SUBARU FORESTER 2004 Service Repair Manual

Manufacturer: SUBARU, Model Year: 2004, Model line: FORESTER, Model: SUBARU FORESTER 2004Pages: 2870, PDF Size: 38.67 MB

Page 131 of 2870

FUJI HEAVY INDUSTRIES LTD. G8080GE7

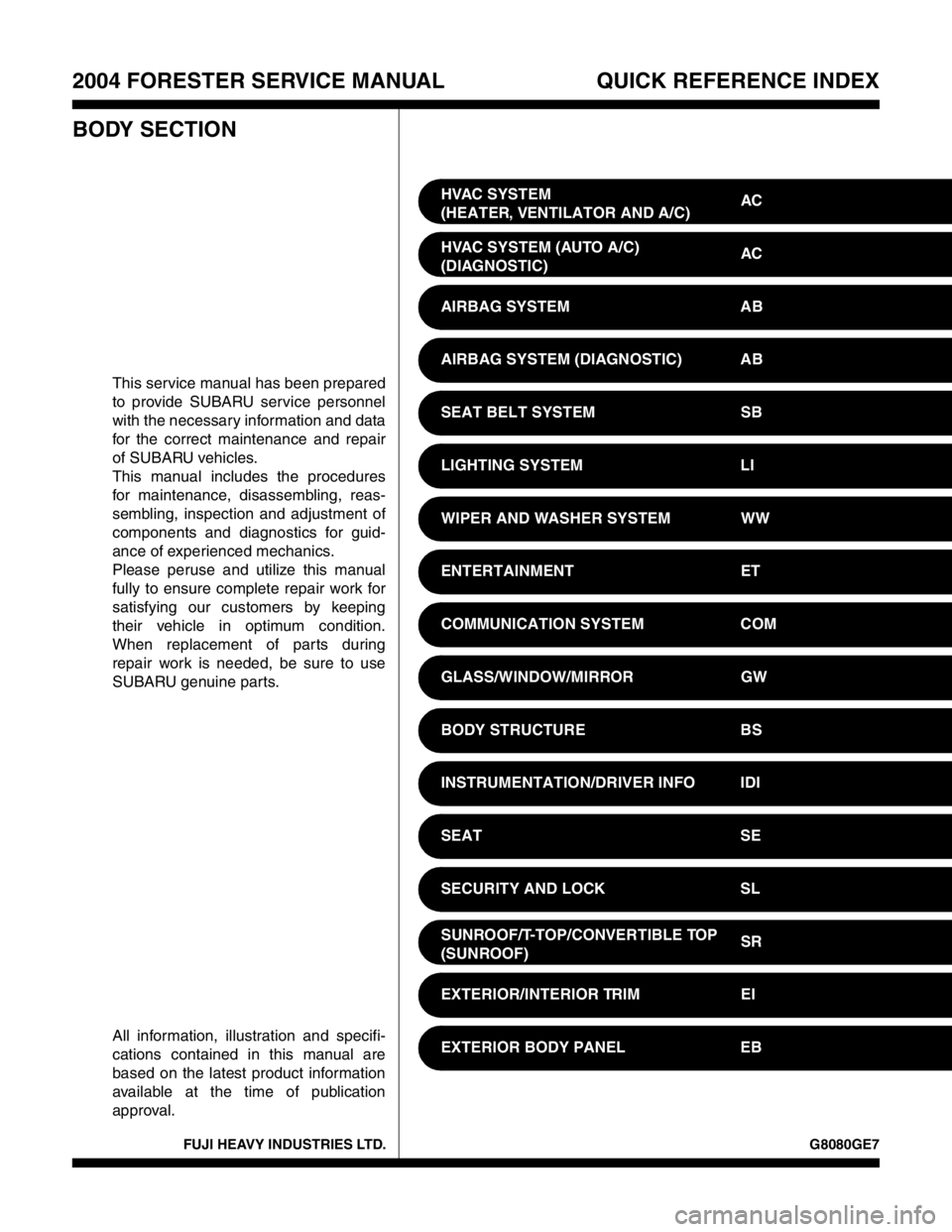

2004 FORESTER SERVICE MANUAL QUICK REFERENCE INDEX

BODY SECTION

This service manual has been prepared

to provide SUBARU service personnel

with the necessary information and data

for the correct maintenance and repair

of SUBARU vehicles.

This manual includes the procedures

for maintenance, disassembling, reas-

sembling, inspection and adjustment of

components and diagnostics for guid-

ance of experienced mechanics.

Please peruse and utilize this manual

fully to ensure complete repair work for

satisfying our customers by keeping

their vehicle in optimum condition.

When replacement of parts during

repair work is needed, be sure to use

SUBARU genuine parts.

All information, illustration and specifi-

cations contained in this manual are

based on the latest product information

available at the time of publication

approval.HVAC SYSTEM

(HEATER, VENTILATOR AND A/C)AC

HVAC SYSTEM (AUTO A/C)

(DIAGNOSTIC)AC

AIRBAG SYSTEM AB

AIRBAG SYSTEM (DIAGNOSTIC) AB

SEAT BELT SYSTEM SB

LIGHTING SYSTEM LI

WIPER AND WASHER SYSTEM WW

ENTERTAINMENT ET

COMMUNICATION SYSTEM COM

GLASS/WINDOW/MIRROR GW

BODY STRUCTURE BS

INSTRUMENTATION/DRIVER INFO IDI

SEAT SE

SECURITY AND LOCK SL

SUNROOF/T-TOP/CONVERTIBLE TOP

(SUNROOF)SR

EXTERIOR/INTERIOR TRIM EI

EXTERIOR BODY PANEL EB

Page 132 of 2870

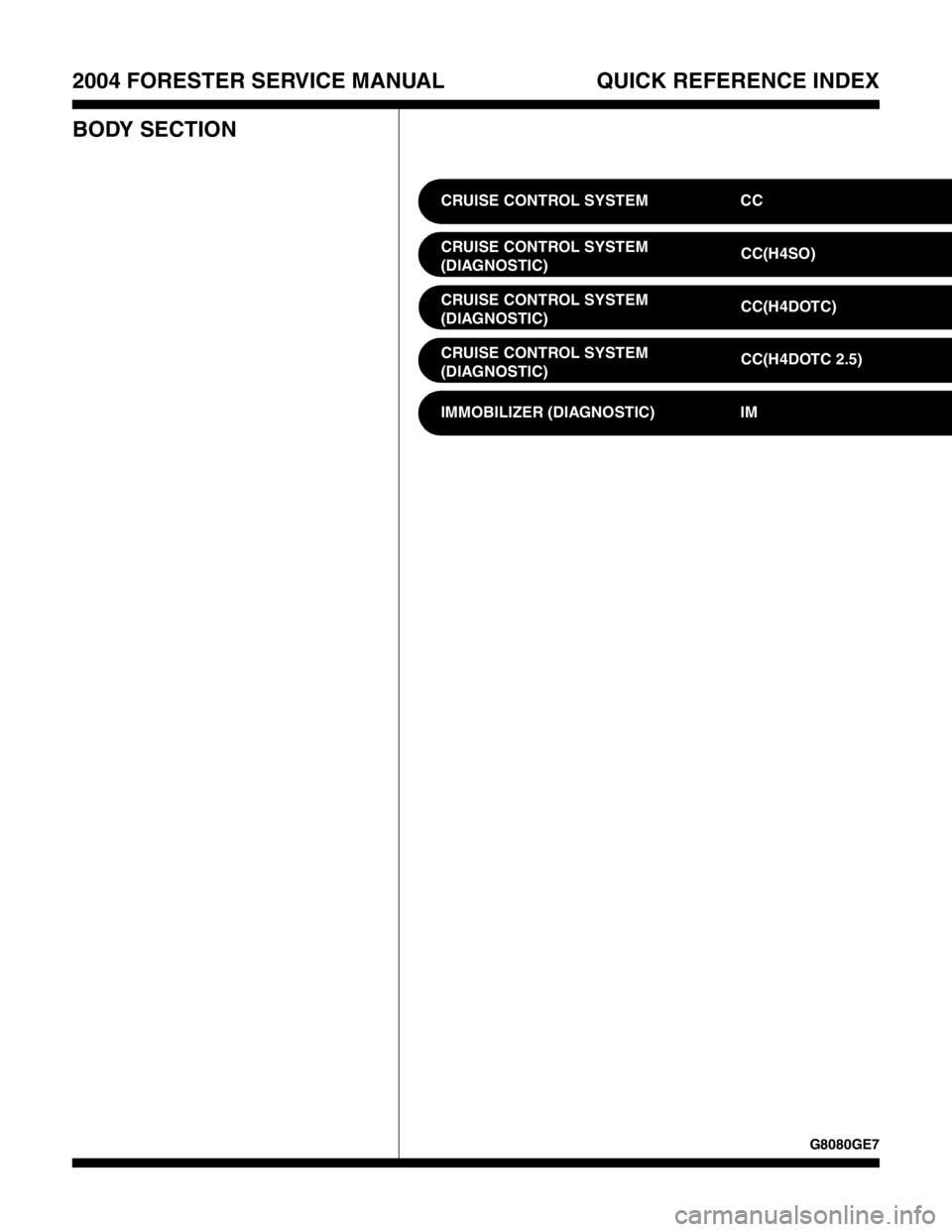

2004 FORESTER SERVICE MANUAL QUICK REFERENCE INDEX

BODY SECTION

G8080GE7

CRUISE CONTROL SYSTEM CC

CRUISE CONTROL SYSTEM

(DIAGNOSTIC)CC(H4SO)

CRUISE CONTROL SYSTEM

(DIAGNOSTIC)CC(H4DOTC)

CRUISE CONTROL SYSTEM

(DIAGNOSTIC)CC(H4DOTC 2.5)

IMMOBILIZER (DIAGNOSTIC) IM

Page 133 of 2870

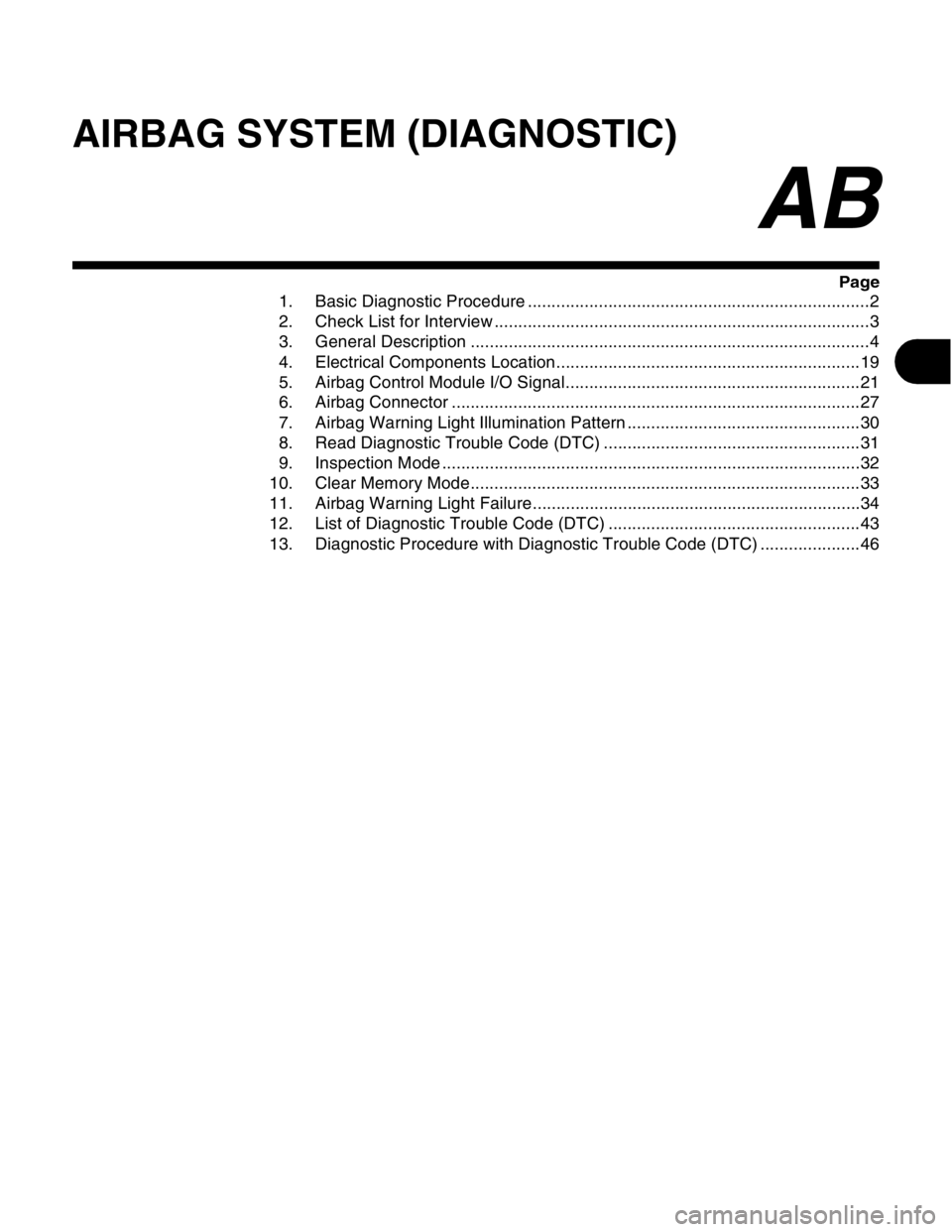

AIRBAG SYSTEM (DIAGNOSTIC)

AB

Page

1. Basic Diagnostic Procedure ........................................................................2

2. Check List for Interview ...............................................................................3

3. General Description ....................................................................................4

4. Electrical Components Location................................................................19

5. Airbag Control Module I/O Signal..............................................................21

6. Airbag Connector ......................................................................................27

7. Airbag Warning Light Illumination Pattern .................................................30

8. Read Diagnostic Trouble Code (DTC) ......................................................31

9. Inspection Mode ........................................................................................32

10. Clear Memory Mode..................................................................................33

11. Airbag Warning Light Failure.....................................................................34

12. List of Diagnostic Trouble Code (DTC) .....................................................43

13. Diagnostic Procedure with Diagnostic Trouble Code (DTC) .....................46

Page 134 of 2870

AB-2

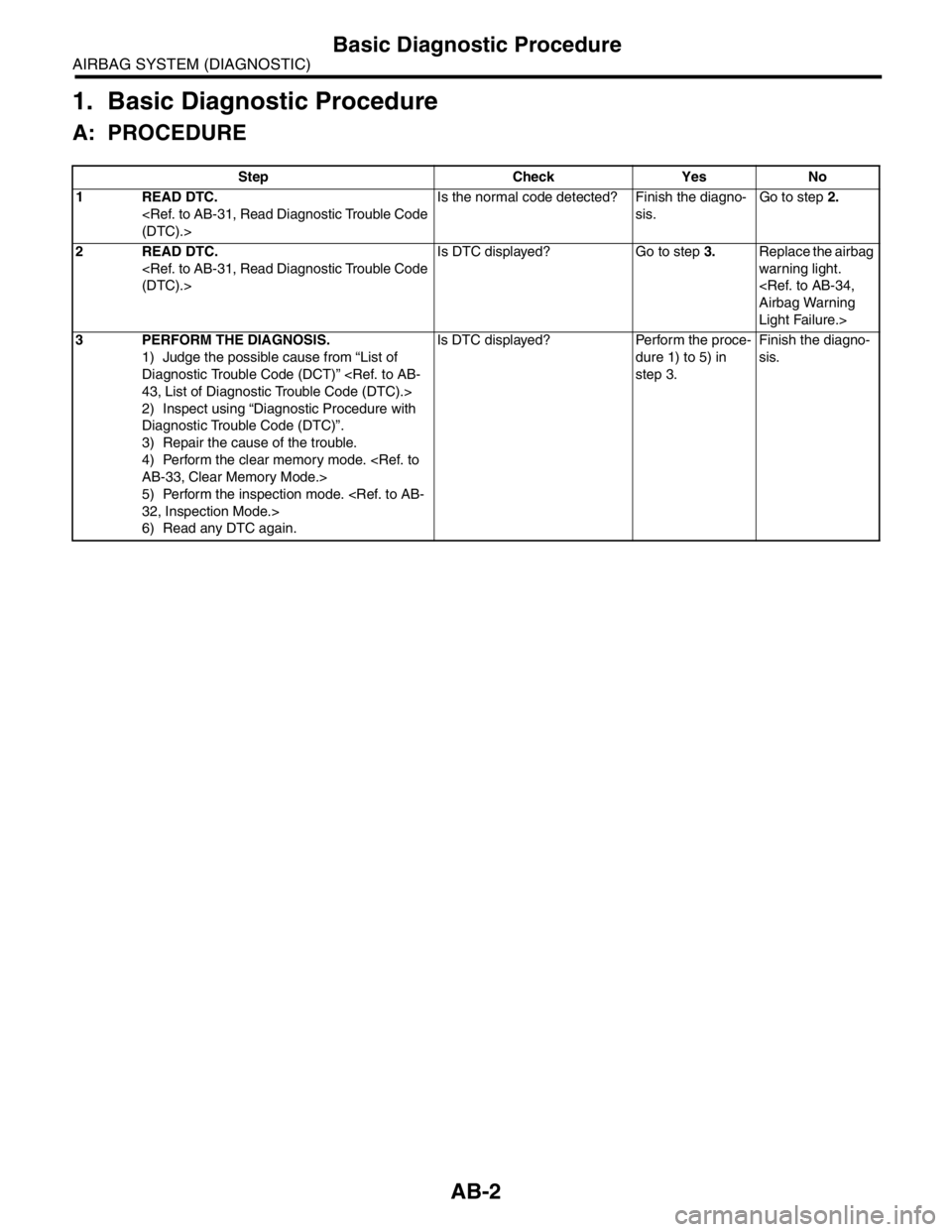

AIRBAG SYSTEM (DIAGNOSTIC)

Basic Diagnostic Procedure

1. Basic Diagnostic Procedure

A: PROCEDURE

Step Check Yes No

1 READ DTC.

sis.Go to step 2.

2 READ DTC.

warning light.

Light Failure.>

3 PERFORM THE DIAGNOSIS.

1) Judge the possible cause from “List of

Diagnostic Trouble Code (DCT)”

2) Inspect using “Diagnostic Procedure with

Diagnostic Trouble Code (DTC)”.

3) Repair the cause of the trouble.

4) Perform the clear memory mode.

5) Perform the inspection mode.

6) Read any DTC again.Is DTC displayed? Perform the proce-

dure 1) to 5) in

step 3.Finish the diagno-

sis.

Page 135 of 2870

AB-3

AIRBAG SYSTEM (DIAGNOSTIC)

Check List for Interview

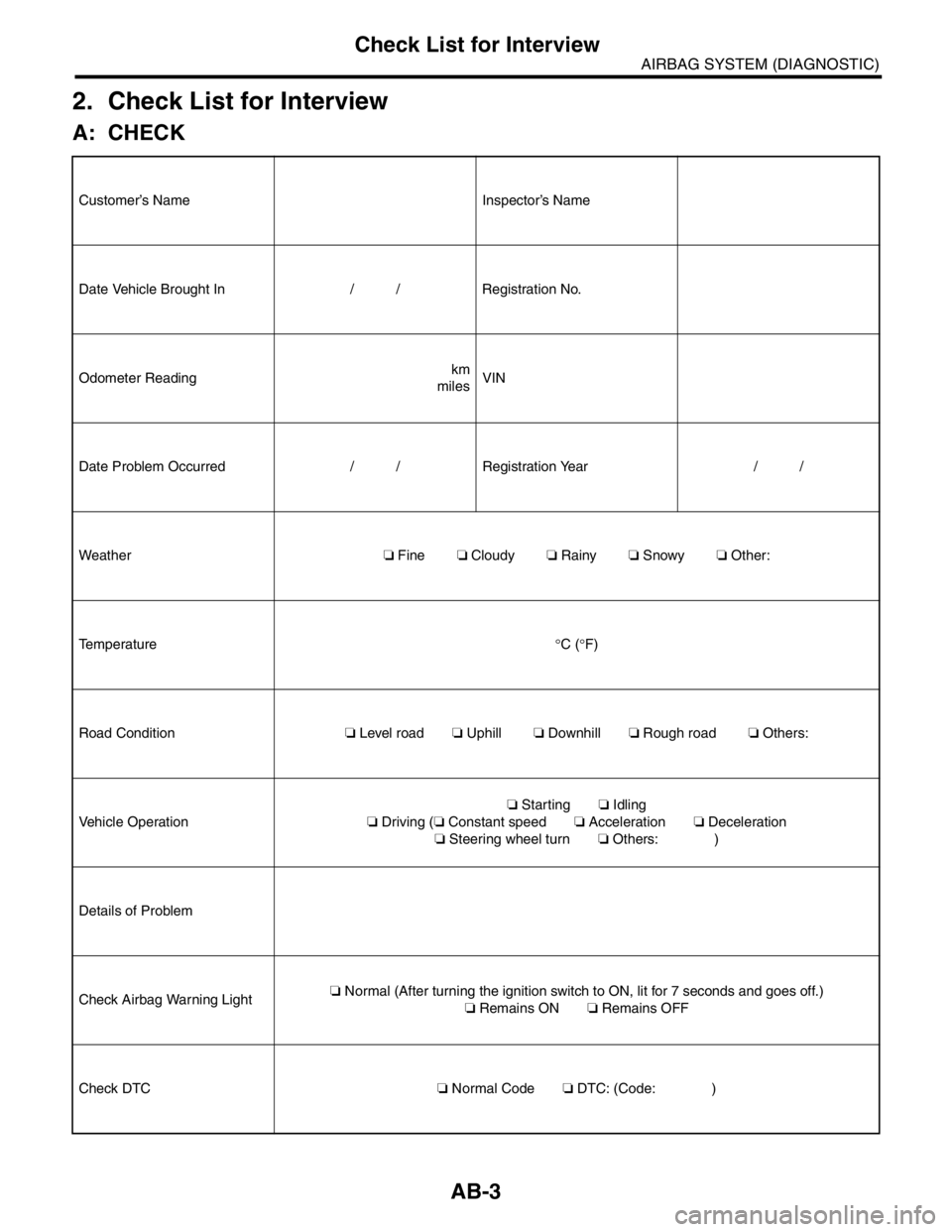

2. Check List for Interview

A: CHECK

Customer’s Name Inspector’s Name

Date Vehicle Brought In / / Registration No.

Odometer Readingkm

milesVIN

Date Problem Occurred / / Registration Year / /

Weather❏ Fine ❏ Cloudy ❏ Rainy ❏ Snowy ❏ Other:

Temperature°C (°F)

Road Condition❏ Level road❏ Uphill ❏ Downhill❏ Rough road ❏ Others:

Vehicle Operation❏ Starting❏ Idling

❏ Driving (❏ Constant speed❏ Acceleration❏ Deceleration

❏ Steering wheel turn❏ Others: )

Details of Problem

Check Airbag Warning Light❏ Normal (After turning the ignition switch to ON, lit for 7 seconds and goes off.)

❏ Remains ON❏ Remains OFF

Check DTC❏ Normal Code❏ DTC: (Code: )

Page 136 of 2870

AB-4

AIRBAG SYSTEM (DIAGNOSTIC)

General Description

3. General Description

A: CAUTION

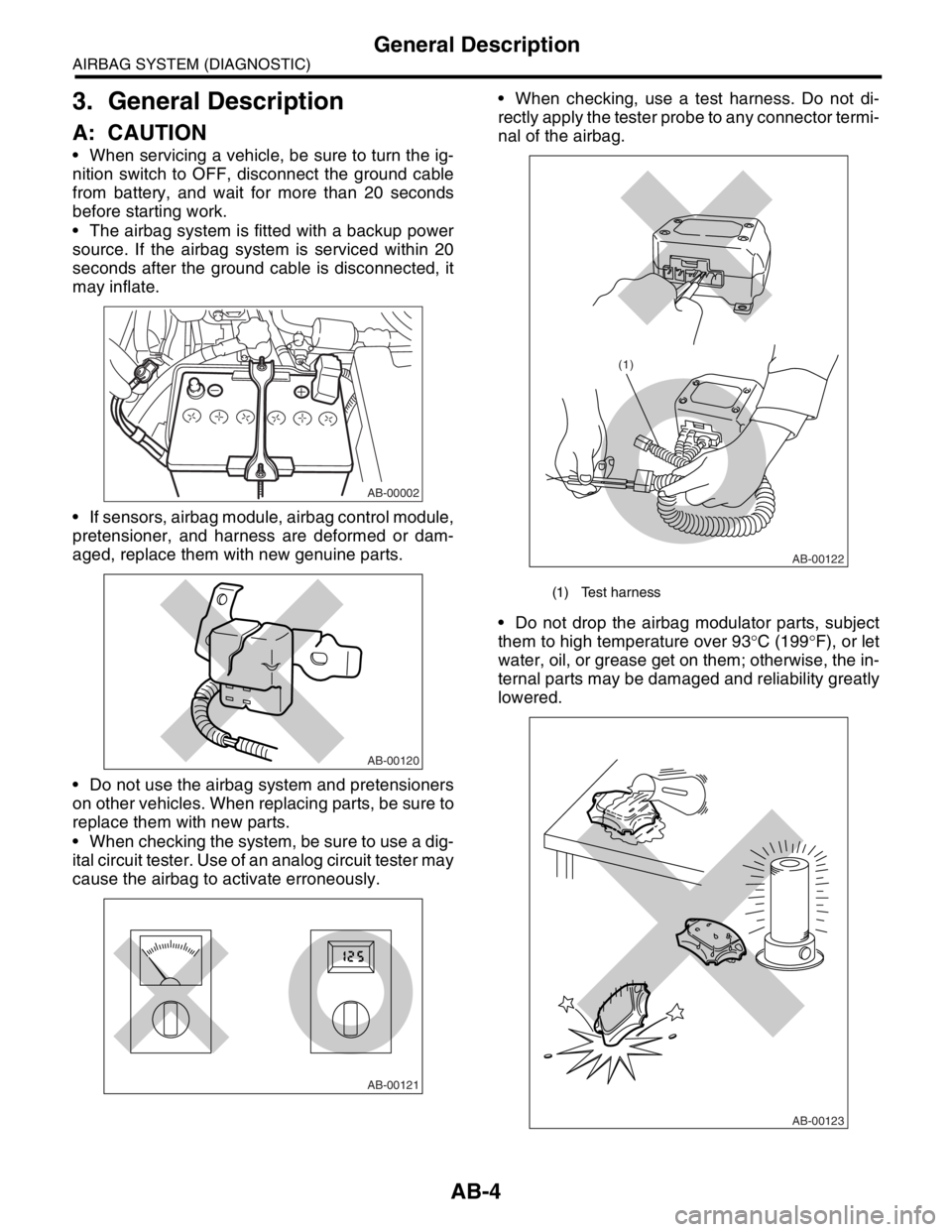

When servicing a vehicle, be sure to turn the ig-

nition switch to OFF, disconnect the ground cable

from battery, and wait for more than 20 seconds

before starting work.

The airbag system is fitted with a backup power

source. If the airbag system is serviced within 20

seconds after the ground cable is disconnected, it

may inflate.

If sensors, airbag module, airbag control module,

pretensioner, and harness are deformed or dam-

aged, replace them with new genuine parts.

Do not use the airbag system and pretensioners

on other vehicles. When replacing parts, be sure to

replace them with new parts.

When checking the system, be sure to use a dig-

ital circuit tester. Use of an analog circuit tester may

cause the airbag to activate erroneously. When checking, use a test harness. Do not di-

rectly apply the tester probe to any connector termi-

nal of the airbag.

Do not drop the airbag modulator parts, subject

them to high temperature over 93°C (199°F), or let

water, oil, or grease get on them; otherwise, the in-

ternal parts may be damaged and reliability greatly

lowered.

AB-00002

AB-00120

AB-00121

(1) Test harness

AB-00122

(1)

AB-00123

Page 137 of 2870

AB-5

AIRBAG SYSTEM (DIAGNOSTIC)

General Description

If any damage, opening, or rust is found on the

airbag system wiring harness, do not attempt to re-

pair using soldering equipment. Be sure to replace

the faulty harness with a new genuine part.

Install the wiring harness securely with the spec-

ified clips to avoid interference or tangled up with

other parts.

Do not allow water or oil to come in contact with

the connector terminals. Do not touch the connec-

tor terminals. Either of the airbag modules for driver, passen-

ger or side, or pretensioner must not be disassem-

bled.

The airbag module cannot be used again once

inflated.

After removal, keep the airbag module with the

pad facing upward on a dry, clean, and flat surface

away from heat and light sources, and moisture

and dust.

Do not check continuity of either of the airbag

modules for driver, passenger or side, or preten-

sioner.

AB-00124

AB-00125

AB-00126

AB-00127

AB-00056

AB-00006

Page 138 of 2870

AB-6

AIRBAG SYSTEM (DIAGNOSTIC)

General Description

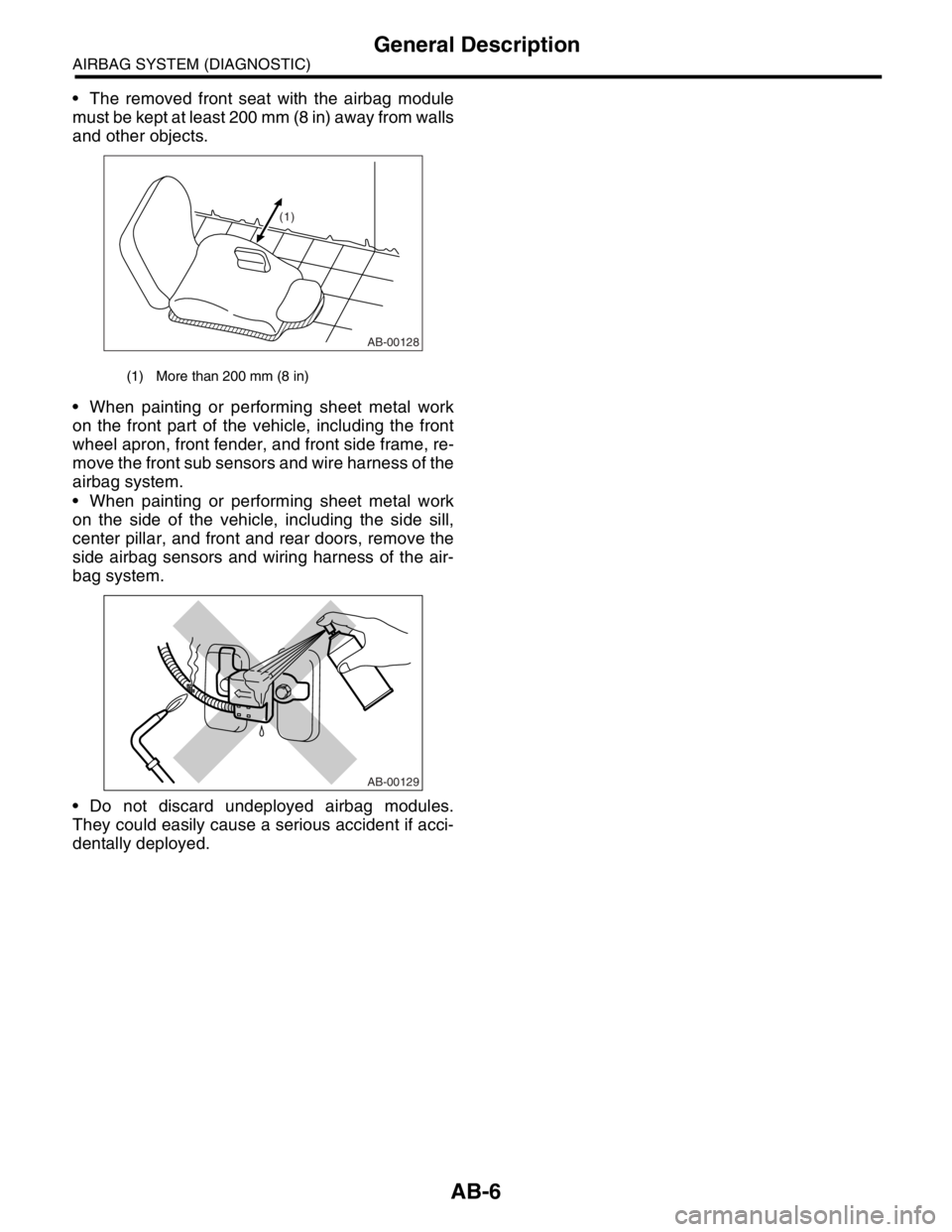

The removed front seat with the airbag module

must be kept at least 200 mm (8 in) away from walls

and other objects.

When painting or performing sheet metal work

on the front part of the vehicle, including the front

wheel apron, front fender, and front side frame, re-

move the front sub sensors and wire harness of the

airbag system.

When painting or performing sheet metal work

on the side of the vehicle, including the side sill,

center pillar, and front and rear doors, remove the

side airbag sensors and wiring harness of the air-

bag system.

Do not discard undeployed airbag modules.

They could easily cause a serious accident if acci-

dentally deployed.

(1) More than 200 mm (8 in)

AB-00128

(1)

AB-00129

Page 139 of 2870

AB-7

AIRBAG SYSTEM (DIAGNOSTIC)

General Description

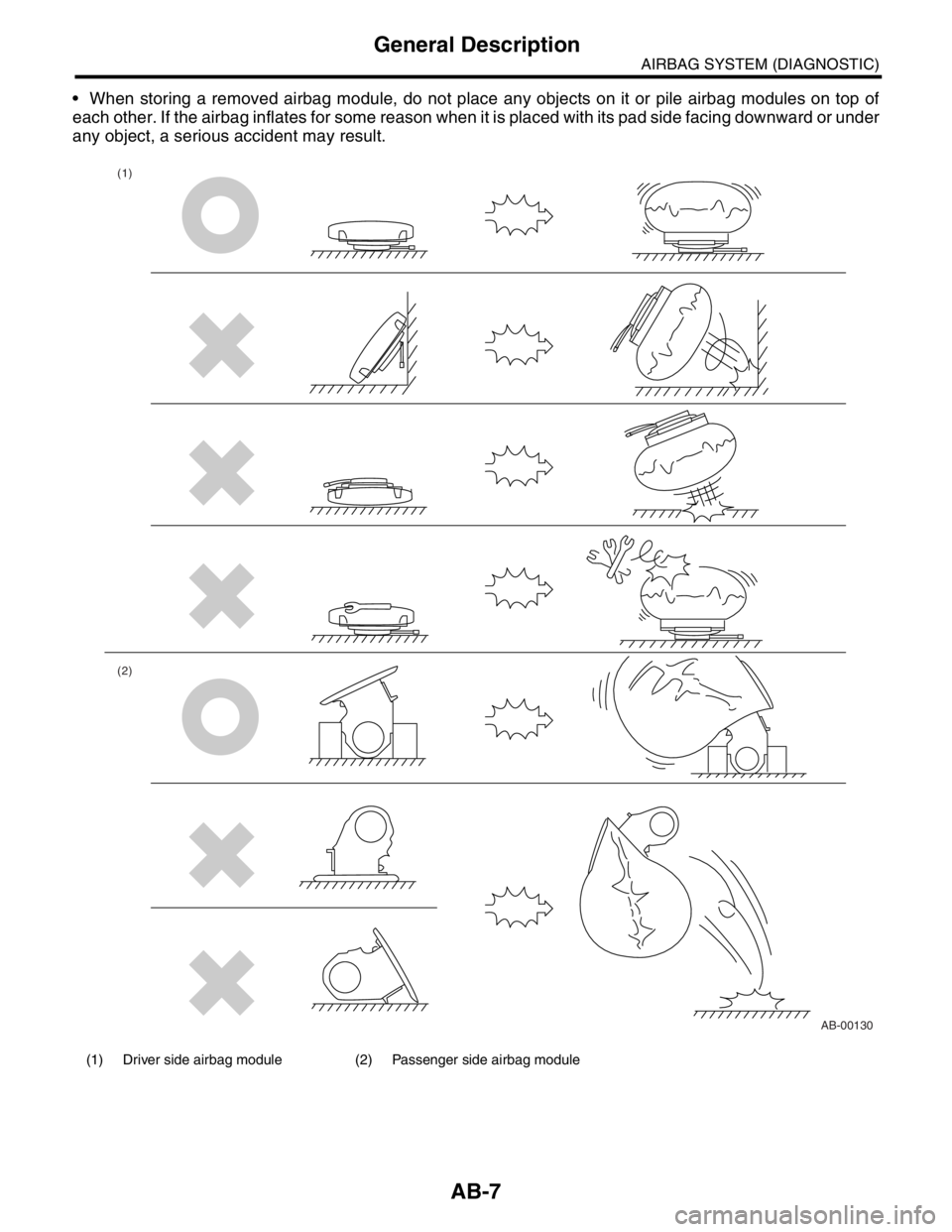

When storing a removed airbag module, do not place any objects on it or pile airbag modules on top of

each other. If the airbag inflates for some reason when it is placed with its pad side facing downward or under

any object, a serious accident may result.

(1) Driver side airbag module (2) Passenger side airbag module

AB-00130

(2) (1)

Page 140 of 2870

AB-8

AIRBAG SYSTEM (DIAGNOSTIC)

General Description

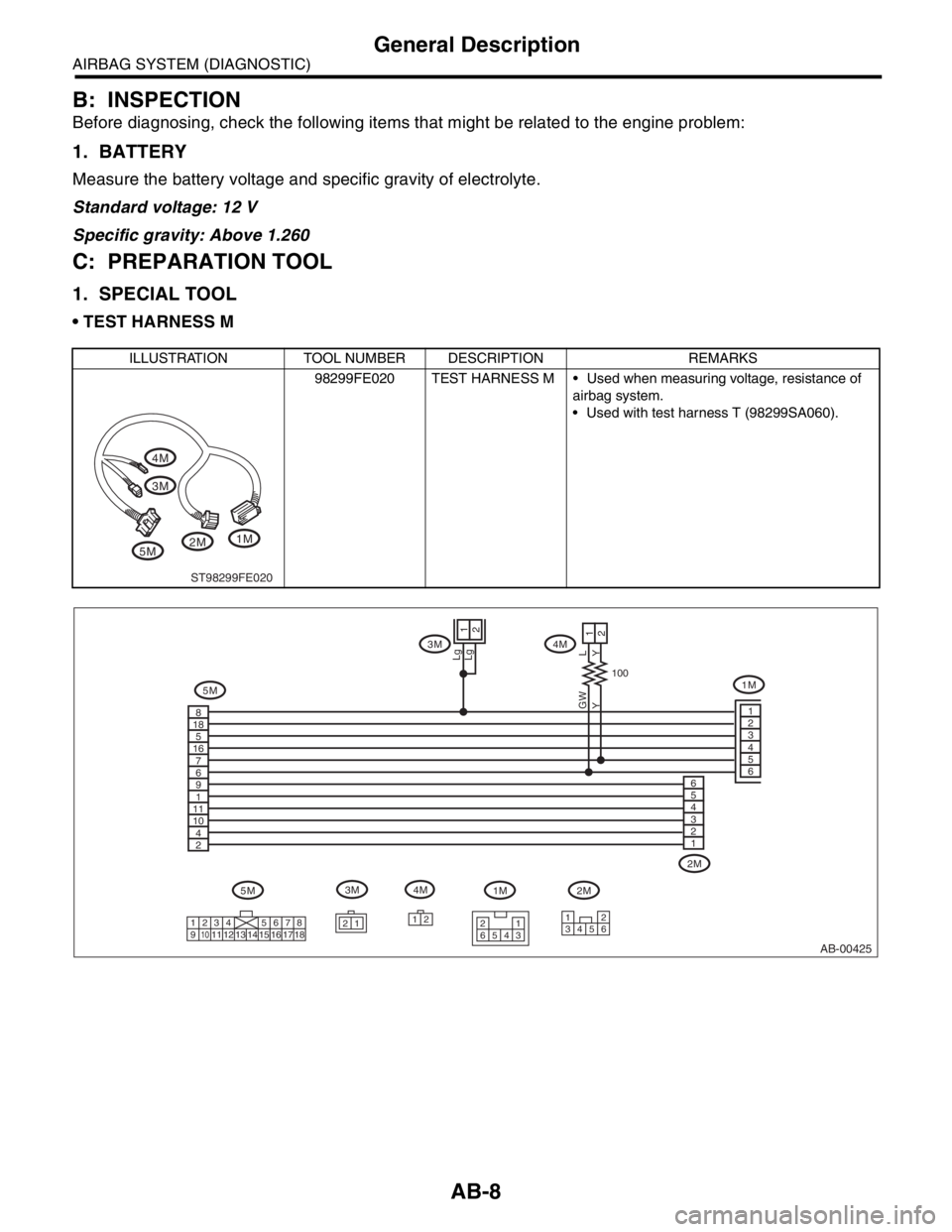

B: INSPECTION

Before diagnosing, check the following items that might be related to the engine problem:

1. BATTERY

Measure the battery voltage and specific gravity of electrolyte.

Standard voltage: 12 V

Specific gravity: Above 1.260

C: PREPARATION TOOL

1. SPECIAL TOOL

TEST HARNESS M

ILLUSTRATION TOOL NUMBER DESCRIPTION REMARKS

98299FE020 TEST HARNESS M Used when measuring voltage, resistance of

airbag system.

Used with test harness T (98299SA060).

5M3M 4M

1M

2M

ST98299FE020

AB-00425

5M

1

21

Lg

2

8

18

5

16

7

6

9

1

11

10

4

2

Lg

YL

Y

100

GW

3M 4M

1M

2M

12

65 21

4334 12

56 21 1

234 5678

91011

12 13 14 15 16 17 18

1

2

3

4

5

6

2M 1M 4M 3M

5M6

5

4

3

2

1