SUBARU FORESTER 2004 Service Repair Manual

Manufacturer: SUBARU, Model Year: 2004, Model line: FORESTER, Model: SUBARU FORESTER 2004Pages: 2870, PDF Size: 38.67 MB

Page 381 of 2870

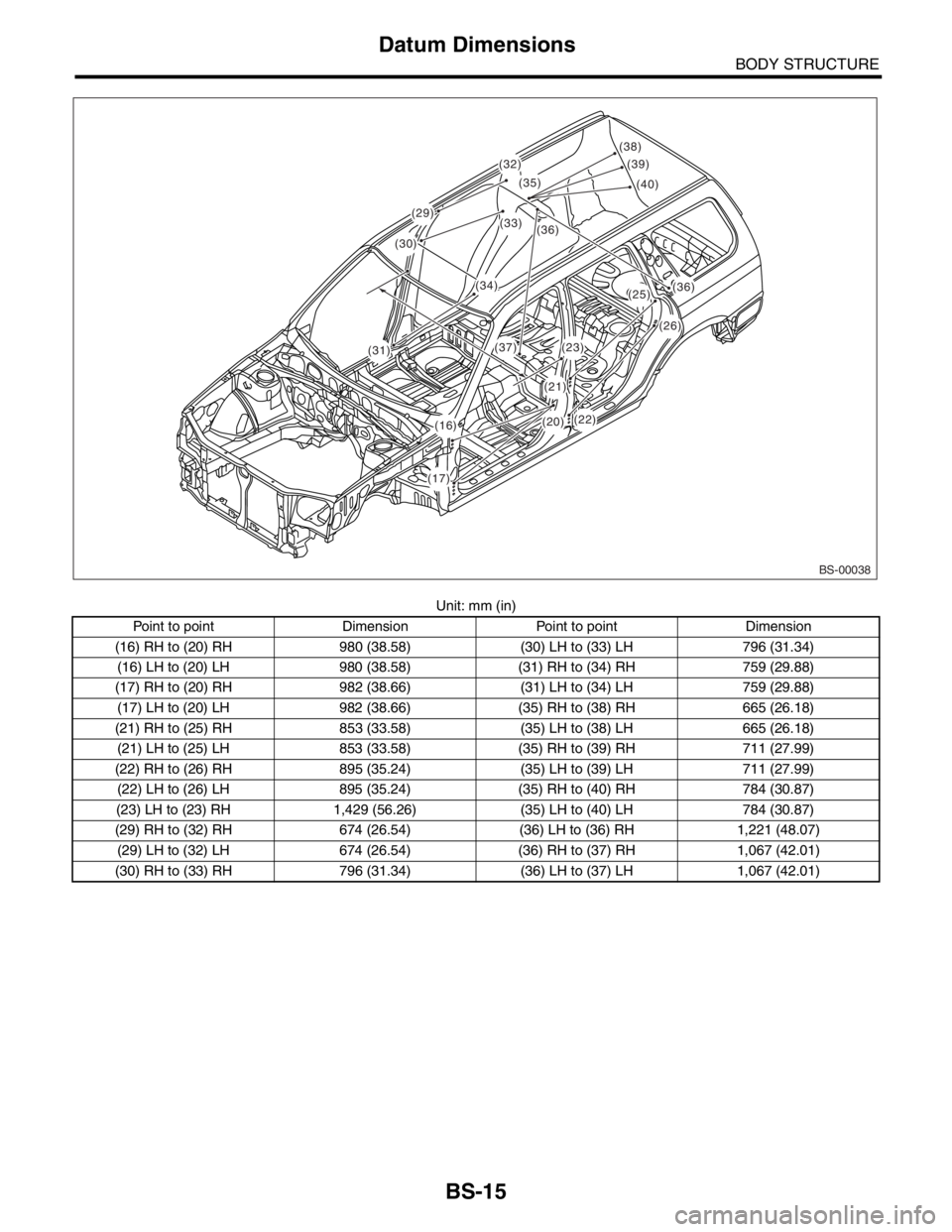

BS-15

BODY STRUCTURE

Datum Dimensions

Unit: mm (in)

Point to point Dimension Point to point Dimension

(16) RH to (20) RH 980 (38.58) (30) LH to (33) LH 796 (31.34)

(16) LH to (20) LH 980 (38.58) (31) RH to (34) RH 759 (29.88)

(17) RH to (20) RH 982 (38.66) (31) LH to (34) LH 759 (29.88)

(17) LH to (20) LH 982 (38.66) (35) RH to (38) RH 665 (26.18)

(21) RH to (25) RH 853 (33.58) (35) LH to (38) LH 665 (26.18)

(21) LH to (25) LH 853 (33.58) (35) RH to (39) RH 711 (27.99)

(22) RH to (26) RH 895 (35.24) (35) LH to (39) LH 711 (27.99)

(22) LH to (26) LH 895 (35.24) (35) RH to (40) RH 784 (30.87)

(23) LH to (23) RH 1,429 (56.26) (35) LH to (40) LH 784 (30.87)

(29) RH to (32) RH 674 (26.54) (36) LH to (36) RH 1,221 (48.07)

(29) LH to (32) LH 674 (26.54) (36) RH to (37) RH 1,067 (42.01)

(30) RH to (33) RH 796 (31.34) (36) LH to (37) LH 1,067 (42.01)

BS-00038

(30)

(29)

(17)

(16)(22)

(26)

(25)(36)

(36)

(37)(38)

(39)

(40)

(35)

(20)

(21)

(23)

(33)

(34)

(31)

(32)

Page 382 of 2870

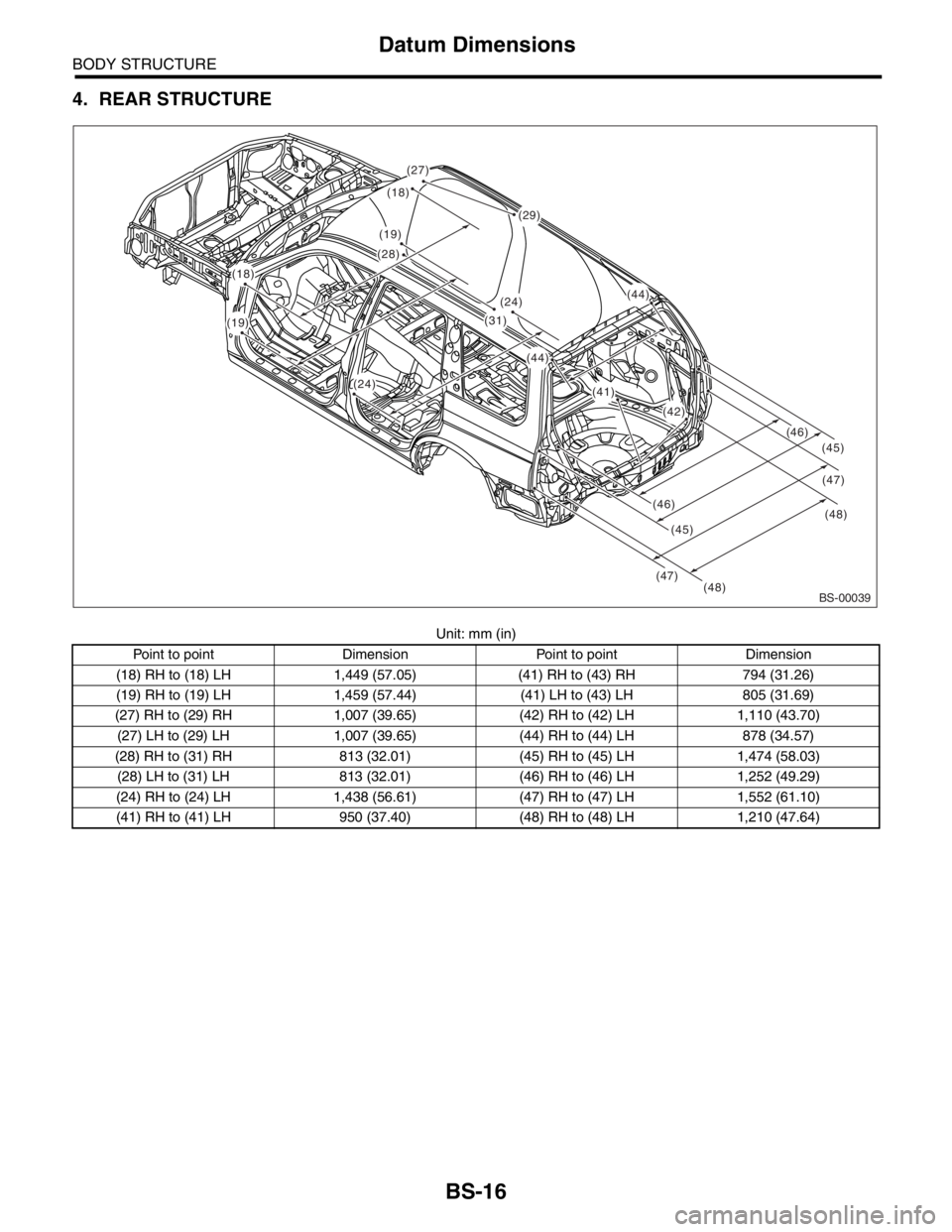

BS-16

BODY STRUCTURE

Datum Dimensions

4. REAR STRUCTURE

Unit: mm (in)

Point to point Dimension Point to point Dimension

(18) RH to (18) LH 1,449 (57.05) (41) RH to (43) RH 794 (31.26)

(19) RH to (19) LH 1,459 (57.44) (41) LH to (43) LH 805 (31.69)

(27) RH to (29) RH 1,007 (39.65) (42) RH to (42) LH 1,110 (43.70)

(27) LH to (29) LH 1,007 (39.65) (44) RH to (44) LH 878 (34.57)

(28) RH to (31) RH 813 (32.01) (45) RH to (45) LH 1,474 (58.03)

(28) LH to (31) LH 813 (32.01) (46) RH to (46) LH 1,252 (49.29)

(24) RH to (24) LH 1,438 (56.61) (47) RH to (47) LH 1,552 (61.10)

(41) RH to (41) LH 950 (37.40) (48) RH to (48) LH 1,210 (47.64)

BS-00039(48)(48) (47)

(47) (46)(46)

(45)(45) (18)

(29)

(44)

(41)

(42)

(44)

(31)

(24)

(24)

(28)

(18)

(19)

(27)

(19)

Page 383 of 2870

FUJI HEAVY INDUSTRIES LTD. G8080GE7

2004 FORESTER SERVICE MANUAL QUICK REFERENCE INDEX

BODY SECTION

This service manual has been prepared

to provide SUBARU service personnel

with the necessary information and data

for the correct maintenance and repair

of SUBARU vehicles.

This manual includes the procedures

for maintenance, disassembling, reas-

sembling, inspection and adjustment of

components and diagnostics for guid-

ance of experienced mechanics.

Please peruse and utilize this manual

fully to ensure complete repair work for

satisfying our customers by keeping

their vehicle in optimum condition.

When replacement of parts during

repair work is needed, be sure to use

SUBARU genuine parts.

All information, illustration and specifi-

cations contained in this manual are

based on the latest product information

available at the time of publication

approval.HVAC SYSTEM

(HEATER, VENTILATOR AND A/C)AC

HVAC SYSTEM (AUTO A/C)

(DIAGNOSTIC)AC

AIRBAG SYSTEM AB

AIRBAG SYSTEM (DIAGNOSTIC) AB

SEAT BELT SYSTEM SB

LIGHTING SYSTEM LI

WIPER AND WASHER SYSTEM WW

ENTERTAINMENT ET

COMMUNICATION SYSTEM COM

GLASS/WINDOW/MIRROR GW

BODY STRUCTURE BS

INSTRUMENTATION/DRIVER INFO IDI

SEAT SE

SECURITY AND LOCK SL

SUNROOF/T-TOP/CONVERTIBLE TOP

(SUNROOF)SR

EXTERIOR/INTERIOR TRIM EI

EXTERIOR BODY PANEL EB

Page 384 of 2870

2004 FORESTER SERVICE MANUAL QUICK REFERENCE INDEX

BODY SECTION

G8080GE7

CRUISE CONTROL SYSTEM CC

CRUISE CONTROL SYSTEM

(DIAGNOSTIC)CC(H4SO)

CRUISE CONTROL SYSTEM

(DIAGNOSTIC)CC(H4DOTC)

CRUISE CONTROL SYSTEM

(DIAGNOSTIC)CC(H4DOTC 2.5)

IMMOBILIZER (DIAGNOSTIC) IM

Page 385 of 2870

INSTRUMENTATION/DRIVER INFO

IDI

Page

1. General Description ....................................................................................2

2. Combination Meter System .........................................................................3

3. Combination Meter Assembly ...................................................................10

4. Speedometer.............................................................................................13

5. Tachometer ...............................................................................................14

6. Fuel Gauge ...............................................................................................15

7. Water Temperature Gauge .......................................................................16

8. Ambient Sensor.........................................................................................17

Page 386 of 2870

IDI-2

INSTRUMENTATION/DRIVER INFO

General Description

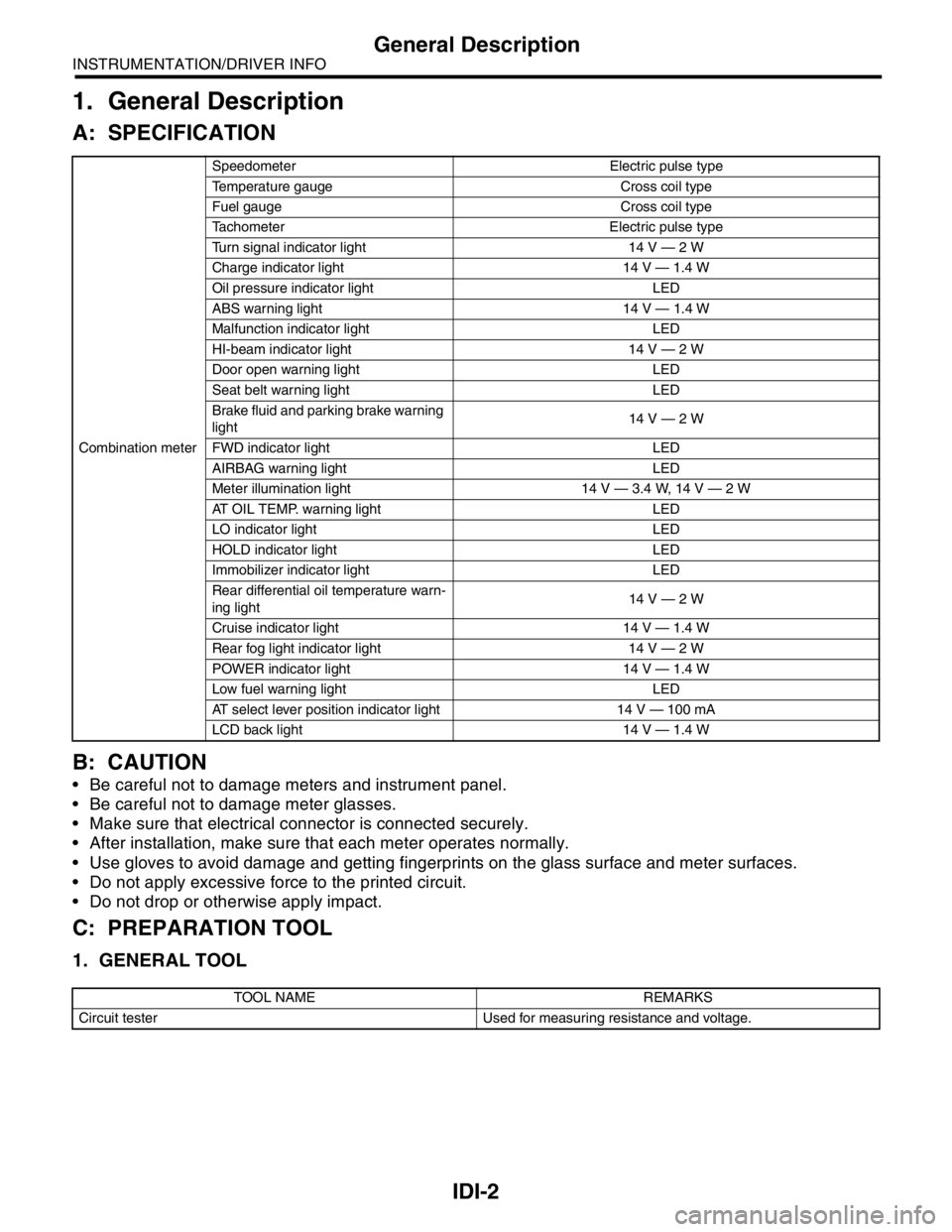

1. General Description

A: SPECIFICATION

B: CAUTION

Be careful not to damage meters and instrument panel.

Be careful not to damage meter glasses.

Make sure that electrical connector is connected securely.

After installation, make sure that each meter operates normally.

Use gloves to avoid damage and getting fingerprints on the glass surface and meter surfaces.

Do not apply excessive force to the printed circuit.

Do not drop or otherwise apply impact.

C: PREPARATION TOOL

1. GENERAL TOOL

Combination meterSpeedometer Electric pulse type

Temperature gauge Cross coil type

Fuel gauge Cross coil type

Tachometer Electric pulse type

Turn signal indicator light 14 V — 2 W

Charge indicator light 14 V — 1.4 W

Oil pressure indicator light LED

ABS warning light 14 V — 1.4 W

Malfunction indicator light LED

HI-beam indicator light 14 V — 2 W

Door open warning light LED

Seat belt warning light LED

Brake fluid and parking brake warning

light14 V — 2 W

FWD indicator light LED

AIRBAG warning light LED

Meter illumination light 14 V — 3.4 W, 14 V — 2 W

AT OIL TEMP. warning light LED

LO indicator light LED

HOLD indicator light LED

Immobilizer indicator light LED

Rear differential oil temperature warn-

ing light14 V — 2 W

Cruise indicator light 14 V — 1.4 W

Rear fog light indicator light 14 V — 2 W

POWER indicator light 14 V — 1.4 W

Low fuel warning light LED

AT select lever position indicator light 14 V — 100 mA

LCD back light 14 V — 1.4 W

TOOL NAME REMARKS

Circuit tester Used for measuring resistance and voltage.

Page 387 of 2870

IDI-3

INSTRUMENTATION/DRIVER INFO

Combination Meter System

2. Combination Meter System

A: WIRING DIAGRAM

1. COMBINATION METER

2. OUTSIDE TEMPERATURE INDICATOR

Page 388 of 2870

IDI-4

INSTRUMENTATION/DRIVER INFO

Combination Meter System

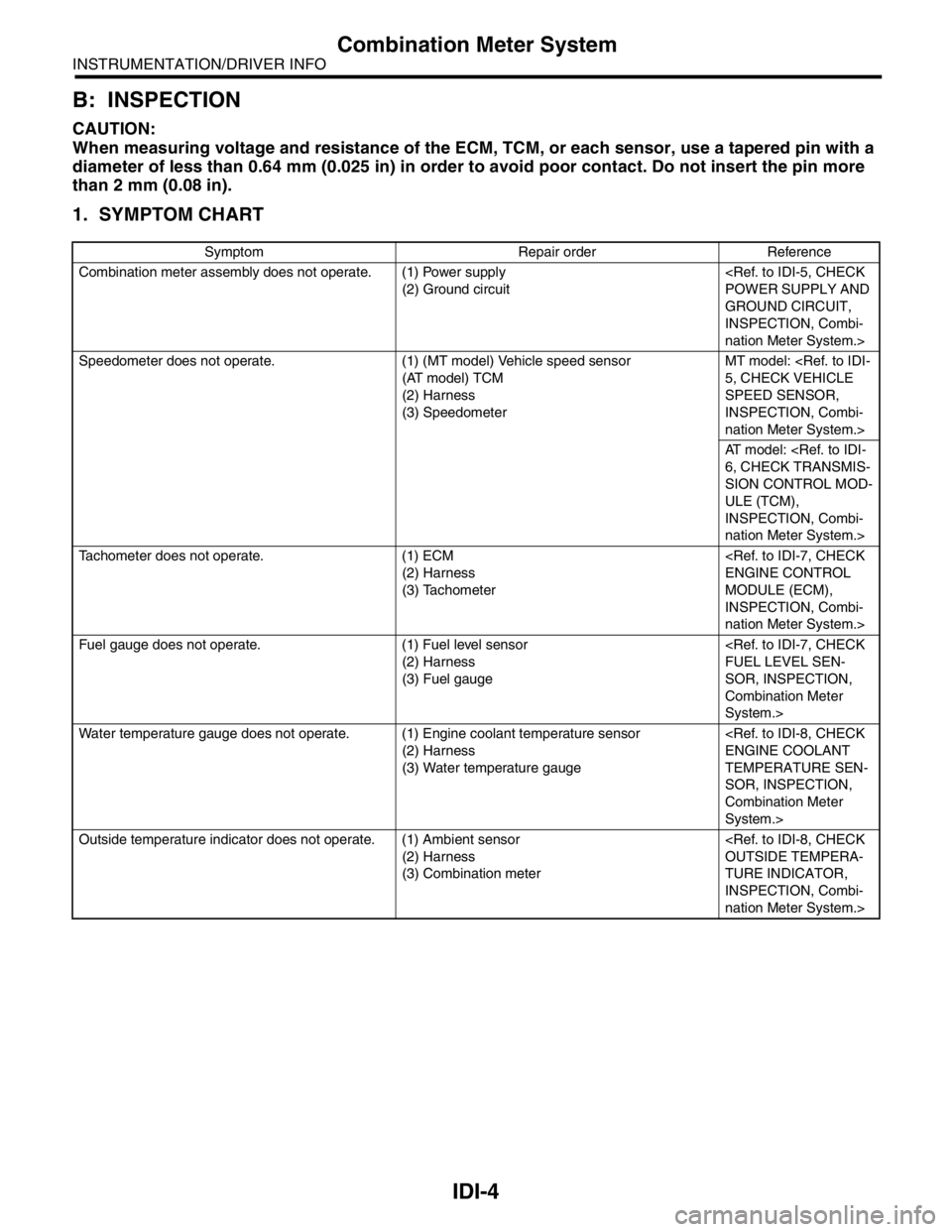

B: INSPECTION

CAUTION:

When measuring voltage and resistance of the ECM, TCM, or each sensor, use a tapered pin with a

diameter of less than 0.64 mm (0.025 in) in order to avoid poor contact. Do not insert the pin more

than 2 mm (0.08 in).

1. SYMPTOM CHART

Symptom Repair order Reference

Combination meter assembly does not operate. (1) Power supply

(2) Ground circuit

GROUND CIRCUIT,

INSPECTION, Combi-

nation Meter System.>

Speedometer does not operate. (1) (MT model) Vehicle speed sensor

(AT model) TCM

(2) Harness

(3) SpeedometerMT model:

SPEED SENSOR,

INSPECTION, Combi-

nation Meter System.>

AT model:

SION CONTROL MOD-

ULE (TCM),

INSPECTION, Combi-

nation Meter System.>

Tachometer does not operate. (1) ECM

(2) Harness

(3) Tachometer

MODULE (ECM),

INSPECTION, Combi-

nation Meter System.>

Fuel gauge does not operate. (1) Fuel level sensor

(2) Harness

(3) Fuel gauge

SOR, INSPECTION,

Combination Meter

System.>

Water temperature gauge does not operate. (1) Engine coolant temperature sensor

(2) Harness

(3) Water temperature gauge

TEMPERATURE SEN-

SOR, INSPECTION,

Combination Meter

System.>

Outside temperature indicator does not operate. (1) Ambient sensor

(2) Harness

(3) Combination meter

TURE INDICATOR,

INSPECTION, Combi-

nation Meter System.>

Page 389 of 2870

IDI-5

INSTRUMENTATION/DRIVER INFO

Combination Meter System

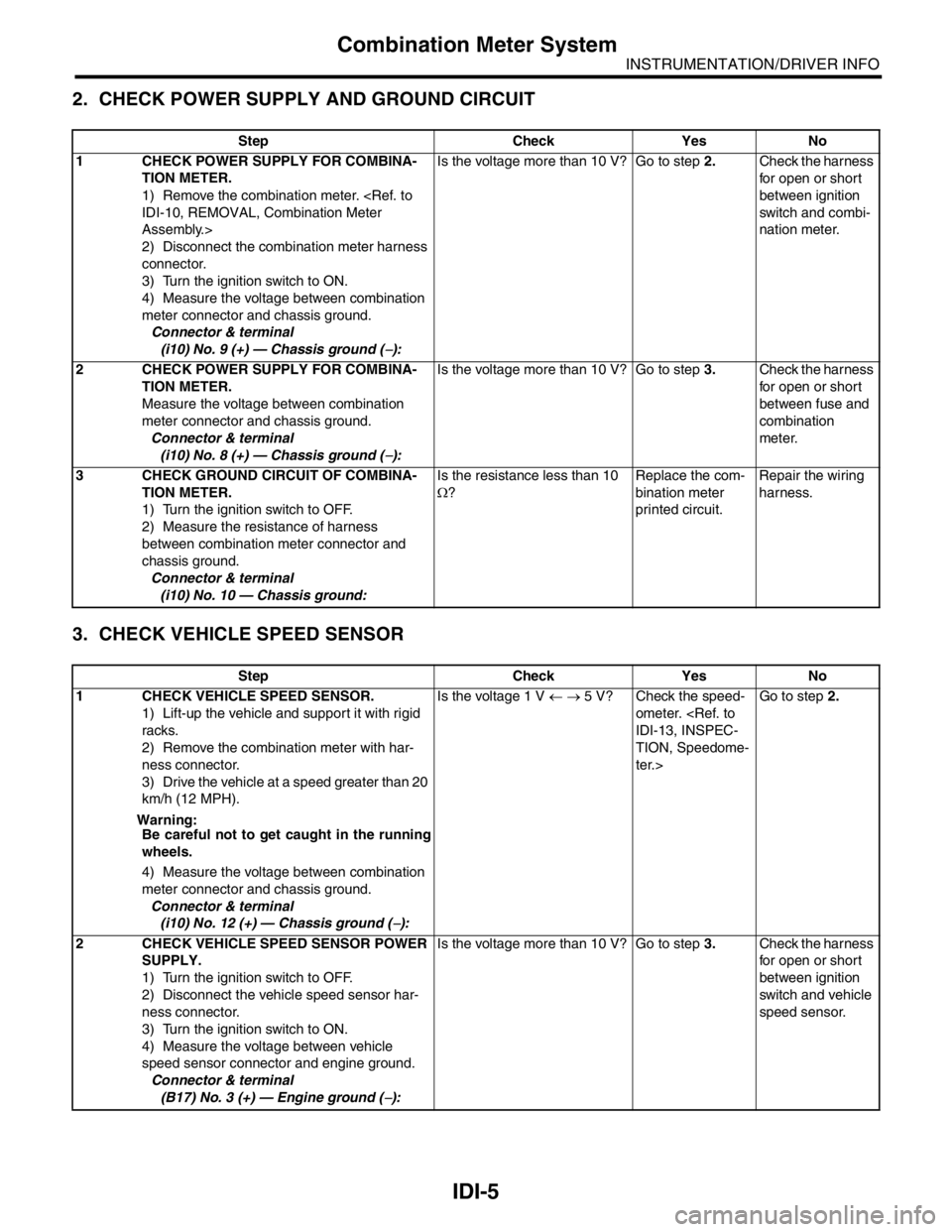

2. CHECK POWER SUPPLY AND GROUND CIRCUIT

3. CHECK VEHICLE SPEED SENSOR

Step Check Yes No

1 CHECK POWER SUPPLY FOR COMBINA-

TION METER.

1) Remove the combination meter.

Assembly.>

2) Disconnect the combination meter harness

connector.

3) Turn the ignition switch to ON.

4) Measure the voltage between combination

meter connector and chassis ground.

Connector & terminal

(i10) No. 9 (+) — Chassis ground (

−):Is the voltage more than 10 V? Go to step 2.Check the harness

for open or short

between ignition

switch and combi-

nation meter.

2 CHECK POWER SUPPLY FOR COMBINA-

TION METER.

Measure the voltage between combination

meter connector and chassis ground.

Connector & terminal

(i10) No. 8 (+) — Chassis ground (

−):Is the voltage more than 10 V? Go to step 3.Check the harness

for open or short

between fuse and

combination

meter.

3 CHECK GROUND CIRCUIT OF COMBINA-

TION METER.

1) Turn the ignition switch to OFF.

2) Measure the resistance of harness

between combination meter connector and

chassis ground.

Connector & terminal

(i10) No. 10 — Chassis ground:Is the resistance less than 10

Ω?Replace the com-

bination meter

printed circuit.Repair the wiring

harness.

Step Check Yes No

1 CHECK VEHICLE SPEED SENSOR.

1) Lift-up the vehicle and support it with rigid

racks.

2) Remove the combination meter with har-

ness connector.

3) Drive the vehicle at a speed greater than 20

km/h (12 MPH).

Warning:

Be careful not to get caught in the running

wheels.

4) Measure the voltage between combination

meter connector and chassis ground.

Connector & terminal

(i10) No. 12 (+) — Chassis ground (

−):Is the voltage 1 V ← → 5 V? Check the speed-

ometer.

TION, Speedome-

ter.>Go to step 2.

2 CHECK VEHICLE SPEED SENSOR POWER

SUPPLY.

1) Turn the ignition switch to OFF.

2) Disconnect the vehicle speed sensor har-

ness connector.

3) Turn the ignition switch to ON.

4) Measure the voltage between vehicle

speed sensor connector and engine ground.

Connector & terminal

(B17) No. 3 (+) — Engine ground (

−):Is the voltage more than 10 V? Go to step 3.Check the harness

for open or short

between ignition

switch and vehicle

speed sensor.

Page 390 of 2870

IDI-6

INSTRUMENTATION/DRIVER INFO

Combination Meter System

4. CHECK TRANSMISSION CONTROL MODULE (TCM)

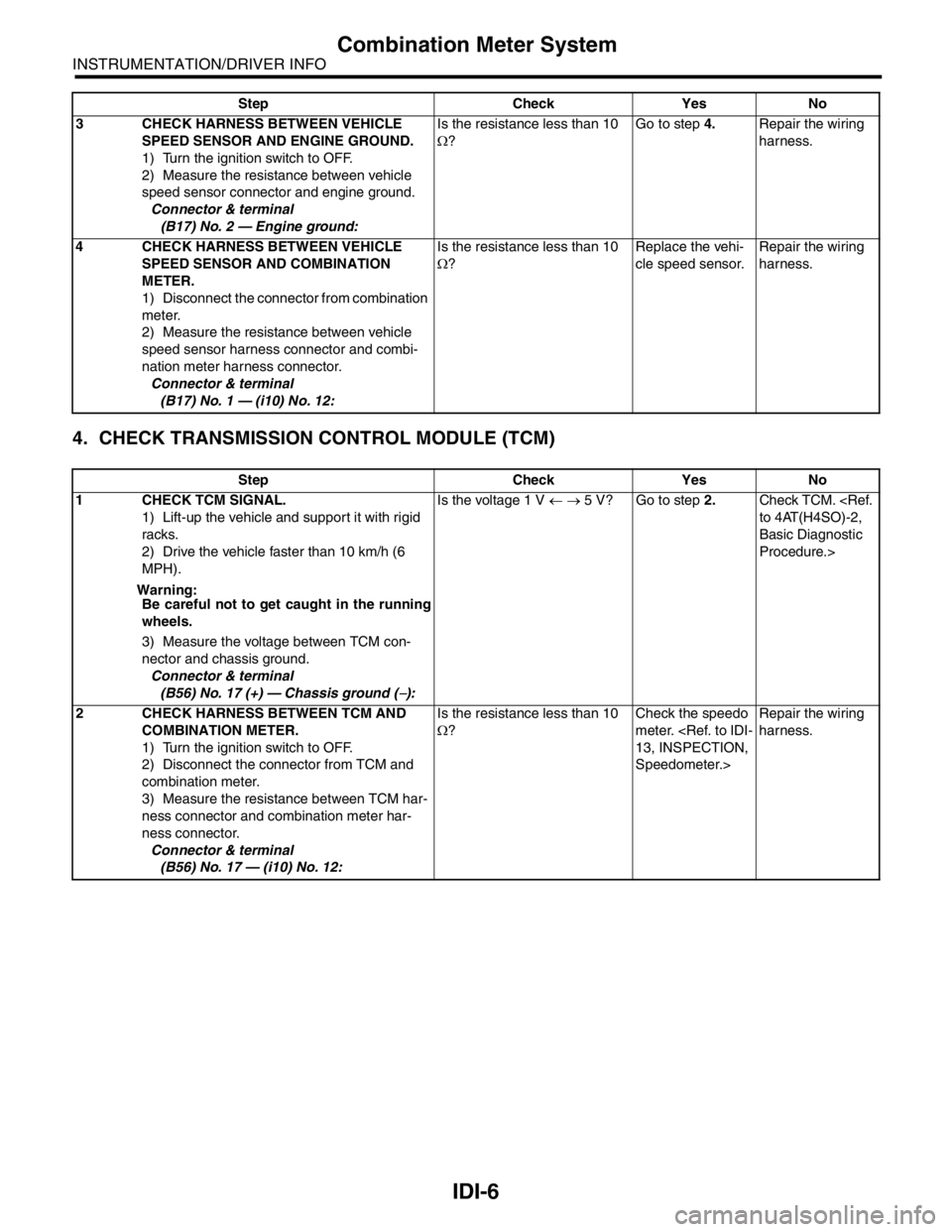

3 CHECK HARNESS BETWEEN VEHICLE

SPEED SENSOR AND ENGINE GROUND.

1) Turn the ignition switch to OFF.

2) Measure the resistance between vehicle

speed sensor connector and engine ground.

Connector & terminal

(B17) No. 2 — Engine ground:Is the resistance less than 10

Ω?Go to step 4.Repair the wiring

harness.

4 CHECK HARNESS BETWEEN VEHICLE

SPEED SENSOR AND COMBINATION

METER.

1) Disconnect the connector from combination

meter.

2) Measure the resistance between vehicle

speed sensor harness connector and combi-

nation meter harness connector.

Connector & terminal

(B17) No. 1 — (i10) No. 12:Is the resistance less than 10

Ω?Replace the vehi-

cle speed sensor.Repair the wiring

harness.

Step Check Yes No

1 CHECK TCM SIGNAL.

1) Lift-up the vehicle and support it with rigid

racks.

2) Drive the vehicle faster than 10 km/h (6

MPH).

Warning:

Be careful not to get caught in the running

wheels.

3) Measure the voltage between TCM con-

nector and chassis ground.

Connector & terminal

(B56) No. 17 (+) — Chassis ground (

−):Is the voltage 1 V ← → 5 V? Go to step 2.Check TCM.

Basic Diagnostic

Procedure.>

2 CHECK HARNESS BETWEEN TCM AND

COMBINATION METER.

1) Turn the ignition switch to OFF.

2) Disconnect the connector from TCM and

combination meter.

3) Measure the resistance between TCM har-

ness connector and combination meter har-

ness connector.

Connector & terminal

(B56) No. 17 — (i10) No. 12:Is the resistance less than 10

Ω?Check the speedo

meter.

Speedometer.>Repair the wiring

harness. Step Check Yes No