SUBARU FORESTER 2004 Service Repair Manual

Manufacturer: SUBARU, Model Year: 2004, Model line: FORESTER, Model: SUBARU FORESTER 2004Pages: 2870, PDF Size: 38.67 MB

Page 2341 of 2870

4AT-29

AUTOMATIC TRANSMISSION

General Description

2. GENERAL TOOL

24082AA230

(Newly adopted tool)CARTRIDGE Troubleshooting for electrical system.

22771AA030 SUBARU SELECT

MONITOR KITTroubleshooting for electrical system.

English: 22771AA030 (Without printer)

German: 22771AA070 (Without printer)

French: 22771AA080 (Without printer)

Spanish: 22771AA090 (Without printer)

TOOL NAME REMARKS

Depth gauge Used for measuring transmission end play.

Thickness gauge Used for measuring clearance of clutch, brake and oil pump.

Micro meter Used for measuring thickness of drive pinion.

Spring balance Used for measuring starting torque of drive pinion.

Circuit tester Used for measuring resistance and voltage.

TO RX

® T70Used for removing and installing differential gear oil drain plug.

Push/pull gauge Used for measuring stroke of low & reverse piston.ILLUSTRATION TOOL NUMBER DESCRIPTION REMARKS

ST24082AA230

ST22771AA030

Page 2342 of 2870

4AT-30

AUTOMATIC TRANSMISSION

Automatic Transmission Fluid

2. Automatic Transmission Flu-

id

A: INSPECTION

NOTE:

The level of ATF varies with fluid temperature. Pay

attention to the ATF temperature when checking

ATF level.

1) Raise the ATF temperature by driving a distance

of 5 to 10 km (3 to 6 miles). Otherwise, idle the en-

gine to raise ATF temperature to 70 — 80°C (158

— 176°F) on Subaru Select Monitor.

TION, Subaru Select Monitor.>

2) Make sure the vehicle is level.

3) After selecting all positions (P, R, N, D, 3, 2, 1),

set the select lever in “P” range. Measure the ATF

level with engine idling for one or two minutes.

4) Make sure that ATF level is above the center of

upper level and lower level at HOT side.

If the ATF level is below the lower level, check for

leaks in the transmission. If there are leaks, it is

necessary to repair or replace gasket, oil seals,

plugs or other parts.

5) If the ATF level is below the center between up-

per level and lower level, add the recommended

ATF until the fluid level is found above the center

between upper level and lower level marks.

CAUTION:

Use care not to exceed the upper level.

Remember that the addition of ATF to the up-

per limit mark when the transmission is cold

will overfilling of ATF, causing a transmission

failure.

6) Check ATF level after raising ATF temperature

to 70 — 80°C (158 — 176°F) by running the vehicle

or by idling the engine again.

B: REPLACEMENT

1) Lift-up the vehicle.2) Drain the ATF completely.

CAUTION:

Directly after the engine has been running, the

ATF is hot. Be careful not to burn yourself.

3) Replace the gasket with new one, and then tight-

en the drain plug (ATF).

Tightening torque:

25 N

⋅m (2.5 kgf-m, 18.1 ft-lb)

4) Lower the vehicle.

5) Pour ATF from the ATF charge pipe.

Recommended fluid:

DEXRON III type automatic transmission flu-

id

Capacity:

Fill the same amount of ATF drained from

drain plug hole.

CAPACITY WHEN TRANSMISSION IS OVER-

HAULED:

2.0 L NON-TURBO MODEL

8.4 — 8.72 (8.9 — 9.2 US qt, 7.4 — 7.7 Imp

qt)

EXCEPT 2.0 L NON-TURBO MODEL

9.3 — 9.62 (9.8 — 10.1 US qt, 8.2 — 8.4 Imp

qt)

6) Check the level and leaks of ATF.

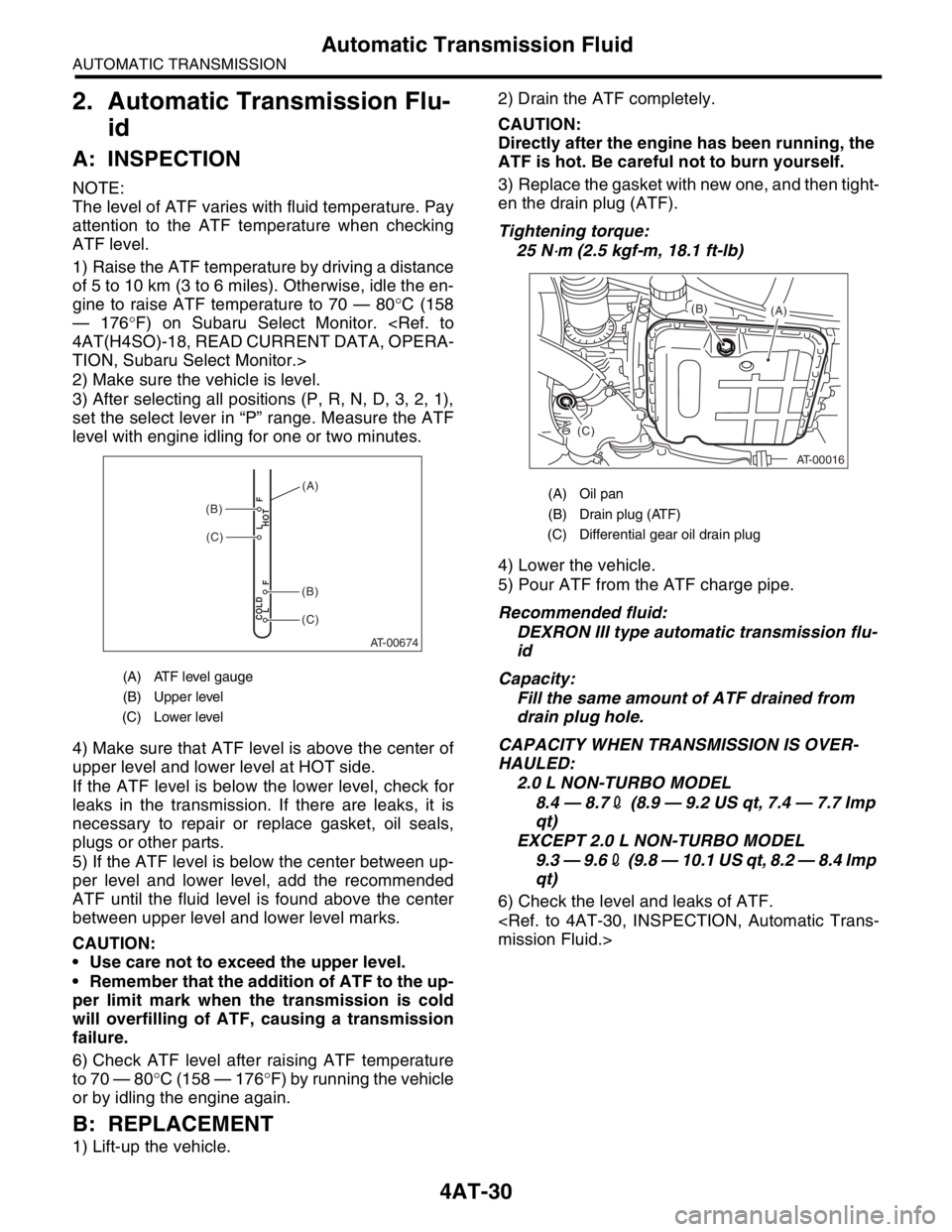

(A) ATF level gauge

(B) Upper level

(C) Lower level

AT-00674

COLD

LFHOT LF

(C)

(C)

(B)

(B)

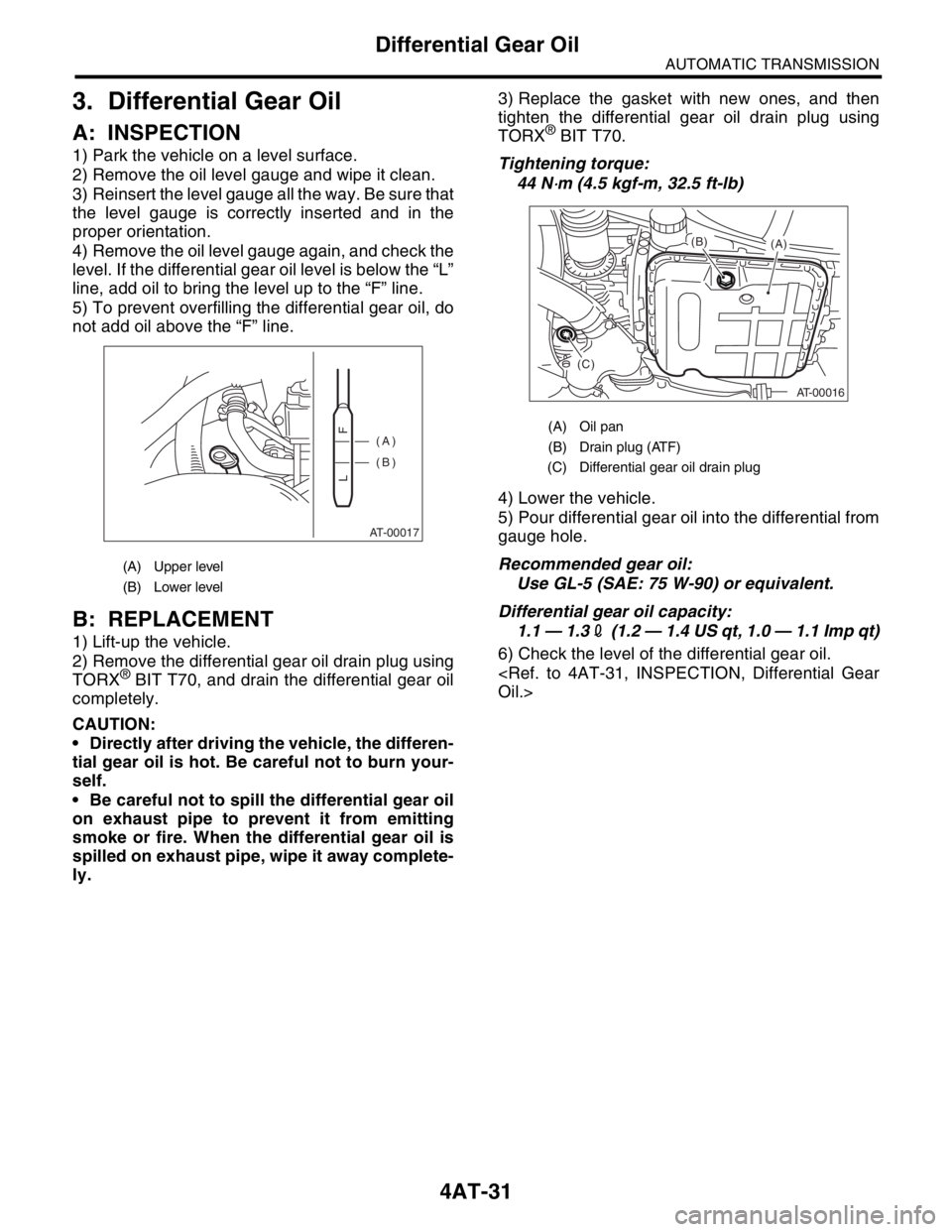

(A)(A) Oil pan

(B) Drain plug (ATF)

(C) Differential gear oil drain plug

AT-00016

(A) (B)

(C)

Page 2343 of 2870

4AT-31

AUTOMATIC TRANSMISSION

Differential Gear Oil

3. Differential Gear Oil

A: INSPECTION

1) Park the vehicle on a level surface.

2) Remove the oil level gauge and wipe it clean.

3) Reinsert the level gauge all the way. Be sure that

the level gauge is correctly inserted and in the

proper orientation.

4) Remove the oil level gauge again, and check the

level. If the differential gear oil level is below the “L”

line, add oil to bring the level up to the “F” line.

5) To prevent overfilling the differential gear oil, do

not add oil above the “F” line.

B: REPLACEMENT

1) Lift-up the vehicle.

2) Remove the differential gear oil drain plug using

TORX

® BIT T70, and drain the differential gear oil

completely.

CAUTION:

Directly after driving the vehicle, the differen-

tial gear oil is hot. Be careful not to burn your-

self.

Be careful not to spill the differential gear oil

on exhaust pipe to prevent it from emitting

smoke or fire. When the differential gear oil is

spilled on exhaust pipe, wipe it away complete-

ly.3) Replace the gasket with new ones, and then

tighten the differential gear oil drain plug using

TORX

® BIT T70.

Tightening torque:

44 N

⋅m (4.5 kgf-m, 32.5 ft-lb)

4) Lower the vehicle.

5) Pour differential gear oil into the differential from

gauge hole.

Recommended gear oil:

Use GL-5 (SAE: 75 W-90) or equivalent.

Differential gear oil capacity:

1.1 — 1.32 (1.2 — 1.4 US qt, 1.0 — 1.1 Imp qt)

6) Check the level of the differential gear oil.

(A) Upper level

(B) Lower level

AT-00017

(A)

(B)

LF

(A) Oil pan

(B) Drain plug (ATF)

(C) Differential gear oil drain plug

AT-00016

(A) (B)

(C)

Page 2344 of 2870

4AT-32

AUTOMATIC TRANSMISSION

Road Test

4. Road Test

A: INSPECTION

1. GENERAL PRECAUTION

Road tests should be conducted to properly diag-

nose the condition of the automatic transmission.

NOTE:

When performing the test, do not exceed posted

speed limit.

2. D RANGE SHIFT FUNCTION

Check shifting between 1st ←→ 2nd ←→ 3rd ←→

4th while driving on normal city streets.

3. D RANGE SHIFT SHOCK

Check the shock level when shifting up during nor-

mal driving.

4. KICK-DOWN FUNCTION

Check kick-down for each gear. Also check the

kick-down shock level.

5. ENGINE BRAKE OPERATION

Check the 3rd gear engine brake when shifting

down from D ←→ 3rd range while driving in 4th

gear of D range [50 — 60 km/h (31 — 37 MPH)].

Check the 2nd gear engine brake when shifting

between 3rd ←→ 2nd range while driving in the 3rd

range of 3rd gear [40 — 50 km/h (25 — 31 MPH)].

Check the 1st gear engine brake when shifting

between 2nd ←→ 1st range while driving in the 2nd

range of 2nd gear [20 — 30 km/h (12 — 19 MPH)].

6. LOCK-UP FUNCTION

Check that rpm does not change sharply when

the axle pedal is lightly depressed when driving on

flat roads at 60 km/h (37 MPH).

Check slip lock-up with following procedure.

Subaru Select Monitor is needed for checking (EC,

EK model).

Before start checking, check that the DTC is not ex-

isted using Subaru Select Monitor. When the DTC

is existed, perform the collective action with DTC

and check that the DTC is not existed again, and

then start the checking.

1) The check performed on flat and straight road or

free roller.

NOTE:

Slip lock-up does not operate when the vehicle is

lifted up, because of not occurring surface resis-

tance.

Also checking on the free roller, check with de-

pressing foot brake lightly to make the checking

easier, because the surface resistance will be defi-

cient2) Connect the Subaru Select Monitor.

3) Check ATF temperature using Subaru Select

Monitor.

NOTE:

ATF temperature is between 50 — 100°C (122

— 212°F).

When the temperature is low, warm-up the ATF

by running the vehicle or etc.

4) Start the engine, and make the lock-up duty be

able to read on data display of Subaru Select Mon-

itor.

5) 35 — 40 Drive the vehicle at a constant speed of

35 — 40 km/h (22 — 25 MPH).

6) Read the lock-up duty while vehicle is running.

Standard value:

25 — 45%

NOTE:

On the free roller, the value sometimes lowers.

Slip lock-up control is not operating when the

lock-up duty is less than 5%, or when the lock-up

duty goes down immediately after starts rise. On

these cases, improper ATF or deterioration of ATF

may be the cause. Check the amount of ATF or re-

place them, and then recheck it.

7. P RANGE OPERATION

Stop the vehicle on an uphill grade of 5% or more

and shift to “P” range. Check that the vehicle does

not move when the parking brake is released.

8. NOISE AND VIBRATION

Check for unusual sounds and vibration while driv-

ing and during shifting.

9. CLIMBING CONTROL FUNCTION

Check that the gear remains in 3rd when going

up a grade.

Check that the gear remains in 3rd when apply-

ing the brakes while going down a grade.

10.TRANSFER CLUTCH

Check tight corner braking when the vehicle started

with steering fully turned.

11.OIL LEAKS

After the driving test, inspect for oil leaks.

Page 2345 of 2870

4AT-33

AUTOMATIC TRANSMISSION

Stall Test

5. Stall Test

A: INSPECTION

NOTE:

The stall test is of extreme importance in diagnos-

ing the condition of the automatic transmission and

the engine. It should be conducted to measure the

engine stall speeds in “R” and “2” ranges (when

HOLD switch is ON).

Purposes of the stall test:

To check the operation of the automatic trans-

mission clutch.

To check the operation of the torque converter

clutch.

To check engine performance.

1) Check that the throttle valve opens fully.

2) Check that the engine oil level is correct.

3) Check that the coolant level is correct.

4) Check that the ATF level is correct.

5) Check that the differential gear oil level is cor-

rect.

6) Increase ATF temperature to 70 — 80°C (158 —

176°F) by idling the engine for approximately 30

minutes (with select lever set to “N” or “P”).

7) Place the wheel chocks at the front and rear of

all wheels and engage the parking brake.

8) Shift the manual linkage to ensure it operates

properly, then shift the select lever to the “2” range

and turn the HOLD switch to ON.

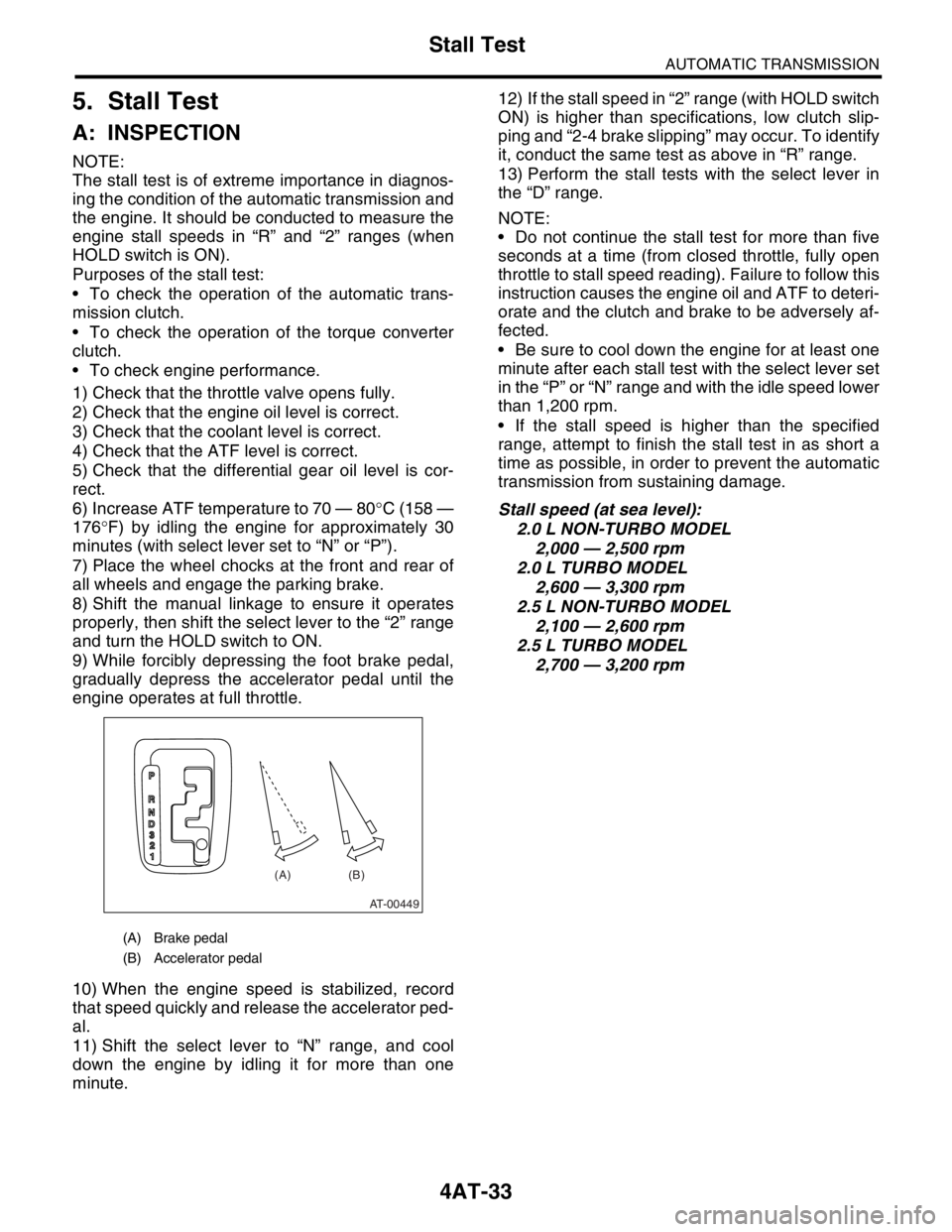

9) While forcibly depressing the foot brake pedal,

gradually depress the accelerator pedal until the

engine operates at full throttle.

10) When the engine speed is stabilized, record

that speed quickly and release the accelerator ped-

al.

11) Shift the select lever to “N” range, and cool

down the engine by idling it for more than one

minute.12) If the stall speed in “2” range (with HOLD switch

ON) is higher than specifications, low clutch slip-

ping and “2-4 brake slipping” may occur. To identify

it, conduct the same test as above in “R” range.

13) Perform the stall tests with the select lever in

the “D” range.

NOTE:

Do not continue the stall test for more than five

seconds at a time (from closed throttle, fully open

throttle to stall speed reading). Failure to follow this

instruction causes the engine oil and ATF to deteri-

orate and the clutch and brake to be adversely af-

fected.

Be sure to cool down the engine for at least one

minute after each stall test with the select lever set

in the “P” or “N” range and with the idle speed lower

than 1,200 rpm.

If the stall speed is higher than the specified

range, attempt to finish the stall test in as short a

time as possible, in order to prevent the automatic

transmission from sustaining damage.

Stall speed (at sea level):

2.0 L NON-TURBO MODEL

2,000 — 2,500 rpm

2.0 L TURBO MODEL

2,600 — 3,300 rpm

2.5 L NON-TURBO MODEL

2,100 — 2,600 rpm

2.5 L TURBO MODEL

2,700 — 3,200 rpm

(A) Brake pedal

(B) Accelerator pedal

(A) (B)

P

R

N

D

3

2

1

AT-00449

Page 2346 of 2870

4AT-34

AUTOMATIC TRANSMISSION

Stall Test

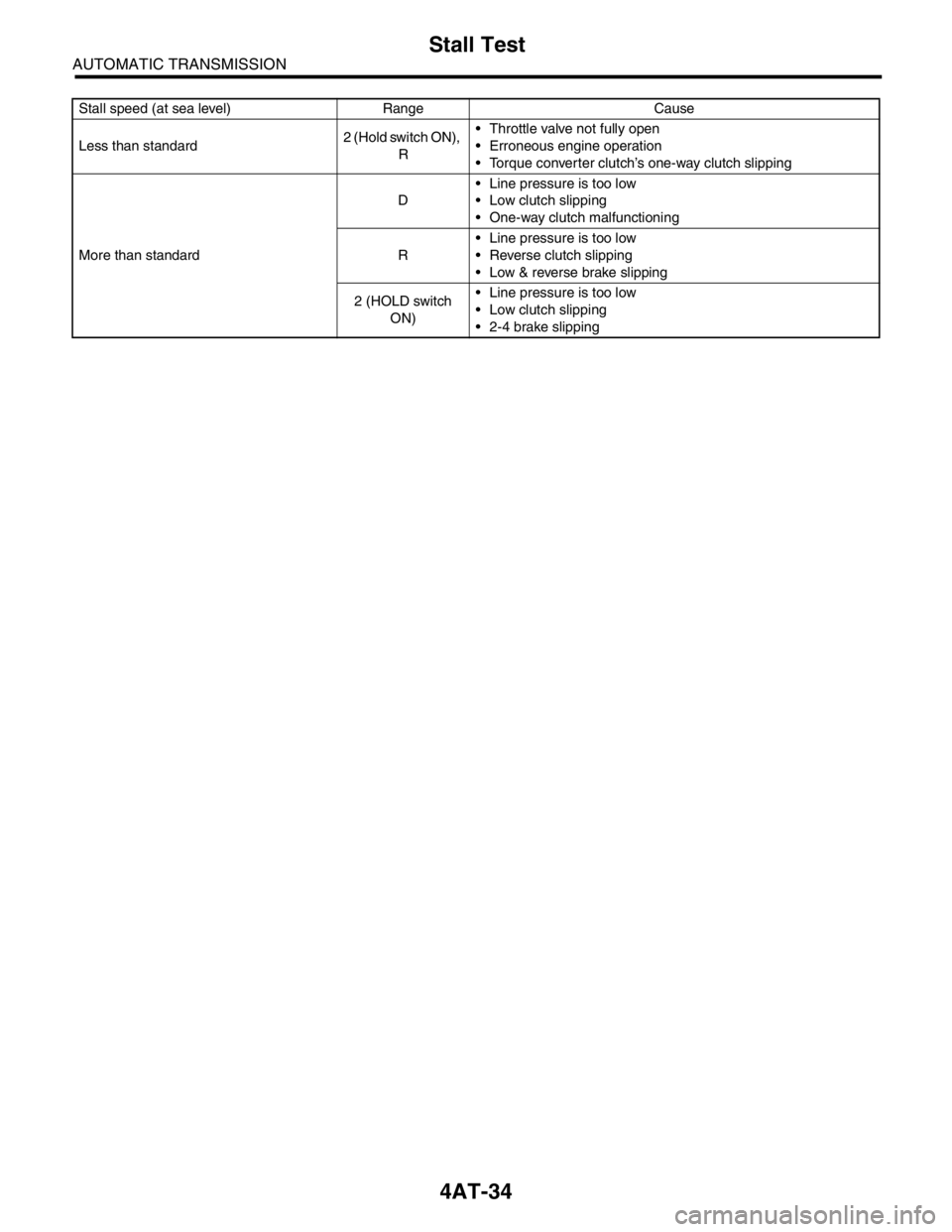

Stall speed (at sea level) Range Cause

Less than standard2 (Hold switch ON),

R Throttle valve not fully open

Erroneous engine operation

Torque converter clutch’s one-way clutch slipping

More than standardD Line pressure is too low

Low clutch slipping

One-way clutch malfunctioning

R Line pressure is too low

Reverse clutch slipping

Low & reverse brake slipping

2 (HOLD switch

ON) Line pressure is too low

Low clutch slipping

2-4 brake slipping

Page 2347 of 2870

4AT-35

AUTOMATIC TRANSMISSION

Time Lag Test

6. Time Lag Test

A: INSPECTION

NOTE:

If the select lever is shifted while the engine is

idling, there will be a certain time elapse or lag be-

fore the shock can be felt. This is used for checking

the condition of the low clutch, reverse clutch, low &

reverse brake and one-way clutch.

Perform the test at normal operation fluid tem-

perature 70 — 80°C (158 — 176°F).

Be sure to allow a one minute interval between

tests.

Perform measurement for three times and take

the average value.

1) Fully apply the parking brake.

2) Start the engine.

Check the idling speed (A/C OFF).

3) Shift the select lever from “N” to “D” range.

Using a stop watch, measure the time it takes from

shifting the lever until the shock is felt.

Time lag: Less than 1.2 seconds

If “N” → “D” time lag is longer than specified:

Line pressure too low

Low clutch worn

One-way clutch not operating properly

D-ring worn

4) In the same manner, measure the time lag for

“N” → “R”.

Time lag: Less than 1.5 seconds

If “N” → “R” time lag is longer than specified:

Line pressure too low

Reverse clutch worn

Low & reverse brake worn

D-ring worn

Page 2348 of 2870

4AT-36

AUTOMATIC TRANSMISSION

Line Pressure Test

7. Line Pressure Test

A: MEASUREMENT

NOTE:

If the clutch or the brake shows a sign of slippage or

shifting sensation is not correct, the line pressure

should be checked.

Excessive shocks during upshifting or shifting

takes place at a higher point than under normal cir-

cumstances, may be due to the line pressure being

too high.

Slippage or inability to operate the vehicle may,

in most cases, be due to insufficient oil pressure for

the operation of the clutch, brake or control valve.

1) Line pressure measurement (under no load):

(1) Before measuring line pressure, jack-up all

wheels.

(2) Maintain the temperature of ATF at approx.

70 — 80°C (158 — 176°F) during measurement.

(ATF will reach the above temperature after

idling the engine for approx. 30 minutes with the

select lever in “N” or “P”.)

2) Line pressure measurement (under heavy load):

(1) Before measuring line pressure, apply both

foot and parking brakes with all wheels chocked

(Same as for “stall” test conditions).

(2) Measure the line pressure when the select

lever is in “D”, “2” (HOLD switch ON) with engine

under stall conditions.

(3) Measure the line pressure within 5 seconds

after shifting the select lever to each position. (If

the line pressure needs to be measured again,

allow the engine to idle and cool it down more

than 1 minute.)

(4) Maintain the ATF temperature at approx. 70

— 80°C (158 — 176°F) during measurement.

(ATF will reach the above temperature after

idling the engine for approx. 30 minutes with the

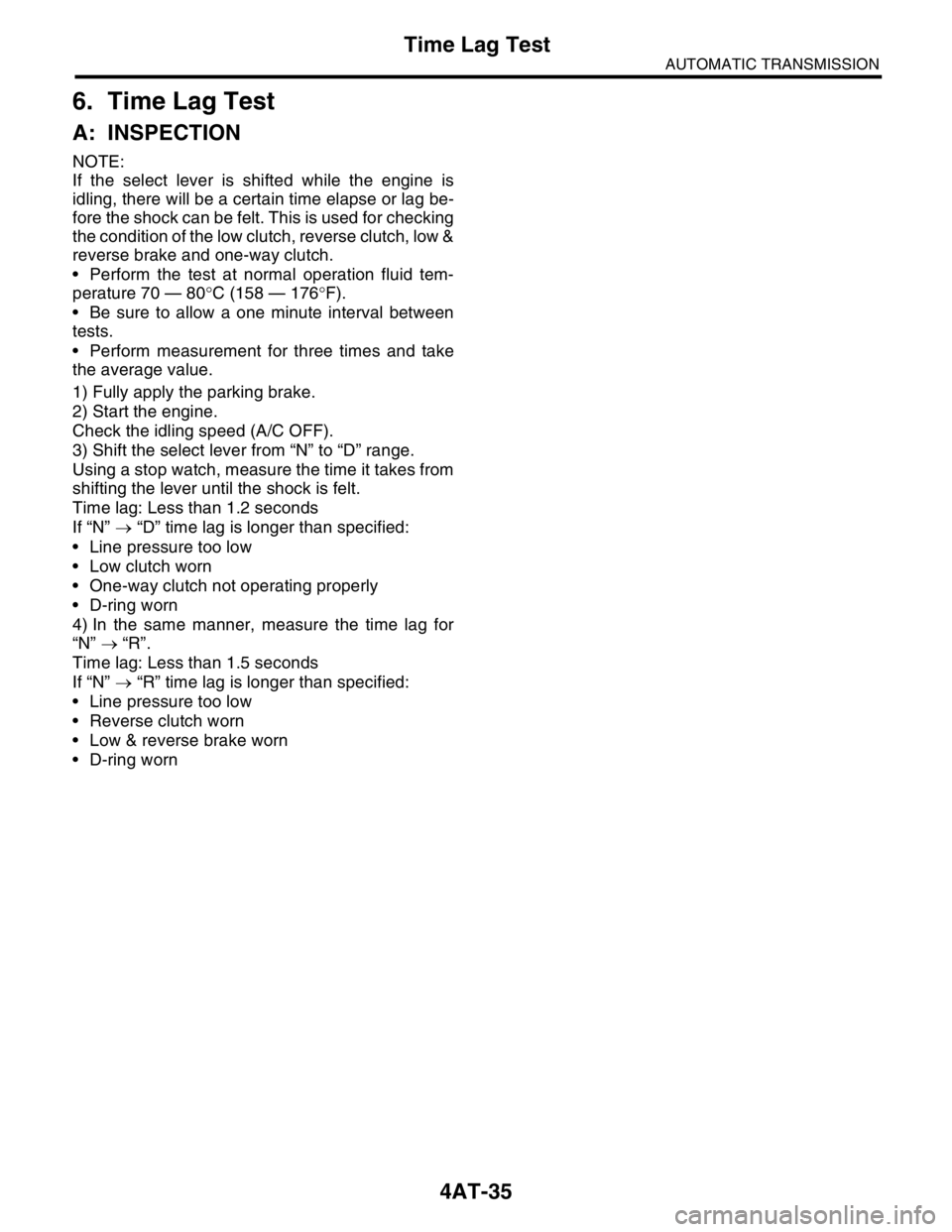

select lever in “N” or “P”.)3) Temporarily attach the ST to a suitable place in

the driver’s compartment, remove the blind plug lo-

cated in front of the toe board and pass the hose of

the ST to the engine compartment.

ST 498575400 OIL PRESSURE GAUGE

ASSY

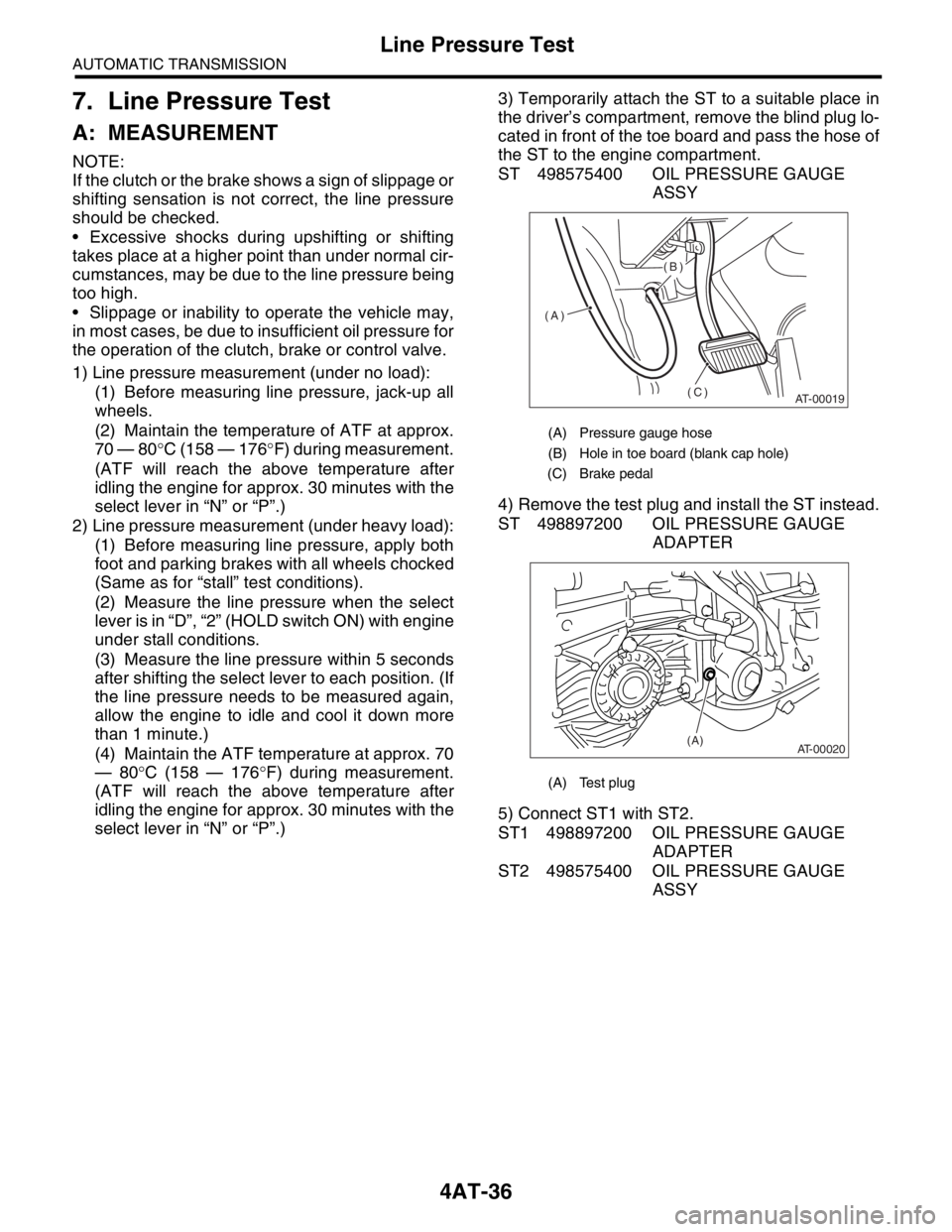

4) Remove the test plug and install the ST instead.

ST 498897200 OIL PRESSURE GAUGE

ADAPTER

5) Connect ST1 with ST2.

ST1 498897200 OIL PRESSURE GAUGE

ADAPTER

ST2 498575400 OIL PRESSURE GAUGE

ASSY

(A) Pressure gauge hose

(B) Hole in toe board (blank cap hole)

(C) Brake pedal

(A) Test plug

AT-00019

(A)(B)

(C)

AT-00020(A)

Page 2349 of 2870

4AT-37

AUTOMATIC TRANSMISSION

Line Pressure Test

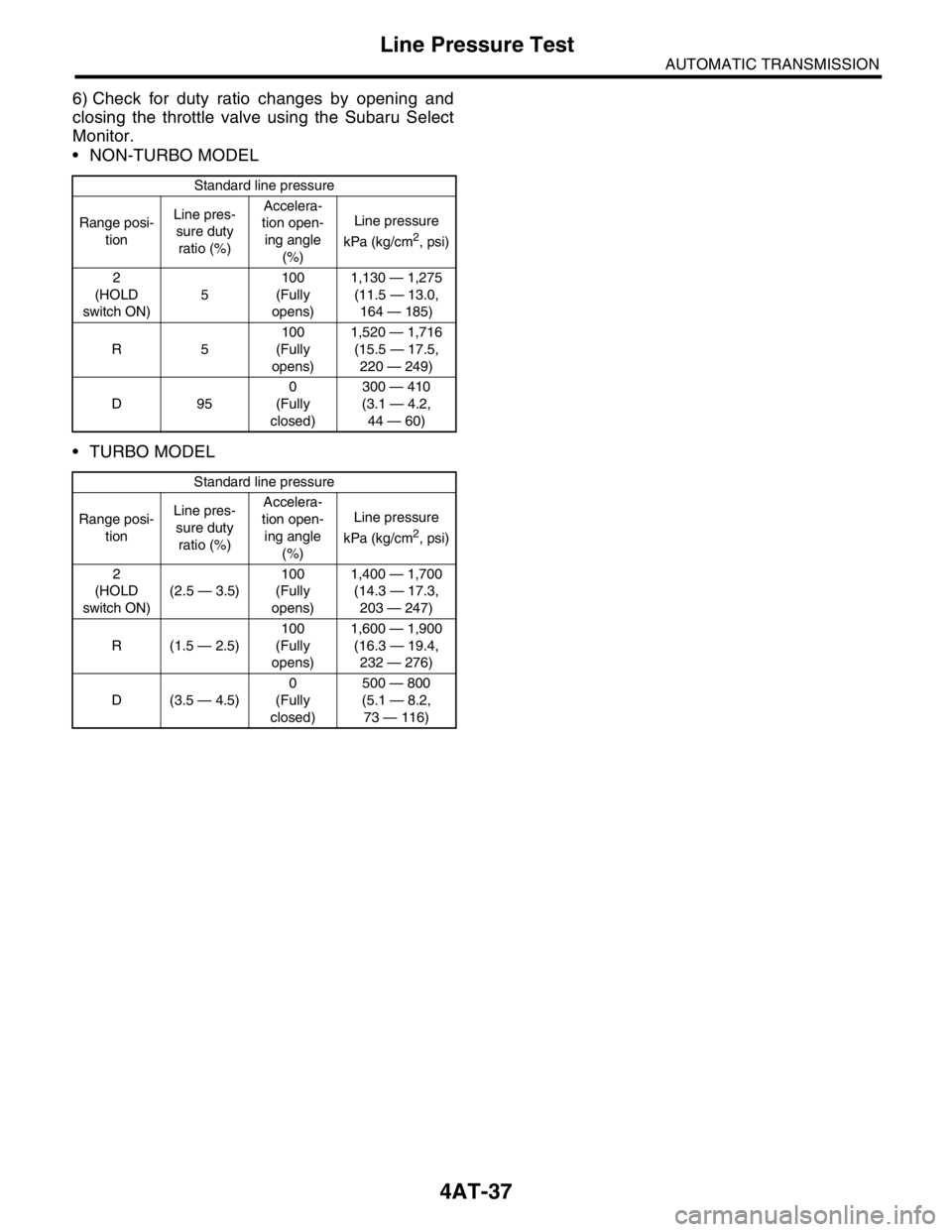

6) Check for duty ratio changes by opening and

closing the throttle valve using the Subaru Select

Monitor.

NON-TURBO MODEL

TURBO MODEL

Standard line pressure

Range posi-

tionLine pres-

sure duty

ratio (%)Accelera-

tion open-

ing angle

(%)Line pressure

kPa (kg/cm

2, psi)

2

(HOLD

switch ON)5100

(Fully

opens)1,130 — 1,275

(11.5 — 13.0,

164 — 185)

R5100

(Fully

opens)1,520 — 1,716

(15.5 — 17.5,

220 — 249)

D950

(Fully

closed)300 — 410

(3.1 — 4.2,

44 — 60)

Standard line pressure

Range posi-

tionLine pres-

sure duty

ratio (%)Accelera-

tion open-

ing angle

(%)Line pressure

kPa (kg/cm

2, psi)

2

(HOLD

switch ON)(2.5 — 3.5)100

(Fully

opens)1,400 — 1,700

(14.3 — 17.3,

203 — 247)

R (1.5 — 2.5)100

(Fully

opens)1,600 — 1,900

(16.3 — 19.4,

232 — 276)

D (3.5 — 4.5)0

(Fully

closed)500 — 800

(5.1 — 8.2,

73 — 116)

Page 2350 of 2870

4AT-38

AUTOMATIC TRANSMISSION

Transfer Clutch Pressure Test

8. Transfer Clutch Pressure

Test

A: INSPECTION

Check the transfer clutch pressure in accordance

with the following steps in the same manner as with

line pressure.

ST 498897700 OIL PRESSURE ADAPTER

SET

ST 498575400 OIL PRESSURE GAUGE

ASSYNOTE:

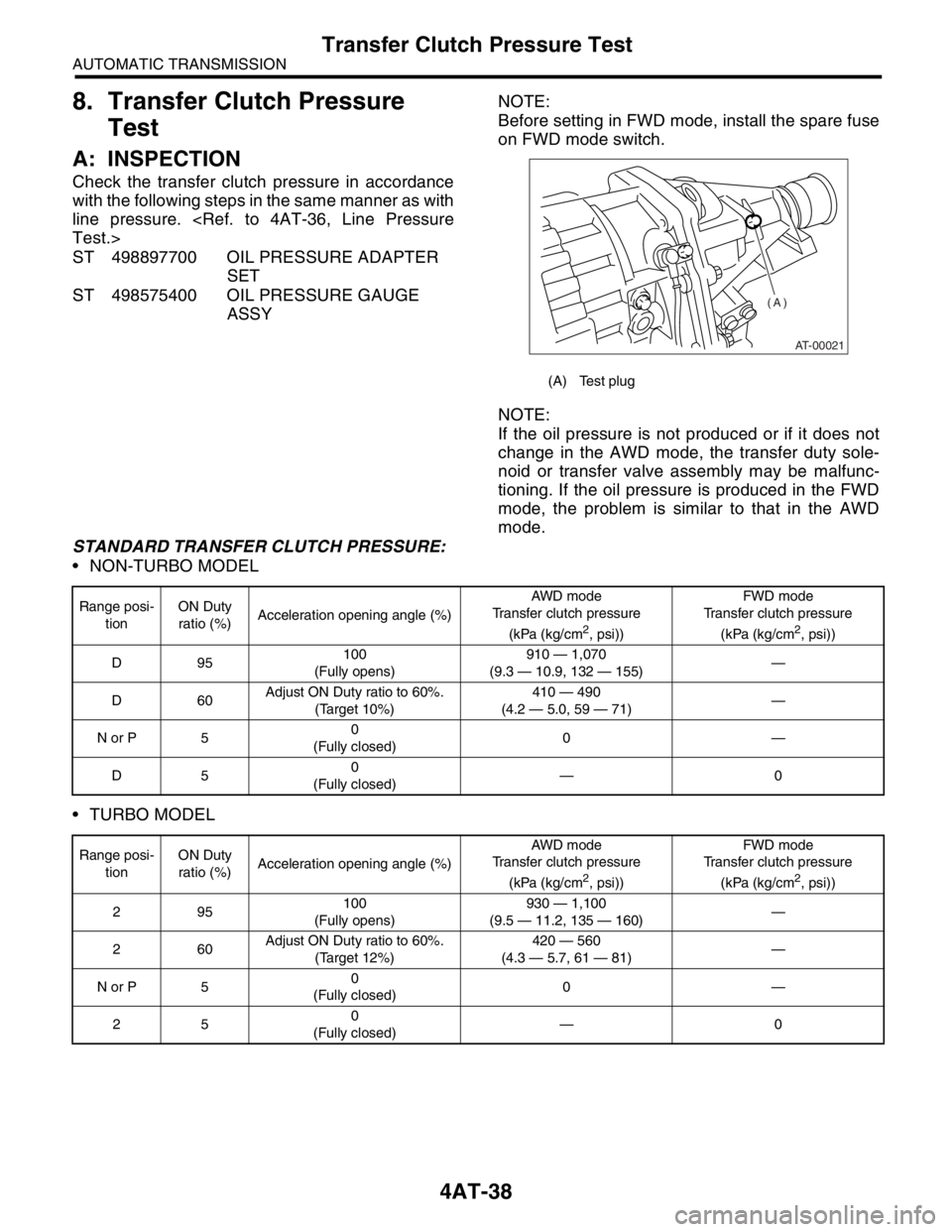

Before setting in FWD mode, install the spare fuse

on FWD mode switch.

NOTE:

If the oil pressure is not produced or if it does not

change in the AWD mode, the transfer duty sole-

noid or transfer valve assembly may be malfunc-

tioning. If the oil pressure is produced in the FWD

mode, the problem is similar to that in the AWD

mode.

STANDARD TRANSFER CLUTCH PRESSURE:

NON-TURBO MODEL

TURBO MODEL

(A) Test plug

AT-00021

(A)

Range posi-

tionON Duty

ratio (%)Acceleration opening angle (%)AWD m od e

Transfer clutch pressure

(kPa (kg/cm

2, psi))FWD mode

Transfer clutch pressure

(kPa (kg/cm2, psi))

D95100

(Fully opens)910 — 1,070

(9.3 — 10.9, 132 — 155)—

D60Adjust ON Duty ratio to 60%.

(Target 10%)410 — 490

(4.2 — 5.0, 59 — 71)—

N or P 50

(Fully closed)0—

D50

(Fully closed)—0

Range posi-

tionON Duty

ratio (%)Acceleration opening angle (%)AWD m od e

Transfer clutch pressure

(kPa (kg/cm

2, psi))FWD mode

Transfer clutch pressure

(kPa (kg/cm2, psi))

295100

(Fully opens)930 — 1,100

(9.5 — 11.2, 135 — 160)—

260Adjust ON Duty ratio to 60%.

(Target 12%)420 — 560

(4.3 — 5.7, 61 — 81)—

N or P 50

(Fully closed)0—

250

(Fully closed)—0