torque SUBARU FORESTER 2004 Service Owners Manual

[x] Cancel search | Manufacturer: SUBARU, Model Year: 2004, Model line: FORESTER, Model: SUBARU FORESTER 2004Pages: 2870, PDF Size: 38.67 MB

Page 779 of 2870

PM-42

PERIODIC MAINTENANCE SERVICE

Steering System (Power Steering)

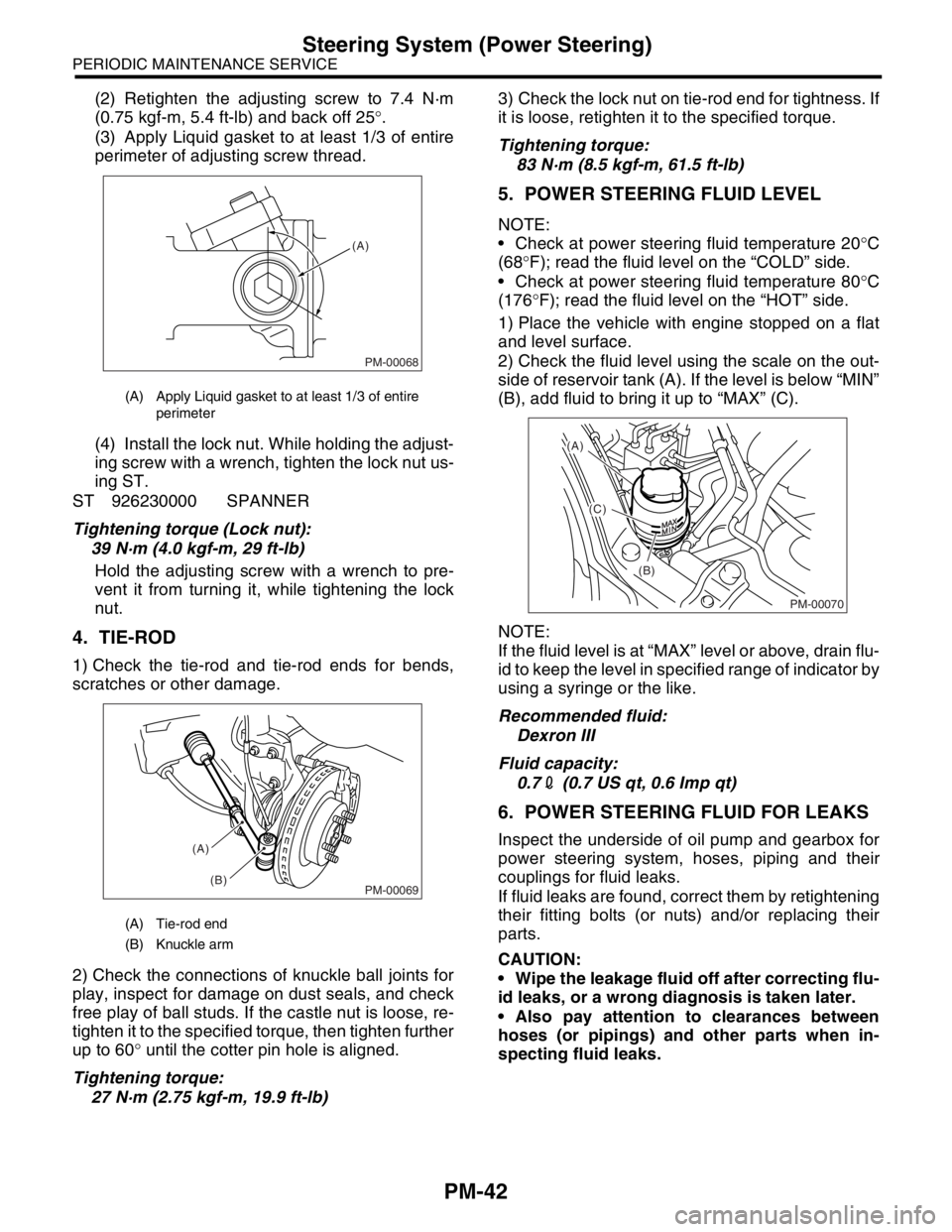

(2) Retighten the adjusting screw to 7.4 N·m

(0.75 kgf-m, 5.4 ft-lb) and back off 25°.

(3) Apply Liquid gasket to at least 1/3 of entire

perimeter of adjusting screw thread.

(4) Install the lock nut. While holding the adjust-

ing screw with a wrench, tighten the lock nut us-

ing ST.

ST 926230000 SPANNER

Tightening torque (Lock nut):

39 N·m (4.0 kgf-m, 29 ft-lb)

Hold the adjusting screw with a wrench to pre-

vent it from turning it, while tightening the lock

nut.

4. TIE-ROD

1) Check the tie-rod and tie-rod ends for bends,

scratches or other damage.

2) Check the connections of knuckle ball joints for

play, inspect for damage on dust seals, and check

free play of ball studs. If the castle nut is loose, re-

tighten it to the specified torque, then tighten further

up to 60° until the cotter pin hole is aligned.

Tightening torque:

27 N·m (2.75 kgf-m, 19.9 ft-lb)3) Check the lock nut on tie-rod end for tightness. If

it is loose, retighten it to the specified torque.

Tightening torque:

83 N·m (8.5 kgf-m, 61.5 ft-lb)

5. POWER STEERING FLUID LEVEL

NOTE:

Check at power steering fluid temperature 20°C

(68°F); read the fluid level on the “COLD” side.

Check at power steering fluid temperature 80°C

(176°F); read the fluid level on the “HOT” side.

1) Place the vehicle with engine stopped on a flat

and level surface.

2) Check the fluid level using the scale on the out-

side of reservoir tank (A). If the level is below “MIN”

(B), add fluid to bring it up to “MAX” (C).

NOTE:

If the fluid level is at “MAX” level or above, drain flu-

id to keep the level in specified range of indicator by

using a syringe or the like.

Recommended fluid:

Dexron III

Fluid capacity:

0.72 (0.7 US qt, 0.6 Imp qt)

6. POWER STEERING FLUID FOR LEAKS

Inspect the underside of oil pump and gearbox for

power steering system, hoses, piping and their

couplings for fluid leaks.

If fluid leaks are found, correct them by retightening

their fitting bolts (or nuts) and/or replacing their

parts.

CAUTION:

Wipe the leakage fluid off after correcting flu-

id leaks, or a wrong diagnosis is taken later.

Also pay attention to clearances between

hoses (or pipings) and other parts when in-

specting fluid leaks.

(A) Apply Liquid gasket to at least 1/3 of entire

perimeter

(A) Tie-rod end

(B) Knuckle arm

PM-00068

(A)

PM-00069

(A)

(B)

PM-00070

(A)

(C)

(B)

Page 786 of 2870

FU(H4SO)-4

FUEL INJECTION (FUEL SYSTEM)

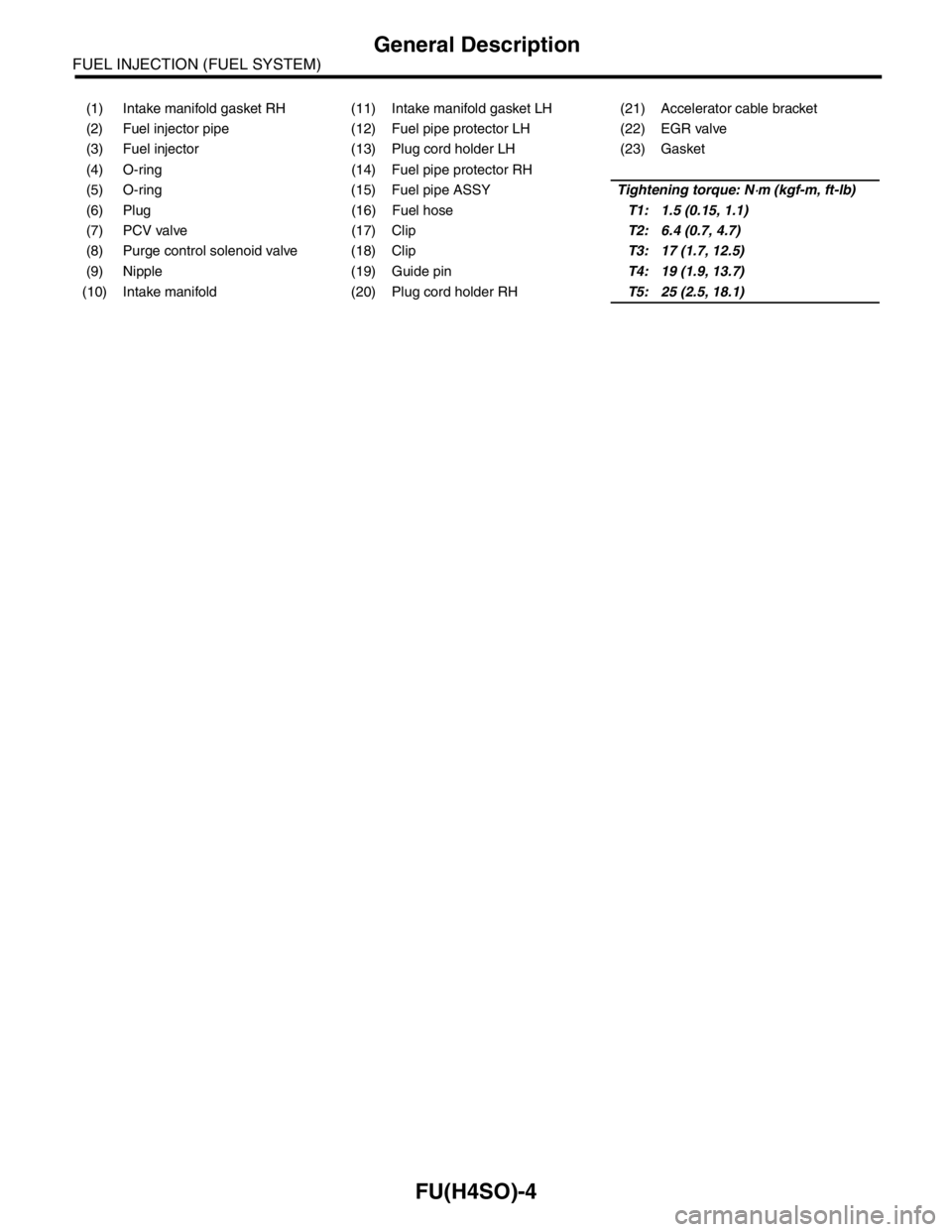

General Description

(1) Intake manifold gasket RH (11) Intake manifold gasket LH (21) Accelerator cable bracket

(2) Fuel injector pipe (12) Fuel pipe protector LH (22) EGR valve

(3) Fuel injector (13) Plug cord holder LH (23) Gasket

(4) O-ring (14) Fuel pipe protector RH

(5) O-ring (15) Fuel pipe ASSYTightening torque: N

⋅m (kgf-m, ft-lb)

(6) Plug (16) Fuel hoseT1: 1.5 (0.15, 1.1)

(7) PCV valve (17) ClipT2: 6.4 (0.7, 4.7)

(8) Purge control solenoid valve (18) ClipT3: 17 (1.7, 12.5)

(9) Nipple (19) Guide pinT4: 19 (1.9, 13.7)

(10) Intake manifold (20) Plug cord holder RHT5: 25 (2.5, 18.1)

Page 787 of 2870

FU(H4SO)-5

FUEL INJECTION (FUEL SYSTEM)

General Description

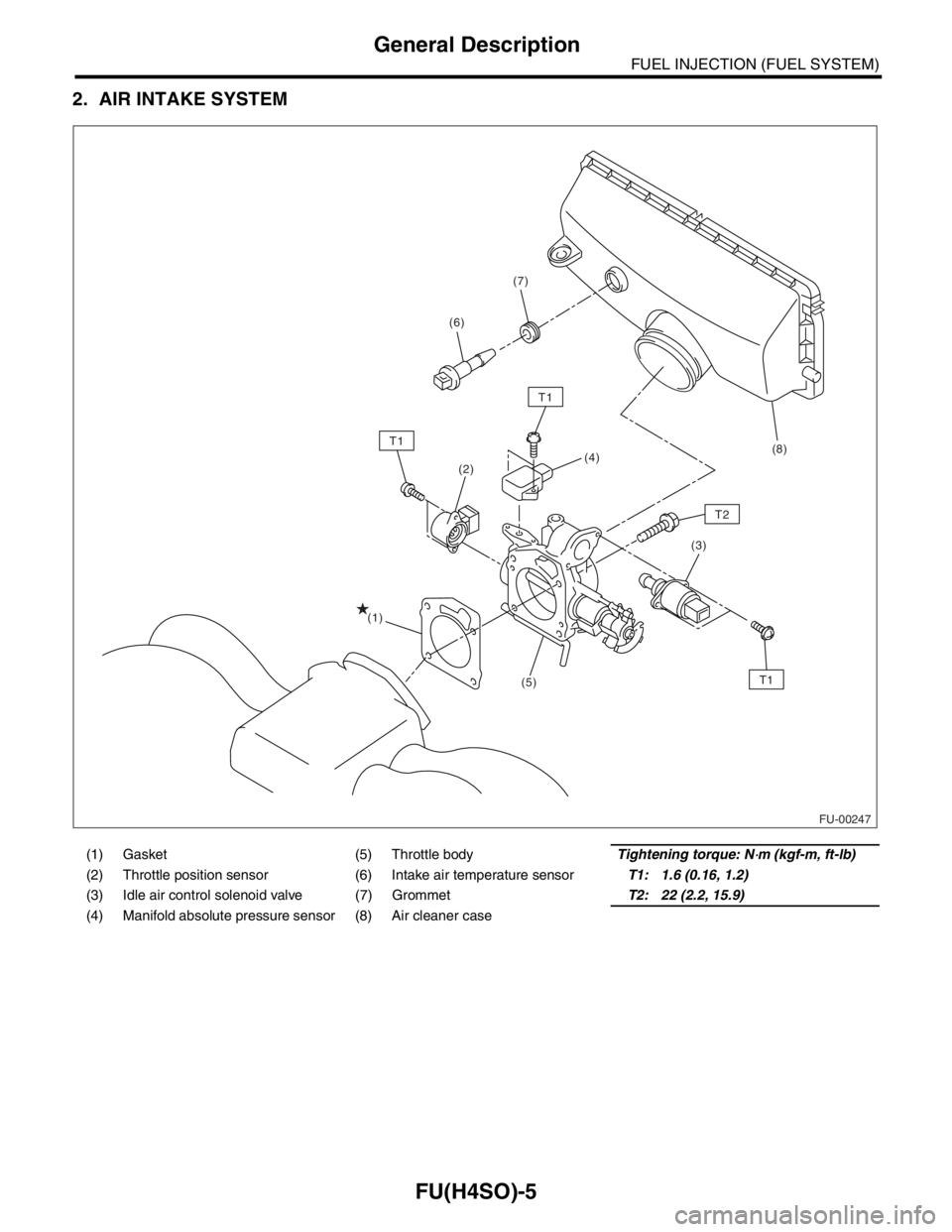

2. AIR INTAKE SYSTEM

(1) Gasket (5) Throttle bodyTightening torque: N⋅m (kgf-m, ft-lb)

(2) Throttle position sensor (6) Intake air temperature sensorT1: 1.6 (0.16, 1.2)

(3) Idle air control solenoid valve (7) GrommetT2: 22 (2.2, 15.9)

(4) Manifold absolute pressure sensor (8) Air cleaner case

FU-00247

(2)

(3) (4)

(5) (1)

T1

T1

T1

T2

(8) (6)(7)

Page 788 of 2870

FU(H4SO)-6

FUEL INJECTION (FUEL SYSTEM)

General Description

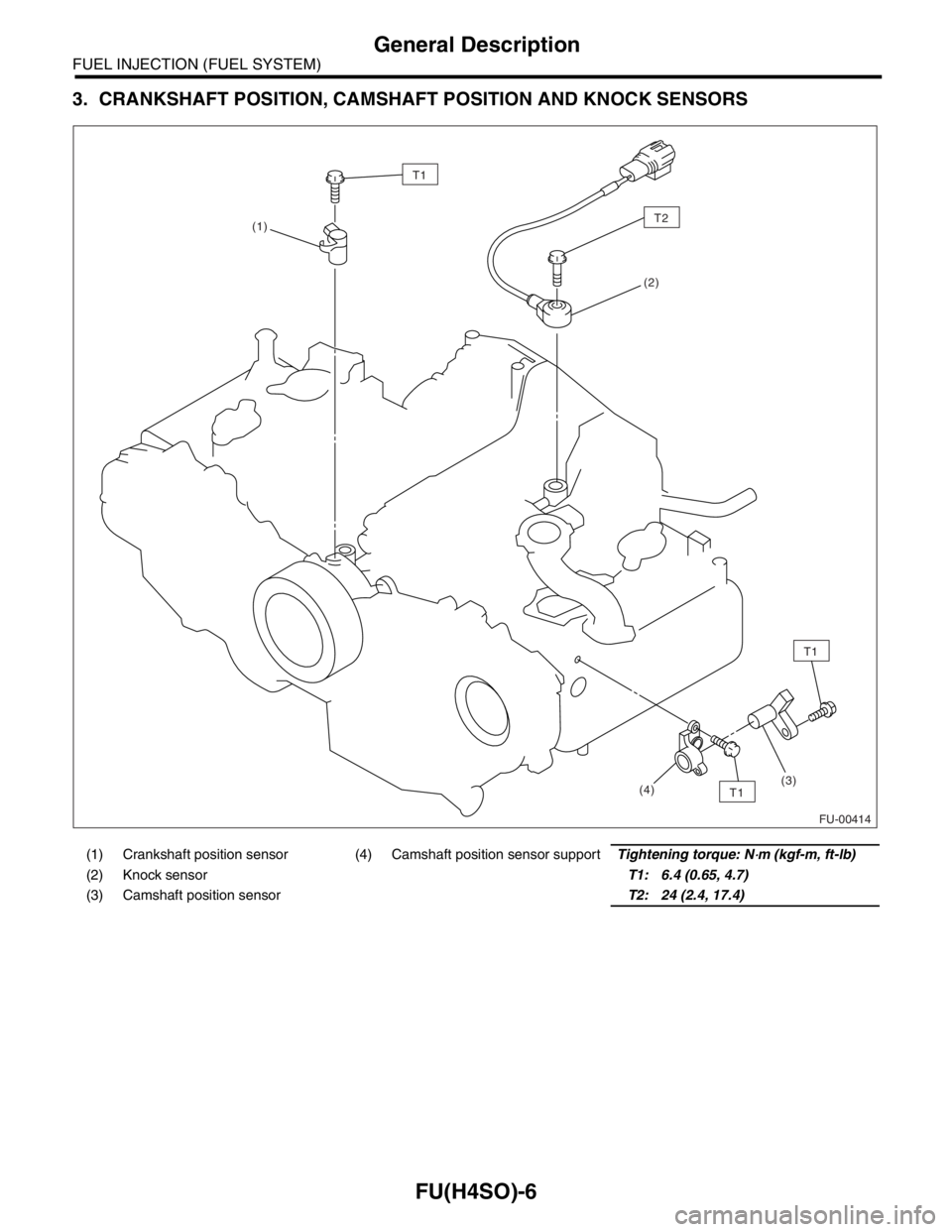

3. CRANKSHAFT POSITION, CAMSHAFT POSITION AND KNOCK SENSORS

(1) Crankshaft position sensor (4) Camshaft position sensor supportTightening torque: N⋅m (kgf-m, ft-lb)

(2) Knock sensorT1: 6.4 (0.65, 4.7)

(3) Camshaft position sensorT2: 24 (2.4, 17.4)

FU-00414

T1

(1)

(2)

T1

T1(3)

(4)

T2

Page 790 of 2870

FU(H4SO)-8

FUEL INJECTION (FUEL SYSTEM)

General Description

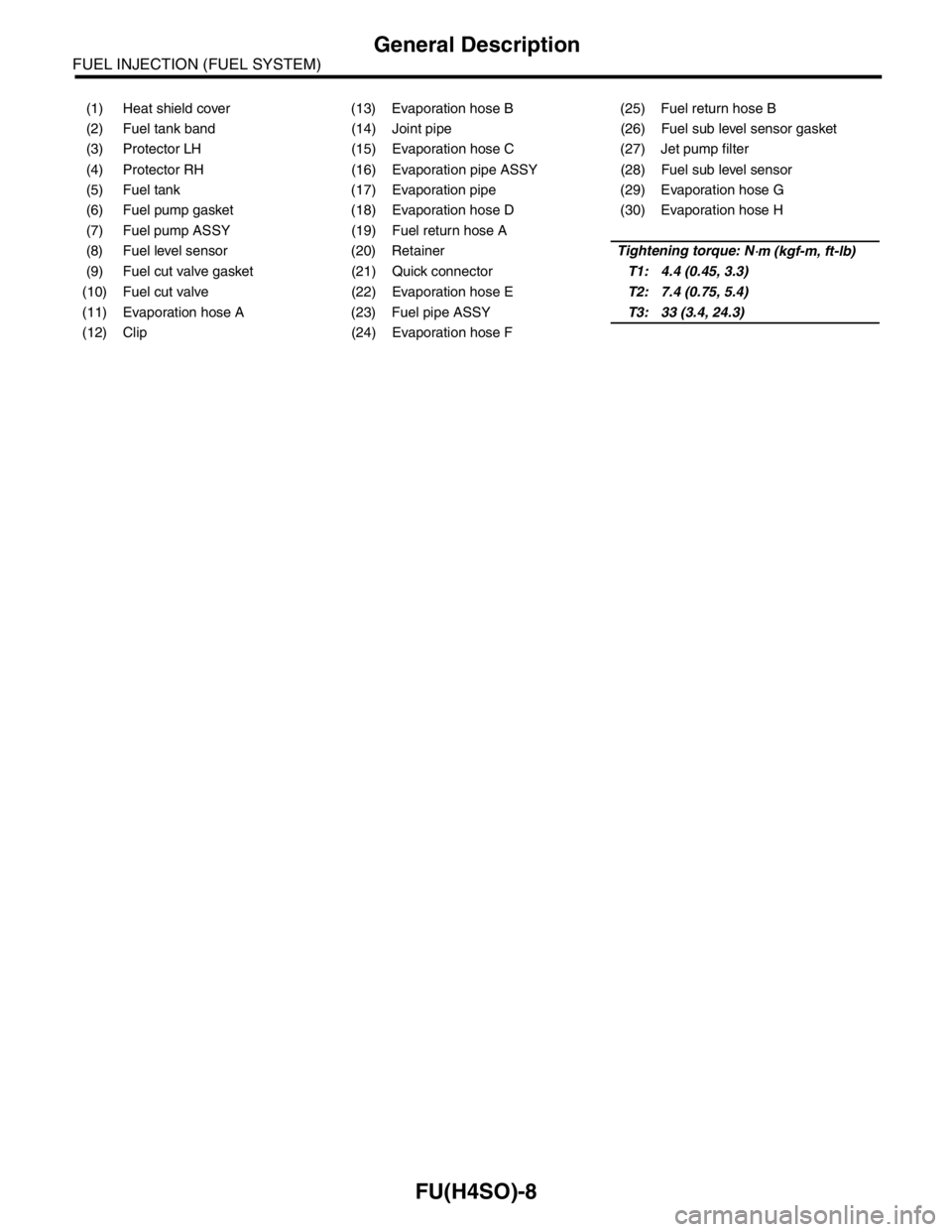

(1) Heat shield cover (13) Evaporation hose B (25) Fuel return hose B

(2) Fuel tank band (14) Joint pipe (26) Fuel sub level sensor gasket

(3) Protector LH (15) Evaporation hose C (27) Jet pump filter

(4) Protector RH (16) Evaporation pipe ASSY (28) Fuel sub level sensor

(5) Fuel tank (17) Evaporation pipe (29) Evaporation hose G

(6) Fuel pump gasket (18) Evaporation hose D (30) Evaporation hose H

(7) Fuel pump ASSY (19) Fuel return hose A

(8) Fuel level sensor (20) RetainerTightening torque: N

⋅m (kgf-m, ft-lb)

(9) Fuel cut valve gasket (21) Quick connectorT1: 4.4 (0.45, 3.3)

(10) Fuel cut valve (22) Evaporation hose ET2: 7.4 (0.75, 5.4)

(11) Evaporation hose A (23) Fuel pipe ASSYT3: 33 (3.4, 24.3)

(12) Clip (24) Evaporation hose F

Page 792 of 2870

FU(H4SO)-10

FUEL INJECTION (FUEL SYSTEM)

General Description

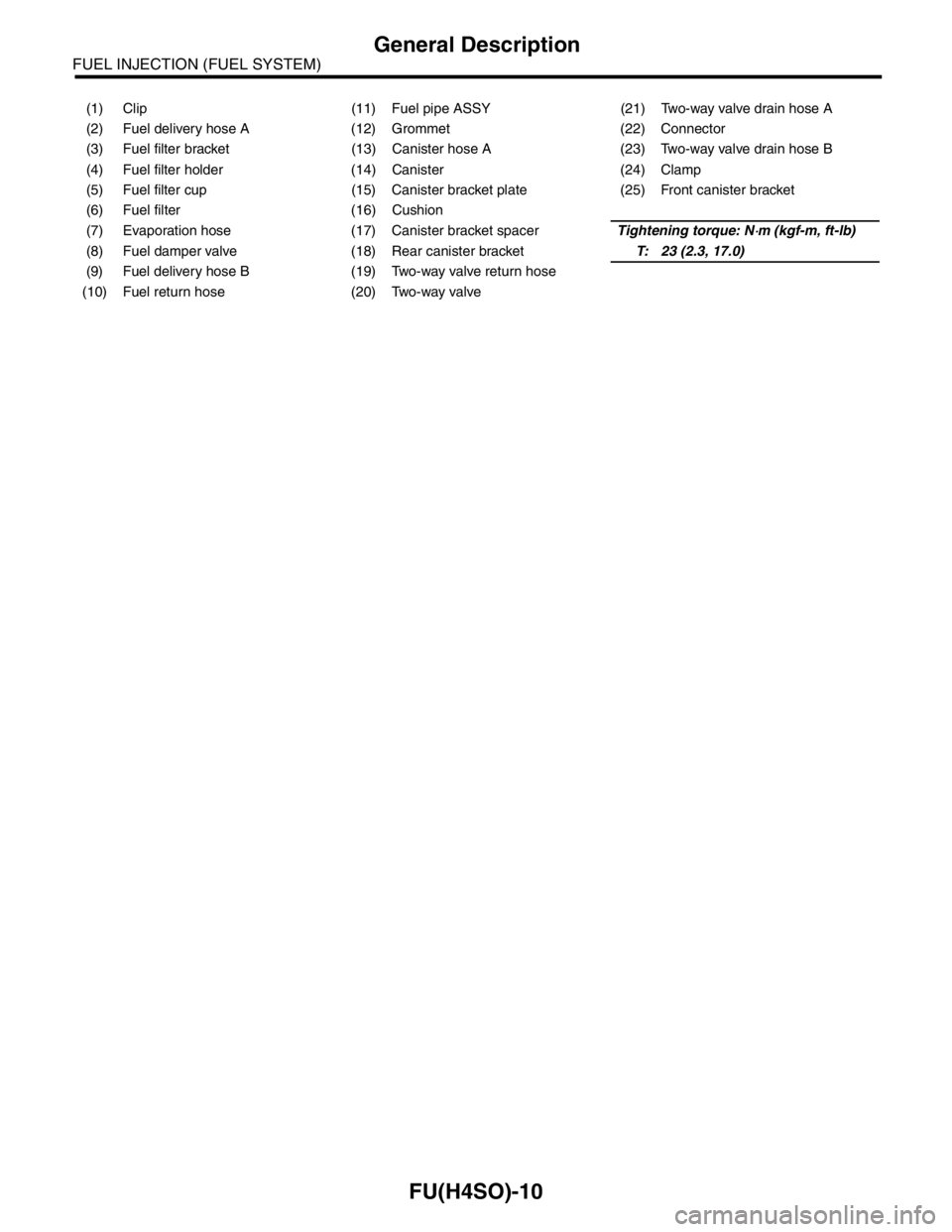

(1) Clip (11) Fuel pipe ASSY (21) Two-way valve drain hose A

(2) Fuel delivery hose A (12) Grommet (22) Connector

(3) Fuel filter bracket (13) Canister hose A (23) Two-way valve drain hose B

(4) Fuel filter holder (14) Canister (24) Clamp

(5) Fuel filter cup (15) Canister bracket plate (25) Front canister bracket

(6) Fuel filter (16) Cushion

(7) Evaporation hose (17) Canister bracket spacerTightening torque: N

⋅m (kgf-m, ft-lb)

(8) Fuel damper valve (18) Rear canister bracketT: 23 (2.3, 17.0)

(9) Fuel deliver y hose B (19) Two-way valve return hose

(10) Fuel return hose (20) Two-way valve

Page 793 of 2870

FU(H4SO)-11

FUEL INJECTION (FUEL SYSTEM)

General Description

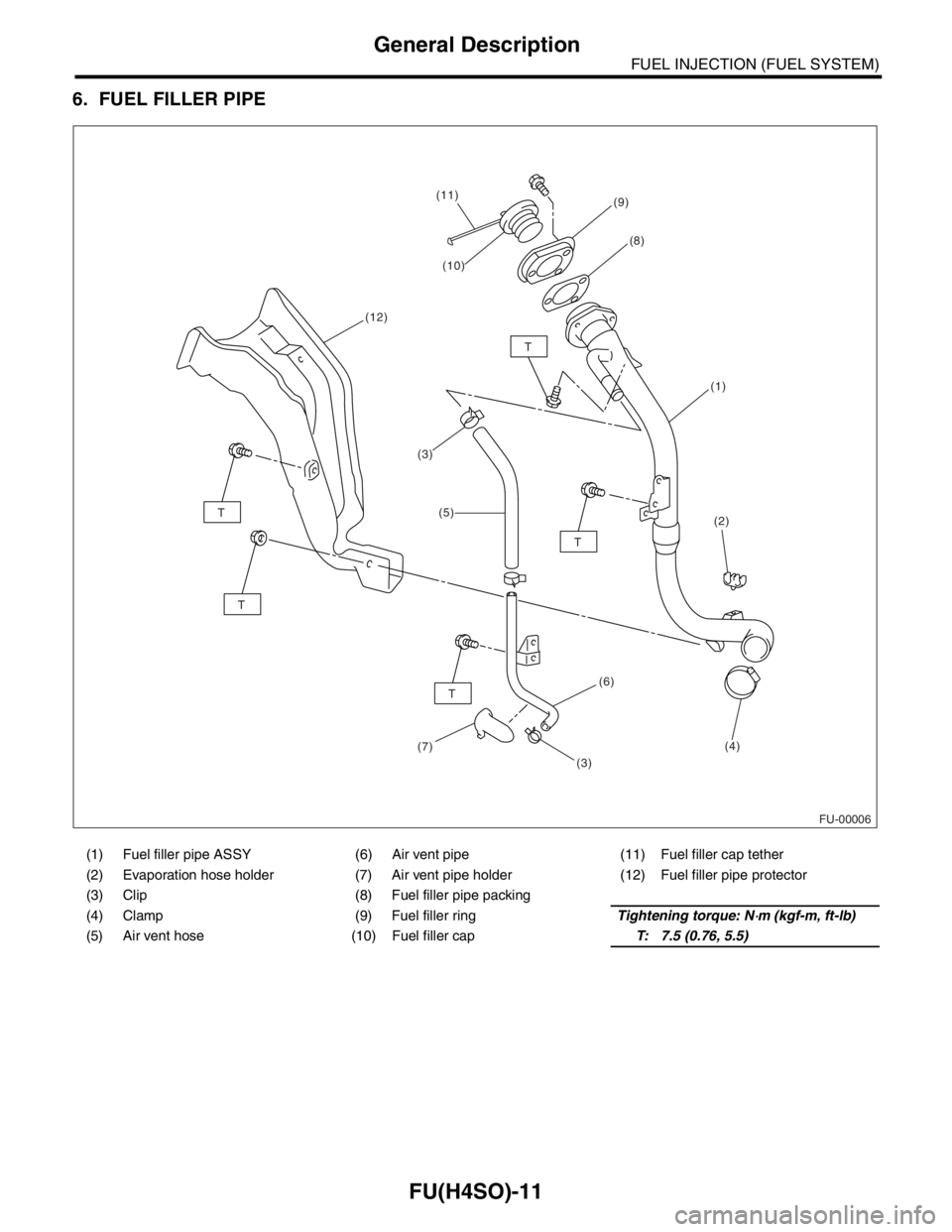

6. FUEL FILLER PIPE

(1) Fuel filler pipe ASSY (6) Air vent pipe (11) Fuel filler cap tether

(2) Evaporation hose holder (7) Air vent pipe holder (12) Fuel filler pipe protector

(3) Clip (8) Fuel filler pipe packing

(4) Clamp (9) Fuel filler ringTightening torque: N

⋅m (kgf-m, ft-lb)

(5) Air vent hose (10) Fuel filler capT: 7.5 (0.76, 5.5)

FU-00006

(4)

(2)

(8)

(1)

(12)(11)

(6)

(7)

(9)

(10)

(5)

(3)

(3)

T

T

T

T

T

Page 794 of 2870

FU(H4SO)-12

FUEL INJECTION (FUEL SYSTEM)

General Description

C: CAUTION

Wear working clothing, including a cap, protec-

tive goggles, and protective shoes during opera-

tion.

Remove contamination including dirt and corro-

sion before removal, installation or disassembly.

Keep the disassembled parts in order and pro-

tect them from dust or dirt.

Before removal, installation or disassembly, be

sure to clarify the failure. Avoid unnecessary re-

moval, installation, disassembly, and replacement. Be careful not to burn yourself, because each

part on the vehicle is hot after running.

Be sure to tighten fasteners including bolts and

nuts to the specified torque.

Place shop jacks or rigid racks at the specified

points.

Before disconnecting electrical connectors of

sensors or units, be sure to disconnect negative

terminal from battery.

Place “NO FIRE” signs near the working area.

Be careful not to spill fuel on the floor.

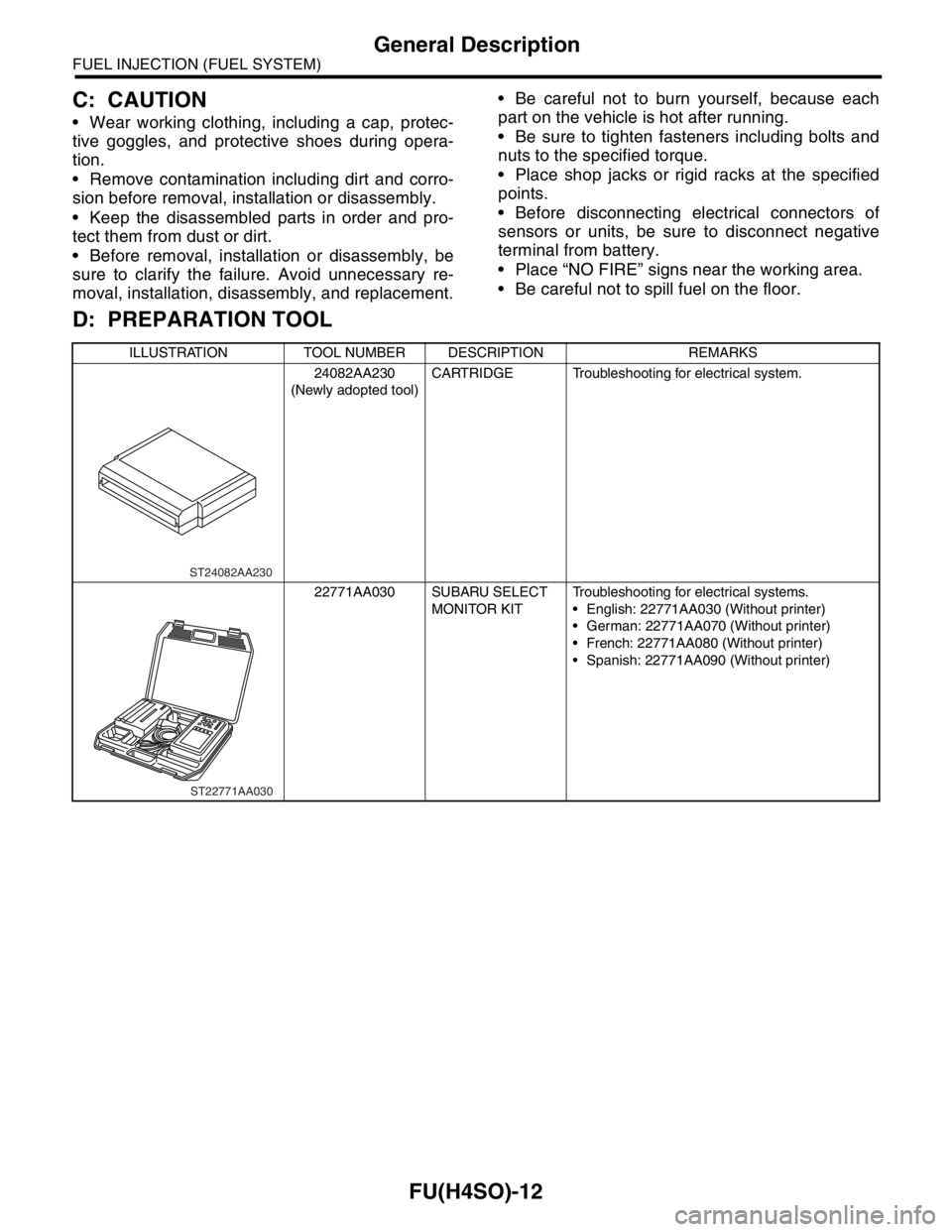

D: PREPARATION TOOL

ILLUSTRATION TOOL NUMBER DESCRIPTION REMARKS

24082AA230

(Newly adopted tool)CARTRIDGE Troubleshooting for electrical system.

22771AA030 SUBARU SELECT

MONITOR KITTroubleshooting for electrical systems.

English: 22771AA030 (Without printer)

German: 22771AA070 (Without printer)

French: 22771AA080 (Without printer)

Spanish: 22771AA090 (Without printer)

ST24082AA230

ST22771AA030

Page 795 of 2870

FU(H4SO)-13

FUEL INJECTION (FUEL SYSTEM)

Throttle Body

2. Throttle Body

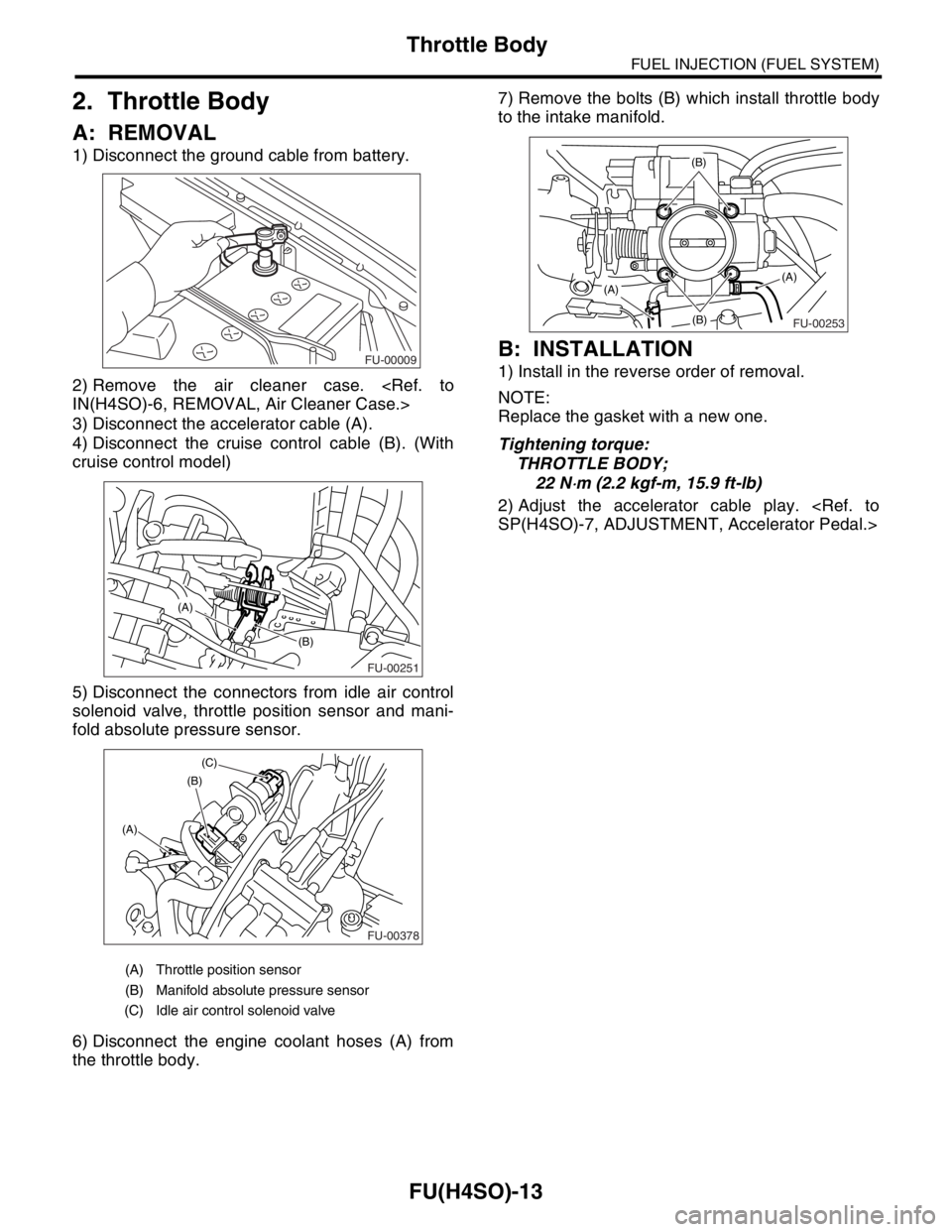

A: REMOVAL

1) Disconnect the ground cable from battery.

2) Remove the air cleaner case.

3) Disconnect the accelerator cable (A).

4) Disconnect the cruise control cable (B). (With

cruise control model)

5) Disconnect the connectors from idle air control

solenoid valve, throttle position sensor and mani-

fold absolute pressure sensor.

6) Disconnect the engine coolant hoses (A) from

the throttle body.7) Remove the bolts (B) which install throttle body

to the intake manifold.

B: INSTALLATION

1) Install in the reverse order of removal.

NOTE:

Replace the gasket with a new one.

Tightening torque:

THROTTLE BODY;

22 N

⋅m (2.2 kgf-m, 15.9 ft-lb)

2) Adjust the accelerator cable play.

(A) Throttle position sensor

(B) Manifold absolute pressure sensor

(C) Idle air control solenoid valve

FU-00009

FU-00251

(B)

(A)

FU-00378

(B)

(A)(C)

FU-00253

(B)

(B)

(A)(A)

Page 798 of 2870

FU(H4SO)-16

FUEL INJECTION (FUEL SYSTEM)

Intake Manifold

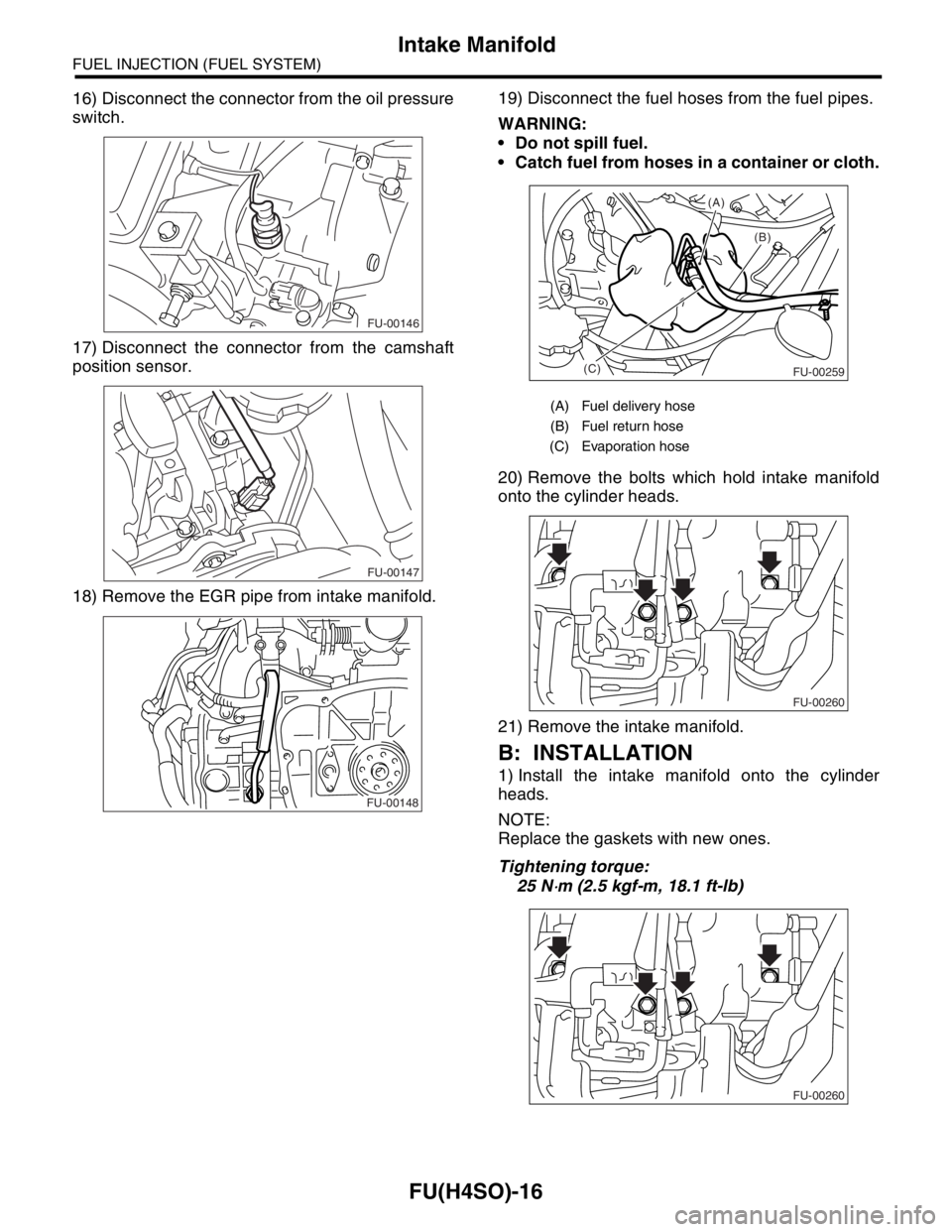

16) Disconnect the connector from the oil pressure

switch.

17) Disconnect the connector from the camshaft

position sensor.

18) Remove the EGR pipe from intake manifold.19) Disconnect the fuel hoses from the fuel pipes.

WARNING:

Do not spill fuel.

Catch fuel from hoses in a container or cloth.

20) Remove the bolts which hold intake manifold

onto the cylinder heads.

21) Remove the intake manifold.

B: INSTALLATION

1) Install the intake manifold onto the cylinder

heads.

NOTE:

Replace the gaskets with new ones.

Tightening torque:

25 N

⋅m (2.5 kgf-m, 18.1 ft-lb)

FU-00146

FU-00147

FU-00148

(A) Fuel delivery hose

(B) Fuel return hose

(C) Evaporation hose

(B) (A)

(C)

FU-00259

FU-00260

FU-00260