torque SUBARU FORESTER 2004 Service Manual PDF

[x] Cancel search | Manufacturer: SUBARU, Model Year: 2004, Model line: FORESTER, Model: SUBARU FORESTER 2004Pages: 2870, PDF Size: 38.67 MB

Page 548 of 2870

EB-18

EXTERIOR BODY PANEL

Rear Gate Panel

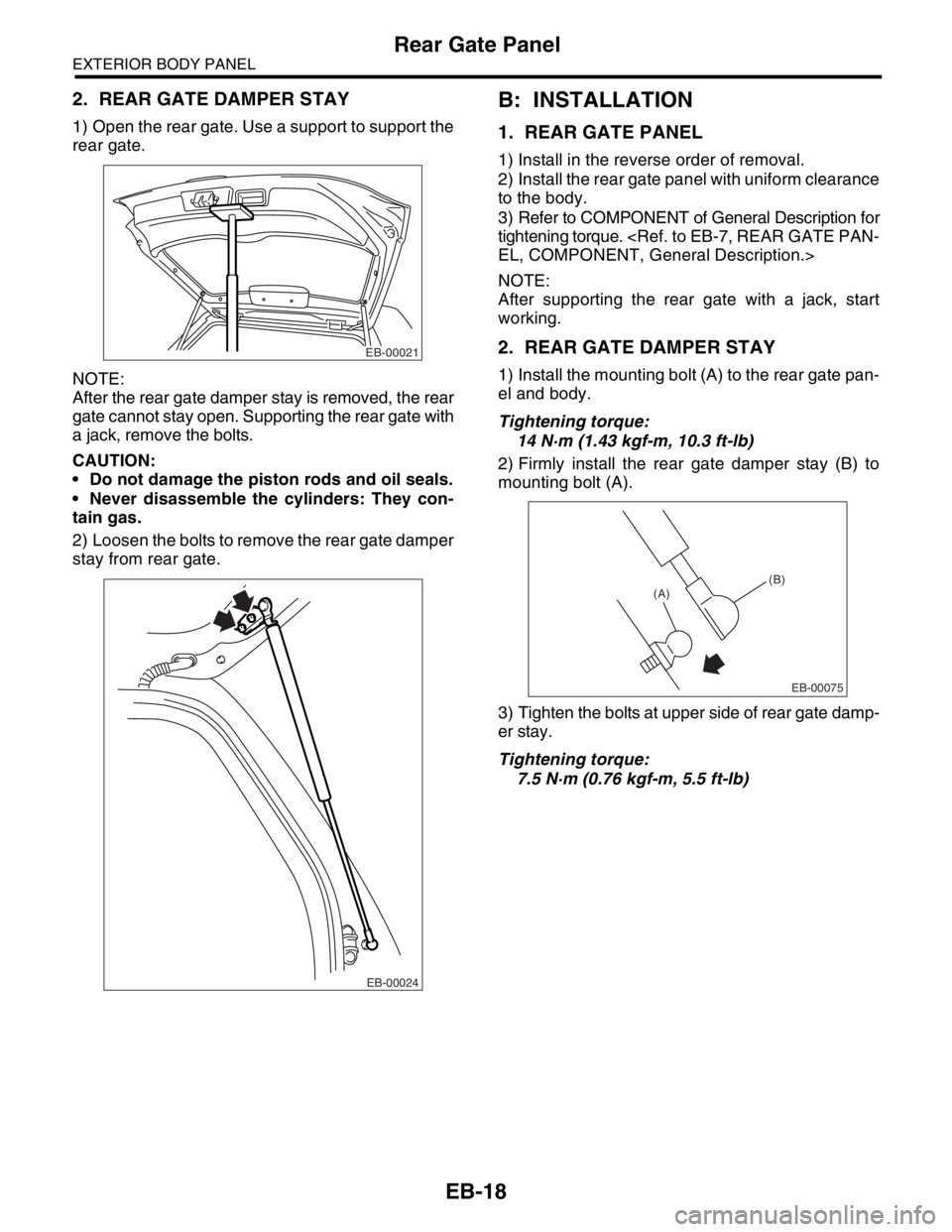

2. REAR GATE DAMPER STAY

1) Open the rear gate. Use a support to support the

rear gate.

NOTE:

After the rear gate damper stay is removed, the rear

gate cannot stay open. Supporting the rear gate with

a jack, remove the bolts.

CAUTION:

Do not damage the piston rods and oil seals.

Never disassemble the cylinders: They con-

tain gas.

2) Loosen the bolts to remove the rear gate damper

stay from rear gate.

B: INSTALLATION

1. REAR GATE PANEL

1) Install in the reverse order of removal.

2) Install the rear gate panel with uniform clearance

to the body.

3) Refer to COMPONENT of General Description for

tightening torque.

NOTE:

After supporting the rear gate with a jack, start

working.

2. REAR GATE DAMPER STAY

1) Install the mounting bolt (A) to the rear gate pan-

el and body.

Tightening torque:

14 N·m (1.43 kgf-m, 10.3 ft-lb)

2) Firmly install the rear gate damper stay (B) to

mounting bolt (A).

3) Tighten the bolts at upper side of rear gate damp-

er stay.

Tightening torque:

7.5 N·m (0.76 kgf-m, 5.5 ft-lb)

EB-00021

EB-00024

(A)(B)

EB-00075

Page 557 of 2870

CC-5

CRUISE CONTROL SYSTEM

Actuator

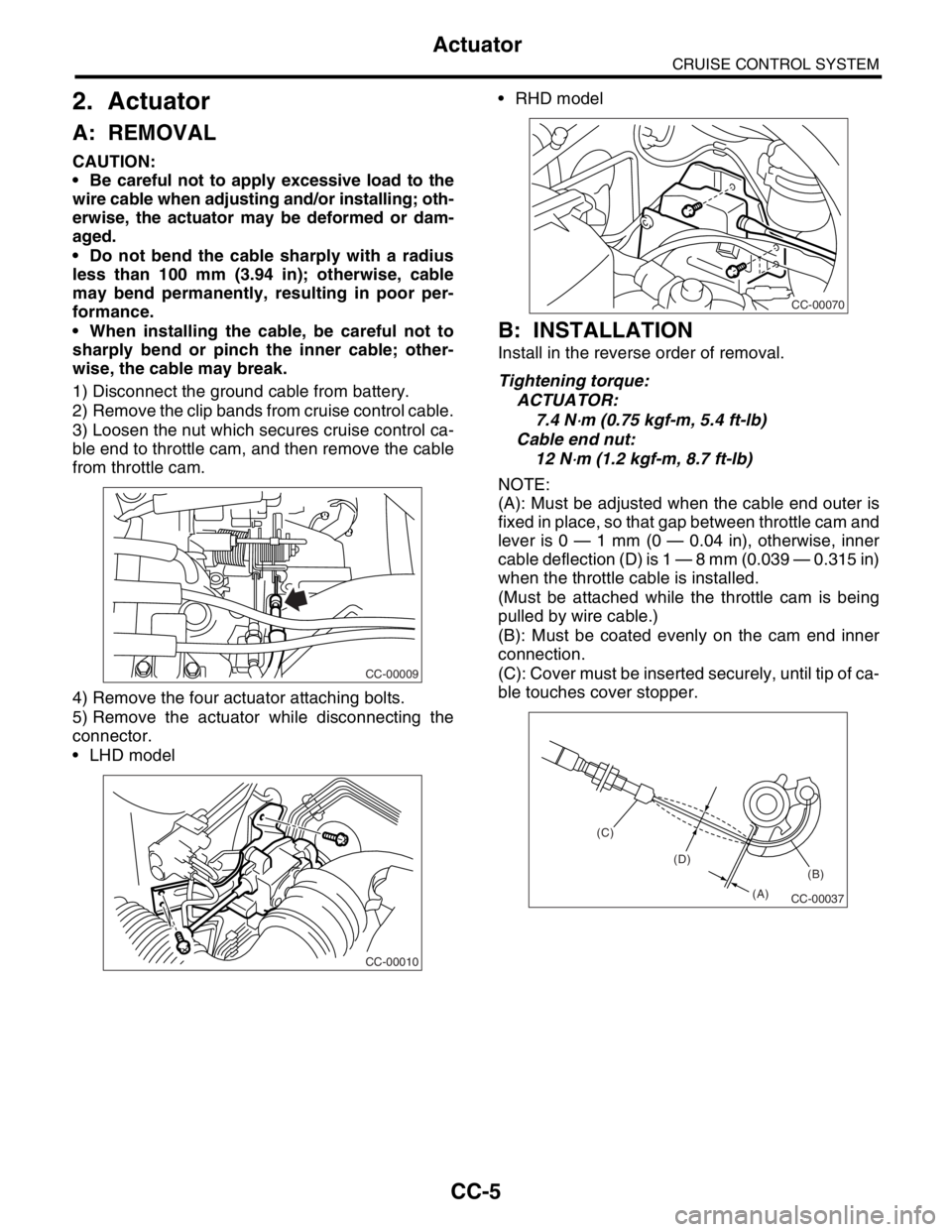

2. Actuator

A: REMOVAL

CAUTION:

Be careful not to apply excessive load to the

wire cable when adjusting and/or installing; oth-

erwise, the actuator may be deformed or dam-

aged.

Do not bend the cable sharply with a radius

less than 100 mm (3.94 in); otherwise, cable

may bend permanently, resulting in poor per-

formance.

When installing the cable, be careful not to

sharply bend or pinch the inner cable; other-

wise, the cable may break.

1) Disconnect the ground cable from battery.

2) Remove the clip bands from cruise control cable.

3) Loosen the nut which secures cruise control ca-

ble end to throttle cam, and then remove the cable

from throttle cam.

4) Remove the four actuator attaching bolts.

5) Remove the actuator while disconnecting the

connector.

LHD model RHD model

B: INSTALLATION

Install in the reverse order of removal.

Tightening torque:

ACTUATOR:

7.4 N

⋅m (0.75 kgf-m, 5.4 ft-lb)

Cable end nut:

12 N

⋅m (1.2 kgf-m, 8.7 ft-lb)

NOTE:

(A): Must be adjusted when the cable end outer is

fixed in place, so that gap between throttle cam and

lever is 0 — 1 mm (0 — 0.04 in), otherwise, inner

cable deflection (D) is 1 — 8 mm (0.039 — 0.315 in)

when the throttle cable is installed.

(Must be attached while the throttle cam is being

pulled by wire cable.)

(B): Must be coated evenly on the cam end inner

connection.

(C): Cover must be inserted securely, until tip of ca-

ble touches cover stopper.

CC-00009

CC-00010

CC-00070

CC-00037

(B)

(A) (D) (C)

Page 686 of 2870

HU-3

HOW TO USE THIS MANUAL

How to Use This Manual

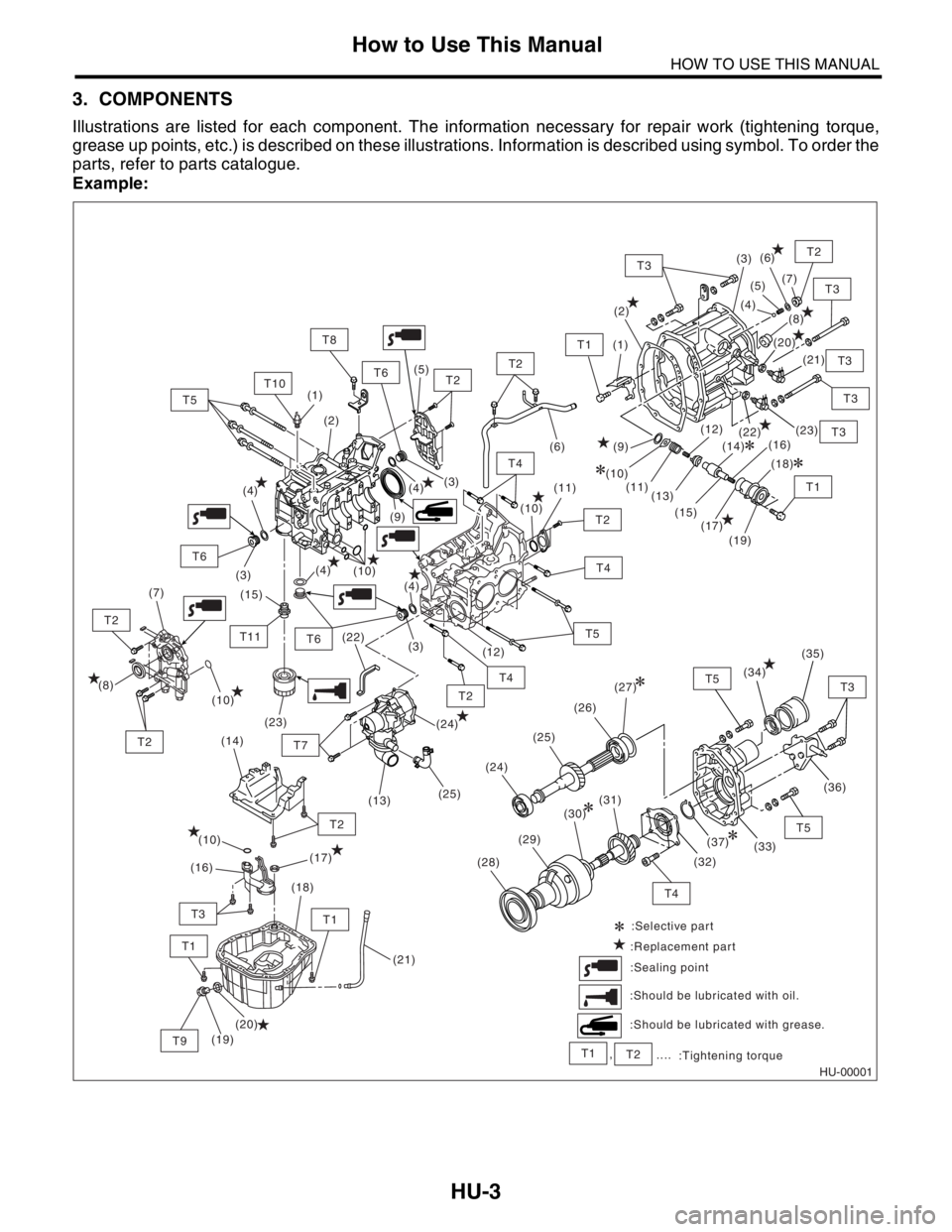

3. COMPONENTS

Illustrations are listed for each component. The information necessary for repair work (tightening torque,

grease up points, etc.) is described on these illustrations. Information is described using symbol. To order the

parts, refer to parts catalogue.

Example:

HU-00001

(14)

(9)

(8)(7)(6)

(10)

(4)

(10)

(22)(11)

(19) (17) (15) (13)(12)

(18) (16) (1)(2)(3)

(4)(5)(6)

(7)

(8)

(11) (10)(9)

(12)

(13)

(19)(18)

(20)(17)

(16)(24)

(10)(25) (5)

(4)

(4)

(4)(3)

(3)

(3) (2) (1)

(21) (15)

(23)

T7

T2

T2

T2

T2

T2

T2

T4

T5

T5

T8

T6

T6

T6T11

T10

T1

T1

T3

T3

T3

T1

T9

T4

T5

T5T3

T4

T3T2

T4

T2

T1

T3

(20)

(21)

(23)

(22)

(10)

(24)(25)(26)(35)

(34)

(27)

(14)

(28)

(29)

(31)

(32)(37)(30)

(33)

(36)

T3

T2T1:Selective part

:Replacement part

:Should be lubricated with grease. :Should be lubricated with oil.:Sealing point

:Tightening torque .... ,

Page 687 of 2870

HU-4

HOW TO USE THIS MANUAL

How to Use This Manual

4. SPECIFICATION

If necessary, specifications are also included.

5. INSPECTION

Inspections are included to be carried out before and after maintenance.

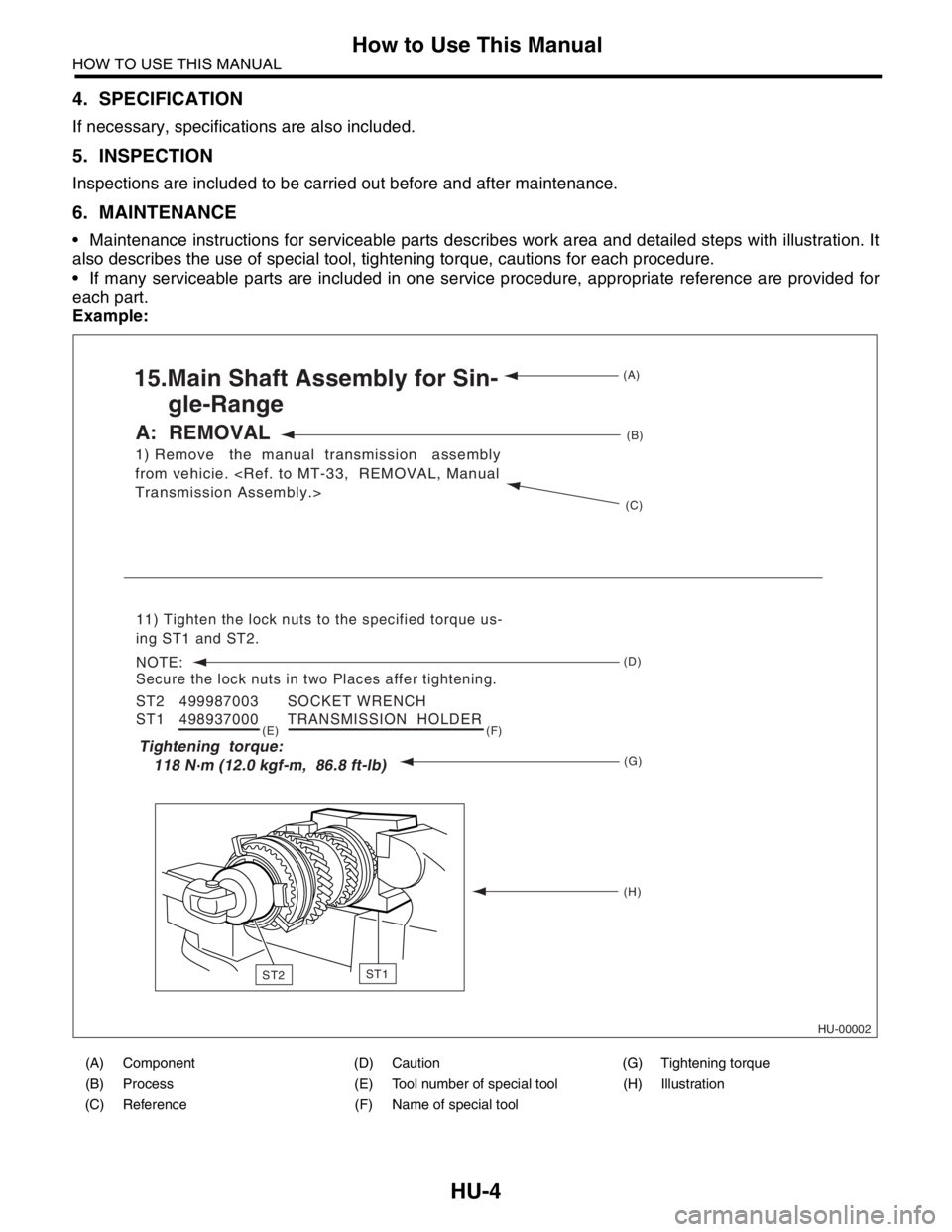

6. MAINTENANCE

• Maintenance instructions for serviceable parts describes work area and detailed steps with illustration. It

also describes the use of special tool, tightening torque, cautions for each procedure.

If many serviceable parts are included in one service procedure, appropriate reference are provided for

each part.

Example:

(A) Component (D) Caution (G) Tightening torque

(B) Process (E) Tool number of special tool (H) Illustration

(C) Reference (F) Name of special tool

HU-00002

1) Remove the manual transmission assembly

from vehicie.

15.Main Shaft Assembly for Sin-

gle-Range

A: REMOVAL

11) Tighten the lock nuts to the specified torque us-

ing ST1 and ST2.

NOTE:

Secure the lock nuts in two Places affer tightening.

ST2 499987003 SOCKET WRENCH

ST1 498937000 TRANSMISSION HOLDER

(A)

(B)

(C)

(D)

(G) (E) (F)

(H)

Tightening torque:

118 N m (12.0 kgf-m, 86.8 ft-lb)

ST1ST2

Page 688 of 2870

HU-5

HOW TO USE THIS MANUAL

How to Use This Manual

7. DIAGNOSIS

Tables showing a step-by-step process make it

easy to conduct diagnosis.

8. SI UNITS

Measurements in these manuals are according to

the SI units. Metric and yard/pound measurements

are also included.

Example:

Tightening torque:

44 N·m (4.5 kgf-m, 33 ft-lb)

Page 691 of 2870

SPC-2

SPECIFICATION

Forester

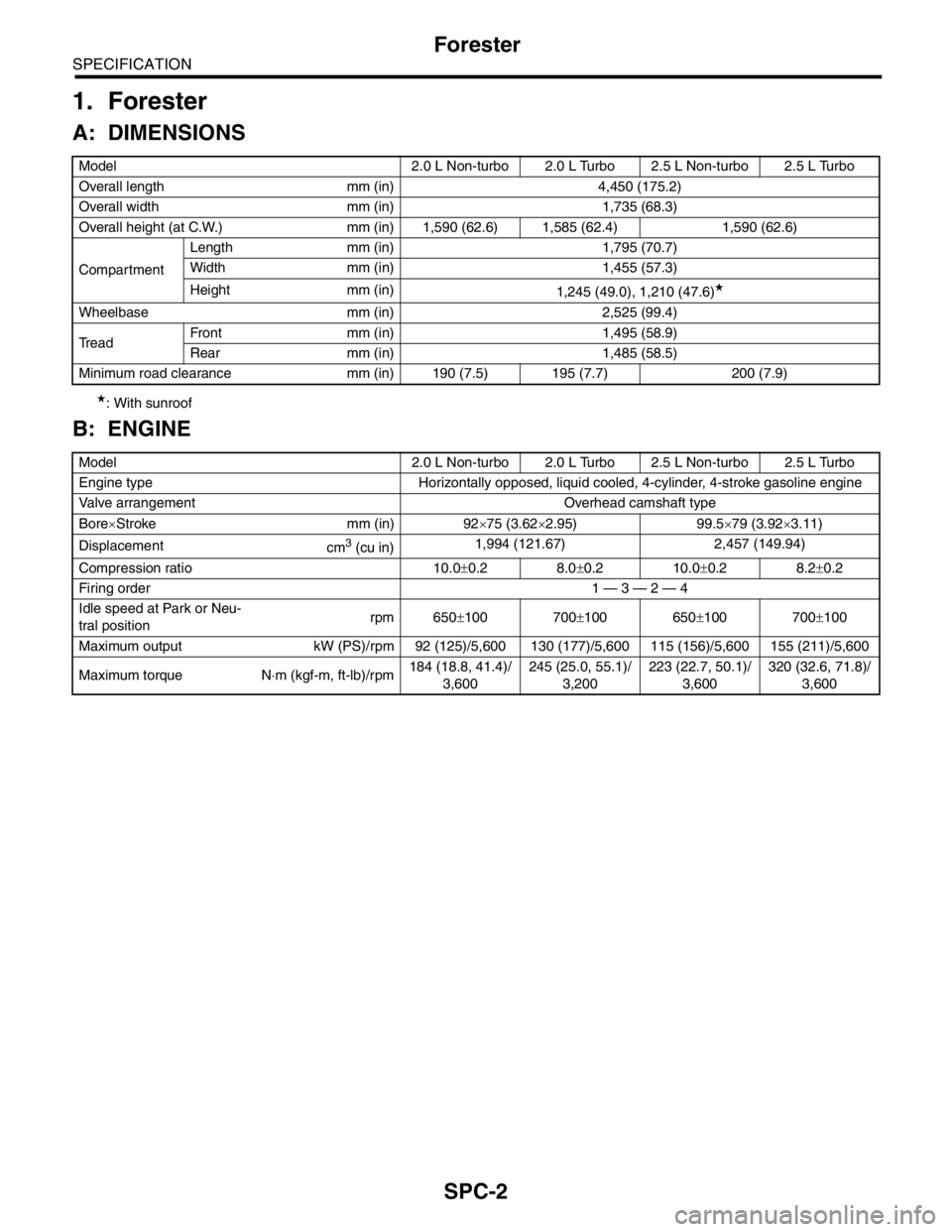

1. Forester

A: DIMENSIONS

★: With sunroof

B: ENGINE

Model 2.0 L Non-turbo 2.0 L Turbo 2.5 L Non-turbo 2.5 L Turbo

Overall length mm (in) 4,450 (175.2)

Overall width mm (in) 1,735 (68.3)

Overall height (at C.W.) mm (in) 1,590 (62.6) 1,585 (62.4) 1,590 (62.6)

CompartmentLength mm (in) 1,795 (70.7)

Width mm (in) 1,455 (57.3)

Height mm (in)

1,245 (49.0), 1,210 (47.6)

★

Wheelbase mm (in) 2,525 (99.4)

Tread Front mm (in) 1,495 (58.9)

Rear mm (in) 1,485 (58.5)

Minimum road clearance mm (in) 190 (7.5) 195 (7.7) 200 (7.9)

Model 2.0 L Non-turbo 2.0 L Turbo 2.5 L Non-turbo 2.5 L Turbo

Engine type Horizontally opposed, liquid cooled, 4-cylinder, 4-stroke gasoline engine

Valve arrangement Overhead camshaft type

Bore×Stroke mm (in) 92×75 (3.62×2.95) 99.5×79 (3.92×3.11)

Displacement

cm

3 (cu in)1,994 (121.67) 2,457 (149.94)

Compression ratio 10.0±0.2 8.0±0.2 10.0±0.2 8.2±0.2

Firing order 1 — 3 — 2 — 4

Idle speed at Park or Neu-

tral positionrpm 650±100 700±100 650±100 700±100

Maximum output kW (PS)/rpm 92 (125)/5,600 130 (177)/5,600 115 (156)/5,600 155 (211)/5,600

Maximum torque N⋅m (kgf-m, ft-lb)/rpm184 (18.8, 41.4)/

3,600245 (25.0, 55.1)/

3,200223 (22.7, 50.1)/

3,600320 (32.6, 71.8)/

3,600

Page 692 of 2870

SPC-3

SPECIFICATION

Forester

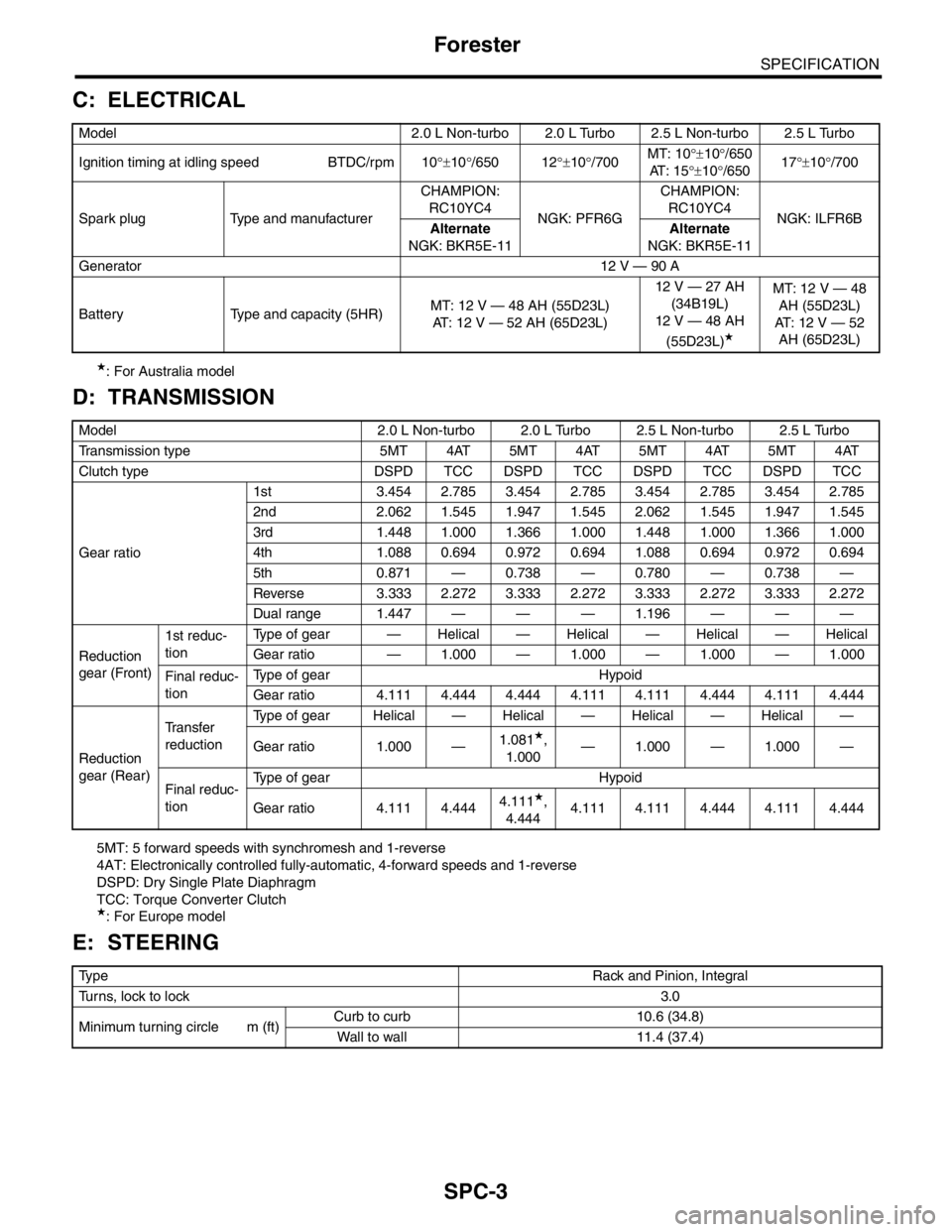

C: ELECTRICAL

★: For Australia model

D: TRANSMISSION

5MT: 5 forward speeds with synchromesh and 1-reverse

4AT: Electronically controlled fully-automatic, 4-forward speeds and 1-reverse

DSPD: Dry Single Plate Diaphragm

TCC: Torque Converter Clutch

★: For Europe model

E: STEERING

Model 2.0 L Non-turbo 2.0 L Turbo 2.5 L Non-turbo 2.5 L Turbo

Ignition timing at idling speed BTDC/rpm 10°±10°/650 12°±10°/700MT: 10°±10°/650

AT : 1 5°±10°/65017°±10°/700

Spark plug Type and manufacturerCHAMPION:

RC10YC4

NGK: PFR6GCHAMPION:

RC10YC4

NGK: ILFR6B

Alternate

NGK: BKR5E-11Alternate

NGK: BKR5E-11

Generator12 V — 90 A

Battery Type and capacity (5HR)MT: 12 V — 48 AH (55D23L)

AT: 12 V — 52 AH (65D23L)12 V — 27 AH

(34B19L)

12 V — 48 AH

(55D23L)

★

MT: 12 V — 48

AH (55D23L)

AT: 12 V — 52

AH (65D23L)

Model 2.0 L Non-turbo 2.0 L Turbo 2.5 L Non-turbo 2.5 L Turbo

Transmission type 5MT 4AT 5MT 4AT 5MT 4AT 5MT 4AT

Clutch type DSPD TCC DSPD TCC DSPD TCC DSPD TCC

Gear ratio1st 3.454 2.785 3.454 2.785 3.454 2.785 3.454 2.785

2nd 2.062 1.545 1.947 1.545 2.062 1.545 1.947 1.545

3rd 1.448 1.000 1.366 1.000 1.448 1.000 1.366 1.000

4th 1.088 0.694 0.972 0.694 1.088 0.694 0.972 0.694

5th 0.871 — 0.738 — 0.780 — 0.738 —

Reverse 3.333 2.272 3.333 2.272 3.333 2.272 3.333 2.272

Dual range 1.447 — — — 1.196 — — —

Reduction

gear (Front)1st reduc-

tionType of gear — Helical — Helical — Helical — Helical

Gear ratio — 1.000 — 1.000 — 1.000 — 1.000

Final reduc-

tionType of gear Hypoid

Gear ratio 4.111 4.444 4.444 4.111 4.111 4.444 4.111 4.444

Reduction

gear (Rear)Transfer

reductionType of gear Helical — Helical — Helical — Helical —

Gear ratio 1.000 —1.081

★,

1.000— 1.000 — 1.000 —

Final reduc-

tionType of gear Hypoid

Gear ratio 4.111 4.4444.111

★,

4.4444.111 4.111 4.444 4.111 4.444

Ty p eRack and Pinion, Integral

Turns, lock to lock3.0

Minimum turning circle m (ft)Curb to curb 10.6 (34.8)

Wall to wall 11.4 (37.4)

Page 703 of 2870

NT-2

NOTE

Note

1. Note

A: NOTE

This is information that can improve efficiency of

maintenance and assure sound work.

1. FASTENER NOTICE

Fasteners are used to prevent parts from damage

and dislocation due to looseness. Fasteners must

be tightened to the specified torque.

Do not apply paint, lubricant, rust retardant, or oth-

er substances to the surface around bolts, fasten-

ers, etc. Doing so will make it difficult to obtain the

correct torque and result in looseness and other

problems.

2. STATIC ELECTRICITY DAMAGE

Do not touch the control unit, connectors, logic

boards, and other such parts when there is a risk of

static electricity. Always use a static electricity pre-

vention cord or touch grounded metal before con-

ducting work.

3. BATTERY

When removing the battery cables, always be sure

to turn the ignition switch off to prevent electrical

damage to the control unit from rush current.

4. SERVICE PARTS

Use authentic service parts for maximum perfor-

mance and maintenance, when conducting repairs.

Subaru/FHI will not be responsible for poor perfor-

mance resulting from the use of parts not specified

by a genuine dealer.

5. PROTECTING VEHICLE UNDER MAIN-

TENANCE

Make sure to attach the fender cover, seat covers,

etc. before work.

6. ENSURING SAFETY DURING WORK

When working in a group of two or more, perform

the work with calling each other to ensure mutual

safety.

Page 722 of 2870

RM-7

RECOMMENDED MATERIAL

Recommended Materials

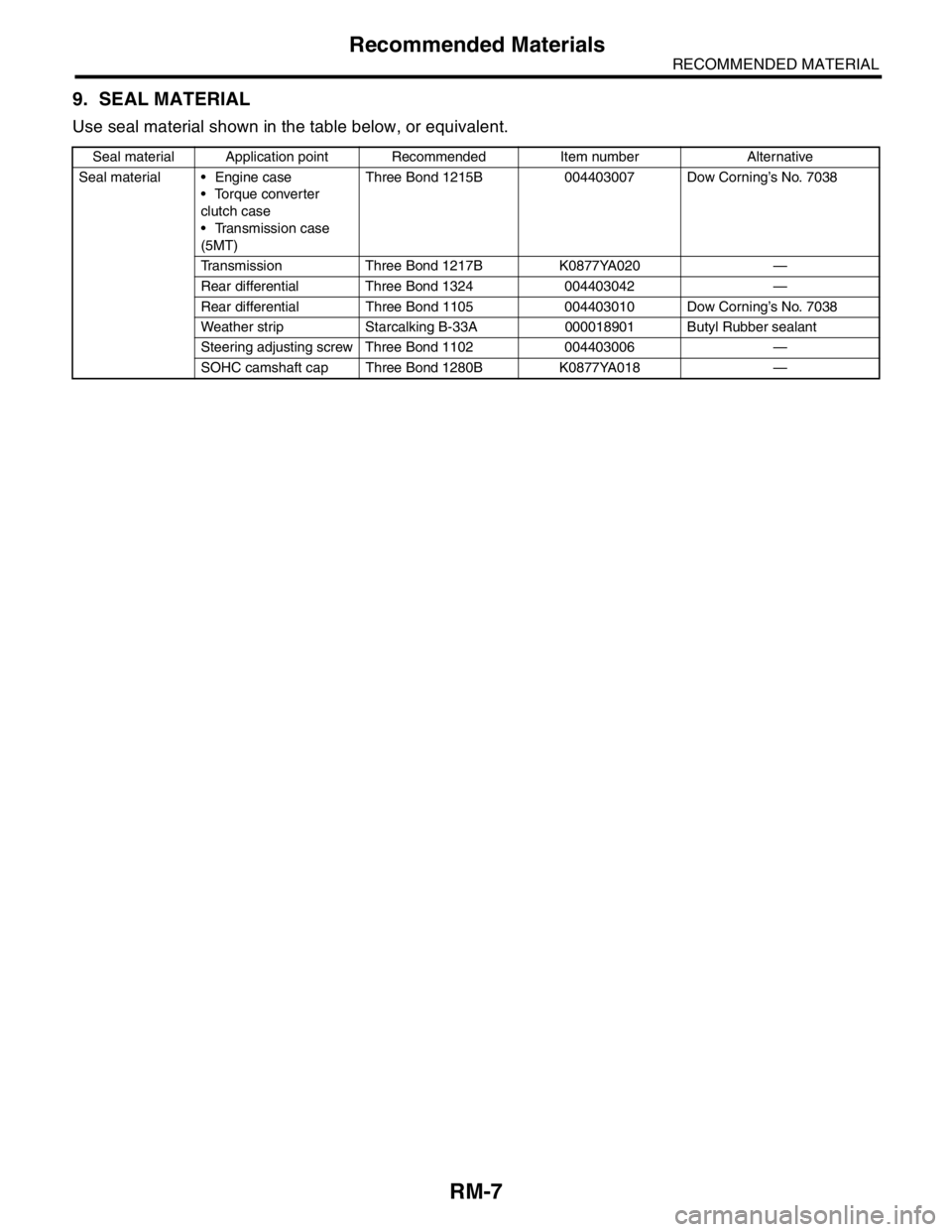

9. SEAL MATERIAL

Use seal material shown in the table below, or equivalent.

Seal material Application point Recommended Item number Alternative

Seal material Engine case

Torque converter

clutch case

Transmission case

(5MT)Three Bond 1215B 004403007 Dow Corning’s No. 7038

Transmission Three Bond 1217B K0877YA020 —

Rear differential Three Bond 1324 004403042 —

Rear differential Three Bond 1105 004403010 Dow Corning’s No. 7038

Weather strip Starcalking B-33A 000018901 Butyl Rubber sealant

Steering adjusting screw Three Bond 1102 004403006 —

SOHC camshaft cap Three Bond 1280B K0877YA018 —

Page 744 of 2870

PM-7

PERIODIC MAINTENANCE SERVICE

Engine Oil

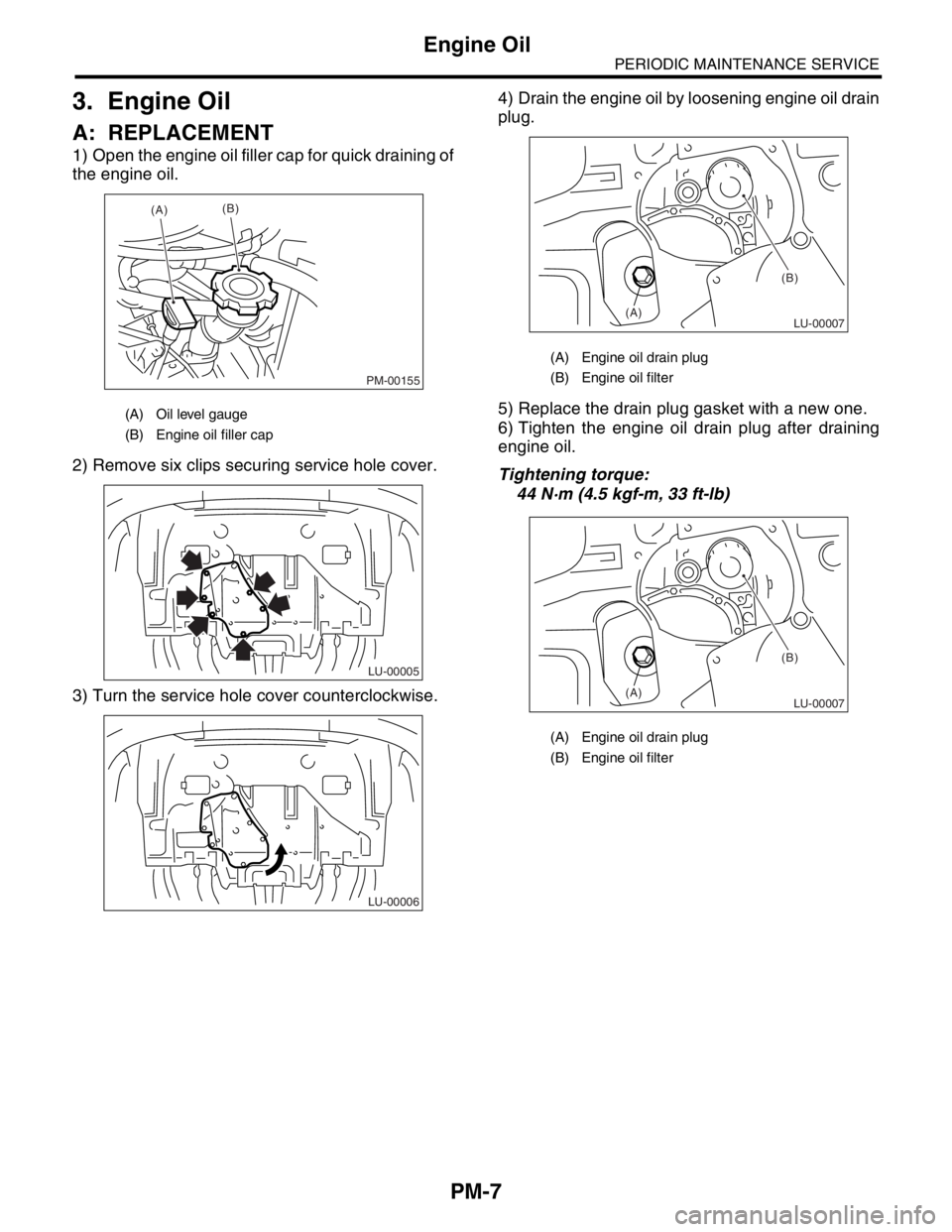

3. Engine Oil

A: REPLACEMENT

1) Open the engine oil filler cap for quick draining of

the engine oil.

2) Remove six clips securing service hole cover.

3) Turn the service hole cover counterclockwise.4) Drain the engine oil by loosening engine oil drain

plug.

5) Replace the drain plug gasket with a new one.

6) Tighten the engine oil drain plug after draining

engine oil.

Tightening torque:

44 N·m (4.5 kgf-m, 33 ft-lb)

(A) Oil level gauge

(B) Engine oil filler cap

PM-00155

(A)(B)

LU-00005

LU-00006

(A) Engine oil drain plug

(B) Engine oil filter

(A) Engine oil drain plug

(B) Engine oil filter

LU-00007

(B)

(A)

LU-00007

(B)

(A)