SUBARU FORESTER 2004 Service Repair Manual

Manufacturer: SUBARU, Model Year: 2004, Model line: FORESTER, Model: SUBARU FORESTER 2004Pages: 2870, PDF Size: 38.67 MB

Page 2361 of 2870

FUJI HEAVY INDUSTRIES LTD. G8080GE5

2004 FORESTER SERVICE MANUAL QUICK REFERENCE INDEX

TRANSMISSION SECTION

This service manual has been prepared

to provide SUBARU service personnel

with the necessary information and data

for the correct maintenance and repair

of SUBARU vehicles.

This manual includes the procedures

for maintenance, disassembling, reas-

sembling, inspection and adjustment of

components and diagnostics for guid-

ance of experienced mechanics.

Please peruse and utilize this manual

fully to ensure complete repair work for

satisfying our customers by keeping

their vehicle in optimum condition.

When replacement of parts during

repair work is needed, be sure to use

SUBARU genuine parts.

All information, illustration and specifi-

cations contained in this manual are

based on the latest product information

available at the time of publication

approval.CONTROL SYSTEM CS

AUTOMATIC TRANSMISSION 4AT

AUTOMATIC TRANSMISSION

(DIAGNOSTIC)4AT(H4SO)

AUTOMATIC TRANSMISSION

(DIAGNOSTIC)4AT(H4DOTC)

AUTOMATIC TRANSMISSION

(DIAGNOSTIC)4AT(H4DOTC 2.5)

MANUAL TRANSMISSION AND

DIFFERENTIAL5MT

CLUTCH SYSTEM CL

Page 2362 of 2870

4AT-49

AUTOMATIC TRANSMISSION

Extension Case Oil Seal

11.Extension Case Oil Seal

A: INSPECTION

Make sure that the ATF does not leak from the joint

of transmission and propeller shaft. If so, replace

the oil seal.

B: REPLACEMENT

1) Clean the transmission exterior.

2) Drain the ATF completely.

NOTE:

Tighten the drain plug (ATF) after draining the ATF.

Tightening torque:

25 N

⋅m (2.5 kgf-m, 18.1 ft-lb)

3) Remove the rear exhaust pipe and muffler.

(Non-turbo model).

(Turbo model)

4) Remove the heat shield cover. (If equipped)

5) Remove the propeller shaft.

6) Using ST, install the oil seal.

ST 398527700 PULLER ASSY

7) Using the ST, install the oil seal.

ST 498057300 INSTALLER

8) Install the propeller shaft.

9) Install the heat shield cover. (If equipped)10) Install the rear exhaust pipe and muffler.

(Non-turbo model).

(Turbo model)

11) Pour ATF and check the ATF level.

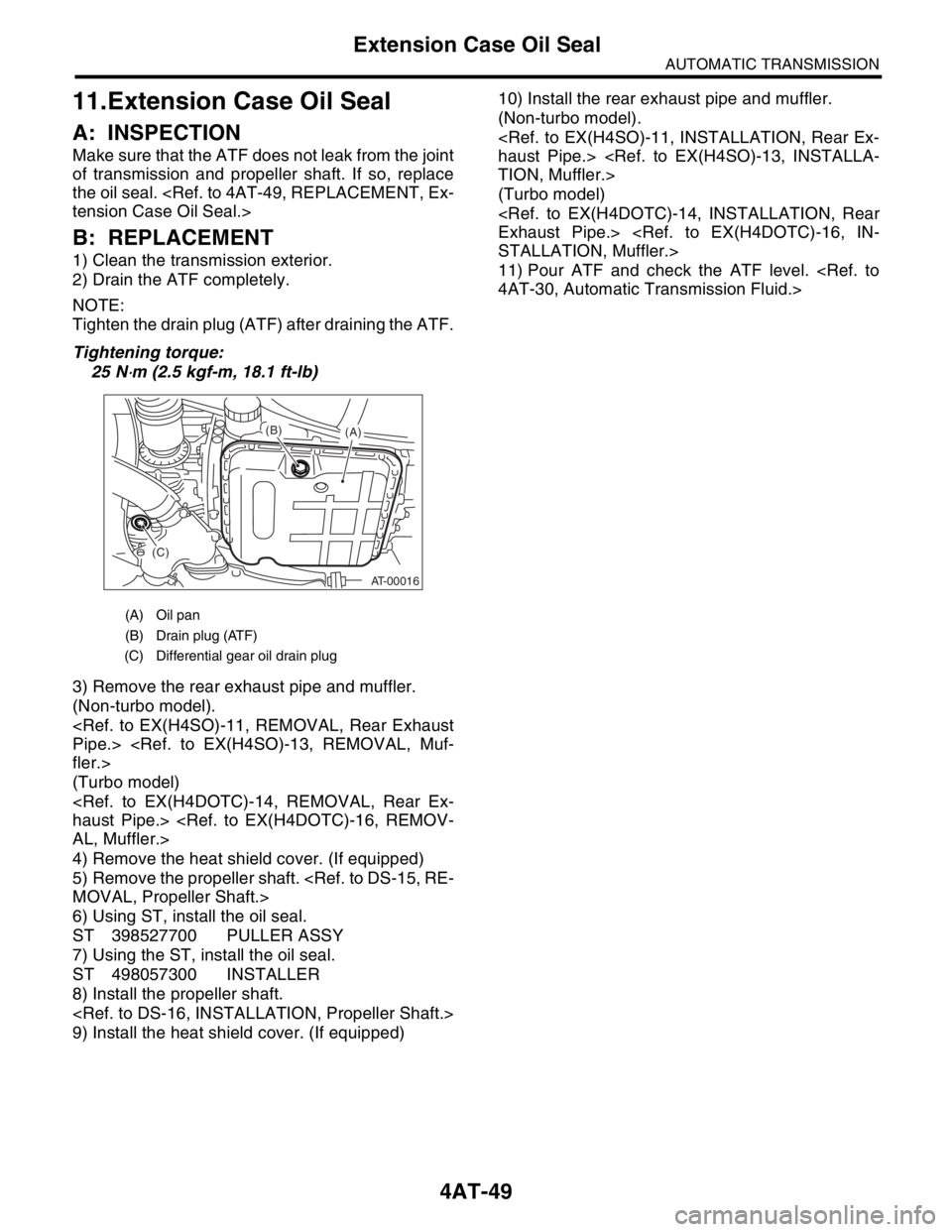

(A) Oil pan

(B) Drain plug (ATF)

(C) Differential gear oil drain plug

AT-00016

(A) (B)

(C)

Page 2363 of 2870

4AT-50

AUTOMATIC TRANSMISSION

Differential Side Retainer Oil Seal

12.Differential Side Retainer Oil

Seal

A: INSPECTION

Check the leakage of gear oil from differential side

retainer oil seal part.

If there is oil leakage, replace the oil seal.

B: REPLACEMENT

1) Lift-up the vehicle.

2) Remove the front exhaust pipe and center ex-

haust pipe.

(Non-turbo model)

(Turbo model)

3) Drain the differential gear by removing differen-

tial gear oil drain plug.

4) Replace new gasket and tighten the differential

oil drain plug.

Tightening torque:

44 N

⋅m (4.5 kgf-m, 32.5 ft-lb)

5) Separate the front drive shaft from transmission.

6) Remove the differential side retainer oil seal us-

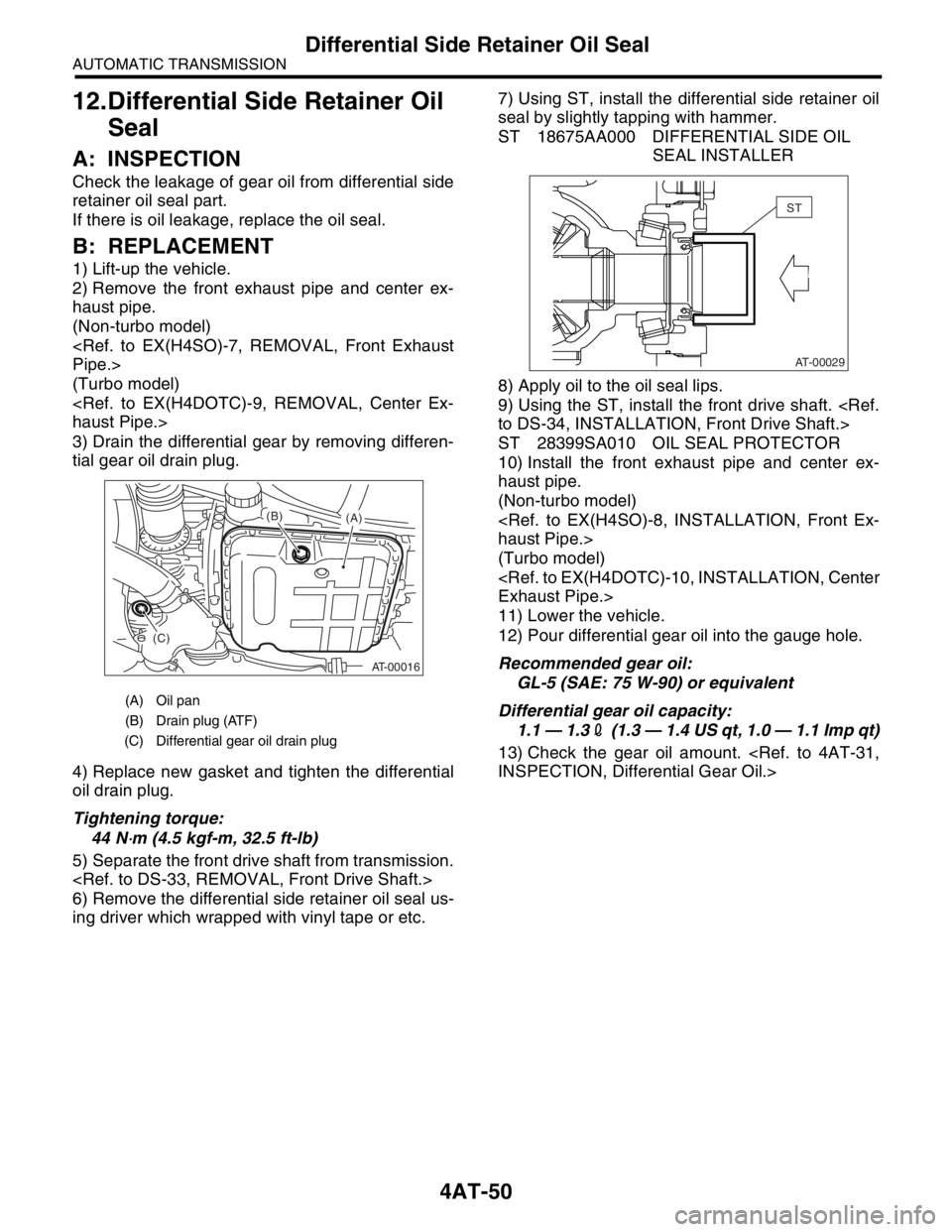

ing driver which wrapped with vinyl tape or etc.7) Using ST, install the differential side retainer oil

seal by slightly tapping with hammer.

ST 18675AA000 DIFFERENTIAL SIDE OIL

SEAL INSTALLER

8) Apply oil to the oil seal lips.

9) Using the ST, install the front drive shaft.

ST 28399SA010 OIL SEAL PROTECTOR

10) Install the front exhaust pipe and center ex-

haust pipe.

(Non-turbo model)

(Turbo model)

11) Lower the vehicle.

12) Pour differential gear oil into the gauge hole.

Recommended gear oil:

GL-5 (SAE: 75 W-90) or equivalent

Differential gear oil capacity:

1.1 — 1.32 (1.3 — 1.4 US qt, 1.0 — 1.1 Imp qt)

13) Check the gear oil amount.

(A) Oil pan

(B) Drain plug (ATF)

(C) Differential gear oil drain plug

AT-00016

(A) (B)

(C)

AT-00029

ST

Page 2364 of 2870

4AT-51

AUTOMATIC TRANSMISSION

Inhibitor Switch

13.Inhibitor Switch

A: INSPECTION

When the driving condition or starter motor opera-

tion is erroneous, first check the shift linkage for im-

proper operation. If the shift linkage is functioning

properly, check the inhibitor switch.

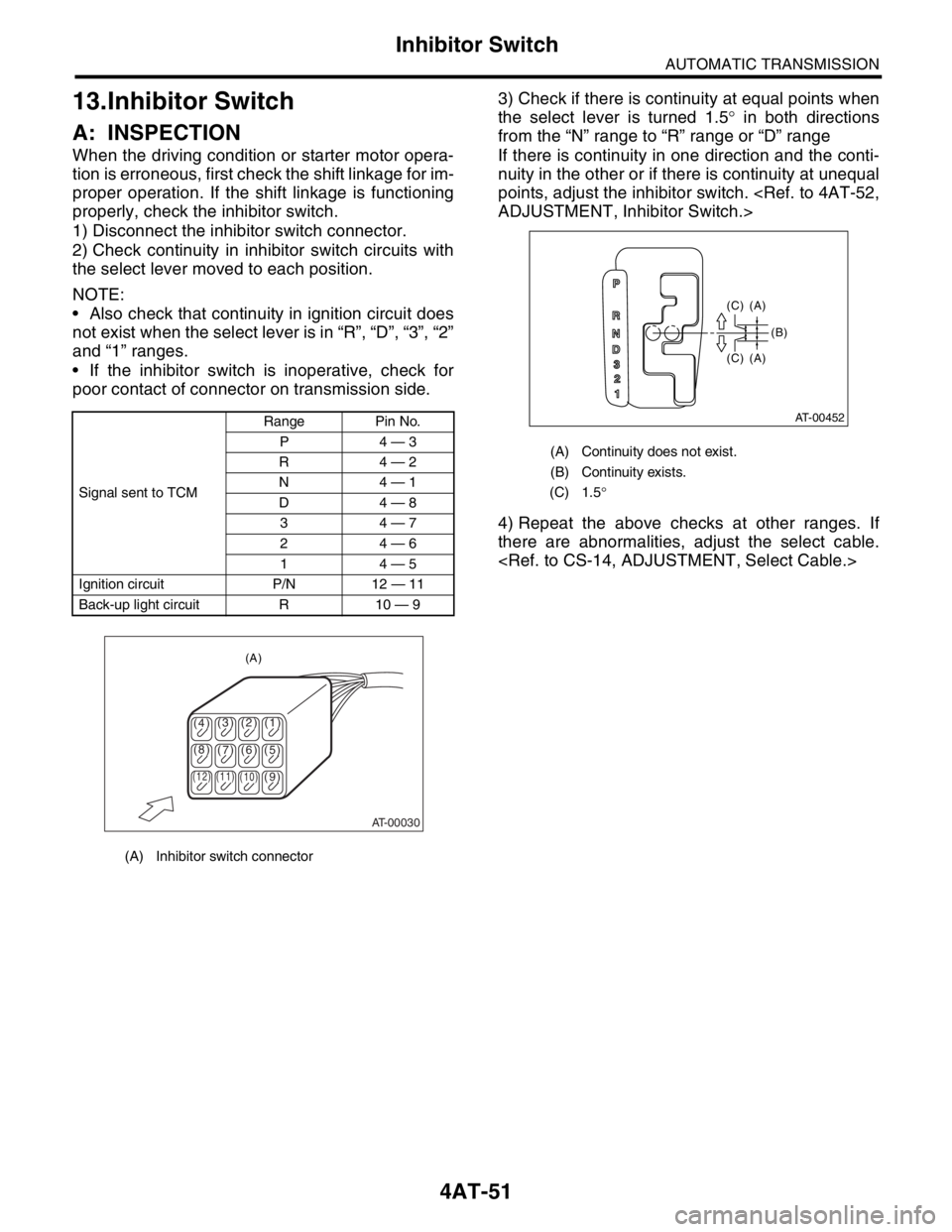

1) Disconnect the inhibitor switch connector.

2) Check continuity in inhibitor switch circuits with

the select lever moved to each position.

NOTE:

Also check that continuity in ignition circuit does

not exist when the select lever is in “R”, “D”, “3”, “2”

and “1” ranges.

If the inhibitor switch is inoperative, check for

poor contact of connector on transmission side.3) Check if there is continuity at equal points when

the select lever is turned 1.5° in both directions

from the “N” range to “R” range or “D” range

If there is continuity in one direction and the conti-

nuity in the other or if there is continuity at unequal

points, adjust the inhibitor switch.

4) Repeat the above checks at other ranges. If

there are abnormalities, adjust the select cable.

Signal sent to TCMRange Pin No.

P4 — 3

R4 — 2

N4 — 1

D4 — 8

34 — 7

24 — 6

14 — 5

Ignition circuit P/N 12 — 11

Back-up light circuit R 10 — 9

(A) Inhibitor switch connector

AT-00030

(4)(3)(2) (1)

(5) (6) (7) (8)

(9)

(10) (11) (12)

(A)

(A) Continuity does not exist.

(B) Continuity exists.

(C) 1.5°

(C) (A) (C) (A)

(B)

AT-00452

P

R

N

D

3

2

1

Page 2365 of 2870

4AT-52

AUTOMATIC TRANSMISSION

Inhibitor Switch

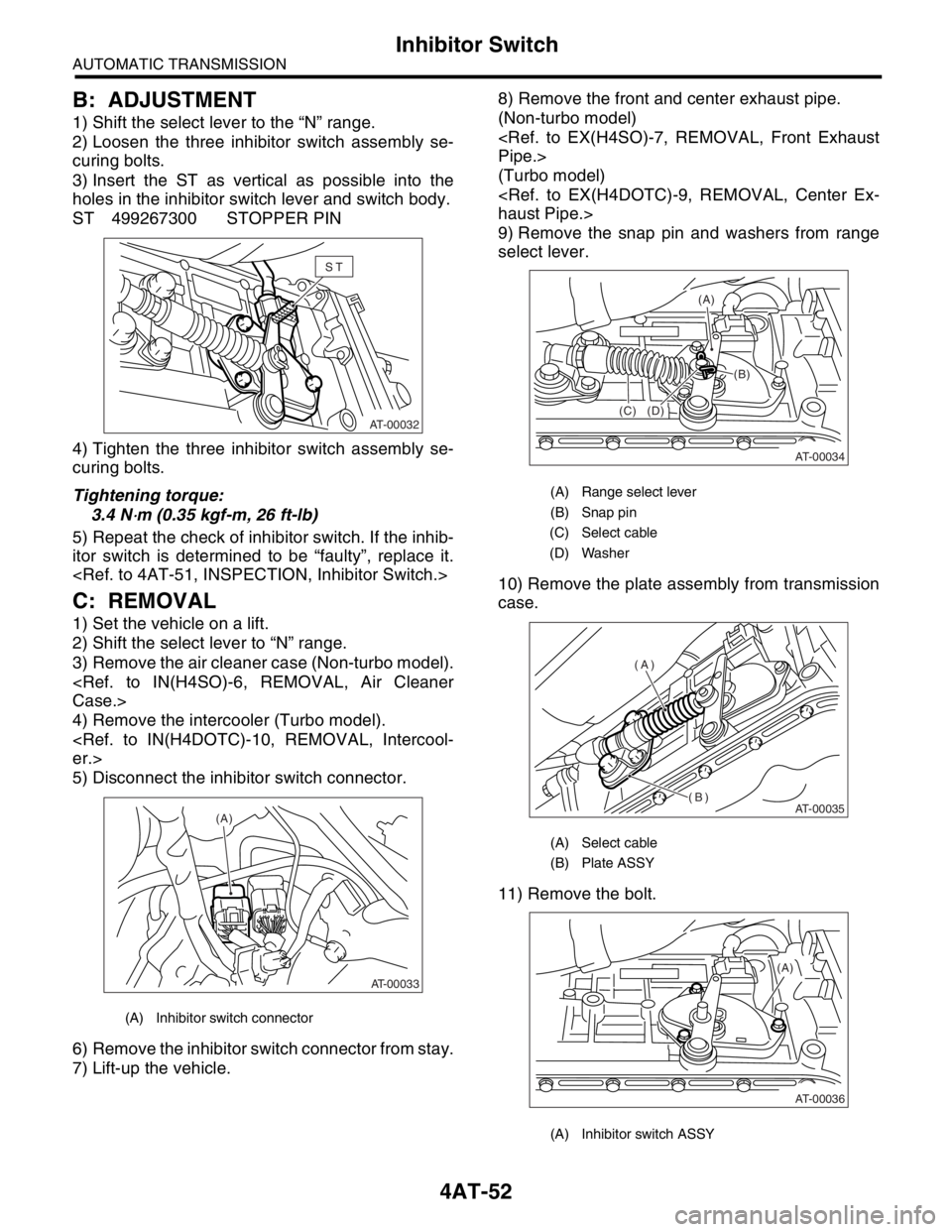

B: ADJUSTMENT

1) Shift the select lever to the “N” range.

2) Loosen the three inhibitor switch assembly se-

curing bolts.

3) Insert the ST as vertical as possible into the

holes in the inhibitor switch lever and switch body.

ST 499267300 STOPPER PIN

4) Tighten the three inhibitor switch assembly se-

curing bolts.

Tightening torque:

3.4 N

⋅m (0.35 kgf-m, 26 ft-lb)

5) Repeat the check of inhibitor switch. If the inhib-

itor switch is determined to be “faulty”, replace it.

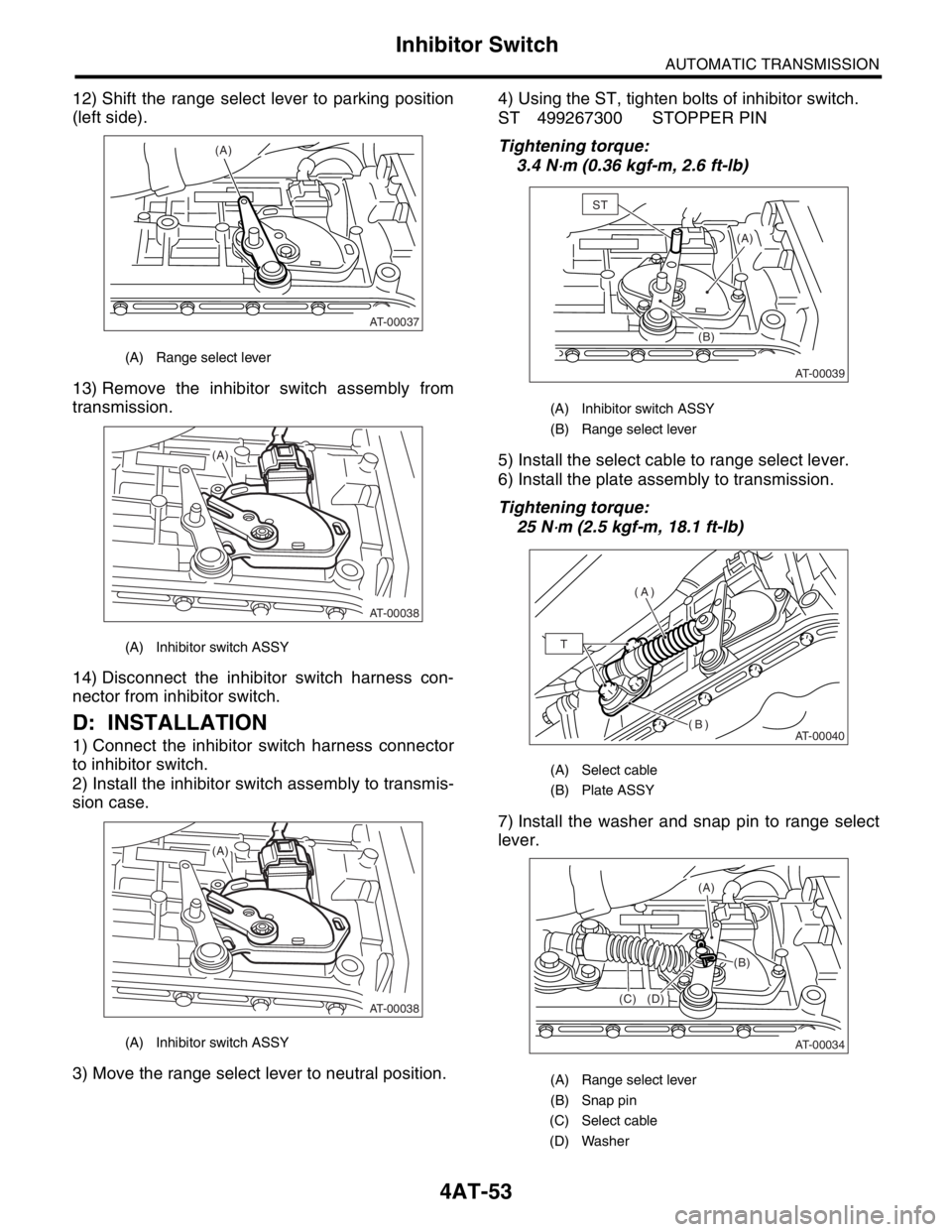

C: REMOVAL

1) Set the vehicle on a lift.

2) Shift the select lever to “N” range.

3) Remove the air cleaner case (Non-turbo model).

4) Remove the intercooler (Turbo model).

5) Disconnect the inhibitor switch connector.

6) Remove the inhibitor switch connector from stay.

7) Lift-up the vehicle.8) Remove the front and center exhaust pipe.

(Non-turbo model)

(Turbo model)

9) Remove the snap pin and washers from range

select lever.

10) Remove the plate assembly from transmission

case.

11) Remove the bolt.

(A) Inhibitor switch connector

ST

AT-00032

AT-00033

(A)

(A) Range select lever

(B) Snap pin

(C) Select cable

(D) Washer

(A) Select cable

(B) Plate ASSY

(A) Inhibitor switch ASSY

AT-00034

(C)(B) (A)

(D)

AT-00035

(A)

(B)

(A)

AT-00036

Page 2366 of 2870

4AT-53

AUTOMATIC TRANSMISSION

Inhibitor Switch

12) Shift the range select lever to parking position

(left side).

13) Remove the inhibitor switch assembly from

transmission.

14) Disconnect the inhibitor switch harness con-

nector from inhibitor switch.

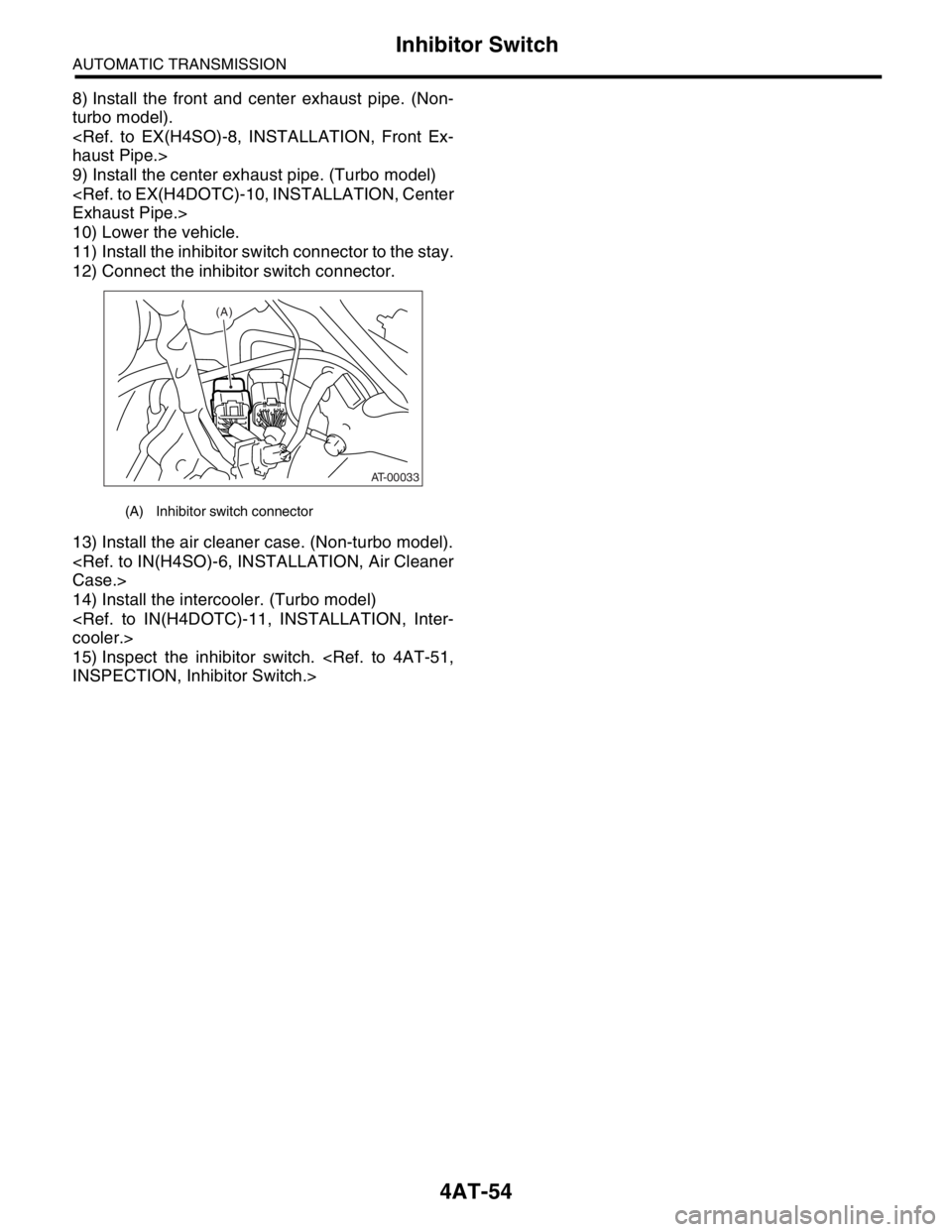

D: INSTALLATION

1) Connect the inhibitor switch harness connector

to inhibitor switch.

2) Install the inhibitor switch assembly to transmis-

sion case.

3) Move the range select lever to neutral position.4) Using the ST, tighten bolts of inhibitor switch.

ST 499267300 STOPPER PIN

Tightening torque:

3.4 N

⋅m (0.36 kgf-m, 2.6 ft-lb)

5) Install the select cable to range select lever.

6) Install the plate assembly to transmission.

Tightening torque:

25 N

⋅m (2.5 kgf-m, 18.1 ft-lb)

7) Install the washer and snap pin to range select

lever.

(A) Range select lever

(A) Inhibitor switch ASSY

(A) Inhibitor switch ASSY

(A)

AT-00037

AT-00038

(A)

AT-00038

(A)

(A) Inhibitor switch ASSY

(B) Range select lever

(A) Select cable

(B) Plate ASSY

(A) Range select lever

(B) Snap pin

(C) Select cable

(D) Washer

(A)

AT-00039

(B)

ST

AT-00040

(A)

(B)

T

AT-00034

(C)(B) (A)

(D)

Page 2367 of 2870

4AT-54

AUTOMATIC TRANSMISSION

Inhibitor Switch

8) Install the front and center exhaust pipe. (Non-

turbo model).

9) Install the center exhaust pipe. (Turbo model)

10) Lower the vehicle.

11) Install the inhibitor switch connector to the stay.

12) Connect the inhibitor switch connector.

13) Install the air cleaner case. (Non-turbo model).

14) Install the intercooler. (Turbo model)

15) Inspect the inhibitor switch.

(A) Inhibitor switch connector

AT-00033

(A)

Page 2368 of 2870

4AT-55

AUTOMATIC TRANSMISSION

Front Vehicle Speed Sensor

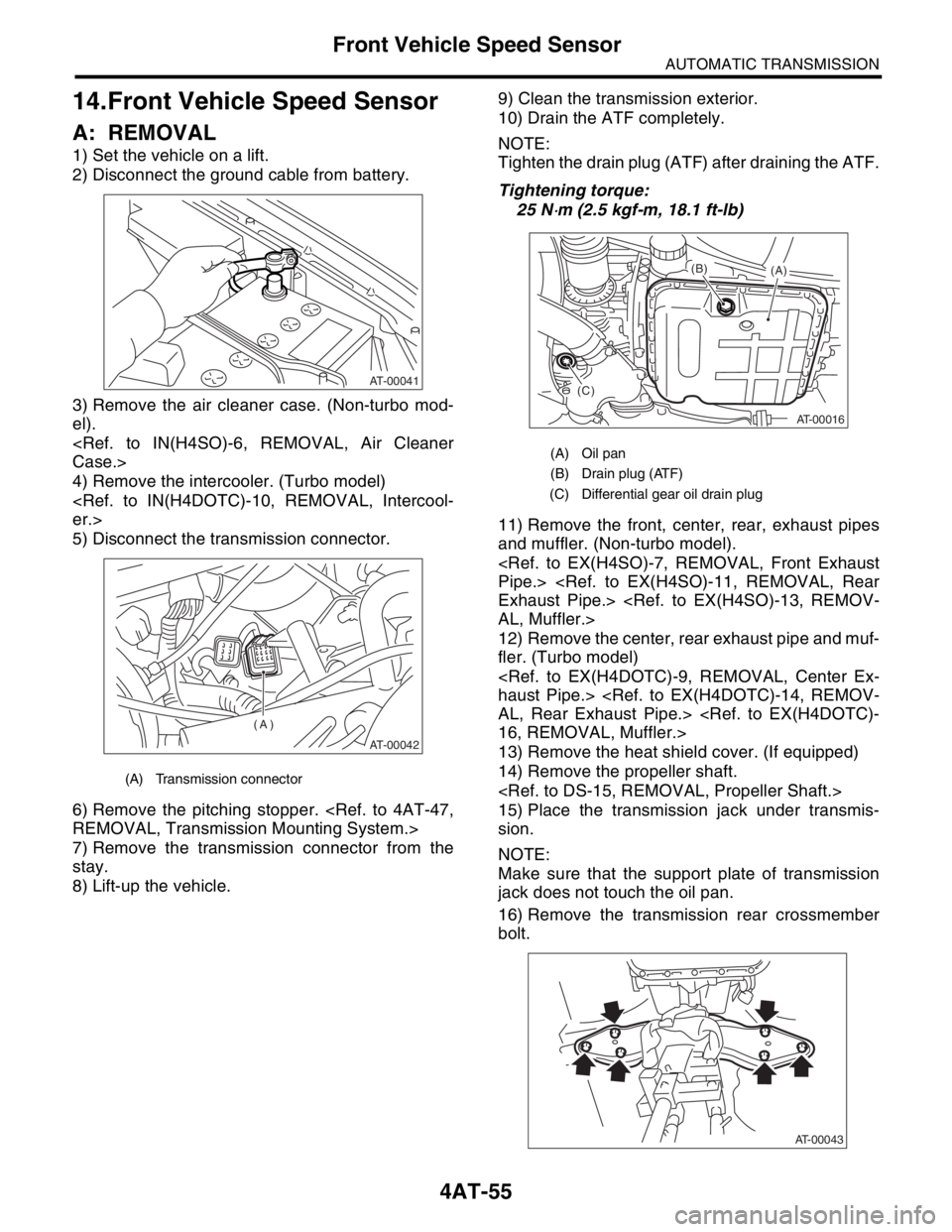

14.Front Vehicle Speed Sensor

A: REMOVAL

1) Set the vehicle on a lift.

2) Disconnect the ground cable from battery.

3) Remove the air cleaner case. (Non-turbo mod-

el).

4) Remove the intercooler. (Turbo model)

5) Disconnect the transmission connector.

6) Remove the pitching stopper.

7) Remove the transmission connector from the

stay.

8) Lift-up the vehicle.9) Clean the transmission exterior.

10) Drain the ATF completely.

NOTE:

Tighten the drain plug (ATF) after draining the ATF.

Tightening torque:

25 N

⋅m (2.5 kgf-m, 18.1 ft-lb)

11) Remove the front, center, rear, exhaust pipes

and muffler. (Non-turbo model).

12) Remove the center, rear exhaust pipe and muf-

fler. (Turbo model)

13) Remove the heat shield cover. (If equipped)

14) Remove the propeller shaft.

15) Place the transmission jack under transmis-

sion.

NOTE:

Make sure that the support plate of transmission

jack does not touch the oil pan.

16) Remove the transmission rear crossmember

bolt.

(A) Transmission connector

AT-00041

AT-00042

(A)

(A) Oil pan

(B) Drain plug (ATF)

(C) Differential gear oil drain plug

AT-00016

(A) (B)

(C)

AT-00043

Page 2369 of 2870

4AT-56

AUTOMATIC TRANSMISSION

Front Vehicle Speed Sensor

17) Lower the transmission jack.

NOTE:

Do not separate the transmission jack and trans-

mission.

18) Remove the ATF cooler inlet and outlet pipes.

CAUTION:

When removing the outlet pipe, be careful not

to lose the ball and spring used with retaining

screw.

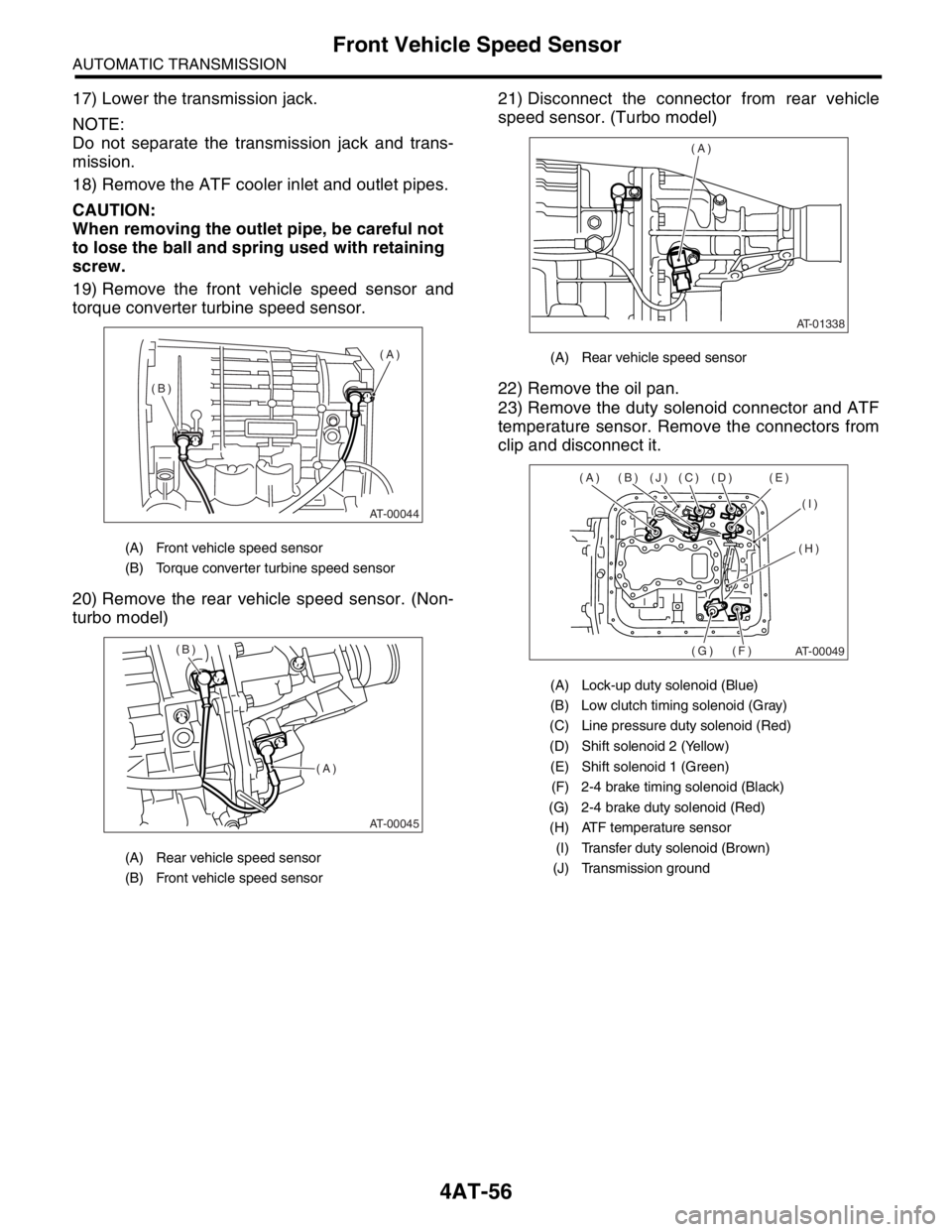

19) Remove the front vehicle speed sensor and

torque converter turbine speed sensor.

20) Remove the rear vehicle speed sensor. (Non-

turbo model)21) Disconnect the connector from rear vehicle

speed sensor. (Turbo model)

22) Remove the oil pan.

23) Remove the duty solenoid connector and ATF

temperature sensor. Remove the connectors from

clip and disconnect it.

(A) Front vehicle speed sensor

(B) Torque converter turbine speed sensor

(A) Rear vehicle speed sensor

(B) Front vehicle speed sensor

AT-00044

(A)

(B)

AT-00045

(A) (B)

(A) Rear vehicle speed sensor

(A) Lock-up duty solenoid (Blue)

(B) Low clutch timing solenoid (Gray)

(C) Line pressure duty solenoid (Red)

(D) Shift solenoid 2 (Yellow)

(E) Shift solenoid 1 (Green)

(F) 2-4 brake timing solenoid (Black)

(G) 2-4 brake duty solenoid (Red)

(H) ATF temperature sensor

(I) Transfer duty solenoid (Brown)

(J) Transmission ground

AT-01338

(A)

AT-00049

(A) (B) (J) (C) (D) (E)

(I)

(H)

(F) (G)

Page 2370 of 2870

4AT-57

AUTOMATIC TRANSMISSION

Front Vehicle Speed Sensor

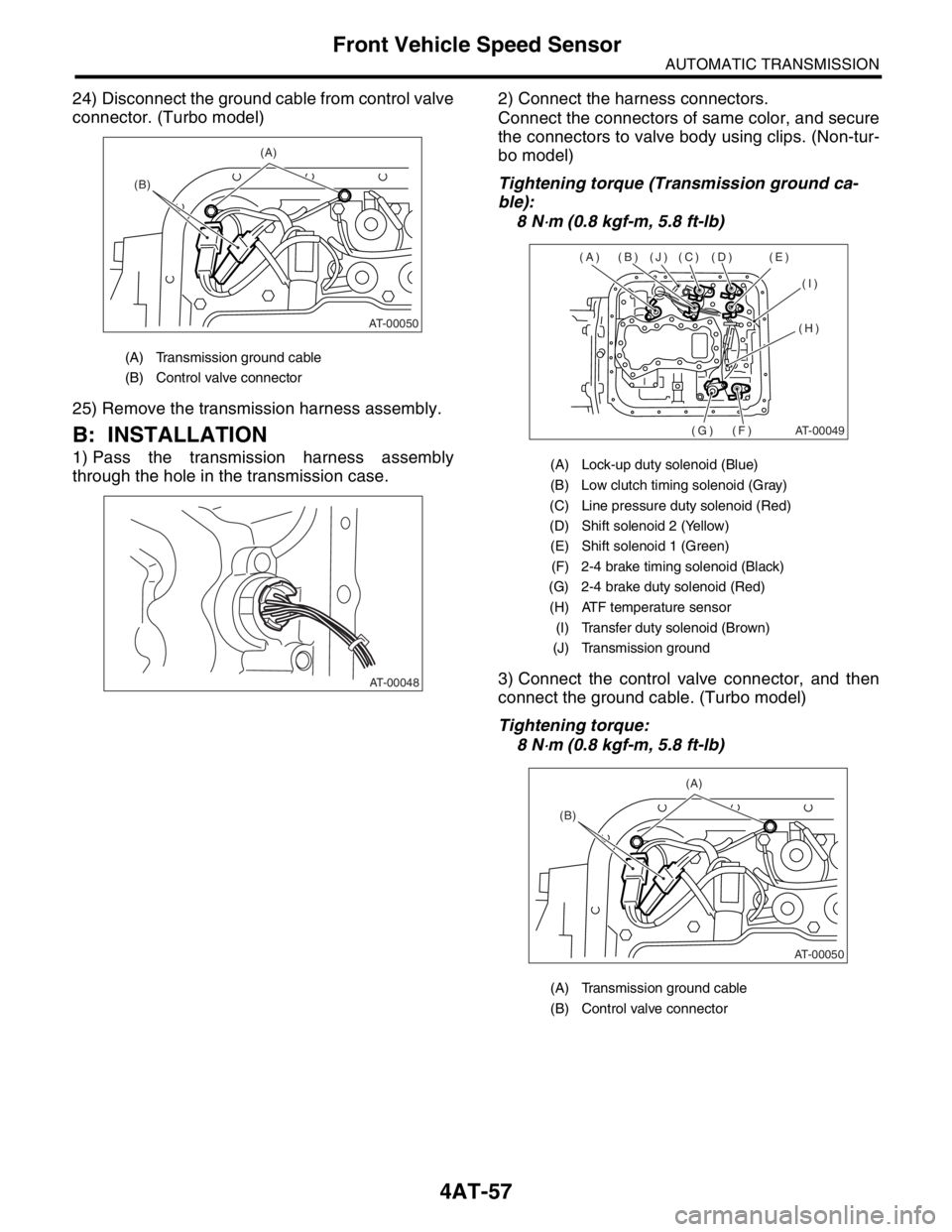

24) Disconnect the ground cable from control valve

connector. (Turbo model)

25) Remove the transmission harness assembly.

B: INSTALLATION

1) Pass the transmission harness assembly

through the hole in the transmission case.2) Connect the harness connectors.

Connect the connectors of same color, and secure

the connectors to valve body using clips. (Non-tur-

bo model)

Tightening torque (Transmission ground ca-

ble):

8 N

⋅m (0.8 kgf-m, 5.8 ft-lb)

3) Connect the control valve connector, and then

connect the ground cable. (Turbo model)

Tightening torque:

8 N

⋅m (0.8 kgf-m, 5.8 ft-lb)

(A) Transmission ground cable

(B) Control valve connector

AT-00050

(B)

(A)

AT-00048

(A) Lock-up duty solenoid (Blue)

(B) Low clutch timing solenoid (Gray)

(C) Line pressure duty solenoid (Red)

(D) Shift solenoid 2 (Yellow)

(E) Shift solenoid 1 (Green)

(F) 2-4 brake timing solenoid (Black)

(G) 2-4 brake duty solenoid (Red)

(H) ATF temperature sensor

(I) Transfer duty solenoid (Brown)

(J) Transmission ground

(A) Transmission ground cable

(B) Control valve connector

AT-00049

(A) (B) (J) (C) (D) (E)

(I)

(H)

(F) (G)

AT-00050

(B)

(A)