least 200 mm (7.87 in) away

from walls or other objects.

B5M0515A

8

5-5[W3A0]SERVICE PROCEDURE

3. Airbag Module

Page 279 of 345

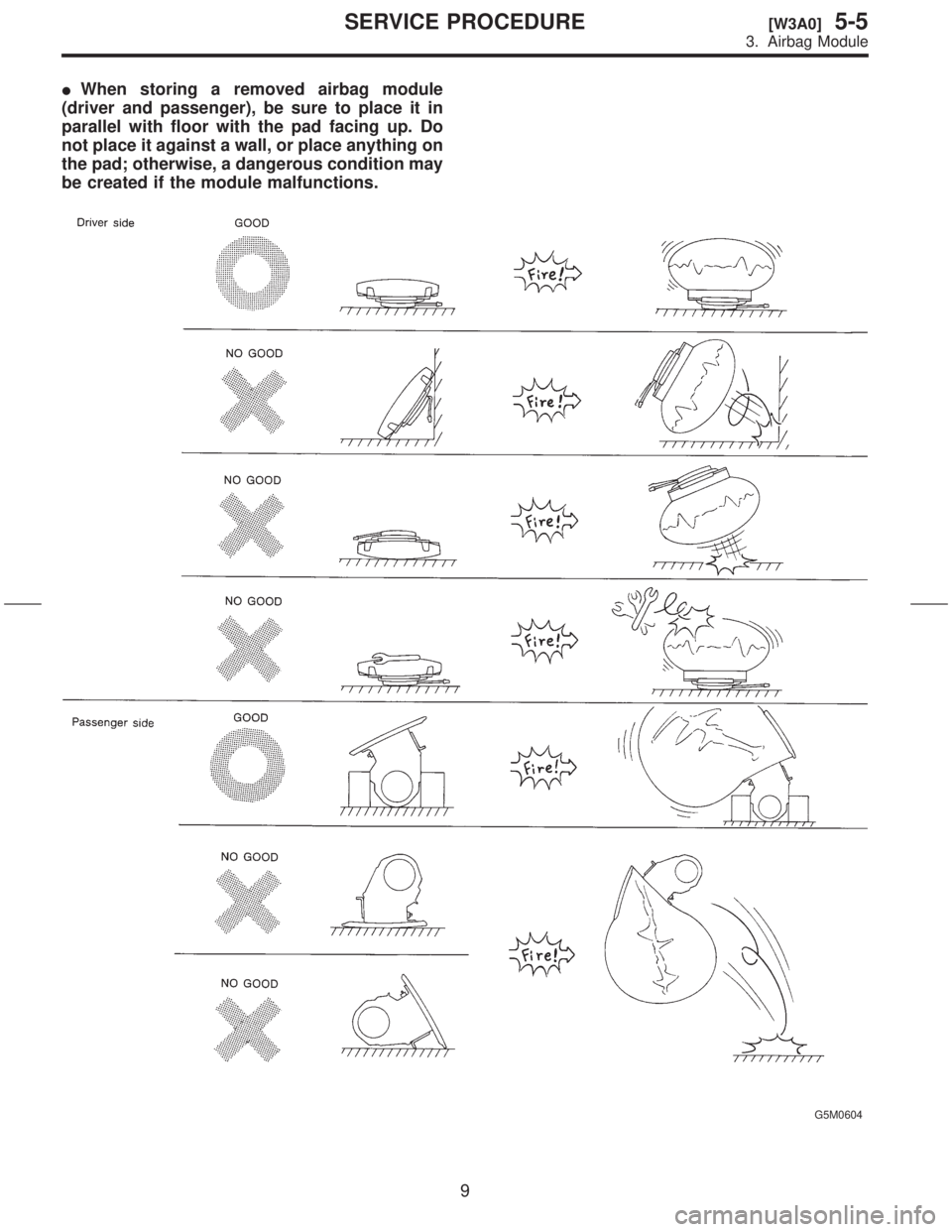

IWhen storing a removed airbag module

(driver and passenger), be sure to place it in

parallel with floor with the pad facing up. Do

not place it against a wall, or place anything on

the pad; otherwise, a dangerous condition may

be created if the module malfunctions.

G5M0604

9

[W3A0]5-5SERVICE PROCEDURE

3. Airbag Module

Page 303 of 345

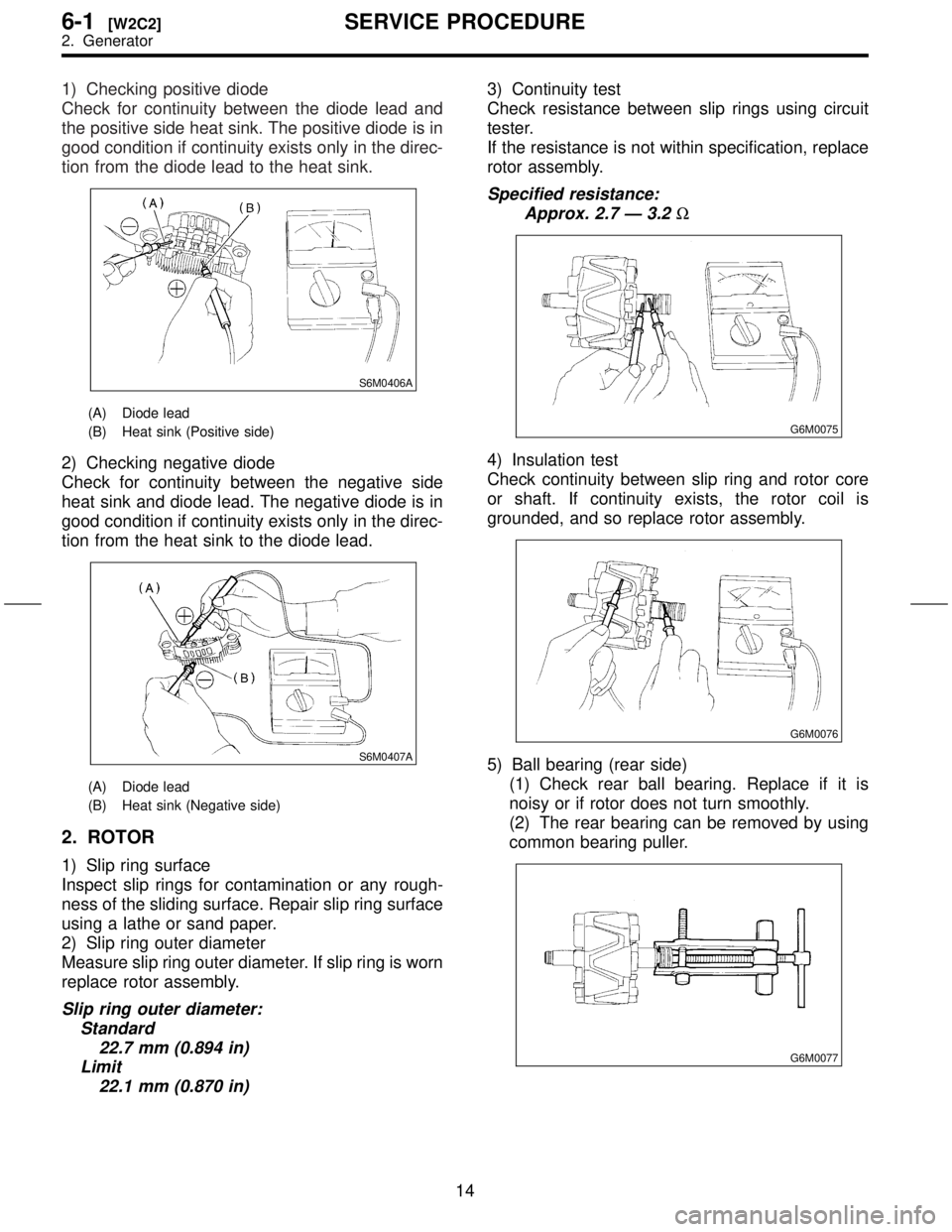

1) Checking positive diode

Check for continuity between the diode lead and

the positive side heat sink. The positive diode is in

good condition if continuity exists only in the direc-

tion from the diode lead to the heat sink.

S6M0406A

(A) Diode lead

(B) Heat sink (Positive side)

2) Checking negative diode

Check for continuity between the negative side

heat sink and diode lead. The negative diode is in

good condition if continuity exists only in the direc-

tion from the heat sink to the diode lead.

S6M0407A

(A) Diode lead

(B) Heat sink (Negative side)

2. ROTOR

1) Slip ring surface

Inspect slip rings for contamination or any rough-

ness of the sliding surface. Repair slip ring surface

using a lathe or sand paper.

2) Slip ring outer diameter

Measure slip ring outer diameter. If slip ring is worn

replace rotor assembly.

Slip ring outer diameter:

Standard

22.7 mm (0.894 in)

Limit

22.1 mm (0.870 in)

3) Continuity test

Check resistance between slip rings using circuit

tester.

If the resistance is not within specification, replace

rotor assembly.

Specified resistance:

Approx. 2.7 Ð 3.2

W

G6M0075

4) Insulation test

Check continuity between slip ring and rotor core

or shaft. If continuity exists, the rotor coil is

grounded, and so replace rotor assembly.

G6M0076

5) Ball bearing (rear side)

(1) Check rear ball bearing. Replace if it is

noisy or if rotor does not turn smoothly.

(2) The rear bearing can be removed by using

common bearing puller.

G6M0077

14

6-1[W2C2]SERVICE PROCEDURE

2. Generator

Page 310 of 345

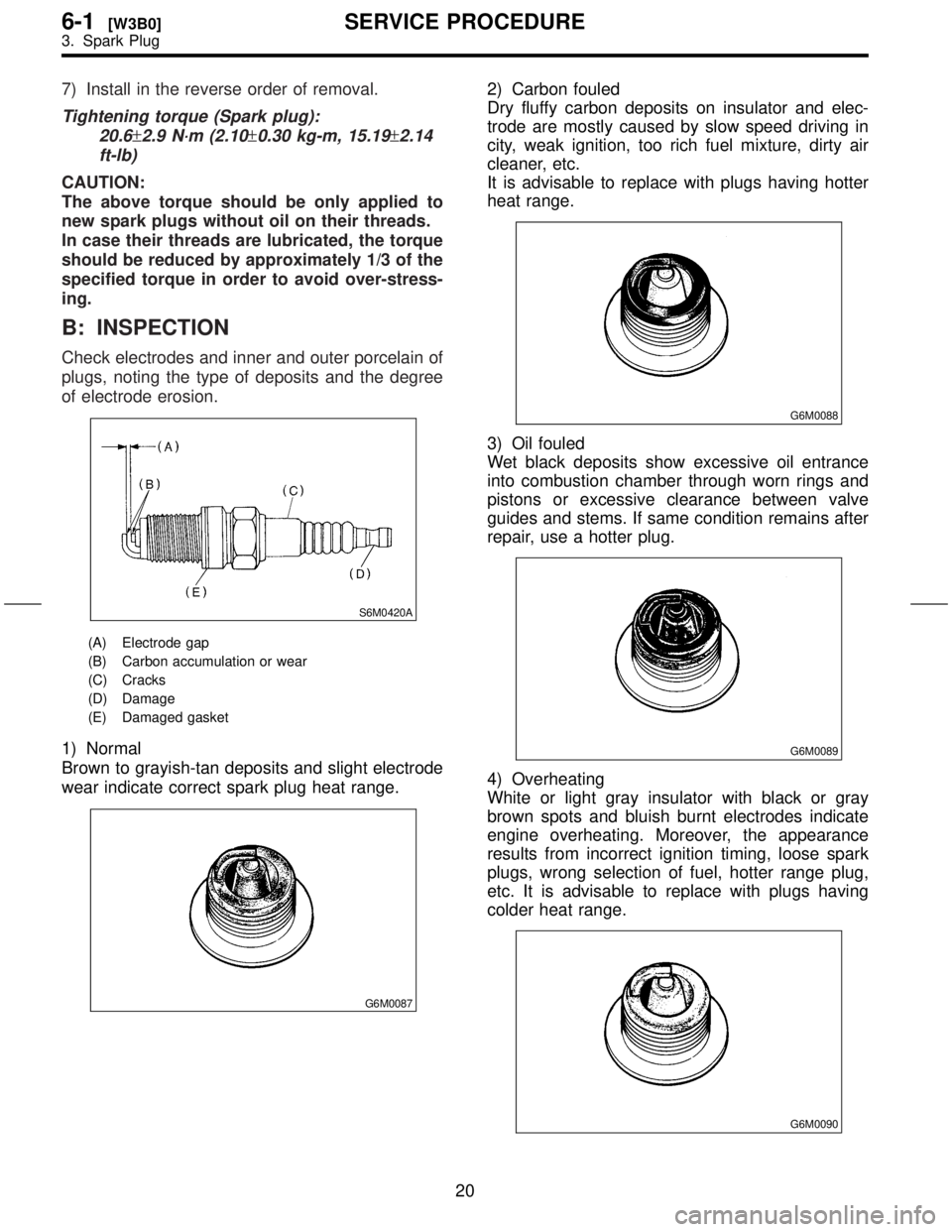

7) Install in the reverse order of removal.

Tightening torque (Spark plug):

20.6

±2.9 N´m (2.10±0.30 kg-m, 15.19±2.14

ft-lb)

CAUTION:

The above torque should be only applied to

new spark plugs without oil on their threads.

In case their threads are lubricated, the torque

should be reduced by approximately 1/3 of the

specified torque in order to avoid over-stress-

ing.

B: INSPECTION

Check electrodes and inner and outer porcelain of

plugs, noting the type of deposits and the degree

of electrode erosion.

S6M0420A

(A) Electrode gap

(B) Carbon accumulation or wear

(C) Cracks

(D) Damage

(E) Damaged gasket

1) Normal

Brown to grayish-tan deposits and slight electrode

wear indicate correct spark plug heat range.

G6M0087

2) Carbon fouled

Dry fluffy carbon deposits on insulator and elec-

trode are mostly caused by slow speed driving in

city, weak ignition, too rich fuel mixture, dirty air

cleaner, etc.

It is advisable to replace with plugs having hotter

heat range.

G6M0088

3) Oil fouled

Wet black deposits show excessive oil entrance

into combustion chamber through worn rings and

pistons or excessive clearance between valve

guides and stems. If same condition remains after

repair, use a hotter plug.

G6M0089

4) Overheating

White or light gray insulator with black or gray

brown spots and bluish burnt electrodes indicate

engine overheating. Moreover, the appearance

results from incorrect ignition timing, loose spark

plugs, wrong selection of fuel, hotter range plug,

etc. It is advisable to replace with plugs having

colder heat range.

G6M0090

20

6-1[W3B0]SERVICE PROCEDURE

3. Spark Plug