SUBARU FORESTER 2004 Service Repair Manual

Manufacturer: SUBARU, Model Year: 2004, Model line: FORESTER, Model: SUBARU FORESTER 2004Pages: 2870, PDF Size: 38.67 MB

Page 2381 of 2870

4AT-68

AUTOMATIC TRANSMISSION

Control Valve Body

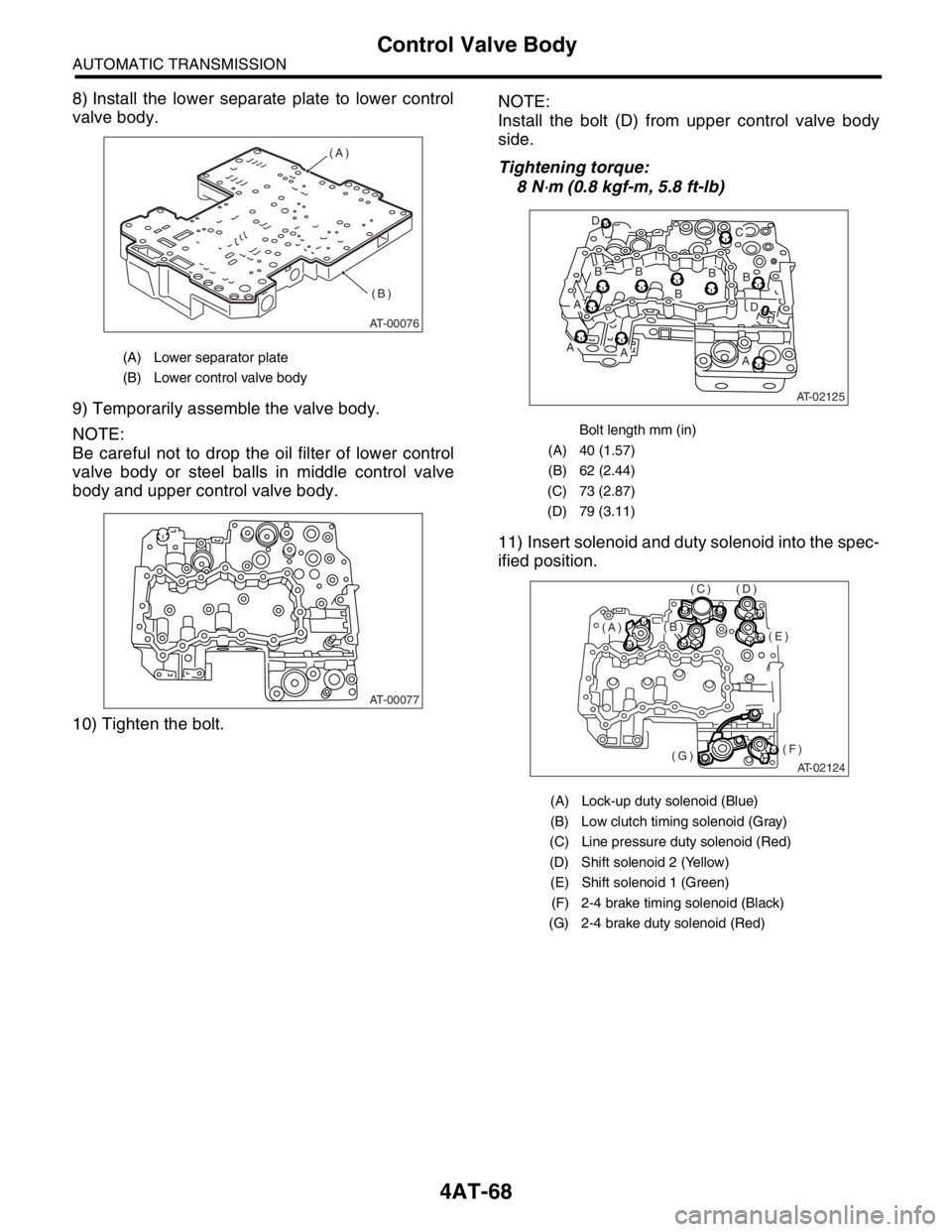

8) Install the lower separate plate to lower control

valve body.

9) Temporarily assemble the valve body.

NOTE:

Be careful not to drop the oil filter of lower control

valve body or steel balls in middle control valve

body and upper control valve body.

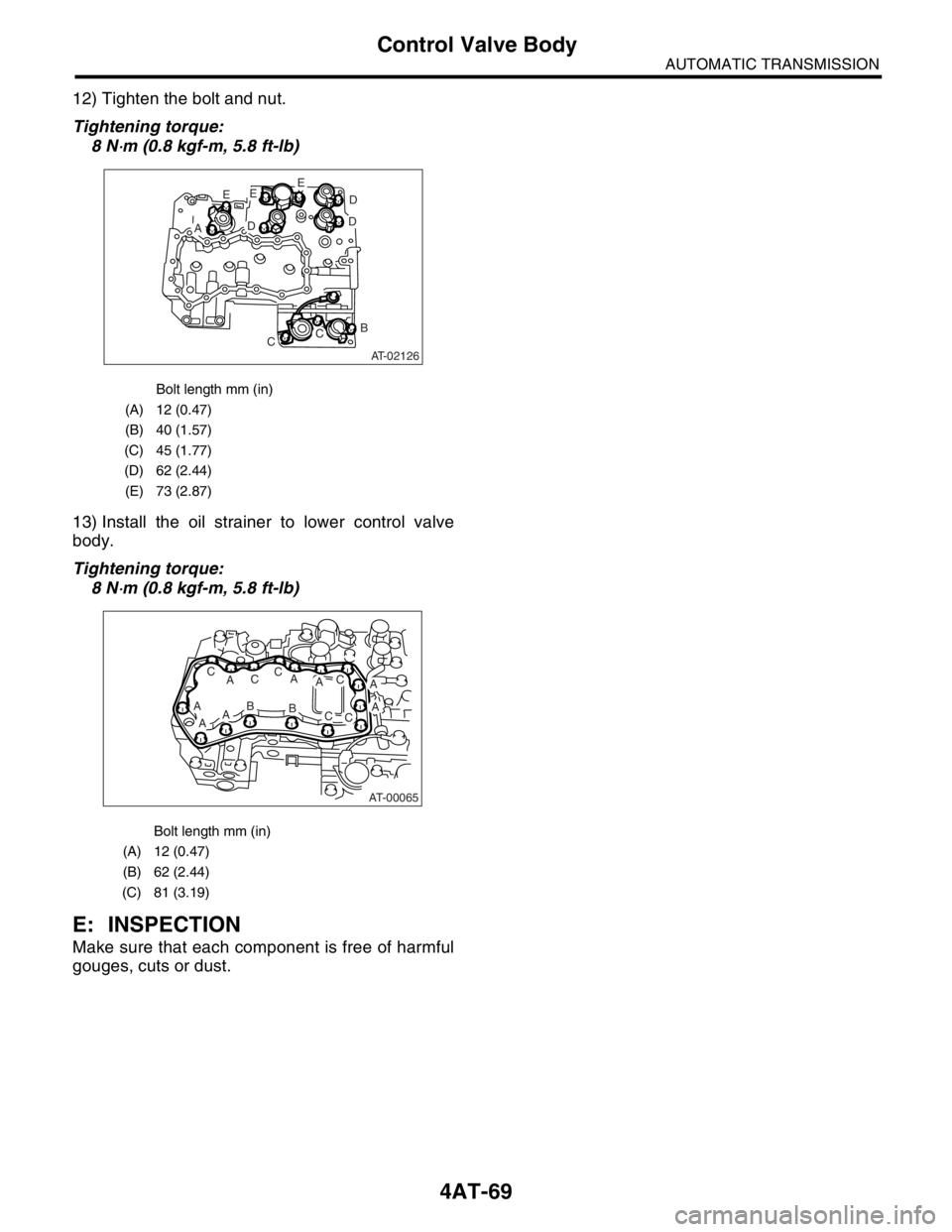

10) Tighten the bolt.NOTE:

Install the bolt (D) from upper control valve body

side.

Tightening torque:

8 N

⋅m (0.8 kgf-m, 5.8 ft-lb)

11) Insert solenoid and duty solenoid into the spec-

ified position.

(A) Lower separator plate

(B) Lower control valve body

AT-00076

(A)

(B)

AT-00077

Bolt length mm (in)

(A) 40 (1.57)

(B) 62 (2.44)

(C) 73 (2.87)

(D) 79 (3.11)

(A) Lock-up duty solenoid (Blue)

(B) Low clutch timing solenoid (Gray)

(C) Line pressure duty solenoid (Red)

(D) Shift solenoid 2 (Yellow)

(E) Shift solenoid 1 (Green)

(F) 2-4 brake timing solenoid (Black)

(G) 2-4 brake duty solenoid (Red)

AT-02125

B

B

BB D

C

B

D

AA

AA

AT-02124

(E)

(F)(G)

(D)(C)

(B)(A)

Page 2382 of 2870

4AT-69

AUTOMATIC TRANSMISSION

Control Valve Body

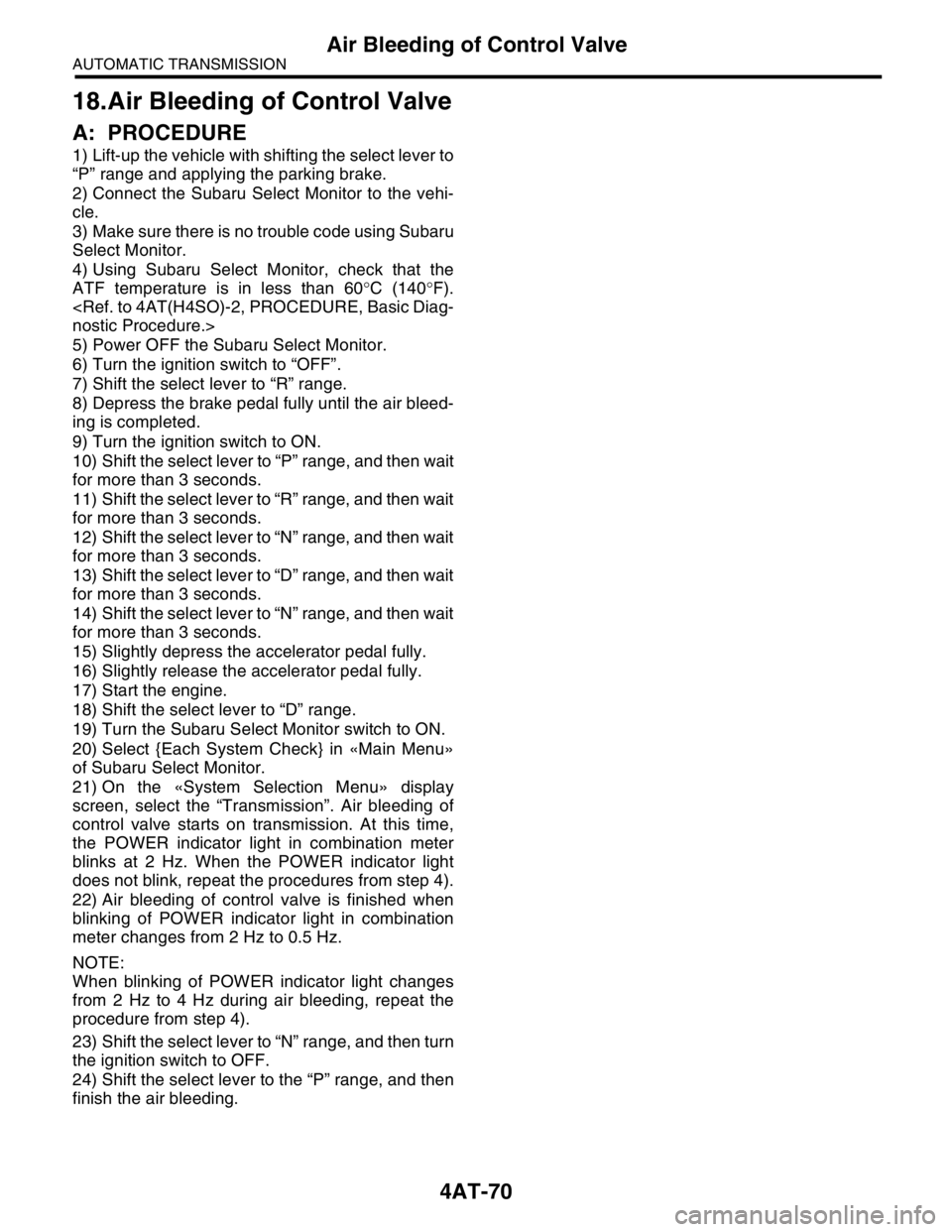

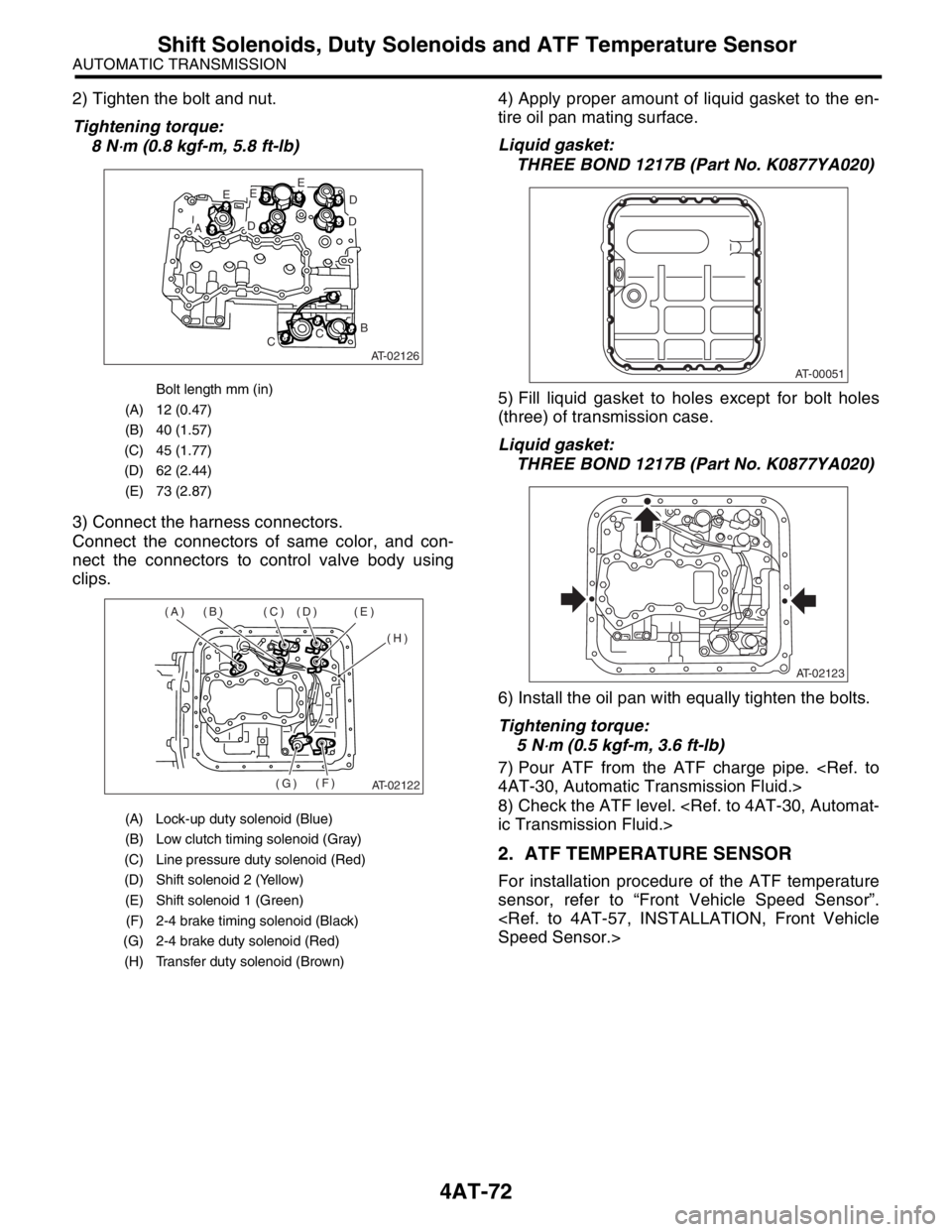

12) Tighten the bolt and nut.

Tightening torque:

8 N

⋅m (0.8 kgf-m, 5.8 ft-lb)

13) Install the oil strainer to lower control valve

body.

Tightening torque:

8 N

⋅m (0.8 kgf-m, 5.8 ft-lb)

E: INSPECTION

Make sure that each component is free of harmful

gouges, cuts or dust.

Bolt length mm (in)

(A) 12 (0.47)

(B) 40 (1.57)

(C) 45 (1.77)

(D) 62 (2.44)

(E) 73 (2.87)

Bolt length mm (in)

(A) 12 (0.47)

(B) 62 (2.44)

(C) 81 (3.19)

AT-02126

E

AD

EE

D

D

B

CC

AT-00065

A

ABAA

AC

ACC

AB

AC

CC

Page 2383 of 2870

4AT-70

AUTOMATIC TRANSMISSION

Air Bleeding of Control Valve

18.Air Bleeding of Control Valve

A: PROCEDURE

1) Lift-up the vehicle with shifting the select lever to

“P” range and applying the parking brake.

2) Connect the Subaru Select Monitor to the vehi-

cle.

3) Make sure there is no trouble code using Subaru

Select Monitor.

4) Using Subaru Select Monitor, check that the

ATF temperature is in less than 60°C (140°F).

5) Power OFF the Subaru Select Monitor.

6) Turn the ignition switch to “OFF”.

7) Shift the select lever to “R” range.

8) Depress the brake pedal fully until the air bleed-

ing is completed.

9) Turn the ignition switch to ON.

10) Shift the select lever to “P” range, and then wait

for more than 3 seconds.

11) Shift the select lever to “R” range, and then wait

for more than 3 seconds.

12) Shift the select lever to “N” range, and then wait

for more than 3 seconds.

13) Shift the select lever to “D” range, and then wait

for more than 3 seconds.

14) Shift the select lever to “N” range, and then wait

for more than 3 seconds.

15) Slightly depress the accelerator pedal fully.

16) Slightly release the accelerator pedal fully.

17) Start the engine.

18) Shift the select lever to “D” range.

19) Turn the Subaru Select Monitor switch to ON.

20) Select {Each System Check} in «Main Menu»

of Subaru Select Monitor.

21) On the «System Selection Menu» display

screen, select the “Transmission”. Air bleeding of

control valve starts on transmission. At this time,

the POWER indicator light in combination meter

blinks at 2 Hz. When the POWER indicator light

does not blink, repeat the procedures from step 4).

22) Air bleeding of control valve is finished when

blinking of POWER indicator light in combination

meter changes from 2 Hz to 0.5 Hz.

NOTE:

When blinking of POWER indicator light changes

from 2 Hz to 4 Hz during air bleeding, repeat the

procedure from step 4).

23) Shift the select lever to “N” range, and then turn

the ignition switch to OFF.

24) Shift the select lever to the “P” range, and then

finish the air bleeding.

Page 2384 of 2870

4AT-71

AUTOMATIC TRANSMISSION

Shift Solenoids, Duty Solenoids and ATF Temperature Sensor

19.Shift Solenoids, Duty Sole-

noids and ATF Temperature

Sensor

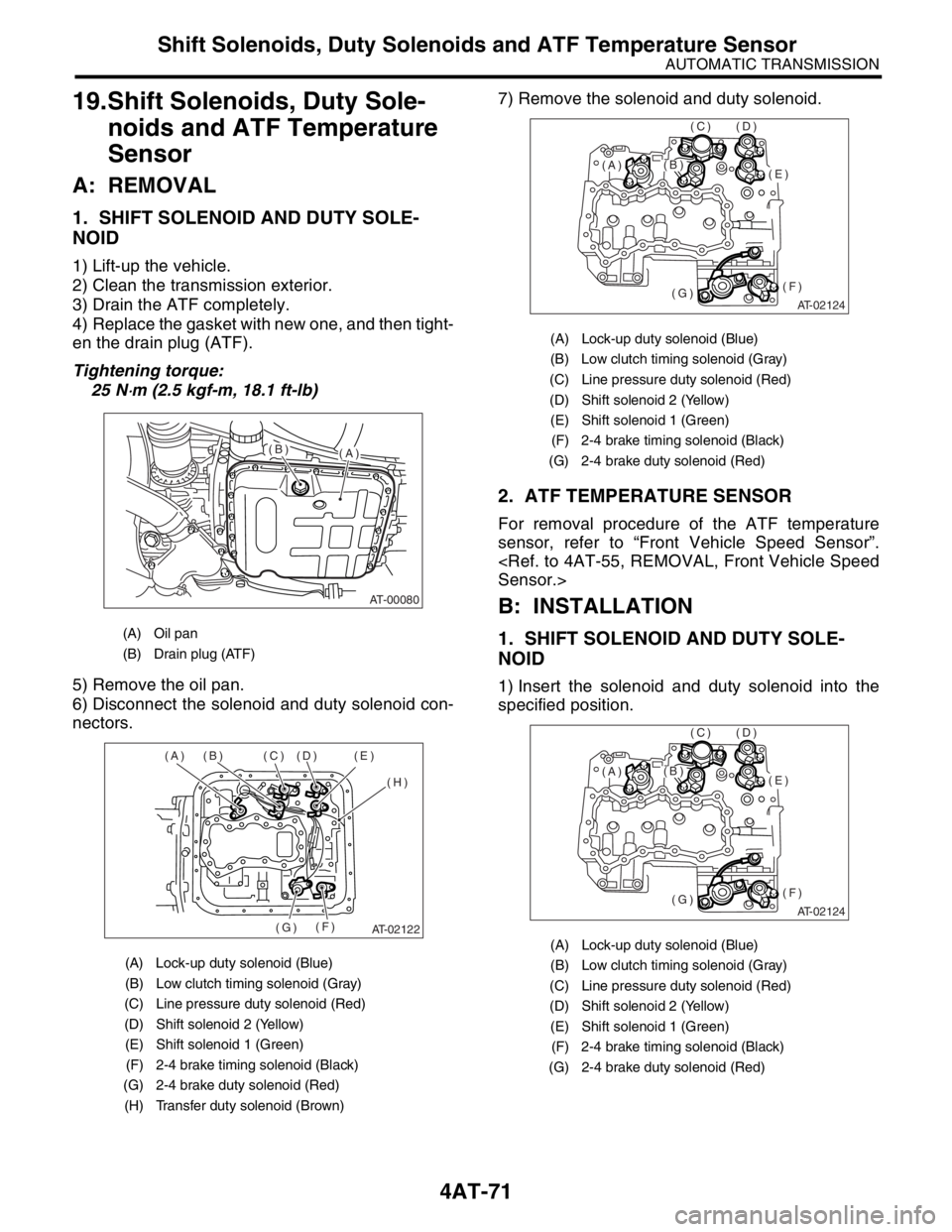

A: REMOVAL

1. SHIFT SOLENOID AND DUTY SOLE-

NOID

1) Lift-up the vehicle.

2) Clean the transmission exterior.

3) Drain the ATF completely.

4) Replace the gasket with new one, and then tight-

en the drain plug (ATF).

Tightening torque:

25 N

⋅m (2.5 kgf-m, 18.1 ft-lb)

5) Remove the oil pan.

6) Disconnect the solenoid and duty solenoid con-

nectors.7) Remove the solenoid and duty solenoid.

2. ATF TEMPERATURE SENSOR

For removal procedure of the ATF temperature

sensor, refer to “Front Vehicle Speed Sensor”.

B: INSTALLATION

1. SHIFT SOLENOID AND DUTY SOLE-

NOID

1) Insert the solenoid and duty solenoid into the

specified position.

(A) Oil pan

(B) Drain plug (ATF)

(A) Lock-up duty solenoid (Blue)

(B) Low clutch timing solenoid (Gray)

(C) Line pressure duty solenoid (Red)

(D) Shift solenoid 2 (Yellow)

(E) Shift solenoid 1 (Green)

(F) 2-4 brake timing solenoid (Black)

(G) 2-4 brake duty solenoid (Red)

(H) Transfer duty solenoid (Brown)

AT-00080

(A)(B)

AT-02122

(A) (B) (C) (D) (E)

(H)

(F)

(G)

(A) Lock-up duty solenoid (Blue)

(B) Low clutch timing solenoid (Gray)

(C) Line pressure duty solenoid (Red)

(D) Shift solenoid 2 (Yellow)

(E) Shift solenoid 1 (Green)

(F) 2-4 brake timing solenoid (Black)

(G) 2-4 brake duty solenoid (Red)

(A) Lock-up duty solenoid (Blue)

(B) Low clutch timing solenoid (Gray)

(C) Line pressure duty solenoid (Red)

(D) Shift solenoid 2 (Yellow)

(E) Shift solenoid 1 (Green)

(F) 2-4 brake timing solenoid (Black)

(G) 2-4 brake duty solenoid (Red)

AT-02124

(E)

(F)(G)

(D)(C)

(B)(A)

AT-02124

(E)

(F)(G)

(D)(C)

(B)(A)

Page 2385 of 2870

4AT-72

AUTOMATIC TRANSMISSION

Shift Solenoids, Duty Solenoids and ATF Temperature Sensor

2) Tighten the bolt and nut.

Tightening torque:

8 N

⋅m (0.8 kgf-m, 5.8 ft-lb)

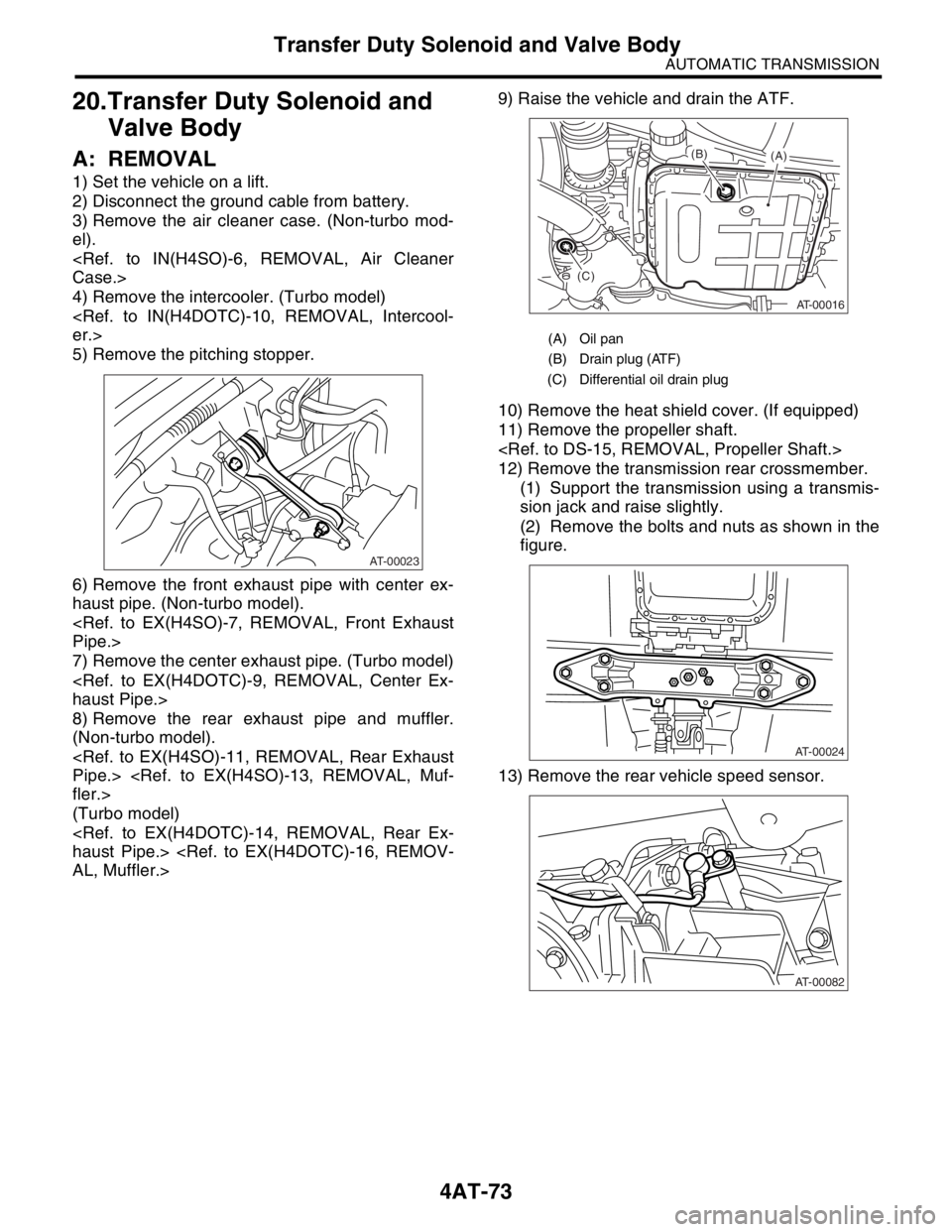

3) Connect the harness connectors.

Connect the connectors of same color, and con-

nect the connectors to control valve body using

clips.4) Apply proper amount of liquid gasket to the en-

tire oil pan mating surface.

Liquid gasket:

THREE BOND 1217B (Part No. K0877YA020)

5) Fill liquid gasket to holes except for bolt holes

(three) of transmission case.

Liquid gasket:

THREE BOND 1217B (Part No. K0877YA020)

6) Install the oil pan with equally tighten the bolts.

Tightening torque:

5 N

⋅m (0.5 kgf-m, 3.6 ft-lb)

7) Pour ATF from the ATF charge pipe.

8) Check the ATF level.

2. ATF TEMPERATURE SENSOR

For installation procedure of the ATF temperature

sensor, refer to “Front Vehicle Speed Sensor”.

Bolt length mm (in)

(A) 12 (0.47)

(B) 40 (1.57)

(C) 45 (1.77)

(D) 62 (2.44)

(E) 73 (2.87)

(A) Lock-up duty solenoid (Blue)

(B) Low clutch timing solenoid (Gray)

(C) Line pressure duty solenoid (Red)

(D) Shift solenoid 2 (Yellow)

(E) Shift solenoid 1 (Green)

(F) 2-4 brake timing solenoid (Black)

(G) 2-4 brake duty solenoid (Red)

(H) Transfer duty solenoid (Brown)

AT-02126

E

AD

EE

D

D

B

CC

AT-02122

(A) (B) (C) (D) (E)

(H)

(F)

(G)

AT-00051

AT-02123

Page 2386 of 2870

4AT-73

AUTOMATIC TRANSMISSION

Transfer Duty Solenoid and Valve Body

20.Transfer Duty Solenoid and

Valve Body

A: REMOVAL

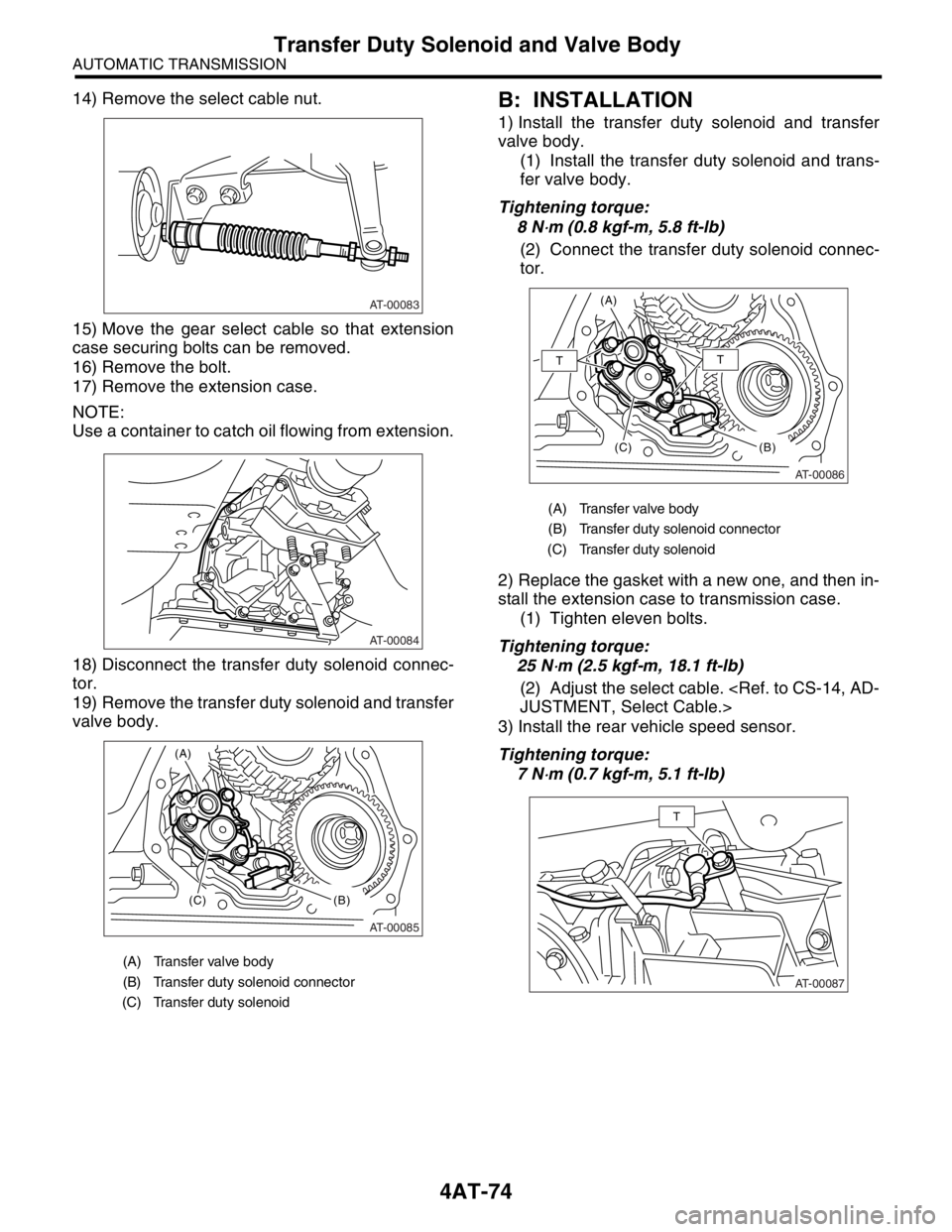

1) Set the vehicle on a lift.

2) Disconnect the ground cable from battery.

3) Remove the air cleaner case. (Non-turbo mod-

el).

4) Remove the intercooler. (Turbo model)

5) Remove the pitching stopper.

6) Remove the front exhaust pipe with center ex-

haust pipe. (Non-turbo model).

7) Remove the center exhaust pipe. (Turbo model)

8) Remove the rear exhaust pipe and muffler.

(Non-turbo model).

(Turbo model)

10) Remove the heat shield cover. (If equipped)

11) Remove the propeller shaft.

12) Remove the transmission rear crossmember.

(1) Support the transmission using a transmis-

sion jack and raise slightly.

(2) Remove the bolts and nuts as shown in the

figure.

13) Remove the rear vehicle speed sensor.

AT-00023

(A) Oil pan

(B) Drain plug (ATF)

(C) Differential oil drain plug

AT-00016

(A) (B)

(C)

AT-00024

AT-00082

Page 2387 of 2870

4AT-74

AUTOMATIC TRANSMISSION

Transfer Duty Solenoid and Valve Body

14) Remove the select cable nut.

15) Move the gear select cable so that extension

case securing bolts can be removed.

16) Remove the bolt.

17) Remove the extension case.

NOTE:

Use a container to catch oil flowing from extension.

18) Disconnect the transfer duty solenoid connec-

tor.

19) Remove the transfer duty solenoid and transfer

valve body.B: INSTALLATION

1) Install the transfer duty solenoid and transfer

valve body.

(1) Install the transfer duty solenoid and trans-

fer valve body.

Tightening torque:

8 N

⋅m (0.8 kgf-m, 5.8 ft-lb)

(2) Connect the transfer duty solenoid connec-

tor.

2) Replace the gasket with a new one, and then in-

stall the extension case to transmission case.

(1) Tighten eleven bolts.

Tightening torque:

25 N

⋅m (2.5 kgf-m, 18.1 ft-lb)

(2) Adjust the select cable.

3) Install the rear vehicle speed sensor.

Tightening torque:

7 N

⋅m (0.7 kgf-m, 5.1 ft-lb)

(A) Transfer valve body

(B) Transfer duty solenoid connector

(C) Transfer duty solenoid

AT-00083

AT-00084

AT-00085

(A)

(C)

(B)

(A) Transfer valve body

(B) Transfer duty solenoid connector

(C) Transfer duty solenoid

AT-00086

(A)

(C)

(B)

TT

AT-00087

T

Page 2388 of 2870

4AT-75

AUTOMATIC TRANSMISSION

Transfer Duty Solenoid and Valve Body

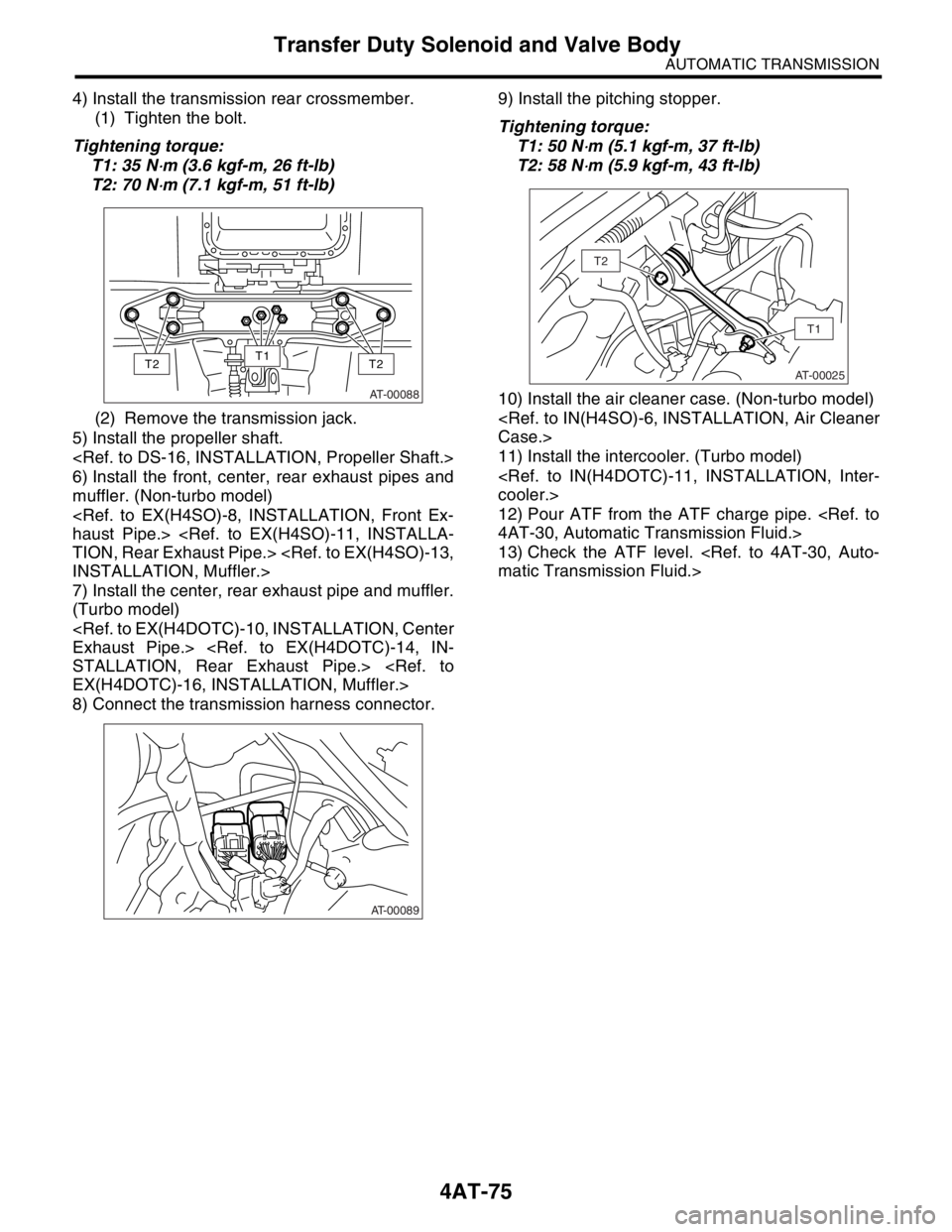

4) Install the transmission rear crossmember.

(1) Tighten the bolt.

Tightening torque:

T1: 35 N

⋅m (3.6 kgf-m, 26 ft-lb)

T2: 70 N

⋅m (7.1 kgf-m, 51 ft-lb)

(2) Remove the transmission jack.

5) Install the propeller shaft.

6) Install the front, center, rear exhaust pipes and

muffler. (Non-turbo model)

7) Install the center, rear exhaust pipe and muffler.

(Turbo model)

8) Connect the transmission harness connector.9) Install the pitching stopper.

Tightening torque:

T1: 50 N

⋅m (5.1 kgf-m, 37 ft-lb)

T2: 58 N

⋅m (5.9 kgf-m, 43 ft-lb)

10) Install the air cleaner case. (Non-turbo model)

11) Install the intercooler. (Turbo model)

12) Pour ATF from the ATF charge pipe.

13) Check the ATF level.

AT-00088

T2T2T1

AT-00089

AT-00025

T1

T2

Page 2389 of 2870

4AT-76

AUTOMATIC TRANSMISSION

ATF Filter

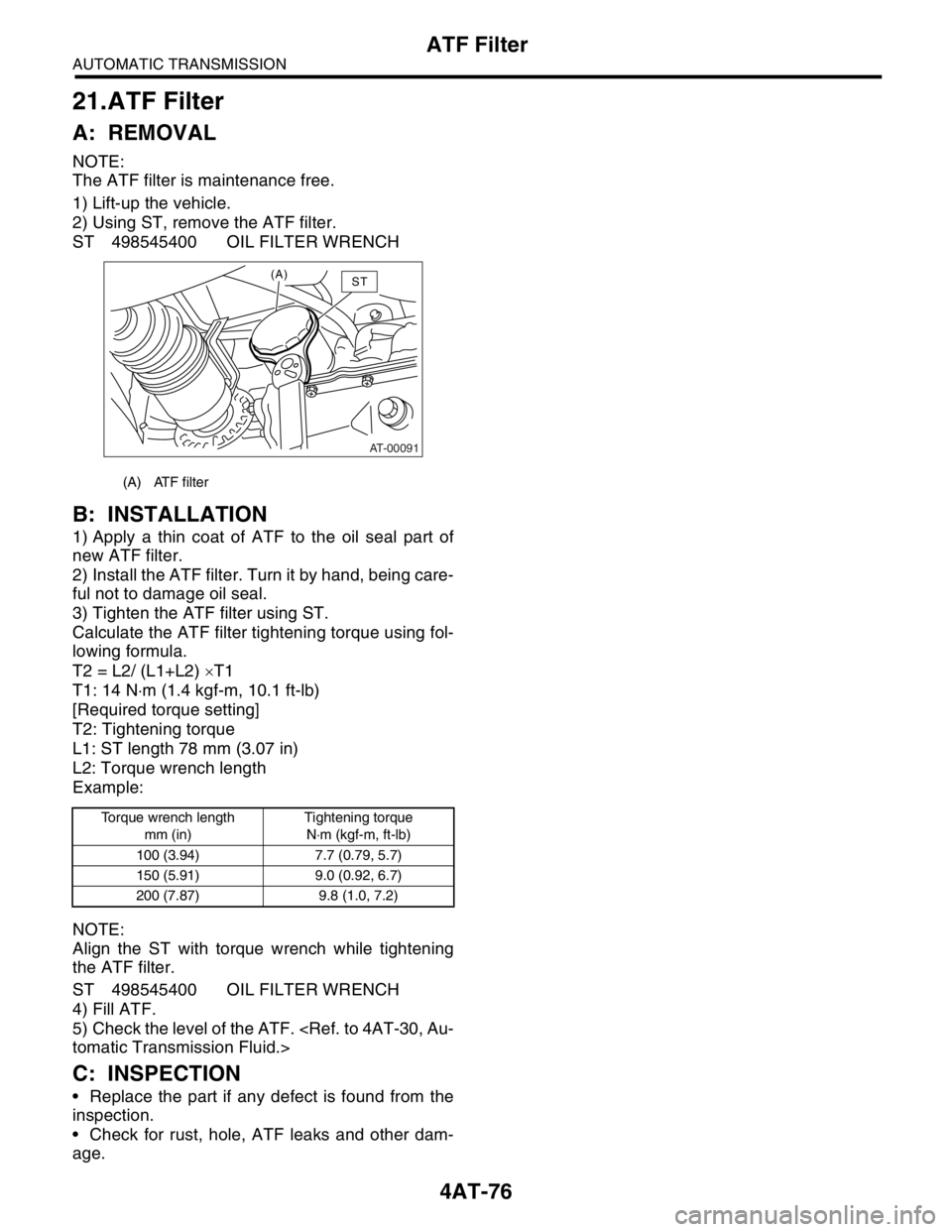

21.ATF Filter

A: REMOVAL

NOTE:

The ATF filter is maintenance free.

1) Lift-up the vehicle.

2) Using ST, remove the ATF filter.

ST 498545400 OIL FILTER WRENCH

B: INSTALLATION

1) Apply a thin coat of ATF to the oil seal part of

new ATF filter.

2) Install the ATF filter. Turn it by hand, being care-

ful not to damage oil seal.

3) Tighten the ATF filter using ST.

Calculate the ATF filter tightening torque using fol-

lowing formula.

T2 = L2/ (L1+L2) ×T1

T1: 14 N⋅m (1.4 kgf-m, 10.1 ft-lb)

[Required torque setting]

T2: Tightening torque

L1: ST length 78 mm (3.07 in)

L2: Torque wrench length

Example:

NOTE:

Align the ST with torque wrench while tightening

the ATF filter.

ST 498545400 OIL FILTER WRENCH

4) Fill ATF.

5) Check the level of the ATF.

C: INSPECTION

Replace the part if any defect is found from the

inspection.

Check for rust, hole, ATF leaks and other dam-

age.

(A) ATF filter

Torque wrench length

mm (in)Tightening torque

N⋅m (kgf-m, ft-lb)

100 (3.94) 7.7 (0.79, 5.7)

150 (5.91) 9.0 (0.92, 6.7)

200 (7.87) 9.8 (1.0, 7.2)

AT-00091

(A)ST

Page 2390 of 2870

4AT-77

AUTOMATIC TRANSMISSION

Transmission Control Module (TCM)

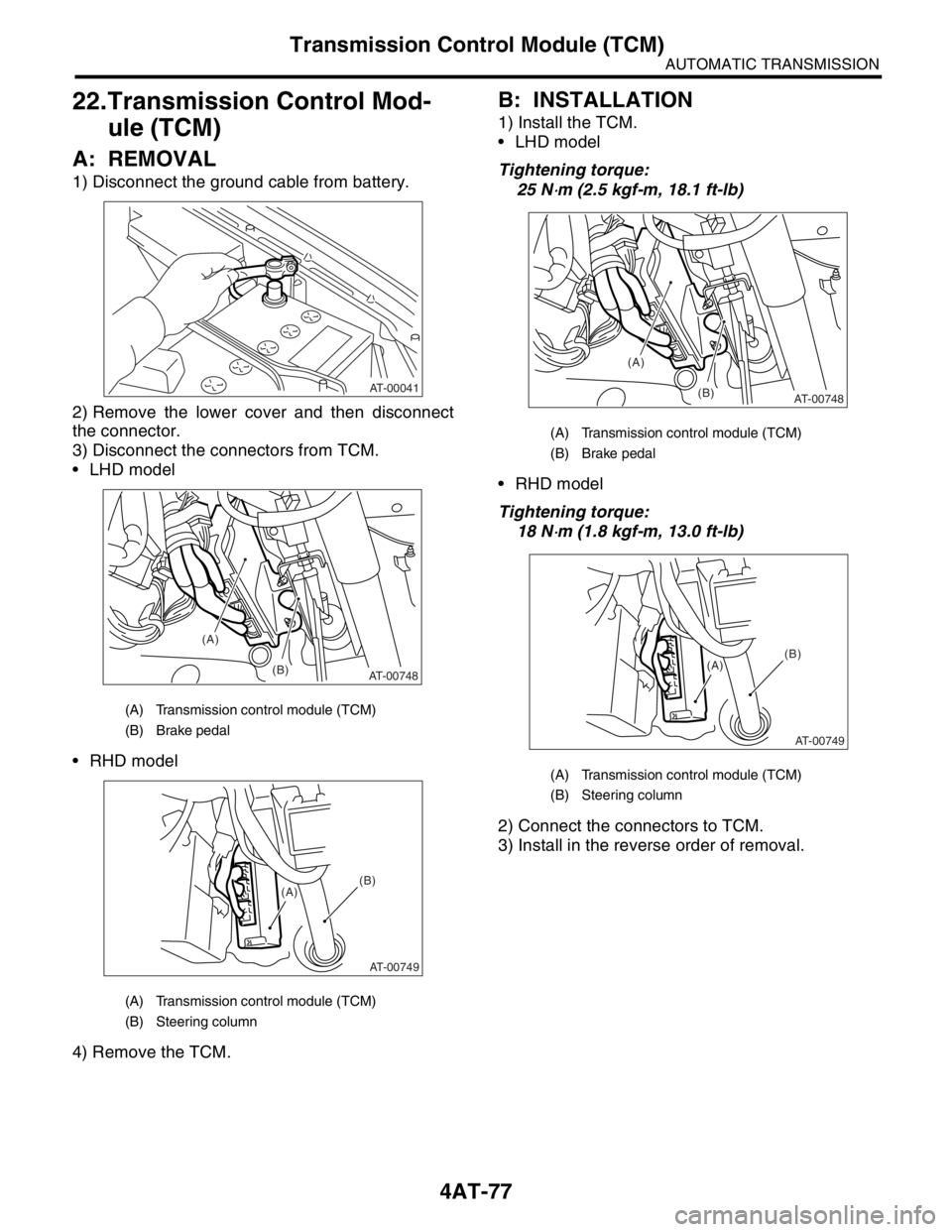

22.Transmission Control Mod-

ule (TCM)

A: REMOVAL

1) Disconnect the ground cable from battery.

2) Remove the lower cover and then disconnect

the connector.

3) Disconnect the connectors from TCM.

LHD model

RHD model

4) Remove the TCM.

B: INSTALLATION

1) Install the TCM.

LHD model

Tightening torque:

25 N

⋅m (2.5 kgf-m, 18.1 ft-lb)

RHD model

Tightening torque:

18 N

⋅m (1.8 kgf-m, 13.0 ft-lb)

2) Connect the connectors to TCM.

3) Install in the reverse order of removal.

(A) Transmission control module (TCM)

(B) Brake pedal

(A) Transmission control module (TCM)

(B) Steering column

AT-00041

(A)

(B)

AT-00748

AT-00749

(A)(B)

(A) Transmission control module (TCM)

(B) Brake pedal

(A) Transmission control module (TCM)

(B) Steering column

(A)

(B)

AT-00748

AT-00749

(A)(B)