SUBARU FORESTER 2004 Service Repair Manual

Manufacturer: SUBARU, Model Year: 2004, Model line: FORESTER, Model: SUBARU FORESTER 2004Pages: 2870, PDF Size: 38.67 MB

Page 391 of 2870

IDI-7

INSTRUMENTATION/DRIVER INFO

Combination Meter System

5. CHECK ENGINE CONTROL MODULE (ECM)

6. CHECK FUEL LEVEL SENSOR

Step Check Yes No

1 CHECK ECM SIGNAL.

1) Start the engine.

2) Measure the voltage between ECM con-

nector and engine ground.

Connector & terminal

Non-turbo model

(B134) No. 10 (+) — Engine ground (

−):

Turbo model

(B134) No. 23 (+) — Engine ground (

−):Is the voltage 0 V ← → 14 V? Go to step 2.Check ECM.

Basic Diagnostics

Procedure.>

Basic Diagnostics

Procedure.>

2 CHECK HARNESS BETWEEN COMBINA-

TION METER AND ECM.

1) Turn the ignition switch to OFF.

2) Disconnect the connector from ECM and

combination meter.

3) Measure the resistance between ECM har-

ness connector and combination meter har-

ness connector.

Connector & terminal

Non-turbo model

(B134) No. 10 — (i10) No. 11:

Turbo model

(B134) No. 23 — (i10) No. 11:Is the resistance less than 10

Ω?Check the tachom-

eter.

Tachometer.>Repair the wiring

harness.

Step Check Yes No

1 CHECK FUEL LEVEL SENSOR.

1) Remove the fuel level sensor.

sor.>

2) Measure the resistance between fuel level

sensor terminals when setting the float to

FULL and EMPTY position.

Te r m i n a l s

No. 3 — No. 5:Is the resistance 0.5 to 2.5 Ω

(FULL) and 50 to 52 Ω

(EMPTY)?Go to step 2.Replace the fuel

level sensor.

2 CHECK FUEL SUB LEVEL SENSOR.

1) Remove the fuel sub level sensor.

Sensor.>

2) Measure the resistance between fuel sub

level sensor terminals when setting the float to

FULL and EMPTY position.

Te r m i n a l s

No. 1 — No. 2:Is the resistance 0.5 to 2.5 Ω

(FULL) and 42 to 44 Ω

(EMPTY)?Go to step 3.Replace the fuel

sub level sensor.

3 CHECK HARNESS BETWEEN FUEL SUB

LEVEL SENSOR AND COMBINATION

METER.

1) Disconnect the connector from combination

meter.

2) Measure the resistance between fuel sub

level sensor harness connector terminal and

combination meter harness connector termi-

nal.

Connector & terminal

(R59) No. 1 — (i11) No. 1:Is the resistance less than 10

Ω?Go to step 4.Repair the wiring

harness.

Page 392 of 2870

IDI-8

INSTRUMENTATION/DRIVER INFO

Combination Meter System

7. CHECK ENGINE COOLANT TEMPERATURE SENSOR

8. CHECK OUTSIDE TEMPERATURE INDICATOR

4 CHECK HARNESS BETWEEN FUEL LEVEL

SENSOR AND FUEL SUB LEVEL SENSOR.

Measure the resistance between fuel level sen-

sor harness connector terminal and fuel sub

level sensor harness connector terminal.

Connector & terminal

(R58) No. 3 — (R59) No. 2:Is the resistance less than 10

Ω?Go to step 5.Repair the wiring

harness.

5 CHECK FUEL LEVEL SENSOR GROUND

CIRCUIT.

Measure the resistance between fuel level sen-

sor harness connector terminal and chassis

ground.

Connector & terminal

(R58) No. 5 — Chassis ground:Is the resistance less than 10

Ω?Check the fuel

gauge.

TION, Fuel

Gauge.>Repair the wiring

harness.

Step Check Yes No

1 CHECK ENGINE COOLANT TEMPERATURE

SENSOR.

Check the engine coolant temperature sensor.

ture sensor OK?Go to step 2.Replace the

engine coolant

temperature sen-

sor.

2 CHECK HARNESS BETWEEN ENGINE

COOLANT TEMPERATURE SENSOR AND

COMBINATION METER.

1) Turn the ignition switch to OFF.

2) Disconnect the connector from engine cool-

ant temperature sensor and combination

meter.

3) Measure the resistance between engine

coolant temperature sensor harness connector

and combination meter harness connector.

Connector & terminal

(E8) No. 3 — (i11) No. 10:Is the resistance less than 10

Ω?Go to step 3.Repair the wiring

harness.

3 CHECK WATER TEMPERATURE GAUGE

GROUND CIRCUIT.

Measure the resistance between combination

meter harness connector terminal and chassis

ground.

Connector & terminal

(i11) No. 9 — Chassis ground:Is the resistance less than 10

Ω?Check the water

temperature

gauge.

TION, Water Tem-

perature Gauge.>Repair the wiring

harness.

Step Check Yes No

1 CHECK POWER SUPPLY FOR AMBIENT

SENSOR.

1) Turn the ignition switch to OFF.

2) Disconnect the connector from outside

temperature sensor.

3) Turn the ignition switch to ON.

4) Measure the voltage between outside tem-

perature sensor harness connector terminal

and chassis ground.

Connector & terminal

(F78) No. 2 (+) — Chassis ground (

−):Is the voltage more than 4 V? Go to step 3.Go to step 2. Step Check Yes No

Page 393 of 2870

IDI-9

INSTRUMENTATION/DRIVER INFO

Combination Meter System

2 CHECK HARNESS BETWEEN AMBIENT

SENSOR AND COMBINATION METER.

1) Turn the ignition switch to OFF.

2) Disconnect the connector from combination

meter.

3) Measure the resistance between ambient

sensor harness connector terminal and combi-

nation meter harness connector terminal.

Connector & terminal

(F78) No. 1 — (i10) No. 25:

(F78) No. 2 — (i10) No. 24:Is the resistance less than 10

Ω?Replace the com-

bination meter

printed circuit.Repair the wiring

harness.

3 CHECK AMBIENT SENSOR.

1) Remove the ambient sensor.

2) Check the ambient sensor.

ent sensor.

4 CHECK OUTSIDE TEMPERATURE INDICA-

TOR.

1) Connect the combination meter harness

connector.

2) Connect a resistor (3 kΩ) between termi-

nals of ambient sensor harness connector.

3) Turn the ignition switch to ON and check

the outside temperature indicator display.Does the outside temperature

indicator indicate 25°C (77°F)?Repair the poor

contact of ambient

sensor harness

connector.Replace the com-

bination meter

printed circuit. Step Check Yes No

Page 394 of 2870

IDI-10

INSTRUMENTATION/DRIVER INFO

Combination Meter Assembly

3. Combination Meter Assem-

bly

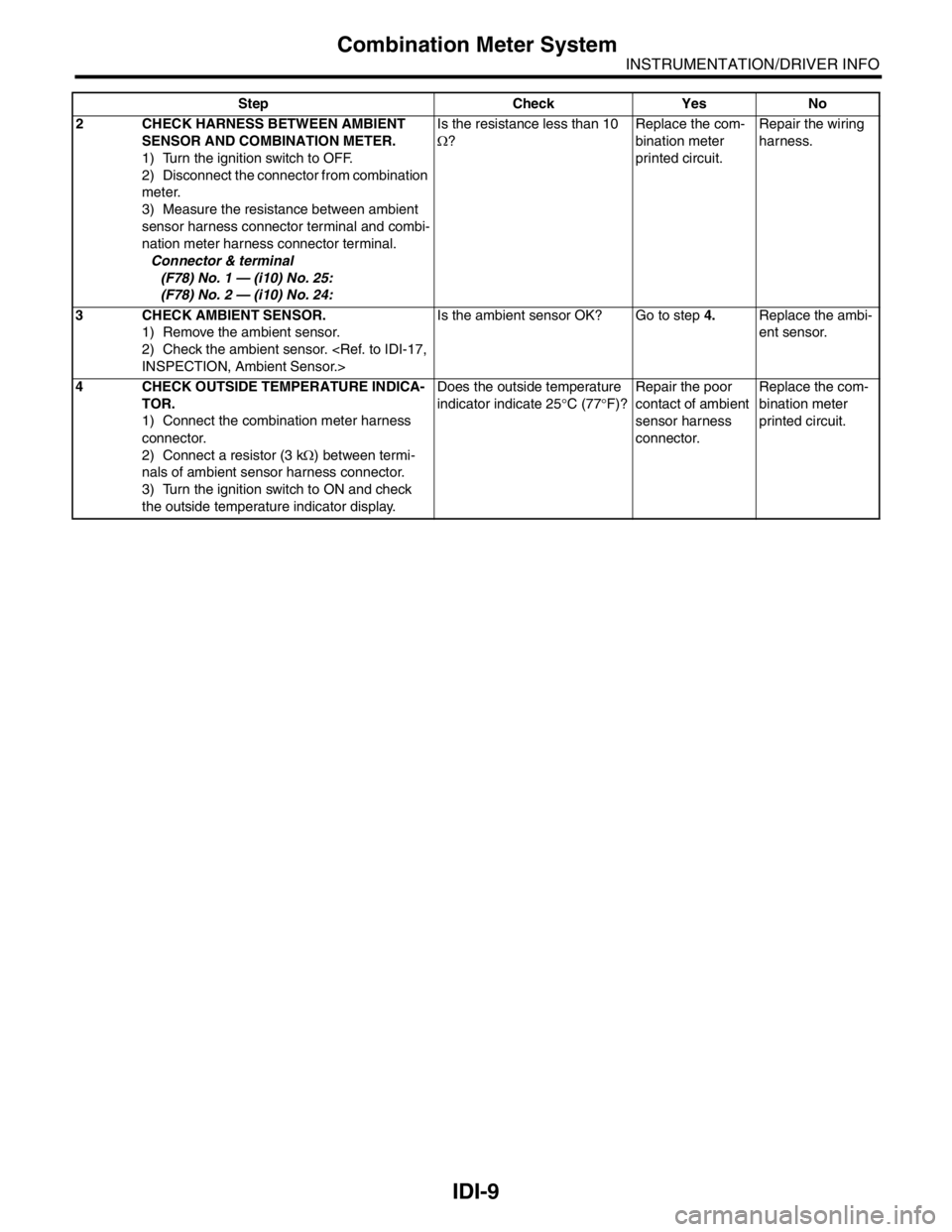

A: REMOVAL

1) Disconnect the ground cable from battery.

2) Set the tilt steering at lowest position.

3) Remove the screws and detach meter visor.

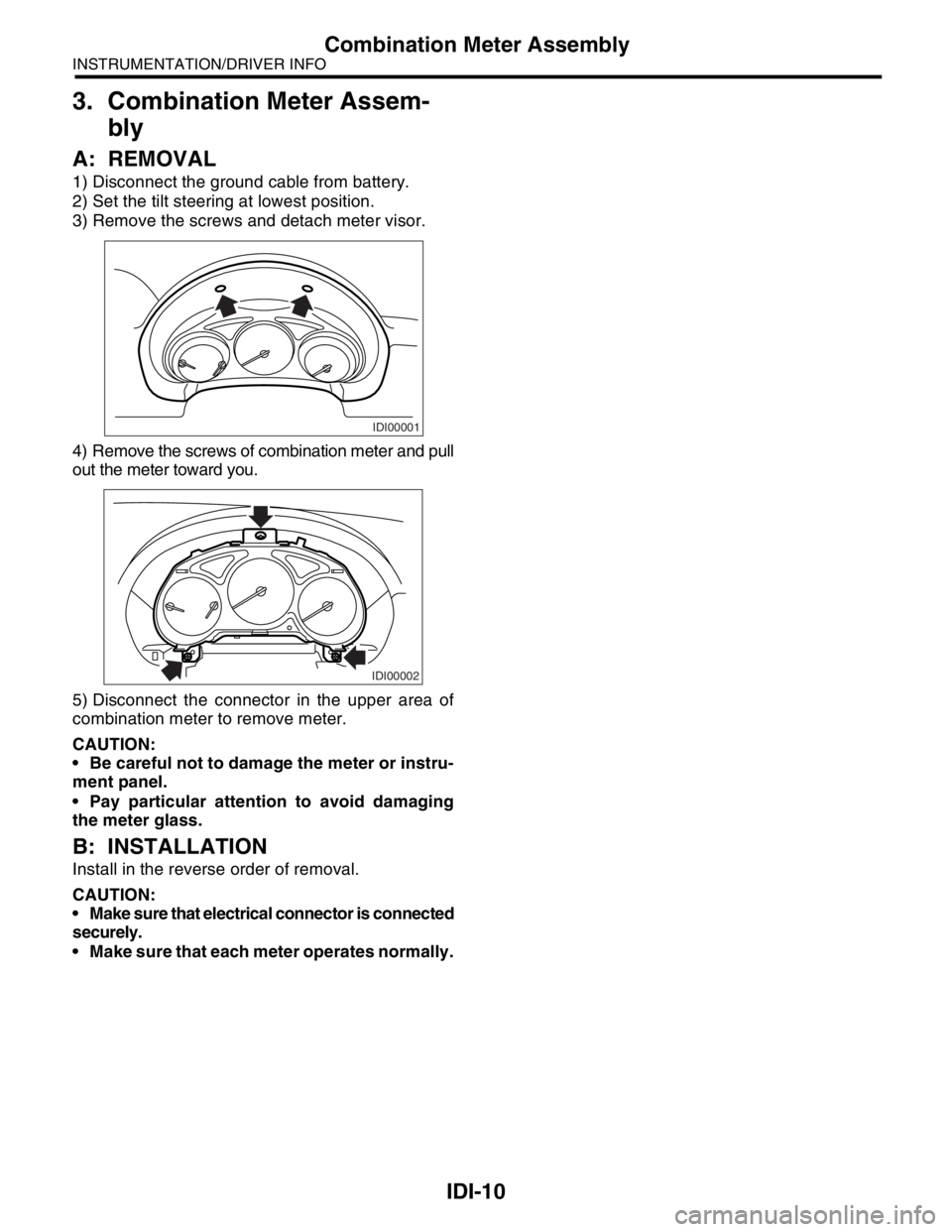

4) Remove the screws of combination meter and pull

out the meter toward you.

5) Disconnect the connector in the upper area of

combination meter to remove meter.

CAUTION:

Be careful not to damage the meter or instru-

ment panel.

Pay particular attention to avoid damaging

the meter glass.

B: INSTALLATION

Install in the reverse order of removal.

CAUTION:

Make sure that electrical connector is connected

securely.

Make sure that each meter operates normally.

IDI00001

IDI00002

Page 395 of 2870

IDI-11

INSTRUMENTATION/DRIVER INFO

Combination Meter Assembly

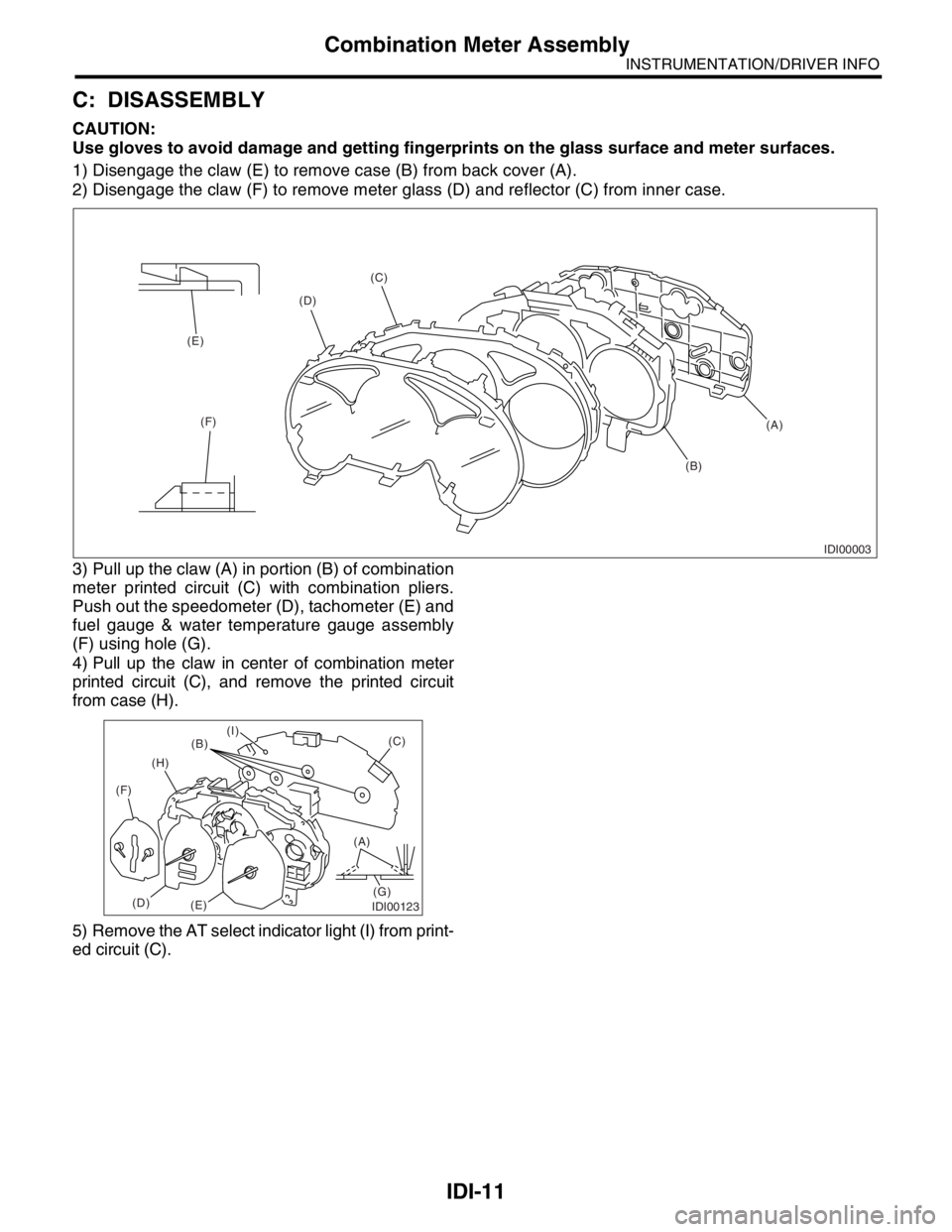

C: DISASSEMBLY

CAUTION:

Use gloves to avoid damage and getting fingerprints on the glass surface and meter surfaces.

1) Disengage the claw (E) to remove case (B) from back cover (A).

2) Disengage the claw (F) to remove meter glass (D) and reflector (C) from inner case.

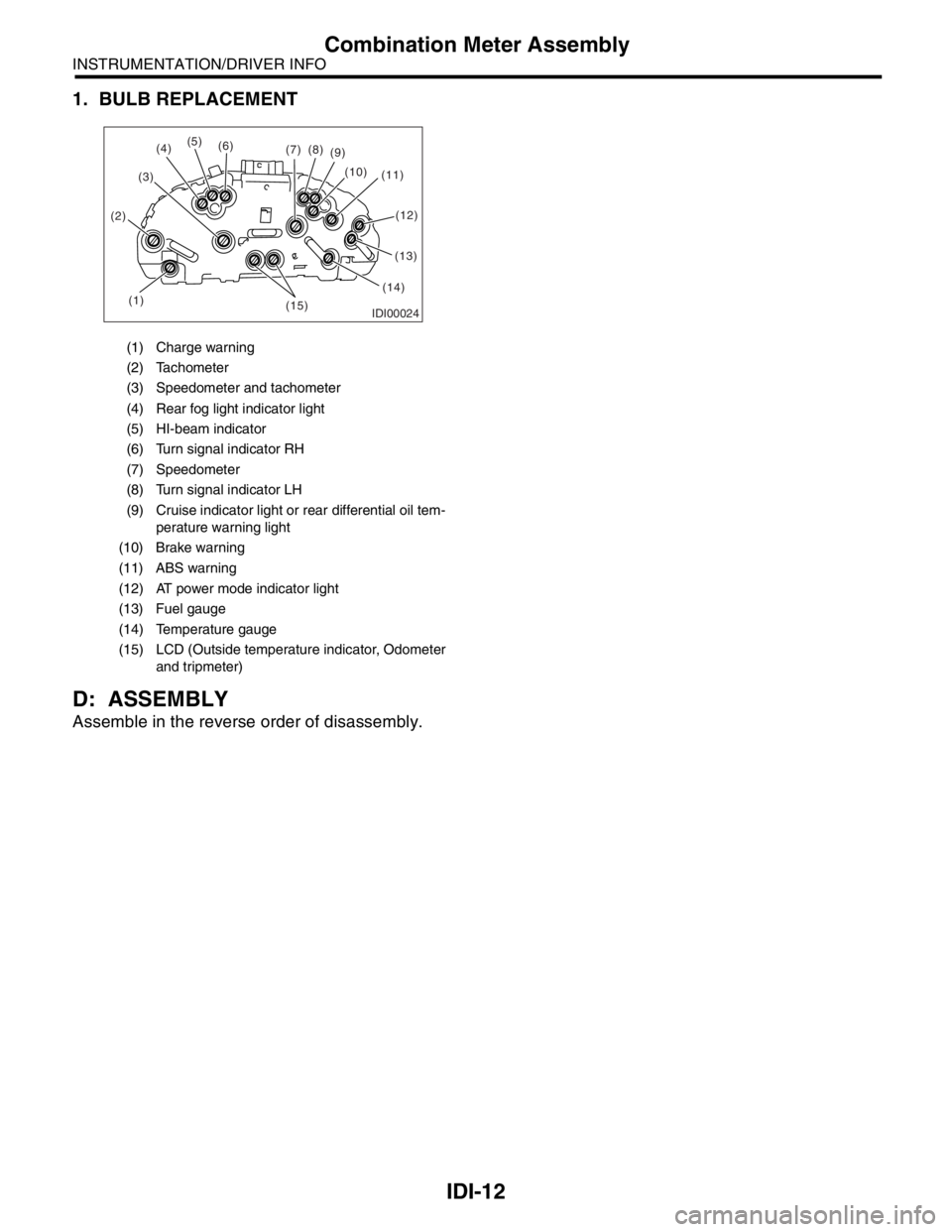

3) Pull up the claw (A) in portion (B) of combination

meter printed circuit (C) with combination pliers.

Push out the speedometer (D), tachometer (E) and

fuel gauge & water temperature gauge assembly

(F) using hole (G).

4) Pull up the claw in center of combination meter

printed circuit (C), and remove the printed circuit

from case (H).

5) Remove the AT select indicator light (I) from print-

ed circuit (C).

IDI00003

(A) (C)

(D)

(E)

(F)

(B)

IDI00123

(A)

(G)(C)

(B)

(H)

(F)

(D)

(E)

(I)

Page 396 of 2870

IDI-12

INSTRUMENTATION/DRIVER INFO

Combination Meter Assembly

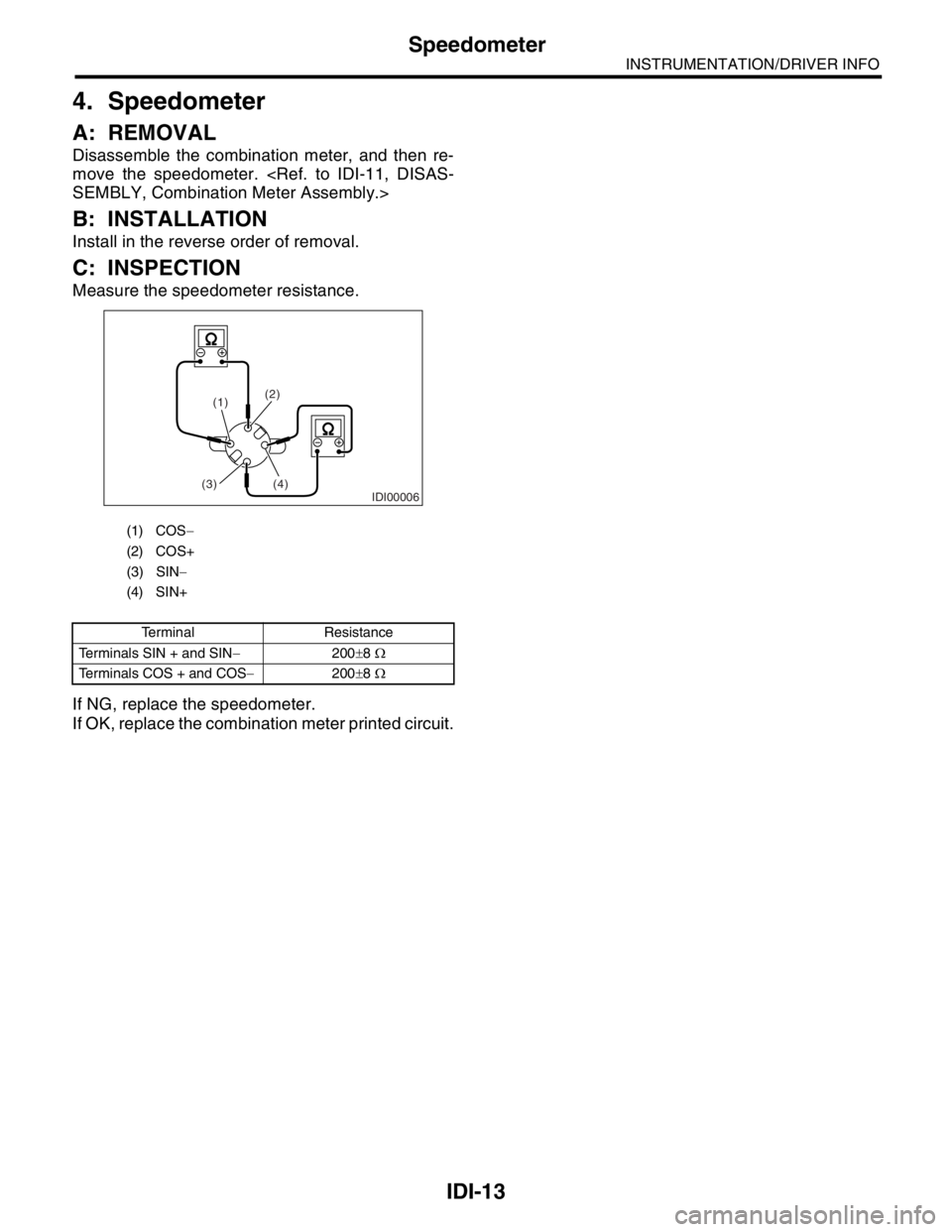

1. BULB REPLACEMENT

D: ASSEMBLY

Assemble in the reverse order of disassembly.

(1) Charge warning

(2) Tachometer

(3) Speedometer and tachometer

(4) Rear fog light indicator light

(5) HI-beam indicator

(6) Turn signal indicator RH

(7) Speedometer

(8) Turn signal indicator LH

(9) Cruise indicator light or rear differential oil tem-

perature warning light

(10) Brake warning

(11) ABS warning

(12) AT power mode indicator light

(13) Fuel gauge

(14) Temperature gauge

(15) LCD (Outside temperature indicator, Odometer

and tripmeter)

IDI00024(1) (2)(3)(5)

(6)

(7)(8)

(9)

(10)

(11)

(13)

(14)

(15)

(4)

(12)

Page 397 of 2870

IDI-13

INSTRUMENTATION/DRIVER INFO

Speedometer

4. Speedometer

A: REMOVAL

Disassemble the combination meter, and then re-

move the speedometer.

B: INSTALLATION

Install in the reverse order of removal.

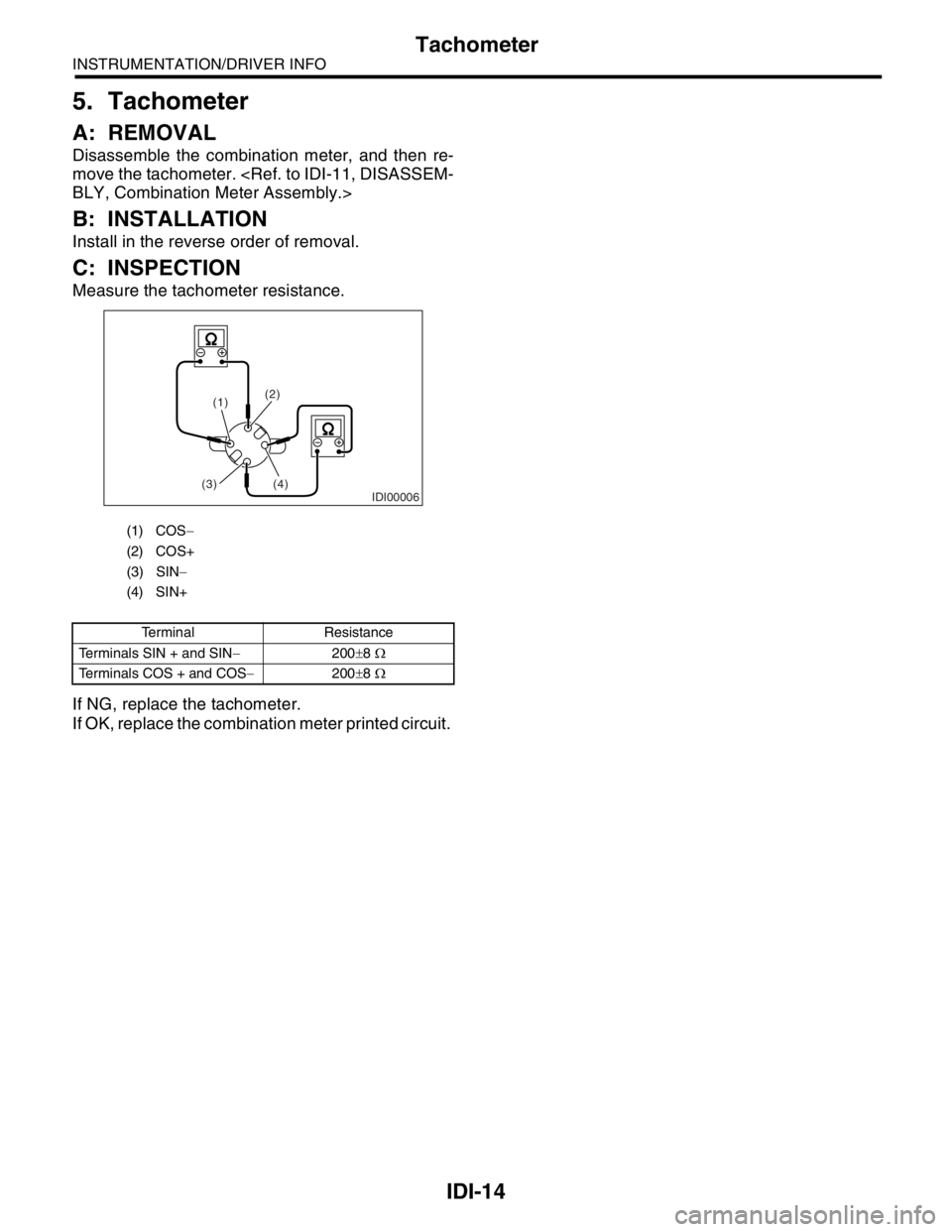

C: INSPECTION

Measure the speedometer resistance.

If NG, replace the speedometer.

If OK, replace the combination meter printed circuit.

(1) COS−

(2) COS+

(3) SIN−

(4) SIN+

Terminal Resistance

Terminals SIN + and SIN−200±8 Ω

Terminals COS + and COS−200±8 Ω

IDI00006

(1)(2)

(4)

(3)

Page 398 of 2870

IDI-14

INSTRUMENTATION/DRIVER INFO

Tachometer

5. Tachometer

A: REMOVAL

Disassemble the combination meter, and then re-

move the tachometer.

B: INSTALLATION

Install in the reverse order of removal.

C: INSPECTION

Measure the tachometer resistance.

If NG, replace the tachometer.

If OK, replace the combination meter printed circuit.

(1) COS−

(2) COS+

(3) SIN−

(4) SIN+

Terminal Resistance

Terminals SIN + and SIN−200±8 Ω

Terminals COS + and COS−200±8 Ω

IDI00006

(1)(2)

(4)

(3)

Page 399 of 2870

IDI-15

INSTRUMENTATION/DRIVER INFO

Fuel Gauge

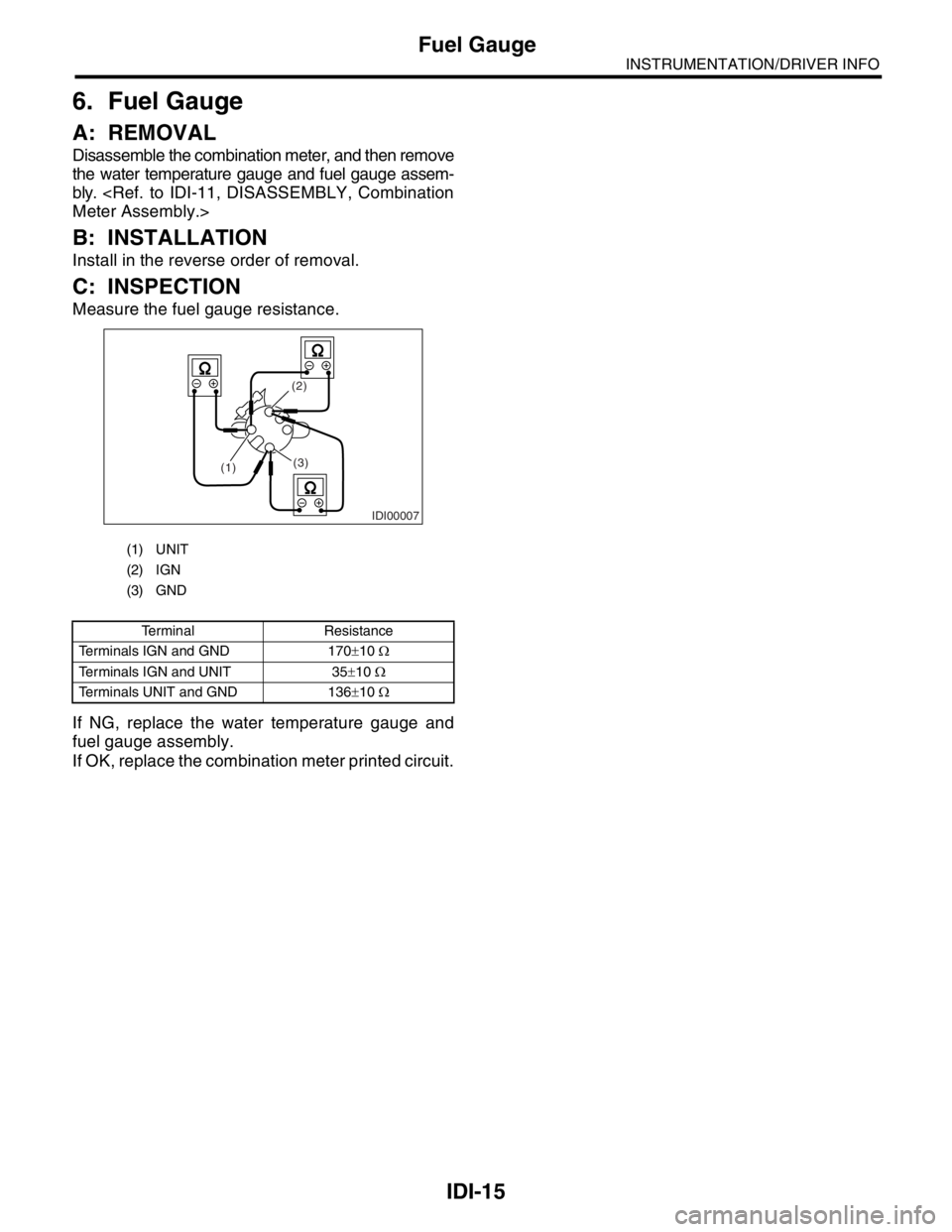

6. Fuel Gauge

A: REMOVAL

Disassemble the combination meter, and then remove

the water temperature gauge and fuel gauge assem-

bly.

B: INSTALLATION

Install in the reverse order of removal.

C: INSPECTION

Measure the fuel gauge resistance.

If NG, replace the water temperature gauge and

fuel gauge assembly.

If OK, replace the combination meter printed circuit.

(1) UNIT

(2) IGN

(3) GND

Terminal Resistance

Terminals IGN and GND 170±10 Ω

Terminals IGN and UNIT 35±10 Ω

Terminals UNIT and GND 136±10 Ω

IDI00007

(3) (2)

(1)

Page 400 of 2870

IDI-16

INSTRUMENTATION/DRIVER INFO

Water Temperature Gauge

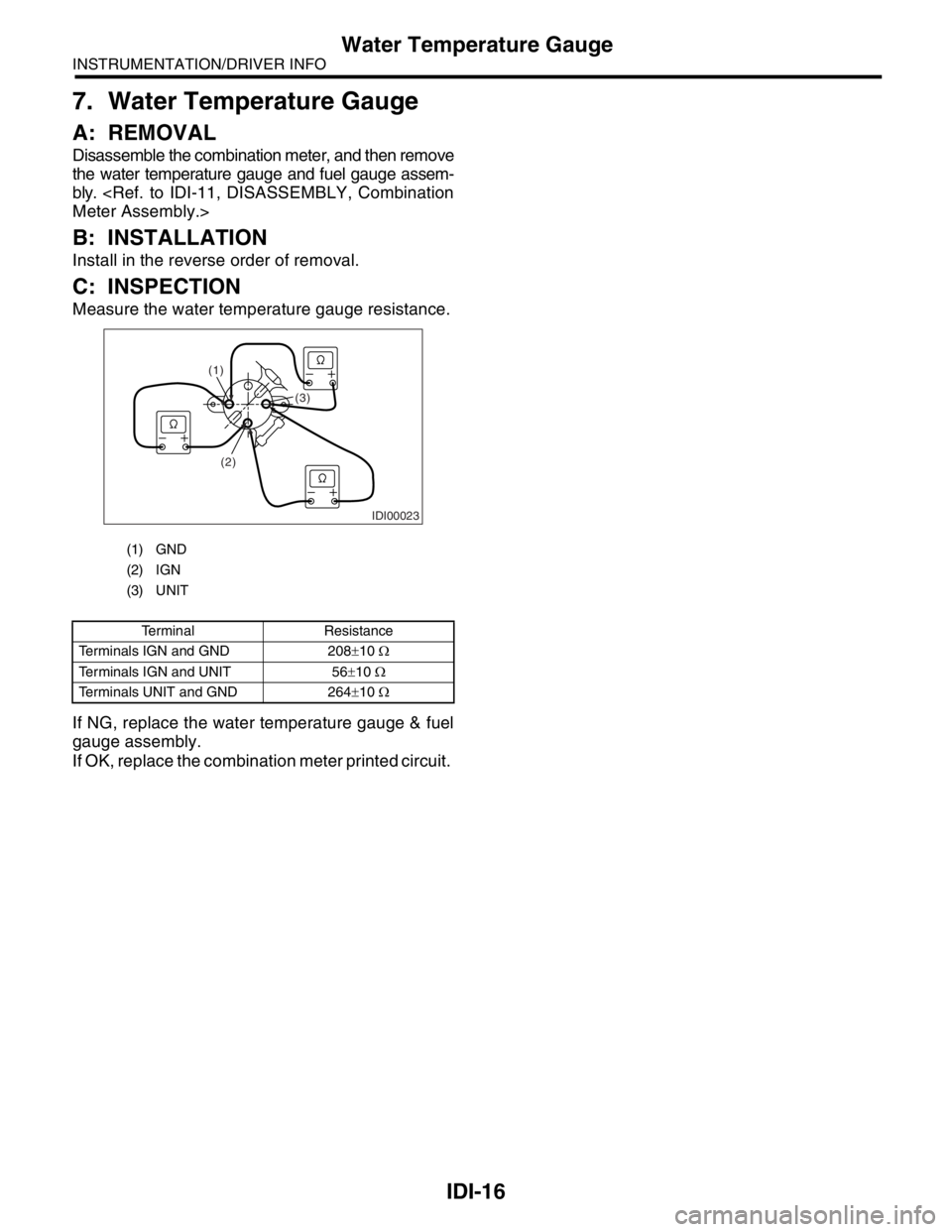

7. Water Temperature Gauge

A: REMOVAL

Disassemble the combination meter, and then remove

the water temperature gauge and fuel gauge assem-

bly.

B: INSTALLATION

Install in the reverse order of removal.

C: INSPECTION

Measure the water temperature gauge resistance.

If NG, replace the water temperature gauge & fuel

gauge assembly.

If OK, replace the combination meter printed circuit.

(1) GND

(2) IGN

(3) UNIT

Terminal Resistance

Terminals IGN and GND 208±10 Ω

Terminals IGN and UNIT 56±10 Ω

Terminals UNIT and GND 264±10 Ω

IDI00023

(1)

(2)(3)